The PT deck does offer adjustment of motor speed but not motor positioning for adjusting belt tension. This is pretty common, I think decks without tension adjustment are probably in the majority. The way the motor is mounted would be compromised if the position was made adjustable.Great intel!

I'm just shocked that the PT deck didn't offer any motor adjustment. Or perhaps it does - but the new OL belt was so much bigger that any motor adjustment had already been consumed.

Belt material sure does make a massive difference...

LOVING our ultra-stretchy, ultra-grippy, super-loose BLUE SILICONE BELT.

I have a couple of OL belts that I had made for my deck when I was using a single flat belt. By shear Serendipity my OL belts are exactly the correct size for his PT and should result in a belt tension of about 0.55N and a side force on the motor pulley of 0.75N. Perfect.

I'll be dropping them off with him soon.

Niffy

I took my OL belt to my friends and fitted it on his PT Anniversary. My belt is 412mm long compared to his 433. This belt sounded almost identical to how his OL belt sounded (when it was behaving) .

I calculated the tension that the two belts would have. His would have been only around 0.06N, mine was 0.55N.

With this belt material it would seem that belt tension doesn't have much effect on sound quality (once you get to the point where it isn't slipping).

When calculating friction the contact area, say between belt and pulley, doesn't actually matter. It is the contact force that matters. If you look at the equations used for calculating friction there is no term for area.

The final ingredient for my new (and hopefully improved) belt gluing system has just arrived so I should now be able to make silicone belts.

I currently have 7 different materials with another 5 on order. I have measured the properties of the 7 I have. I'm going to pair materials that have similar compliance but very different damping characteristics so that I can see if high or low damping is preferable. I will also pair materials with similar damping but very different compliances. This should help me to determine the best combination of properties.

All belts will be made so that they have the same tension. I might make extra sets of belts of the winning material to test different tension.

One surprise finding is that I had expected silicone to have very high damping. It actually has by far the lowest of any material so far tested.

Niffy

I calculated the tension that the two belts would have. His would have been only around 0.06N, mine was 0.55N.

With this belt material it would seem that belt tension doesn't have much effect on sound quality (once you get to the point where it isn't slipping).

When calculating friction the contact area, say between belt and pulley, doesn't actually matter. It is the contact force that matters. If you look at the equations used for calculating friction there is no term for area.

The final ingredient for my new (and hopefully improved) belt gluing system has just arrived so I should now be able to make silicone belts.

I currently have 7 different materials with another 5 on order. I have measured the properties of the 7 I have. I'm going to pair materials that have similar compliance but very different damping characteristics so that I can see if high or low damping is preferable. I will also pair materials with similar damping but very different compliances. This should help me to determine the best combination of properties.

All belts will be made so that they have the same tension. I might make extra sets of belts of the winning material to test different tension.

One surprise finding is that I had expected silicone to have very high damping. It actually has by far the lowest of any material so far tested.

Niffy

Standard silicone is very staticy and attracts a layer of surface dust - there are specialist suppliers providing ESD-safe silicone though.

Well, I agree that it's the forces that matter, but the perpendicular force that can be applied on a body is usually (always?) a function of contact area. Just to be certain that I am not misguided, out of curiosity, I asked chatGPT "is friction force related to contact area between two bodies in contact?", and I am quoting its response......

When calculating friction the contact area, say between belt and pulley, doesn't actually matter. It is the contact force that matters. If you look at the equations used for calculating friction there is no term for area.

....

"Yes, the friction force is indeed related to the contact area between two bodies in contact. According to the laws of friction, the frictional force is directly proportional to the normal force and the coefficient of friction. The normal force is the force exerted by a surface to support the weight of an object resting on it, and it acts perpendicular to the surface.

The coefficient of friction represents the frictional characteristics of the two surfaces in contact. It can be subdivided into two types: static friction and kinetic (or dynamic) friction. The static friction coefficient determines the maximum amount of force required to initiate motion between the two surfaces, while the kinetic friction coefficient determines the force required to maintain motion once it has started.

