I am thinking of using the bix 40mm platter(ie no sub platter) and bearing what is my best way to go about getting 45rpm as an option?

BIX pods are available in Black and Silver. They have 8 of each in stock.

Silver will be very nice with the alu custom plate.

Let me know if some of you want silver pods.

Thanks...

SB

Silver will be very nice with the alu custom plate.

Let me know if some of you want silver pods.

Thanks...

SB

Algar_emi said:BIX pods are available in Black and Silver. They have 8 of each in stock.

Silver will be very nice with the alu custom plate.

Let me know if some of you want silver pods.

Thanks...

SB

Is silver a clear anodized alumunum?

Stan

pulley question

Hi All,

i have ordered a VPI Scout platter and bearing to make my turntable with, but i dont have the dimensions for it, can anyone help?

Also, i have a pulley from the first MK group buy and ordered the Bix pulley for flexability, Can you guys tell me which would be the best one to use for this platter, i do require 33 and 45 rpm?

Many thanks

Webby

Hi All,

i have ordered a VPI Scout platter and bearing to make my turntable with, but i dont have the dimensions for it, can anyone help?

Also, i have a pulley from the first MK group buy and ordered the Bix pulley for flexability, Can you guys tell me which would be the best one to use for this platter, i do require 33 and 45 rpm?

Many thanks

Webby

Hi sklimek. It is called "gloss silver", no more details for now.

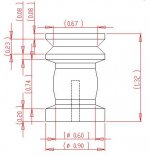

I got the ACAD and Solidworks file of the original pulley, thanks to DaveM. Here it is.

The top section, for string/rubber belt drive is has 0.67" diam or 17mm.

That give a pulley to platter ratio or 305/17 = 17.9, much lower than the maximum of 24 specified by Mark.

I got the ACAD and Solidworks file of the original pulley, thanks to DaveM. Here it is.

The top section, for string/rubber belt drive is has 0.67" diam or 17mm.

That give a pulley to platter ratio or 305/17 = 17.9, much lower than the maximum of 24 specified by Mark.

Attachments

The pods are not all in stock and furthermore, there is two colors to choose from Silver/Black. I asked all Pods buyers to specified their color, default will be Black if not specified.

Express shipping of all pods is really expensive at 259$

I asked Simon of diysupply to ship me one pod by express and to delay the rest of the shipping once I know what color to order.

I also asked him the find a cheaper (slower) delivery method for the rest of the pods.

Bye...

Express shipping of all pods is really expensive at 259$

I asked Simon of diysupply to ship me one pod by express and to delay the rest of the shipping once I know what color to order.

I also asked him the find a cheaper (slower) delivery method for the rest of the pods.

Bye...

Hi Webby,

I'm doing the same platter/bearing set-up as you, so I have the same pulley question. According to the lpgear.com website, the platter is 11.55" dia. or 294mm. There is a page there that compares the VPI lineup.

Also, with all the time Algar_emi is devoting to this project, I think he deserves some financial gratuities. I'm up for sending him a few extra bucks.

Eric

I'm doing the same platter/bearing set-up as you, so I have the same pulley question. According to the lpgear.com website, the platter is 11.55" dia. or 294mm. There is a page there that compares the VPI lineup.

Also, with all the time Algar_emi is devoting to this project, I think he deserves some financial gratuities. I'm up for sending him a few extra bucks.

Eric

Wasted said:Anyone have the diameter of the spindle on the maxon motor unit?

Maxon Motor # 110191

Attachments

please Algar don't give up the custom pulley gb as it is essential to make the mk reg to work at best and it isn't easy to have done as single pieces.

It is not a matter of giving up. We can get anything we want from any machine shop. It is just a question of money. If a given shop cannot make any money on our part, we just need to ask want does he want to build it.

The real question is: do we want to pay the price for it?

The real question is: do we want to pay the price for it?

Custom Plates and Pods Orders

Hi. I just sent the money for the 21 custom plates.

I also ordered half the pods, 3 Blacks, 6 Silvers.

I ordered the rest once I get all the color choices and that the pods are all in stock from HiFiSupply.

