Hi, Not strange but normal. All machinery gets quieter after a few hours to days of use. It's called the break in period.

Cheers

Cheers

Niffy and DNic,

yes, indeed strange. The only explanation I have is that when I initially realized that the bearings were rather noisy (with a knocking sound, while the motor was turning), I added a drop of oil (for my Xerxes main bearing) and let it work for a few hours. At that time there was no improvement. But perhaps during storage the oil might have sunk in and reduced the noise.

Yesterday, I left the motor running overnight. The noise is not completely eliminated. It's worse than it was yesterday, when I unpacked the motor after storage.

What is clear though is that when the motor is turning anticlockwise (by switching the connection polarity), it is much quieter (almost completely quiet) than when turning clockwise.

Enclosed you can find a short video, where you can hear the noise while the motor is running.

Niffy, what's your opinion? Since you have the exact same motor, does your motor sound similar to what you can hear on the video?

Furthermore, I have seen that although my motor shaft has absolutely no tolerance (movement) vertically (or radially), it has approx. 0.5-1mm play axially. Is that the same with your motor, Niffy?

I am trying to figure out whether my motor unit is faulty and perhaps I should ask Maxon to send me a replacement, or whether all units are more or less the same and I should not expect different operation from a replacement unit.

Thoughts, please?

P.S. I have now left the motor turning anti-clockwise and after a few hours, I will try it again clockwise...

yes, indeed strange. The only explanation I have is that when I initially realized that the bearings were rather noisy (with a knocking sound, while the motor was turning), I added a drop of oil (for my Xerxes main bearing) and let it work for a few hours. At that time there was no improvement. But perhaps during storage the oil might have sunk in and reduced the noise.

Yesterday, I left the motor running overnight. The noise is not completely eliminated. It's worse than it was yesterday, when I unpacked the motor after storage.

What is clear though is that when the motor is turning anticlockwise (by switching the connection polarity), it is much quieter (almost completely quiet) than when turning clockwise.

Enclosed you can find a short video, where you can hear the noise while the motor is running.

Niffy, what's your opinion? Since you have the exact same motor, does your motor sound similar to what you can hear on the video?

Furthermore, I have seen that although my motor shaft has absolutely no tolerance (movement) vertically (or radially), it has approx. 0.5-1mm play axially. Is that the same with your motor, Niffy?

I am trying to figure out whether my motor unit is faulty and perhaps I should ask Maxon to send me a replacement, or whether all units are more or less the same and I should not expect different operation from a replacement unit.

Thoughts, please?

P.S. I have now left the motor turning anti-clockwise and after a few hours, I will try it again clockwise...

Hi Panos,

That sounds like the sound of my motor with the damaged bearing. How far away can you hear the motor from? With my damaged motor it was audible from over 3m away.

According to Maxon's spec sheet the motor should have 0.1-0.2mm of axial play, which is what my good motor has. The knackered motor has about 1mm of axial play. I think that these motors are designed for clockwise only long term operation.

It looks like you have a defective motor. I would recommend returning it to Maxon for a replacement.

Niffy

That sounds like the sound of my motor with the damaged bearing. How far away can you hear the motor from? With my damaged motor it was audible from over 3m away.

According to Maxon's spec sheet the motor should have 0.1-0.2mm of axial play, which is what my good motor has. The knackered motor has about 1mm of axial play. I think that these motors are designed for clockwise only long term operation.

It looks like you have a defective motor. I would recommend returning it to Maxon for a replacement.

Niffy

Hi Niffy,

initially I could hear the sound of the motor from 2m away. Now, it has become quieter, but when i approach at approx. 10cm, it's still audible, when turning clockwise. As mentioned, anticlockwise and or when the motor is clockwise and upside-down, then it's almost absolutely quiet. Just like my Premotec motor, which is completely silent.

More importantly, the fact that my motor has approx. 0.5-1mm axial play probably indicates the fact that the motor is out of spec. I have already sent the video to Maxon and am expecting their response.

By the way, when operating at 33rpm, the motor runs at 8.25V.

Do you think that if i go for a replacement motor, I might ask another model of the RE-max line, which has a higher speed constant, so that I can achieve the required speed at lower voltage?

Thanks a lot.

Panos

P.S. I wonder what how such noisy motors pass Maxon's quality control...

initially I could hear the sound of the motor from 2m away. Now, it has become quieter, but when i approach at approx. 10cm, it's still audible, when turning clockwise. As mentioned, anticlockwise and or when the motor is clockwise and upside-down, then it's almost absolutely quiet. Just like my Premotec motor, which is completely silent.

More importantly, the fact that my motor has approx. 0.5-1mm axial play probably indicates the fact that the motor is out of spec. I have already sent the video to Maxon and am expecting their response.