The equation for frictional force is:

Frictional force = Coefficient of friction × Normal force

The normal force is proportional to the weight of the object, and in some cases, it can be influenced by the contact area between the two surfaces. If the contact area changes, the normal force and, consequently, the frictional force can also change, assuming the coefficient of friction remains constant.

It's important to note that the relationship between contact area and friction force can vary depending on the specific circumstances, surface properties, and the nature of the contact (e.g., whether it's a smooth or rough surface). However, in general, an increase in contact area tends to result in a higher normal force and, consequently, a higher frictional force, assuming all other factors remain constant."

In practical terms, my argument is that if you want to transfer a certain force via a belt and you start reducing the width of the belt (and hence the contact area) without changing the friction coefficient (because that's a characteristic of the two materials in contact), at some point the contact area will be so small, that the belt will eventually slip, because the friction force will not be sufficient (due to the normal force having become too little).

Apologies if I may have misinterpreted your thinking.

Cheers,

Panos

Hi Panos,

It's saying pretty much what I was.

Force is equal to pressure times area. If the force remains constant and the area decreases the contact pressure will increase.

If the contact pressure remains the same same but the contact area decreases then the level of friction will decrease. This is because the force will have decreased in this example.

When calculating belt friction it is easier to work out the belt tension and the angle the belt makes over the pulley and from this calculate the normal force. Contact area would not be required for this method.

You would also need to know the coefficient of friction between the platter and pulley, the sizes of pulley and platter and the amount of torque required to overcome bearing friction and stylus drag. This is just for normal running. For spin up you also need to know the inertia of the platter and the torque of the motor.

Much easier to adjust belt tension until you don't get slippage and then adjust from there for optimum sound quality.

Niffy

It's saying pretty much what I was.

Force is equal to pressure times area. If the force remains constant and the area decreases the contact pressure will increase.

If the contact pressure remains the same same but the contact area decreases then the level of friction will decrease. This is because the force will have decreased in this example.

When calculating belt friction it is easier to work out the belt tension and the angle the belt makes over the pulley and from this calculate the normal force. Contact area would not be required for this method.

You would also need to know the coefficient of friction between the platter and pulley, the sizes of pulley and platter and the amount of torque required to overcome bearing friction and stylus drag. This is just for normal running. For spin up you also need to know the inertia of the platter and the torque of the motor.

Much easier to adjust belt tension until you don't get slippage and then adjust from there for optimum sound quality.

Niffy

Just by the feel of Origin Live belt I had assumed that it had a very high level of damping. Trying to gauge things like stretchiness and damping of different materials by feel is difficult and not very accurate. I measured my other OL belt using the same method that I have for the other belt materials. It was somewhat more difficult as the belt is in a loop rather than a single strand so I had to double the loading weights to compensate. It is also much shorter, at about a third the length, of those I've been using for the other materials. This means that the amount of stretch is much smaller for a given load and is more difficult to read off the scale.

It turns out that the compliance and damping of the OL belt is almost exactly the same as the 1.5mm nitrile rubber belt that I am currently using. It would be funny if I ended up discovering that I was using the best material all along.

It turns out that the compliance and damping of the OL belt is almost exactly the same as the 1.5mm nitrile rubber belt that I am currently using. It would be funny if I ended up discovering that I was using the best material all along.

I'm going to borrow the original neoprene belt from the Anniversary and measure it in the same way. As the OL sounded so much better the difference in material properties will hopefully be enlightening.

Niffy,

thank you for the results that you are sharing with us from the very interesting tests that you are doing.

If I am not mistaken, you also have polyester thread to test among all types of belt material. I am curious about how it compares with the rest.

Keep up the good work.

Cheers,

Panos

thank you for the results that you are sharing with us from the very interesting tests that you are doing.

If I am not mistaken, you also have polyester thread to test among all types of belt material. I am curious about how it compares with the rest.

Keep up the good work.

Cheers,

Panos

I do indeed have polyester thread to compare. It is the Sulky brand as recommended in the video you linked. It hasn't arrived so I haven't measured it's properties yet, hopefully it will get here soon.

Great. I have also purchased the same thread brand and I have been impressed by its overall quality and ease of belt 'manufacturing' (as many belts as you want, at practically zero cost).

