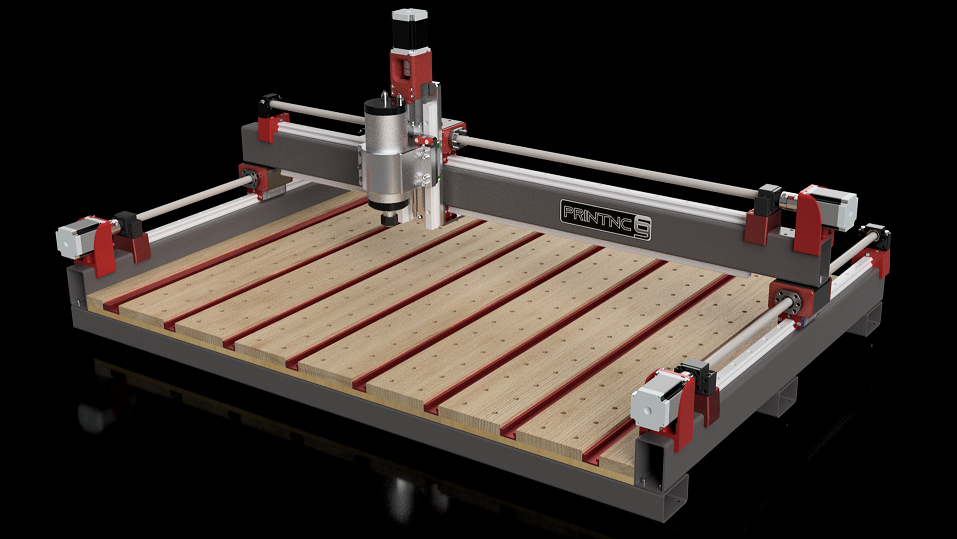

Will this CNC be capable of milling aluminum? I want to get into the CNC hobby, but it has to do more than wood.

Yes it can, the basic workbee can mill aluminium too but it is not really rigid enough to avoid chattering. For holes in amp chassis or simple shapes it would be fine but if you want to do more complex operations then a rigid machine is needed. Using adaptive clearing in Fusion keeps the bit temperature down and allows aluminium to be cut dry without a lubricant.

Video showing it working

https://video.wixstatic.com/video/bdcd45_0ae2847c48964410a19b50e74298079e/480p/mp4/file.mp4

Chatter

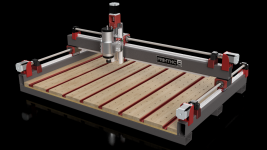

If I didn't already have the workbee I might well have chosen to build a PrintNC

PrintNC V3.0 | PrintNC Wiki

Video showing it working

https://video.wixstatic.com/video/bdcd45_0ae2847c48964410a19b50e74298079e/480p/mp4/file.mp4

Chatter

If I didn't already have the workbee I might well have chosen to build a PrintNC

PrintNC V3.0 | PrintNC Wiki

Attachments

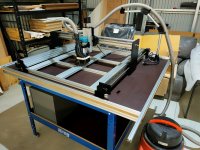

I've now made it past the stage I did with the base kit before getting the urge to upgrade. Next stage is the the wiring and electrical setup before building the enclosure.

The images in my last post seem to have disappeared so here they are again with a few new ones for the Z Plate Mounts and Power Cable Clips to route the router power cable along the X axis.

Attachments

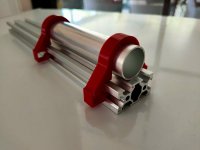

I've been working on a microphone mount to use a tube behind the mic to avoid reflections. The bottom mount attaches to a 3m lighting stand which is much more heavy duty than most mic stands and it came for free as the music store couldn't find it in their system so they gave it to me 🙂

The other half of the mount is bolted into an offcut of 2040 V slot extrusion and the tube is fixed with a piece I designed incorporating the cable clips to hold it in place. The tube in the images is just an offcut test piece the real one will be 2m long.

The other half of the mount is bolted into an offcut of 2040 V slot extrusion and the tube is fixed with a piece I designed incorporating the cable clips to hold it in place. The tube in the images is just an offcut test piece the real one will be 2m long.

Attachments

And people say arrays are a lot of work...

It's nothing compared to 2 way waveguide speakers, or so it seems 😀.

I hope you get it going soon. Or are you planning to build a Klippel NFS next...

