O/L motor controller

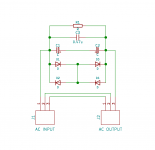

There is a blog on another web site that outlines upgrading the O/L motor controlling. However as I am a total novice I do not understand it. But here are two pictures of before & after

There is a blog on another web site that outlines upgrading the O/L motor controlling. However as I am a total novice I do not understand it. But here are two pictures of before & after

Attachments

O/L Controller Upgrade

This is the description that came with it

''The difference between the advanced and ultra, 2 cheap resistors, 2 transistors, a couple of caps and four 50p diodes''

''Below is my initial upgrade to the O/L control PCB now neater with tidy soldering, heat sink on the voltage regulator from copper pipe better heat conductor than aluminum, 2 x 10000 uf caps to halve ESR, 4 x 5 amp Schottky 5B5100diodes replacing the monolith rectifier also I have now replaced the single diode bottom right with another 5B5100 , Wima 5% 0.1uf + 0.5uf metal film caps above and below PCB on the input prior to the rectifier. the goop under the caps is silicone to hold them in place as the PCB is inverted in it's case. ''

Cheers

This is the description that came with it

''The difference between the advanced and ultra, 2 cheap resistors, 2 transistors, a couple of caps and four 50p diodes''

''Below is my initial upgrade to the O/L control PCB now neater with tidy soldering, heat sink on the voltage regulator from copper pipe better heat conductor than aluminum, 2 x 10000 uf caps to halve ESR, 4 x 5 amp Schottky 5B5100diodes replacing the monolith rectifier also I have now replaced the single diode bottom right with another 5B5100 , Wima 5% 0.1uf + 0.5uf metal film caps above and below PCB on the input prior to the rectifier. the goop under the caps is silicone to hold them in place as the PCB is inverted in it's case. ''

Cheers

Hi, Sorry no, it is well covered over by the way Google handles O/L motor upgrade kits searches. I stumbled upon it by chance, it was mainly talking about using the O/L kit to upgrade the Linn T/T's.

Took the screen shots & info as show closed my computer for the night & then could not find it again.

however there is a little info on the same, on V/E

Cheers

Took the screen shots & info as show closed my computer for the night & then could not find it again.

however there is a little info on the same, on V/E

Cheers

Hi, Sorry no, it is well covered over by the way Google handles O/L motor upgrade kits searches.

Inexpensive alternative to Origin Live PS190 upgrade PSU- Vinyl Engine

(By searching for the text you quoted; an image is there also.)

(Another path is your browser's History, if you have not been dumping it to hide where you been, and if you can remember approximate time and date. See image.)

Attachments

Last edited:

A friend of mine has a couple of truepoint controllers, the type 2 and type 3. He is getting better results from the type 2 which he is using with his Pink Triangle Anniversary. It is an improvement over the original Pink controller. At some point I will be knocking up an adaptor so I can borrow his type 2 and compare it with my Origin Live advance controller. The Truepoint controllers look like they have better construction and much neater soldering.

Niffy

Niffy

I also have an Origin Live motor kit (Premotec motor 18105 and Advanced controller) driving my Roksan Xerxes original turntable. I am not happy with the overall speed stability, so I am considering of changing the motor to something better. But this means that I will have to find the appropriate controller, too.

The cherry on the cake is that I am considering of eliminating the belt altogether and converting to a rim drive, either at the outer or the inner circumference of the platter. I guess a high-torque DC motor would be preferable.

Thoughts, please?

Thanks in advance,

Panos.

Athens, Greece

The cherry on the cake is that I am considering of eliminating the belt altogether and converting to a rim drive, either at the outer or the inner circumference of the platter. I guess a high-torque DC motor would be preferable.

Thoughts, please?

Thanks in advance,

Panos.

Athens, Greece

Attachments

Hi Panos,

I have received your PM. As it is the same question as asked in this thread I'll answer it here.

You have timed your message surprisingly well. I am waiting in for a courier to deliver a new Maxon motor.