Hi Panos,

How accurately can you make the length of a polyester belt? I will probably need to be able to make them to a millimetre's accuracy.

With 2200yrds I can afford to waste some thread experimenting and practicing.

How accurately can you make the length of a polyester belt? I will probably need to be able to make them to a millimetre's accuracy.

With 2200yrds I can afford to waste some thread experimenting and practicing.

Hi Niffy,

with a little bit of practice, I guess, anyone can achieve an accuracy of 1mm. And all of that without any special tools, just a ruler and two nails.

What is impressive in my opinion is that the knot is so small, that it does not affect the movement, while it's turning around the pulley. The polyester thread is not stretchy at all and can work even without a lot of tension. YMMV.

with a little bit of practice, I guess, anyone can achieve an accuracy of 1mm. And all of that without any special tools, just a ruler and two nails.

What is impressive in my opinion is that the knot is so small, that it does not affect the movement, while it's turning around the pulley. The polyester thread is not stretchy at all and can work even without a lot of tension. YMMV.

I've made a batch of different belts today and given them a quick listen.

Based on comments made in this thread is have reduced my target side force on the pulley from 1N to 0.75N. I first made a new set of belts using the 1.5mm nitrile rubber that I have been using to date. The sound with the new lower tension belts was virtually identical to the previous belts, maybe a little bit more open so maybe a little better. The lower tension should also be beneficial for motor life.

I am using the new 1.5mm nitrile belts as a reference and comparing each new set of belts to these in an A-B-A. This will inevitable result in a lot more belt swaps, which is a bit of a pain on my deck, but will give consistency. It's currently looking like I'll have at least a dozen different belts to compare.

I'm scoring each belt in 6 categories, bass, mid and top tonality, imaging, dynamic expression and transparency.

As the 1.5mm nitrile is the reference I'm giving it 5s across the board, total 30. Each other belt is then scored against this. The highest scorers can then be given a more thorough evaluation.

The initial results have totally thrown me as they are all over the place, seemingly having no relationship to the measurements made. I went into these first listening tests with absolutely no idea how the materials would perform but I had expected to start seeing some form of pattern. Not a bit of it.

So far I've tested Nitrile in 1mm, 1.5mm and 2mm diameters and silicone in 1.5mm and 2mm diameters. The 1.5mm silicone is the translucent variety and the 2mm is white.

The 1.5mm silicone was a big disappointment scoring a total of 20. Soft and distant. Bloomy bass. Lack of nuance and fine detail.

The 2mm nitrile was much better with a score of 26.

It had very nice full bass and mids but lacked air and transparency.

A bit messy and unstable sounding.

Run out was a bit wobbly which could point to in being a compatability issue with my deck rather than the material itself.

The 2mm silicone sounded excellent with a score of 29.

It had full midrange and a sweet top end though it was a little rolled off at both frequency extremes.

Very clean sounding - low surface noise.

Little soft on bass transients.

I'll definitely be revisiting this one.

The 1mm nitrile was also excellent with a score of 30.

Very sweet top end.

A little thin in mid and bass.

Open detailed and transparent.

Great imaging.

Not quite as musically involving as 1.5mm nitrile.

Will definitely be revisiting this one too.

Niffy

Based on comments made in this thread is have reduced my target side force on the pulley from 1N to 0.75N. I first made a new set of belts using the 1.5mm nitrile rubber that I have been using to date. The sound with the new lower tension belts was virtually identical to the previous belts, maybe a little bit more open so maybe a little better. The lower tension should also be beneficial for motor life.

I am using the new 1.5mm nitrile belts as a reference and comparing each new set of belts to these in an A-B-A. This will inevitable result in a lot more belt swaps, which is a bit of a pain on my deck, but will give consistency. It's currently looking like I'll have at least a dozen different belts to compare.

I'm scoring each belt in 6 categories, bass, mid and top tonality, imaging, dynamic expression and transparency.

As the 1.5mm nitrile is the reference I'm giving it 5s across the board, total 30. Each other belt is then scored against this. The highest scorers can then be given a more thorough evaluation.

The initial results have totally thrown me as they are all over the place, seemingly having no relationship to the measurements made. I went into these first listening tests with absolutely no idea how the materials would perform but I had expected to start seeing some form of pattern. Not a bit of it.