By the way, when operating at 33rpm, the motor runs at 8.25V.

Do you think that if i go for a replacement motor, I might ask another model of the RE-max line, which has a higher speed constant, so that I can achieve the required speed at lower voltage?

Thanks a lot.

Panos

P.S. I wonder what how such noisy motors pass Maxon's quality control...

Hi Panos,

A lot quieter than my knackered motor. This one was also quieter upside down. I didn't try running it anticlockwise.

What size pulley are you using to get 33rpm at 8.25V?

Maybe they only check one per batch and let the whole batch through if it passes and check the whole batch if it fails. You might have got the one bad apple in a good barrel.

A lot quieter than my knackered motor. This one was also quieter upside down. I didn't try running it anticlockwise.

What size pulley are you using to get 33rpm at 8.25V?

Maybe they only check one per batch and let the whole batch through if it passes and check the whole batch if it fails. You might have got the one bad apple in a good barrel.

Niffy,

I am letting it run until tomorrow and then I will take a decision about what to do. I hope that Maxon may have responded with their feedback by then, too.

The pulley I am using to get the 33rpm at 8.25V has a diameter of 12mm. I have also ordered one with diameter of 22mm from Aliexpress. It will take a few weeks to arrive, but that should give me an operating voltage of around 4.5V. That should also reduce motor noise, i hope, by running the motor at lower speed.

Do you think I should ask for a replacement motor anyway?

I am letting it run until tomorrow and then I will take a decision about what to do. I hope that Maxon may have responded with their feedback by then, too.

The pulley I am using to get the 33rpm at 8.25V has a diameter of 12mm. I have also ordered one with diameter of 22mm from Aliexpress. It will take a few weeks to arrive, but that should give me an operating voltage of around 4.5V. That should also reduce motor noise, i hope, by running the motor at lower speed.

Do you think I should ask for a replacement motor anyway?

The 22mm pulley sounds ideal.

Just as well you have lots of polyester thread for making a slightly longer belt.

I think asking for a replacement motor is a good idea.

Just as well you have lots of polyester thread for making a slightly longer belt.

I think asking for a replacement motor is a good idea.

I've been running the motor and it's gradually getting quieter. One might say that it's completely quiet now. But not exactly as quiet as the Premotec motor. I will see how it performs tomorrow.

From my experiments so far with mylar tape (5mm wide) and polyester thread, the latter has brought the best results. Of course, I have not listened to the Maxon motor yet, as all my tests have been performed with the Premotec.

From my experiments so far with mylar tape (5mm wide) and polyester thread, the latter has brought the best results. Of course, I have not listened to the Maxon motor yet, as all my tests have been performed with the Premotec.

Last edited:

My good Maxon was slightly quieter than the Premotec from the get go and quietened further over the first couple of days. I haven't checked recently to see if it's improved further. I use a mechanics stethoscope as it gives a better indication of the character of the noise.

The Premotec made a "shush-shush-shush" sound with a "tick-tick-tick" overlayed.

The Maxon was more of a "sheasheashea". More consistent with less variation in level.

Do you have a mechanics stethoscope? If not I would highly recommend getting one. Very useful.

Have you determined whether the polyester or the mylar is stretchier? Could be a useful reference point in the stretchy or non-stretchy belt investigation. Hopefully the silicone and polyurethane belt materials I've ordered will turn up soon so I can add another couple of reference points.

Niffy

The Premotec made a "shush-shush-shush" sound with a "tick-tick-tick" overlayed.

The Maxon was more of a "sheasheashea". More consistent with less variation in level.

Do you have a mechanics stethoscope? If not I would highly recommend getting one. Very useful.

Have you determined whether the polyester or the mylar is stretchier? Could be a useful reference point in the stretchy or non-stretchy belt investigation. Hopefully the silicone and polyurethane belt materials I've ordered will turn up soon so I can add another couple of reference points.

Niffy

Hi Niffy,

I am quoting below Maxon's response, which I've just received.

"Hello Panos,

in this type of bearing, we need to have some play to make the bearing work. Especial the missing axial Preload causes an axial play of roughly 0.15 mm. This necessary bearing play can lead to minor, orientation-dependent noises developing.

Please note that these motors were developed for industrial applications and are therefore not optimized for acoustic properties.

We can only make a more precise statement about your case once we have analyzed the unit at our facility. It would then also depend on whether an improvement can be expected with another RE-max motor (226764) or not."

I happen to have a doctor's stethoscope. I do not know whether it's better or worse than a mechanic's stethoscope, but it helps me determine various sounds that are not audible without some kind of tool.

The Maxon motor has become sufficiently quiet until now and I am hopeful that it will further improve until tomorrow. I will leave it running overnight.