The motor that I have ordered is from the Re-Max range. The 226764. This range of motors is not in their normal stock range but are still available. The lead time is unfortunately quite long at around 10 weeks for most models. I chose this range as my research seems to point to this being the ultimate motor solution.

The exact model that you would require will most likely be different from the one I have selected. From what I can gather the Origin Live controllers work their best with an output of around 5volts. I selected my motor, based on the diameters of my sub-platter and pulley, so that the voltage would be 5volts at 33 1/3rpm. The important specification for setting this is the speed constant which is in rpm/volt. I did make a slightly larger pulley so that the motor speed would be lower at around 300rpm. Any motor or pulley variation should be at 5hz, well below the audio band.

I did pick up a second hand version of this motor but the bearings had been damaged. I suspect this was due to too great a force having been applied whilst press fitting a pulley. The specifications state that the maximum press fit force is 80N. Make sure that you stay well below this. I did fit the damaged motor to my deck just to see if it would work. I could clearly hear the motor from the listening position. The increased noise did seem to decrease transparency, soundstage size and transient response, the leading edges of notes being softened. It was surprisingly much better than the Premotec in the tonal qualities being much richer. The decay of notes was also superior. I think that this is likely due to the Maxon having higher torque and more importantly lower torque ripple.

I can't wait to try a non-knackered version of this motor.

I have recently tried my Origin live advanced controller in a three way shoot-out against a couple of other controllers on my friends fully enfunkated pink triangle anniversary. The other controllers were the original Pink Triangle and a Truepoint. Using the original wall-wart supply the OL was the worst and the Truepoint was the best. Using my upgraded external power supply the OL was clearly and easily the best. I have compared my DIY power supply to the OL top supply and mine is significantly better. The difference is that the OL is just a large 15v transformer that feeds AC to the controller where mine is a 24v DC. My supply is basically the same as a medium sized power amp power supply.

Once I have the new motor fitted and run in I am planning on taking advantage of OLs money back scheme and trying the Ultra controller. OL do offer a trade in on the controllers so the cost of upgrading is considerably less than buying new.

I hope this information is useful.

Niffy

PS. Nice deck. Excellent choice of mat and cartridge, they are both the same as used by my friend on his Anniversary. Have you tried the Funk Houdini? I was shocked by how much difference it made to his deck.

I have received your PM. As it is the same question as asked in this thread I'll answer it here.

You have timed your message surprisingly well. I am waiting in for a courier to deliver a new Maxon motor.

The motor that I have ordered is from the Re-Max range. The 226764. This range of motors is not in their normal stock range but are still available. The lead time is unfortunately quite long at around 10 weeks for most models. I chose this range as my research seems to point to this being the ultimate motor solution.

The exact model that you would require will most likely be different from the one I have selected. From what I can gather the Origin Live controllers work their best with an output of around 5volts. I selected my motor, based on the diameters of my sub-platter and pulley, so that the voltage would be 5volts at 33 1/3rpm. The important specification for setting this is the speed constant which is in rpm/volt. I did make a slightly larger pulley so that the motor speed would be lower at around 300rpm. Any motor or pulley variation should be at 5hz, well below the audio band.

I did pick up a second hand version of this motor but the bearings had been damaged. I suspect this was due to too great a force having been applied whilst press fitting a pulley. The specifications state that the maximum press fit force is 80N. Make sure that you stay well below this. I did fit the damaged motor to my deck just to see if it would work. I could clearly hear the motor from the listening position. The increased noise did seem to decrease transparency, soundstage size and transient response, the leading edges of notes being softened. It was surprisingly much better than the Premotec in the tonal qualities being much richer. The decay of notes was also superior. I think that this is likely due to the Maxon having higher torque and more importantly lower torque ripple.

I can't wait to try a non-knackered version of this motor.

I have recently tried my Origin live advanced controller in a three way shoot-out against a couple of other controllers on my friends fully enfunkated pink triangle anniversary. The other controllers were the original Pink Triangle and a Truepoint. Using the original wall-wart supply the OL was the worst and the Truepoint was the best. Using my upgraded external power supply the OL was clearly and easily the best. I have compared my DIY power supply to the OL top supply and mine is significantly better. The difference is that the OL is just a large 15v transformer that feeds AC to the controller where mine is a 24v DC. My supply is basically the same as a medium sized power amp power supply.