It's nothing compared to 2 way waveguide speakers, or so it seems 😀.

I hope you get it going soon. Or are you planning to build a Klippel NFS next...

They are awesome do it 😀3D printers seem to be pretty awesome, gotta buy one.

I could have it done tomorrow if I used the XT1464 I have sitting in the garage, but where would the fun be in that, or the challenge 😉And people say arrays are a lot of work...

It's nothing compared to 2 way waveguide speakers, or so it seems 😀.

I hope you get it going soon. Or are you planning to build a Klippel NFS next...

Don't think I haven't thought long and hard about how I could DIY a nearfield scanner. For now I have decided gated with as long a window as I can manage, combined with ground plane or nearfield splice will be good enough.

Last edited:

I've been working on a microphone mount to use a tube behind the mic to avoid reflections. The bottom mount attaches to a 3m lighting stand which is much more heavy duty than most mic stands and it came for free as the music store couldn't find it in their system so they gave it to me 🙂

The other half of the mount is bolted into an offcut of 2040 V slot extrusion and the tube is fixed with a piece I designed incorporating the cable clips to hold it in place. The tube in the images is just an offcut test piece the real one will be 2m long.

This is pretty cool, but it’s quite bulky in itself and the mic is still pretty close to the upright part which is one of the main issues (other than the clip) that I took from their report. Have you read the B&K paper on mic stand reflections?

I recently did a bunch of work in a hemi-anechoic and found that my Manfrotto nano stands were far better than a typical mic stand for reducing reflections. They're quite stable with the legs folded out flat too, so I was toying with the idea of making a contraption to dangle the mic from a wire to really get the stand influence out of the data.

In practice I just ended up hot gluing some leftover bits of acoustic foam to the whole stand though 😁

This is pretty cool, but it’s quite bulky in itself and the mic is still pretty close to the upright part which is one of the main issues (other than the clip) that I took from their report. Have you read the B&K paper on mic stand reflections?

I don't know if you missed this part or it didn't make sense?

The mic will go inside an aluminium tube which will be anywhere from 1 to 2m from the mount. I don't think the mount is that bulky given how far away it will be from the mic. I think the most interesting picture from the B&K measurements is this one as it shows the negative influence of the 90 degree mounting. I have some felt off cuts which I use in my current measurements to reduce the influence of the mic mount. I will most likely use more over the mount and 90 degree section unless it turns out to be unnecessary.The tube in the images is just an offcut test piece the real one will be 2m long.

Attachments

Ahh sorry I missed that part entirely ����*♂️ Makes perfect sense. A little bit too chunky for portable use unless it’s an extendable tube, but if you’re using it in a fixed location then all good. I have to juggle the balance between stability and Peli case weight sadly.

The labs seem to use B&K tiny electrets for most of their work, which are pretty much just clipped to something or hung by their thin wires.

The labs seem to use B&K tiny electrets for most of their work, which are pretty much just clipped to something or hung by their thin wires.

You won't be able to throw it in a Pelican case, that is for sure 🙂 I was aiming for effective without much cost. I plan to measure in my workshop and see how long a gate I can get and maybe make a concrete pad outside for ground plane.

I am sorely tempted to buy an Earthworks mic or a Clio pocket but I keep resisting.

I am sorely tempted to buy an Earthworks mic or a Clio pocket but I keep resisting.

I am sorely tempted to buy an Earthworks mic or a Clio pocket...

I just received my MicW M215 (Link and pics here MicW.)

The M215 is a clone of a Bruel & Kjaer at a fraction of the price.

It's not quite as excellent, of course, but does come with an individual calibration chart.

Comparison with William Cowan's Earthworks 23 indicate the chart is pretty much spot on.

The metal membrane should be more stable over time, temperature and humidity than a plastic mic.

Sensitivity is better than the Earthworks.

SNR should be better too but I haven't checked that yet.

It did roll off a little earlier than pictures in the publicity photos, around 15 kHz, but this is can be fully equalised so no real problem.

Just over $500 AUD, so cheaper than an Earthworks.

It takes a B&K capsule if one ever decides to move up.

I can send details if you succumb to temptation.

Best wishes

David

I revisited this thread after I was reminded by your posts over in AudioScienceReview.

WTF is up with JJ? Your questions and responses were more than reasonable, if it's any consolation to have the opinion of someone with no side in that particular debate.