So far I've tested Nitrile in 1mm, 1.5mm and 2mm diameters and silicone in 1.5mm and 2mm diameters. The 1.5mm silicone is the translucent variety and the 2mm is white.

The 1.5mm silicone was a big disappointment scoring a total of 20. Soft and distant. Bloomy bass. Lack of nuance and fine detail.

The 2mm nitrile was much better with a score of 26.

It had very nice full bass and mids but lacked air and transparency.

A bit messy and unstable sounding.

Run out was a bit wobbly which could point to in being a compatability issue with my deck rather than the material itself.

The 2mm silicone sounded excellent with a score of 29.

It had full midrange and a sweet top end though it was a little rolled off at both frequency extremes.

Very clean sounding - low surface noise.

Little soft on bass transients.

I'll definitely be revisiting this one.

The 1mm nitrile was also excellent with a score of 30.

Very sweet top end.

A little thin in mid and bass.

Open detailed and transparent.

Great imaging.

Not quite as musically involving as 1.5mm nitrile.

Will definitely be revisiting this one too.

Niffy

Last edited:

Hi Niffy,

I may have missed it, but I am wondering whether the belts you are testing have circular or rectangular cross section. Can you please enlighten us about that?

Thanks

P.

I may have missed it, but I am wondering whether the belts you are testing have circular or rectangular cross section. Can you please enlighten us about that?

Thanks

P.

Round belts.

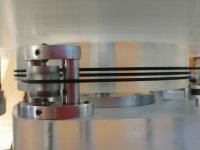

I have the rather unusual bearing and drive configuration with two idler wheels in addition to the motor pulley. I use a separate belt around each idler and the motor pulley.

This is with the 1.5mm nitrile belts, which are still my favourite so far. Hopefully I'll get to testing a couple more belt materials in the next couple of days.

Niffy

I have the rather unusual bearing and drive configuration with two idler wheels in addition to the motor pulley. I use a separate belt around each idler and the motor pulley.

This is with the 1.5mm nitrile belts, which are still my favourite so far. Hopefully I'll get to testing a couple more belt materials in the next couple of days.

Niffy

I've made 4 more sets of belts today and given each a quick test.

The first up was some 1.5mm Viton. This was very disappointing as it didn't work at all. Even though I made the belts to have exactly the same tension as the other materials these suffered from massive slipping. The platter barely moved even though the pulley was spinning at full speed. Extra disappointing as this was by far the most expensive material I've purchased and I had had high hopes for it.

The next material tested was a bit of a long shot that I didn't expect to work at all. It is 2mm foamed neoprene. I've not seen foamed rubber being used for drive belts before. I thought that the foamed structure might have benefits for improving damping. The measured hysteresis was about average for the test group. The compliance was very high, similar to the 1mm nitrile.

This belt material performed pretty well with a score of 25.

It had a smooth and relaxed sound.

Image focus is a little vague but had good depth.

Nice mid-tone but lacked solidity.

The bass was quite soft and dynamics were muted.

The whole was better than the sum of the parts, I quite enjoyed the sound of these belts.

Next up was some 1.6mm EPDM.

This sounded very similar to the 1.5mm nitrile with a score of 29.

In comparison it was a little lacking in bass detail and transients very slightly softened. On the plus side it had a slightly warmer, richer mid-tone.

This material feels very similar to the Origin Live belt, I wonder if this is the material they use.

Finally I tested some 2mm EPDM.

This is the first material to beat my reference 1.5mm nitrile belts with a score of 34.

Again, similar to the 1.5mm nitrile but with richer tonality across the board.

Good image focus and solidity.

Good depth and layering of soundstage.

Real listen through transparency, low noise and blacker background.

My favourite to date.

Niffy

The first up was some 1.5mm Viton. This was very disappointing as it didn't work at all. Even though I made the belts to have exactly the same tension as the other materials these suffered from massive slipping. The platter barely moved even though the pulley was spinning at full speed. Extra disappointing as this was by far the most expensive material I've purchased and I had had high hopes for it.