With respect to belt materials, although I have not reached any definite conclusions, the polyester thread seems quieter than the mylar tape belt. Over the next few days I will spend some time to make a more careful comparison. I think that mylar is a bit 'stretchier', but both materials are stretch-free for all intents and purposes of a turntable application.

I am quoting below Maxon's response, which I've just received.

"Hello Panos,

in this type of bearing, we need to have some play to make the bearing work. Especial the missing axial Preload causes an axial play of roughly 0.15 mm. This necessary bearing play can lead to minor, orientation-dependent noises developing.

Please note that these motors were developed for industrial applications and are therefore not optimized for acoustic properties.

We can only make a more precise statement about your case once we have analyzed the unit at our facility. It would then also depend on whether an improvement can be expected with another RE-max motor (226764) or not."

I happen to have a doctor's stethoscope. I do not know whether it's better or worse than a mechanic's stethoscope, but it helps me determine various sounds that are not audible without some kind of tool.

The Maxon motor has become sufficiently quiet until now and I am hopeful that it will further improve until tomorrow. I will leave it running overnight.

With respect to belt materials, although I have not reached any definite conclusions, the polyester thread seems quieter than the mylar tape belt. Over the next few days I will spend some time to make a more careful comparison. I think that mylar is a bit 'stretchier', but both materials are stretch-free for all intents and purposes of a turntable application.

First sound impression with the Maxon RE-max 226764...

Hmmm, how should I put it? The sound is more dynamic (stronger and tighter bass) compared to the Premotec motor. It starts and stops faster, has more impact and eventually is more lifelike.

It's like listening to an idler turntable (e.g. a Lenco L7x), but with all sound details included.

I am sure it can get even better, because currently I have bolted the Maxon motor with a metal plate on the top plinth and does not yet have a dedicated motor pod detached from the plinth (like the one I have with the Premotec). After I have created the motor pod, I will report again about any further improvements (if any).

It is definitely a quite significant upgrade.

@niffy, you were right and thank you for directing me towards the 226764 motor.

Hmmm, how should I put it? The sound is more dynamic (stronger and tighter bass) compared to the Premotec motor. It starts and stops faster, has more impact and eventually is more lifelike.

It's like listening to an idler turntable (e.g. a Lenco L7x), but with all sound details included.

I am sure it can get even better, because currently I have bolted the Maxon motor with a metal plate on the top plinth and does not yet have a dedicated motor pod detached from the plinth (like the one I have with the Premotec). After I have created the motor pod, I will report again about any further improvements (if any).

It is definitely a quite significant upgrade.

@niffy, you were right and thank you for directing me towards the 226764 motor.

Hi Panos,

That is excellent news.

I found that the Maxon wrought improvements across the board.

The biggest is tonal richness especially in the midrange. Soundstage depth was another big improvement as was bottom end extension.

I've just received a package containing a couple of different belt materials to play with. The silicone is much stretchier than the nitrile rubber that I'm currently using. The polyurethane is much less stretchy, making belts of exacting enough length to give even tension between the three belts might be challenging with this one.

Should give me a definitive answer to the belt stretchiness question.

That is excellent news.

I found that the Maxon wrought improvements across the board.

The biggest is tonal richness especially in the midrange. Soundstage depth was another big improvement as was bottom end extension.

I've just received a package containing a couple of different belt materials to play with. The silicone is much stretchier than the nitrile rubber that I'm currently using. The polyurethane is much less stretchy, making belts of exacting enough length to give even tension between the three belts might be challenging with this one.

Should give me a definitive answer to the belt stretchiness question.

Hi Niffy,

yes, yes the Maxon motor is indeed a significant upgrade. The sound is now more solid and it hasn't lost any of the details. As said, it will get even better, when I have a dedicated motor pod built.

In terms of belt material, I will be looking forward to your feedback with great interest. I will also experiment a bit more with the mylar tape. And i will also install an idler pulley just opposite to the motor, although I am not so optimistic that that might have any positive effects on the sound (it might even worsen it, but let's see).

As a recap, for the time being, I am working with the Origin Live controller, upgraded with the 6,800μF Nichicon cap, and operating at 12V input voltage. The motor is the Maxon RE-max 226764 and the 'belt' is made of very thin polyester thread.

yes, yes the Maxon motor is indeed a significant upgrade. The sound is now more solid and it hasn't lost any of the details. As said, it will get even better, when I have a dedicated motor pod built.

In terms of belt material, I will be looking forward to your feedback with great interest. I will also experiment a bit more with the mylar tape. And i will also install an idler pulley just opposite to the motor, although I am not so optimistic that that might have any positive effects on the sound (it might even worsen it, but let's see).