Once I have the new motor fitted and run in I am planning on taking advantage of OLs money back scheme and trying the Ultra controller. OL do offer a trade in on the controllers so the cost of upgrading is considerably less than buying new.

I hope this information is useful.

Niffy

PS. Nice deck. Excellent choice of mat and cartridge, they are both the same as used by my friend on his Anniversary. Have you tried the Funk Houdini? I was shocked by how much difference it made to his deck.

Niffy,

thanks very much for your detailed response. I am very interested in your impressions, when you receive the new Maxon motor. Based on its specs it definitely provides much higher torque than the Premotec motor (actually 2.7x). This of course does not say anything about the vibrations that the motor produces, and more importantly whether it has any cogging.

Earlier today, I managed to try something that I have been thinking lately, namely to remove the belt and convert my Roksan Xerxes to a belt drive. I placed an o-ring on the Premotec's pulley (see enclosed photo) and then placed the motor below the platter, so that the o-ring drives the inner rim of the platter. The concept seems to be working fine, at least functionally, because I have not had the time to do any auditioning yet. A first finding is that if I slow down the platter with my hand, the resistance I feel with the rim drive is noticeably greater than with the belt drive (with the same Premotec motor of course).

I've left the motor running for an hour and measured the speed. It seems quite stable, at least not less stable than with the belt. So, what's next? First of all an audition is needed. I must experience how this rim-drive sounds. If it is even marginally better than the belt-drive, then I will pursue it further. More specifically:

1) I will explore a new motor with higher torque, probably the Maxon RE-226764 or even one of Maxon's DCX line. Hopefully, if those motors are not compatible with the OL advanced controller (how can I find out, really?), I will fall back to the Premotec 16703 motor, which has similar characteristics with my existing Premotec 18105 motor, but with higher torque (22mNm instead of 10mNm).

2) I will place a second o-ring at the bottom part of the pulley

3) I will create a 'real' motor pod (what I have now is a joke, not a pod)

4) I will investigate whether a linear power supply can further improve on the motor's performance, having the sonic performance as the ultimate goal.

So, quite a few things to play with.

Any ideas/suggestions are of course welcome.

Cheers,

Panos

P.S. Yes, the Achromat was definitely an improvement. And the Audiomods Series 6 tonearm, even more so. The only thing that remains from the original Xerxes is just the bearing. Everything else is different.

thanks very much for your detailed response. I am very interested in your impressions, when you receive the new Maxon motor. Based on its specs it definitely provides much higher torque than the Premotec motor (actually 2.7x). This of course does not say anything about the vibrations that the motor produces, and more importantly whether it has any cogging.

Earlier today, I managed to try something that I have been thinking lately, namely to remove the belt and convert my Roksan Xerxes to a belt drive. I placed an o-ring on the Premotec's pulley (see enclosed photo) and then placed the motor below the platter, so that the o-ring drives the inner rim of the platter. The concept seems to be working fine, at least functionally, because I have not had the time to do any auditioning yet. A first finding is that if I slow down the platter with my hand, the resistance I feel with the rim drive is noticeably greater than with the belt drive (with the same Premotec motor of course).

I've left the motor running for an hour and measured the speed. It seems quite stable, at least not less stable than with the belt. So, what's next? First of all an audition is needed. I must experience how this rim-drive sounds. If it is even marginally better than the belt-drive, then I will pursue it further. More specifically:

1) I will explore a new motor with higher torque, probably the Maxon RE-226764 or even one of Maxon's DCX line. Hopefully, if those motors are not compatible with the OL advanced controller (how can I find out, really?), I will fall back to the Premotec 16703 motor, which has similar characteristics with my existing Premotec 18105 motor, but with higher torque (22mNm instead of 10mNm).

2) I will place a second o-ring at the bottom part of the pulley

3) I will create a 'real' motor pod (what I have now is a joke, not a pod)

4) I will investigate whether a linear power supply can further improve on the motor's performance, having the sonic performance as the ultimate goal.