Last edited:

I've read your mic thread and seen mention of this one before. Good to to know it you are pretty happy with it. With a really expensive mic I think that the Focusrite Scarlett mic pre and interface I have is probably not up to the same standard which is what made the Clio seem interesting. I've seen William post shots that came from Clio, do you know what he is using there?I just received my MicW M215 ...

I can send details if you succumb to temptation.

I think he has been shadowboxing for too long and sees bad intent everywhere. It is a shame he behaves that way. I see the mistake I made, playing forum Russian Roulette with 5 rounds is not something I will look for again.WTF is up with JJ? Your questions and responses were more than reasonable, if it's any consolation to have the opinion of someone with no side in that particular debate.

The support is appreciated 🙂

I've seen William post shots that came from Clio, do you know what he is using there?

I have a Clio Pocket but will upgrade to the full version. Pocket is too limited. Using a proper mic like my M23 is clumsy and the supplied mic isn't accurate enough for some work. A mic cal can't be used. My M23 is good enough to be used uncalibrated. Also Pocket doesn't allow the use of target response curves and it will only display H2 and H3 distortion products. The frustrating thing is the hardware is capable, it's the software that is hobbled.

Thanks for the info, lucky I resisted 🙂Pocket is too limited.

Wouldn't know why not. Distortion, noise and linearity of even cheap preamps are top class most of the time. Even a cheap Yamaha Audiogram 3 I have lying around does a better job than most other components in the chain, apart from it's 48kHz limit. AD/DA is pretty generic, a Clio doesn't do better there. And if in doubt, you could always upgrade to a Motu M4. But I'd think twice. Or run a loopback test.I think that the Focusrite Scarlett mic pre and interface I have is probably not up to the same standard

About the microphone: a XLR female fits snugly in a standard metal broom rod of 20mm outside. The rod itself fits most microphone stand clamps. I built such a rod quite a while ago, works good for me.

Last edited:

This has been my conundrum and the reason why I haven't actually bought anything new. Other than getting a better calibration or an inherently flatter mic (Earthworks) for my use I'm not sure quite what benefit I would get. The desire to have a top class mic just because is strong though 🙂Wouldn't know why not. Distortion, noise and linearity of even cheap preamps are top class most of the time. Even a cheap Yamaha Audiogram 3 I have lying around does a better job than most other components in the chain, apart from it's 48kHz limit. AD/DA is pretty generic, a Clio doesn't do better there. And if in doubt, you could always upgrade to a Motu M4. But I'd think twice. Or run a loopback test.

I've already reinvented the wheel there as I didn't like most of the stand clamps I could get. Time will tell if my contraption is any better. 25mm aluminium tube is easy for me to get and is quite cheap so I went with that.About the microphone: a XLR female fits snugly in a standard metal broom rod of 20mm outside. The rod itself fits most microphone stand clamps. I built such a rod quite a while ago, works good for me.

Hardly any progress has been made in the real world towards making the CNC functional, but in the land of make believe and wishes an interesting idea has emerged, the look of which is growing on me greatly.

I have been involved in some group work with docali and DonVK that stemmed out of a Yuichi A-290 simulation I tried and tacked onto the work they had been doing with different horn curves. I intend to create some separate threads with more details but one very promising candidate has emerged that simulates very well indeed, given that it is still using a 2" source.

I very much like the idea of making something K2 inspired in looks. While it's bigger than I would like at 610mm wide, I could happily stare at it in the living room. The render is missing fins and a throat adapter, but the general idea is there.

I have parts for a second system and I think that will be a freestanding OSSE variant, maybe mabat's CE360 with BMS 5530Nd and 12PR320 in a passive or active cardioid mid enclosure.

I have been involved in some group work with docali and DonVK that stemmed out of a Yuichi A-290 simulation I tried and tacked onto the work they had been doing with different horn curves. I intend to create some separate threads with more details but one very promising candidate has emerged that simulates very well indeed, given that it is still using a 2" source.

I very much like the idea of making something K2 inspired in looks. While it's bigger than I would like at 610mm wide, I could happily stare at it in the living room. The render is missing fins and a throat adapter, but the general idea is there.

I have parts for a second system and I think that will be a freestanding OSSE variant, maybe mabat's CE360 with BMS 5530Nd and 12PR320 in a passive or active cardioid mid enclosure.

Attachments

- Home

- Loudspeakers

- Multi-Way

- 2 way waveguide speaker build ABEC modelling