The next material tested was a bit of a long shot that I didn't expect to work at all. It is 2mm foamed neoprene. I've not seen foamed rubber being used for drive belts before. I thought that the foamed structure might have benefits for improving damping. The measured hysteresis was about average for the test group. The compliance was very high, similar to the 1mm nitrile.

This belt material performed pretty well with a score of 25.

It had a smooth and relaxed sound.

Image focus is a little vague but had good depth.

Nice mid-tone but lacked solidity.

The bass was quite soft and dynamics were muted.

The whole was better than the sum of the parts, I quite enjoyed the sound of these belts.

Next up was some 1.6mm EPDM.

This sounded very similar to the 1.5mm nitrile with a score of 29.

In comparison it was a little lacking in bass detail and transients very slightly softened. On the plus side it had a slightly warmer, richer mid-tone.

This material feels very similar to the Origin Live belt, I wonder if this is the material they use.

Finally I tested some 2mm EPDM.

This is the first material to beat my reference 1.5mm nitrile belts with a score of 34.

Again, similar to the 1.5mm nitrile but with richer tonality across the board.

Good image focus and solidity.

Good depth and layering of soundstage.

Real listen through transparency, low noise and blacker background.

My favourite to date.

Niffy

Please don't take this as criticism, but do you think the differences are big enough to pass a double blind evaluation? If so it should be possible to measure the changes, maybe with an fft of the output from a good test record?

Hi Ralph,

Not taken as a criticism, constructive criticism is always welcome.

The difference between some of the belts is quite pronounced and should be easily decernible in a blind test. The difference between others is more subtle and might be more difficult to repeatedly identify.

I'm not sure what I'd be looking for if I did take measurements and I'm not sure anyone else does either. The measurement guys say all cables sound the same because they measure the same when anyone who knows how to listen can easily tell them apart.

Plus I don't have a laptop and my PC is in my office which is two floors away from my listening room.

I'm not a fan of blind testing for a couple of reasons. Quick A-B comparisons can be useful for creating a shortlist. I then want to live with a choice for a while. Sometimes what appeared to be a plus on a quick listen can turn into a negative longterm. It is nye on impossible to blind A-B over a couple of days or longer.

The very act of blind A-B comparison changes the way in which we listen. It creates an anxiety over being able to decern that stresses the listener colouring the experience. Blind you are much more likely to choose something that is brighter, louder or running slightly faster.

I find that it's much better to learn to listen without bias. I'm honest enough with myself that I am constantly finding that I actually prefer the piece of kit that I have expected to not like as much.

With my current belts experiment I had the added advantage of going in with absolutely no expectations as to how each will perform, zero bias.

Niffy

Not taken as a criticism, constructive criticism is always welcome.

The difference between some of the belts is quite pronounced and should be easily decernible in a blind test. The difference between others is more subtle and might be more difficult to repeatedly identify.

I'm not sure what I'd be looking for if I did take measurements and I'm not sure anyone else does either. The measurement guys say all cables sound the same because they measure the same when anyone who knows how to listen can easily tell them apart.

Plus I don't have a laptop and my PC is in my office which is two floors away from my listening room.

I'm not a fan of blind testing for a couple of reasons. Quick A-B comparisons can be useful for creating a shortlist. I then want to live with a choice for a while. Sometimes what appeared to be a plus on a quick listen can turn into a negative longterm. It is nye on impossible to blind A-B over a couple of days or longer.

The very act of blind A-B comparison changes the way in which we listen. It creates an anxiety over being able to decern that stresses the listener colouring the experience. Blind you are much more likely to choose something that is brighter, louder or running slightly faster.

I find that it's much better to learn to listen without bias. I'm honest enough with myself that I am constantly finding that I actually prefer the piece of kit that I have expected to not like as much.

With my current belts experiment I had the added advantage of going in with absolutely no expectations as to how each will perform, zero bias.

Niffy

I did a bit more listening today comparing directly against each other rather than via the 1.5mm nitrile reference. I also played with adjusting tension with a couple. More listening tests are required.

The polyester monofilament still hasn't arrived.

The polyester monofilament still hasn't arrived.

- Home

- Source & Line

- Analogue Source

- 12VDC motor for the turntable. Power, torque, PCB questions