So, quite a few things to play with.

Any ideas/suggestions are of course welcome.

Cheers,

Panos

P.S. Yes, the Achromat was definitely an improvement. And the Audiomods Series 6 tonearm, even more so. The only thing that remains from the original Xerxes is just the bearing. Everything else is different.

Attachments

I had noticed that you have upgraded the plinth to a quality ply rather than the original mdf which had a tendency to sag with age. Also looks much nicer than the original.

If you have the ability to make a new pulley/idler wheel it might be beneficial to make one that is 25-30mm in diameter. This will require the motor to run at a much lower speed than with the ~10mm you are currently using. This will dramatically reduce motor noise. If you have a mechanics stethoscope try placing the tip against the motor when it is running and listen to the amount of motor noise,then reset the controller to run at approximately a third the speed and listen again. Should be much quieter. Reducing motor speed will theoretically reduce the available torque. Having higher torque means that the motor can accelerate the platter more rapidly which is not necessarily beneficial but it may be. I think that the benefits of a higher grade motor will mainly be lower noise and lower torque ripple. Motors like the Premotec and Maxon both have slanted windings so neither of them should have any cogging. Torque ripple is due to variation in the windings and strength of the permanent magnets. Higher quality motors have less less variation and thus less ripple.

Having higher instantaneous current availability from the power supply seems to help suppress torque ripple which is probably the main reason that the bigger power supplies sound so much better.

Niffy

If you have the ability to make a new pulley/idler wheel it might be beneficial to make one that is 25-30mm in diameter. This will require the motor to run at a much lower speed than with the ~10mm you are currently using. This will dramatically reduce motor noise. If you have a mechanics stethoscope try placing the tip against the motor when it is running and listen to the amount of motor noise,then reset the controller to run at approximately a third the speed and listen again. Should be much quieter. Reducing motor speed will theoretically reduce the available torque. Having higher torque means that the motor can accelerate the platter more rapidly which is not necessarily beneficial but it may be. I think that the benefits of a higher grade motor will mainly be lower noise and lower torque ripple. Motors like the Premotec and Maxon both have slanted windings so neither of them should have any cogging. Torque ripple is due to variation in the windings and strength of the permanent magnets. Higher quality motors have less less variation and thus less ripple.

Having higher instantaneous current availability from the power supply seems to help suppress torque ripple which is probably the main reason that the bigger power supplies sound so much better.

Niffy

Hi Niffy,

Indeed, the original plinth of the Xerxes showed the notorious sag, so I had no choice other than replacing it with another plinth of similar design concept, but built of much sturdier birch ply wood (Inspire hi-fi).

I am quite excited by the fact that my Xerxes seems to be working fine with the conversion of drive method from belt to rim. This has been tested with measurements, although I have not yet the chance to make any serious auditioning. It seems it may worth pursuing this approach.

Unfortunately, I do not have the tools to create a larger pulley for the motor, so I will have to turn to a machinist, who may do it for me on a lathe. Do you think that the pulley should better be metallic (i.e. stainless steel or brass) or acrylic? Should it be press-fitted on the motor shaft or should I use an allen bolt to connect the pulley on the shaft?

In any case, a larger pulley means I will have to reduce the current speed of the motor from the OL controller by ½ or by ⅓ (depending on the diameter of the pulley). Can the controller operate in that range? Perhaps I am mistaken, but I've read that DC motor can achieve better speed stability when they operate at higher rather than lower revs. If I understand correctly, you are not concerned about that. But how does this relate to available torque of a DC motor? Running at lower speeds means that the motor has higher available torque? Or is it the contrary?

In terms of the motor itself, I am really curious about your feedback concerning the Maxon RE motor. I am wondering whether the OL controller may be able to drive it properly. As a matter of fact, can the OL controller work with other motors other than the actual motor it has been designed for (initially Premotec and later Maxon)? If yes, what characteristics should I look for, so that I eliminate any incompatibilities? For example should I look only at 12V motors or would 24V be an option? So, if I may consider other motors too, why not have a look at one of the Maxon DCX series, which are supposed to be very high quality?