Hi. I just sent the money for the 21 custom plates.

I also ordered half the pods, 3 Blacks, 6 Silvers.

I ordered the rest once I get all the color choices and that the pods are all in stock from HiFiSupply.

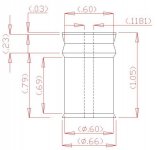

With the help of DaveM, I started to work on an upgraded (ver 2.0) custom pulley. We will try to get a quote for it.

Changes that I suggested:

Some of the original pulley problems, according to some, I don't know myself, I never use it, were:

-Mass. I think it was made in brass and it had also both string and tape pulleys in just one assembly. It seems that the best pulley has the lowest mass. Is it possible to have the pulley made of aluminium instead of brass?

Is it also possible to reduce the pulley dimensions. Look at the included proposed drawing. You can see that the shoulders are much smallers.

I kept the original diameter of 0.6'' (15mm) that was recommended by Mark kelly.

-Blind hole. It prevents the use of a puller to remove the pulley without stress to the motor bearings. Is it possible to have an open mounting hole (thru hole)?

An other advantage of the thru hole is you can mount the pulley in the direction you want for best result according to your drive system. For example, if using tape mount the tape pulley side first closer to the motor bearing for reduce mechanical stress on the motor. If using the string, belt, mount it up side down, to get the string pulley closer to the motor, same advantage

Just suggestions, I'm not an expert in mechanic.

It is open for your comments as well.

Changes that I suggested:

Some of the original pulley problems, according to some, I don't know myself, I never use it, were:

-Mass. I think it was made in brass and it had also both string and tape pulleys in just one assembly. It seems that the best pulley has the lowest mass. Is it possible to have the pulley made of aluminium instead of brass?

Is it also possible to reduce the pulley dimensions. Look at the included proposed drawing. You can see that the shoulders are much smallers.

I kept the original diameter of 0.6'' (15mm) that was recommended by Mark kelly.

-Blind hole. It prevents the use of a puller to remove the pulley without stress to the motor bearings. Is it possible to have an open mounting hole (thru hole)?

An other advantage of the thru hole is you can mount the pulley in the direction you want for best result according to your drive system. For example, if using tape mount the tape pulley side first closer to the motor bearing for reduce mechanical stress on the motor. If using the string, belt, mount it up side down, to get the string pulley closer to the motor, same advantage

Just suggestions, I'm not an expert in mechanic.

It is open for your comments as well.

Attachments

The pulley drawings is ok to me, I reccomend a light material , alluminium or pvc, delrin etc..

Of course I I agree to pay the right amount of money for it

Of course I I agree to pay the right amount of money for it

Algar_emi said:It means that with the Teres or BIX pulley we can operate only at 33-/13rpm not 45.

To support both speeds , we need a custom pulley, diameter 13mm.

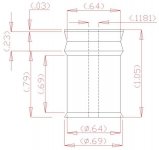

Hi Sylvain, was the diameter 13mm or 15mm?. Sorry if I missed a post that supports the 15mm or some new revision, just checkin'...

According to Dave, Mark said the the optimal diameter is 0.67" (17mm) to get the best stability at 33-1/3rpm and still support 45 rpm.

I tried to compromise at 15mm instead of 17 to reduce dimensions and mass. Here an increased diameter pulley from 0.60 to 0.64"

The pulley ratio of 24 was an absolute maximum. The optimal is rather 17 (300/17mm).

I tried to compromise at 15mm instead of 17 to reduce dimensions and mass. Here an increased diameter pulley from 0.60 to 0.64"

The pulley ratio of 24 was an absolute maximum. The optimal is rather 17 (300/17mm).

Attachments

Some members still need to choose their pod color, Black or Silver:

Michi24, Webby, bakus11

Thanks...

Michi24, Webby, bakus11

Thanks...

I am interested in the custom pulley instead of the teres and bix and I like having the option for a string or tape. I think the through hole as you suggested is probably a good idea and aluminum would probably be the best choice for material. Is it necessary to crown the pulley for the tape to keep it from walking around?

Mark

Mark

- Home

- Group Buys

- 2007 Maxon Motor Group Buy