As a recap, for the time being, I am working with the Origin Live controller, upgraded with the 6,800μF Nichicon cap, and operating at 12V input voltage. The motor is the Maxon RE-max 226764 and the 'belt' is made of very thin polyester thread.

@pkonstantinidis

Hey Panos!

It was great to read that the MAXON motor has settled down.

As you rightly point out, there will be dramatic improvement when you mount the motor properly.

On my LP12, top-plate mounting is life or death to the sound. I found that introducing slightly compliant washers (POM or PTFE I think) between BOTH motor and top-plate AND between both ends of the bolt-heads and top-plate, delivered night and day improvements.

Not sure how relevant this is to the XERXES configuration.

@niffy

I very much look forward to your findings with these new belts.

On my LP12, the silicone belt is ridiculously loose - actually, I have it on the minimum tension offered by the top-plate hole location - but hangs on nicely and delivers solid speed consistency and primo sound.

Hey Panos!

It was great to read that the MAXON motor has settled down.

As you rightly point out, there will be dramatic improvement when you mount the motor properly.

On my LP12, top-plate mounting is life or death to the sound. I found that introducing slightly compliant washers (POM or PTFE I think) between BOTH motor and top-plate AND between both ends of the bolt-heads and top-plate, delivered night and day improvements.

Not sure how relevant this is to the XERXES configuration.

@niffy

I very much look forward to your findings with these new belts.

On my LP12, the silicone belt is ridiculously loose - actually, I have it on the minimum tension offered by the top-plate hole location - but hangs on nicely and delivers solid speed consistency and primo sound.

Hey Sondeknz,

you are absolutely right that moving the motor off the plinth makes a hell of a difference. I could not resist the temptation, and instead of waiting for a new motor pod to be built, I took the decision and transplanted the Maxon motor in my existing, crude motor pod, replacing the Premotec motor. The sound has become even clearer, especially in the upper region, e.g. acoustic guitar, etc.

Yes, an external motor pod is the way to go (for me at least).

The good thing is that my OL controller seems to be rock solid in terms of speed, even overnight. Second digit accuracy, i.e. 33.3x. Even the 'x' remains unchanged. Can you believe that? Wow!

For the time being, with the 12mm pulley the motor is running at 8.21V, now that it seems to have run it (somehow at least). When I receive the 22mm, it will run at around 4.5-5V (for 33rpm).

I am very glad that you are happy with the silicone belt. I will try that too, sooner than later, I guess. For the moment I am very satisfied with the polyester thread...

you are absolutely right that moving the motor off the plinth makes a hell of a difference. I could not resist the temptation, and instead of waiting for a new motor pod to be built, I took the decision and transplanted the Maxon motor in my existing, crude motor pod, replacing the Premotec motor. The sound has become even clearer, especially in the upper region, e.g. acoustic guitar, etc.

Yes, an external motor pod is the way to go (for me at least).

The good thing is that my OL controller seems to be rock solid in terms of speed, even overnight. Second digit accuracy, i.e. 33.3x. Even the 'x' remains unchanged. Can you believe that? Wow!

For the time being, with the 12mm pulley the motor is running at 8.21V, now that it seems to have run it (somehow at least). When I receive the 22mm, it will run at around 4.5-5V (for 33rpm).

I am very glad that you are happy with the silicone belt. I will try that too, sooner than later, I guess. For the moment I am very satisfied with the polyester thread...

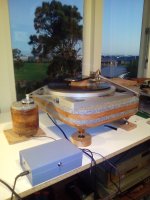

Hi DNic,

thanks for sharing the photo of your t/t. It looks great. If I am not mistaken, your plinth is made of slate and solid wood (not ply)? With respect to the belt, apart from mylar tape, have you also tried polyester thread? If yes, I would be very interested in your impressions and comparison of the two.

Thanks

thanks for sharing the photo of your t/t. It looks great. If I am not mistaken, your plinth is made of slate and solid wood (not ply)? With respect to the belt, apart from mylar tape, have you also tried polyester thread? If yes, I would be very interested in your impressions and comparison of the two.

Thanks

Hi, My T/T is made from re-cycled Rimu (a NZ wood) & Corian top plate. No I have not tried the polyester belt. Although I plan to in the future.

You can buy a ready made Mylar belt from Galibier Turntables, I believe, but do not know the diameter.

https://www.google.com/url?sa=t&rct...rdesign.com/&usg=AOvVaw2-jb50gx3pV4RBQpvHrqqd

Cheers

You can buy a ready made Mylar belt from Galibier Turntables, I believe, but do not know the diameter.

https://www.google.com/url?sa=t&rct...rdesign.com/&usg=AOvVaw2-jb50gx3pV4RBQpvHrqqd

Cheers

- Home

- Source & Line

- Analogue Source

- 12VDC motor for the turntable. Power, torque, PCB questions