I am glad that we are both investigating the possibilities of the OL controller, so that we can exchange ideas and experiences. -))

Cheers,

Panos

P.S. I have recently restored a Lenco L78 with DIY plinth made of corian and birch ply wood, a high precision bearing and new idler wheel. I would be interested in making a head-to-head comparison of the rim-drive Xerxes with the idler-wheel Lenco...

P.S.2. I have an idler wheel from my Lenco restoration. Would I be able to use that for my rim-drive experiment on the Roksan motor, or is it too large, i.e. it would require reducing the motor speed to a very low level? If I remember correctly, the Lenco idler wheel is around 6.5cm in diameter -))

Indeed, the original plinth of the Xerxes showed the notorious sag, so I had no choice other than replacing it with another plinth of similar design concept, but built of much sturdier birch ply wood (Inspire hi-fi).

I am quite excited by the fact that my Xerxes seems to be working fine with the conversion of drive method from belt to rim. This has been tested with measurements, although I have not yet the chance to make any serious auditioning. It seems it may worth pursuing this approach.

Unfortunately, I do not have the tools to create a larger pulley for the motor, so I will have to turn to a machinist, who may do it for me on a lathe. Do you think that the pulley should better be metallic (i.e. stainless steel or brass) or acrylic? Should it be press-fitted on the motor shaft or should I use an allen bolt to connect the pulley on the shaft?

In any case, a larger pulley means I will have to reduce the current speed of the motor from the OL controller by ½ or by ⅓ (depending on the diameter of the pulley). Can the controller operate in that range? Perhaps I am mistaken, but I've read that DC motor can achieve better speed stability when they operate at higher rather than lower revs. If I understand correctly, you are not concerned about that. But how does this relate to available torque of a DC motor? Running at lower speeds means that the motor has higher available torque? Or is it the contrary?

In terms of the motor itself, I am really curious about your feedback concerning the Maxon RE motor. I am wondering whether the OL controller may be able to drive it properly. As a matter of fact, can the OL controller work with other motors other than the actual motor it has been designed for (initially Premotec and later Maxon)? If yes, what characteristics should I look for, so that I eliminate any incompatibilities? For example should I look only at 12V motors or would 24V be an option? So, if I may consider other motors too, why not have a look at one of the Maxon DCX series, which are supposed to be very high quality?

I am glad that we are both investigating the possibilities of the OL controller, so that we can exchange ideas and experiences. -))

Cheers,

Panos

P.S. I have recently restored a Lenco L78 with DIY plinth made of corian and birch ply wood, a high precision bearing and new idler wheel. I would be interested in making a head-to-head comparison of the rim-drive Xerxes with the idler-wheel Lenco...

P.S.2. I have an idler wheel from my Lenco restoration. Would I be able to use that for my rim-drive experiment on the Roksan motor, or is it too large, i.e. it would require reducing the motor speed to a very low level? If I remember correctly, the Lenco idler wheel is around 6.5cm in diameter -))

Last edited:

Hi Panos,

I've not had much experience with rim drive decks. I have heard a couple of restored and upgraded Garrards which both sounded excellent.

I think that press fit is going to be the better option. A grub screw is going want to push the pulley off centre though if the fit between the shaft and pulley is reasonably tight this shouldn't be a problem. I don't think I have seen any "high end" decks use a grub screw, they all seem to be press fit. There is probably a good reason for this.

All the rim drives I've seen have metal idler wheels but I can't see any reason why a quality engineering plastic could not be used. The pulley I made for my deck is Delrin. Delrin will probably be easier to press fit than aluminium.

Although DC motors may be slightly less speed stable at lower speeds they are also much quieter at lower speeds. The amount of noise seems to increase to the square of the motor speed as general rule of thumb. Double the speed quadruple the noise.

Origin Live motor kits are designed to be fitted to almost any deck. The crown of their pulley is 7.8mm diameter, (from memory). This can be used to drive the outer edge of a platter ,300mm+, or a small sub-platter like with the Rega at 101mm. My sub-platter is 111mm and my pulley 12mm, so this would be slower still. I have had no issues with speed stability. The controller has a very wide range. I would recommend selecting a motor so that with your idler and platter diameters the controller is outputting 5 volts for 33 1/3 RPM. Good idea to make sure of the idler diameter and if you are going to invest in having one made before selecting the motor.

The actual rated voltage of the motor is not important. This is just the voltage required to achieve full speed. You will be running MUCH lower than this. What is important is the speed constant which tells you how fast the motor spins per volt input. The Maxon motor is have on order (still hasn't turned up ☹️) is rated at 48v.

I'll have a look at the DCX range.

I'd be interested to see what Linn are using for the Radikal Mk2. It's definitely a Maxon but is covered in foam so the legend is obscured. It looks like an older A-Max but I can't find the exact model. Anyone got any info on this? Linn are typically very tight lipped.

Niffy

I've not had much experience with rim drive decks. I have heard a couple of restored and upgraded Garrards which both sounded excellent.

I think that press fit is going to be the better option. A grub screw is going want to push the pulley off centre though if the fit between the shaft and pulley is reasonably tight this shouldn't be a problem. I don't think I have seen any "high end" decks use a grub screw, they all seem to be press fit. There is probably a good reason for this.

All the rim drives I've seen have metal idler wheels but I can't see any reason why a quality engineering plastic could not be used. The pulley I made for my deck is Delrin. Delrin will probably be easier to press fit than aluminium.

Although DC motors may be slightly less speed stable at lower speeds they are also much quieter at lower speeds. The amount of noise seems to increase to the square of the motor speed as general rule of thumb. Double the speed quadruple the noise.

Origin Live motor kits are designed to be fitted to almost any deck. The crown of their pulley is 7.8mm diameter, (from memory). This can be used to drive the outer edge of a platter ,300mm+, or a small sub-platter like with the Rega at 101mm. My sub-platter is 111mm and my pulley 12mm, so this would be slower still. I have had no issues with speed stability. The controller has a very wide range. I would recommend selecting a motor so that with your idler and platter diameters the controller is outputting 5 volts for 33 1/3 RPM. Good idea to make sure of the idler diameter and if you are going to invest in having one made before selecting the motor.

The actual rated voltage of the motor is not important. This is just the voltage required to achieve full speed. You will be running MUCH lower than this. What is important is the speed constant which tells you how fast the motor spins per volt input. The Maxon motor is have on order (still hasn't turned up ☹️) is rated at 48v.

I'll have a look at the DCX range.

I'd be interested to see what Linn are using for the Radikal Mk2. It's definitely a Maxon but is covered in foam so the legend is obscured. It looks like an older A-Max but I can't find the exact model. Anyone got any info on this? Linn are typically very tight lipped.

Niffy

Hi Niffy,

thanks for the insightful feedback.

So, I understand that I do not have to stick to 12V motors only, since that's simply a nominal value.

At the same time, the lower the operating speed of the motor, the better in terms of vibrations, provided we do not face any speed instability issues. But, if -for a moment- we take motor vibrations out of the equation, how does motor speed affect motor torque? For a given power, the motor torque and speed and inversely proportional. This means that if the motor is operating at a low speed, it should also have high torque available to overcome resistance (e.g. stylus drag). Can you please confirm?

With respect to the Maxon DCX range, the famous Kronos Sparta turntable uses such motors (as showcased on the Maxon website https://www.maxongroup.com/maxon/view/application/TURNTABLE-AB). I will have a look whether a motor from that range might be appropriate for my rim drive application.

Last, can you please let me know the exact model of the Maxon motor you are expecting? Are you sure it's the 226764? I could only find the 226774, but that's 24V. I must be missing something.

Cheers,

P.

thanks for the insightful feedback.

So, I understand that I do not have to stick to 12V motors only, since that's simply a nominal value.

At the same time, the lower the operating speed of the motor, the better in terms of vibrations, provided we do not face any speed instability issues. But, if -for a moment- we take motor vibrations out of the equation, how does motor speed affect motor torque? For a given power, the motor torque and speed and inversely proportional. This means that if the motor is operating at a low speed, it should also have high torque available to overcome resistance (e.g. stylus drag). Can you please confirm?

With respect to the Maxon DCX range, the famous Kronos Sparta turntable uses such motors (as showcased on the Maxon website https://www.maxongroup.com/maxon/view/application/TURNTABLE-AB). I will have a look whether a motor from that range might be appropriate for my rim drive application.

Last, can you please let me know the exact model of the Maxon motor you are expecting? Are you sure it's the 226764? I could only find the 226774, but that's 24V. I must be missing something.

Cheers,

P.

I believe the Radikal2 is a DC-max26. The Radikal 1 is RE-max part number 531434. RE-max is obsolete which is why Linn made the change. The specific model is a special not available for public to purchase. Precious metal brushes with a gold flake coating.Hi Panos,

I've not had much experience with rim drive decks. I have heard a couple of restored and upgraded Garrards which both sounded excellent.

I think that press fit is going to be the better option. A grub screw is going want to push the pulley off centre though if the fit between the shaft and pulley is reasonably tight this shouldn't be a problem. I don't think I have seen any "high end" decks use a grub screw, they all seem to be press fit. There is probably a good reason for this.

All the rim drives I've seen have metal idler wheels but I can't see any reason why a quality engineering plastic could not be used. The pulley I made for my deck is Delrin. Delrin will probably be easier to press fit than aluminium.

Although DC motors may be slightly less speed stable at lower speeds they are also much quieter at lower speeds. The amount of noise seems to increase to the square of the motor speed as general rule of thumb. Double the speed quadruple the noise.

Origin Live motor kits are designed to be fitted to almost any deck. The crown of their pulley is 7.8mm diameter, (from memory). This can be used to drive the outer edge of a platter ,300mm+, or a small sub-platter like with the Rega at 101mm. My sub-platter is 111mm and my pulley 12mm, so this would be slower still. I have had no issues with speed stability. The controller has a very wide range. I would recommend selecting a motor so that with your idler and platter diameters the controller is outputting 5 volts for 33 1/3 RPM. Good idea to make sure of the idler diameter and if you are going to invest in having one made before selecting the motor.

The actual rated voltage of the motor is not important. This is just the voltage required to achieve full speed. You will be running MUCH lower than this. What is important is the speed constant which tells you how fast the motor spins per volt input. The Maxon motor is have on order (still hasn't turned up ☹️) is rated at 48v.

I'll have a look at the DCX range.

I'd be interested to see what Linn are using for the Radikal Mk2. It's definitely a Maxon but is covered in foam so the legend is obscured. It looks like an older A-Max but I can't find the exact model. Anyone got any info on this? Linn are typically very tight lipped.

Niffy

DCX22 is another good motor. If you are buying one beware of problems with speed stability when running so slowly. I bought 3x DCX22 motors and only one has remained stable. If I were to buy another I would try a carbon brush version..

Hi deano1712,

thanks for the info.

I've just sent an email to Maxon, stating my use case and asking their recommendation for one of their motors.

Based on my calculations for my rim-drive use case, I would like to have a motor speed that should range between 130-727rpm (at approx. 5V), depending on the pulley diameter that I will place on the motor shaft (the 6.5cm diameter of a typical Lenco idler wheel will require the motor to run at approx. 134rpm, while a pulley of 1.2cm diameter will require a speed of approx. 727rpm). I guess torque should be in the range 20-50 mNm (the more the better).

I am going to connect the motor to the Origin Live controller that I already have for the Premotec motor and see if I get any better results in terms of speed reliability and torque (because I cannot complain about too high vibrations from the Premotec motor).

So, the question is whether I should look at the DCX range or at any of the other lines they have (RE, etc.). Hmm.

Cheers,

Panos

thanks for the info.

I've just sent an email to Maxon, stating my use case and asking their recommendation for one of their motors.

Based on my calculations for my rim-drive use case, I would like to have a motor speed that should range between 130-727rpm (at approx. 5V), depending on the pulley diameter that I will place on the motor shaft (the 6.5cm diameter of a typical Lenco idler wheel will require the motor to run at approx. 134rpm, while a pulley of 1.2cm diameter will require a speed of approx. 727rpm). I guess torque should be in the range 20-50 mNm (the more the better).

I am going to connect the motor to the Origin Live controller that I already have for the Premotec motor and see if I get any better results in terms of speed reliability and torque (because I cannot complain about too high vibrations from the Premotec motor).

So, the question is whether I should look at the DCX range or at any of the other lines they have (RE, etc.). Hmm.

Cheers,

Panos

Hi Panos,

By increasing the ratio between the size of the pulley and platter and also increasing motor speed to match the maximum torque available at the platter will also be increased.

The big question is "what benefits are there to having greater torque?"

The motor has to supply enough torque to overcome bearing friction, belt/idler hysteresis and stylus drag. If it supplies more torque than this the platter will accelerate which is not what we want. In most decks a tiny motor would be able to deliver enough torque. It is not the motor that has to adjust to accommodate momentary variations in friction due to drag ect. This is the job of the controller. I don't think that higher torque motors sound better just because they have a higher torque ability. I think that higher quality motors work better largely because they have lower torque ripple. Higher torque motors are often higher quality.

It is possible that higher torque is beneficial in the same way that higher power in amplifiers "can" be beneficial. Though this analogy would seem to fit with the controller more than the motor.

The motor I have on order is the Re-Max 226764. It has a speed constant of just 56.8rpm/volt. I do not think that this motor would be suitable for your deck unless you increase the size of the idler wheel. Your current idler appears to be around 10mm in diameter. With this idler the controller would need to output around 15v, more for 45rpm. I'm not sure if the OL can quite manage this. Select a motor of around 160-180rpm/volt.

Interesting info on the Sparta. Thanks for pointing that out.

Niffy

By increasing the ratio between the size of the pulley and platter and also increasing motor speed to match the maximum torque available at the platter will also be increased.

The big question is "what benefits are there to having greater torque?"

The motor has to supply enough torque to overcome bearing friction, belt/idler hysteresis and stylus drag. If it supplies more torque than this the platter will accelerate which is not what we want. In most decks a tiny motor would be able to deliver enough torque. It is not the motor that has to adjust to accommodate momentary variations in friction due to drag ect. This is the job of the controller. I don't think that higher torque motors sound better just because they have a higher torque ability. I think that higher quality motors work better largely because they have lower torque ripple. Higher torque motors are often higher quality.

It is possible that higher torque is beneficial in the same way that higher power in amplifiers "can" be beneficial. Though this analogy would seem to fit with the controller more than the motor.

The motor I have on order is the Re-Max 226764. It has a speed constant of just 56.8rpm/volt. I do not think that this motor would be suitable for your deck unless you increase the size of the idler wheel. Your current idler appears to be around 10mm in diameter. With this idler the controller would need to output around 15v, more for 45rpm. I'm not sure if the OL can quite manage this. Select a motor of around 160-180rpm/volt.

Interesting info on the Sparta. Thanks for pointing that out.

Niffy

Hi Dean,

Do you know what sort of speed the DCX22 were running at when they suffered speed stability issues and do you recall the specific model?

Niffy

Do you know what sort of speed the DCX22 were running at when they suffered speed stability issues and do you recall the specific model?

Niffy

One extra point when selecting a motor. Avoid the ones with ball bearings as these will very likely be much noisier than those with sleeve bearings.

I’m not sure of exact speed but I have the dcx22s 24v motor and drive it around 1.5 volts. Pulley is around 16mm. Precious metal brushes is supposed to be quieter but they can suffer stability issues at very slow speed.Hi Dean,

Do you know what sort of speed the DCX22 were running at when they suffered speed stability issues and do you recall the specific model?

Niffy

I drive mine with a voltage DAC, negative terminal resistance and closed loop control. Speed accuracy can be very good. The best I have seen on my setup is plus minus 0.02%.

- Home

- Source & Line

- Analogue Source

- 12VDC motor for the turntable. Power, torque, PCB questions