Thinking about it I'm not sure that the@niffy

You are correct.

Because my DC motor rarely requires even 1A of current, I was planning on a custom limit of 2A - but have since reconsidered.

I have since asked for 24V output, with maximum current output.

Ohms Law confirms 6.6666666666667A, so you are right on the money.

Hi Sondeknz,For anyone who is still interested in improving the ORIGIN LIVE ADVANCED DC SCU, I've finally made some progress.

Recently, I uprated all resistors to 2W Metal Film, at current specified impedance values.

Frankly, I could not hear any improvement - and the inevitable speed-drift continued - but I have no regrets in uprating, as this hopefully provides something of a safety margin, as I explore other further opportunities to improve this SCU.

Today, I removed the single NICHICON 1,000uF/63V EL cap and replaced it with two NICHICON 4700uF/63V EL caps, wired in parallel.

....

although I am not knowledgeable in electronics, and please correct me if I am wrong, I understand that polypropylene caps are usually more precise and more reliable than electrolytic caps. Why didn't you go for polycaps instead of the EL caps you chose?

Thanks

Panos

Last edited:

Panos,

In principle, you are quite correct.

To my knowledge, they don't yet make poly caps in these high uF values.

If they were available - they would be huge and unusable for this project.

That said, IMHO modern (quality) EL caps are a lot better than their reputation suggests.

In principle, you are quite correct.

To my knowledge, they don't yet make poly caps in these high uF values.

If they were available - they would be huge and unusable for this project.

That said, IMHO modern (quality) EL caps are a lot better than their reputation suggests.

Last edited:

Hi Sondeknz,

is the OL controller continuing sounding better after the change of the capacitors?

If yes, perhaps I should go ahead and try it on my OL controller, too. Have any other operating parameters changed?

Thanks

P.

is the OL controller continuing sounding better after the change of the capacitors?

If yes, perhaps I should go ahead and try it on my OL controller, too. Have any other operating parameters changed?

Thanks

P.

Hi Panos,

I have no way to test capacitors. That said, I am convinced the original 2018-build NICHICON 1,000uF 63V capacitor must be faulty.

I believe this because replacing the original 1,000uF 63V cap with a NICHICON 4,700uF 63V cap solved most of the speed-drift problems - although I fully expect the forthcoming change to DC-24V supply to stabilise platter-speed even further - and delivered a very nice sound quality upgrade. I allowed an overnight platter-spin to allow the new cap to form.

Whilst I have no way to test your PCB myself, I believe that if you would enjoy the same benefits from such an upgrade. You could also "double-up" the way I did, with 02 x 4,700uF 63V caps in this position, if you want to. It's up to you.

There is a ton of room on the PCB and the all through-hole componentry makes soldering tasks a doddle.

Please PM me if you have any specific questions.

I have no way to test capacitors. That said, I am convinced the original 2018-build NICHICON 1,000uF 63V capacitor must be faulty.

I believe this because replacing the original 1,000uF 63V cap with a NICHICON 4,700uF 63V cap solved most of the speed-drift problems - although I fully expect the forthcoming change to DC-24V supply to stabilise platter-speed even further - and delivered a very nice sound quality upgrade. I allowed an overnight platter-spin to allow the new cap to form.

Whilst I have no way to test your PCB myself, I believe that if you would enjoy the same benefits from such an upgrade. You could also "double-up" the way I did, with 02 x 4,700uF 63V caps in this position, if you want to. It's up to you.

There is a ton of room on the PCB and the all through-hole componentry makes soldering tasks a doddle.

Please PM me if you have any specific questions.

Last edited:

Regarding speed-drift, solving this problem is a relative term - as there is probably no such thing as zero speed-drift.

What I can talk about then, is improvements in speed-drift.

The replaced cap greatly improved speed-drift and I expect the forthcoming move from DC-9V to DC-24V supply, to improve speed-drift further - to the point that I can stop worrying about it. 🤣

What I can talk about then, is improvements in speed-drift.

The replaced cap greatly improved speed-drift and I expect the forthcoming move from DC-9V to DC-24V supply, to improve speed-drift further - to the point that I can stop worrying about it. 🤣

Last edited:

I also opened up my OL controller box (for the first time!). I realize that the controller board is designated as both Advanced and Ultra (dual personality? -))

Anyways, I guess that I may proceed and replace the electrolytic capacitor with one or two 4700 μF caps. How about also adding in parallel a much smaller capacitor, say 100 μF, to play the role of a bypass cap (that's common practice in crossover networks, as you probably know).

Any comments?

Cheers,

P.

Anyways, I guess that I may proceed and replace the electrolytic capacitor with one or two 4700 μF caps. How about also adding in parallel a much smaller capacitor, say 100 μF, to play the role of a bypass cap (that's common practice in crossover networks, as you probably know).

Any comments?

Cheers,

P.

Attachments

Panos,

I don't think it would cause any real harm to bypass the big EL cap with a low-value cap, but bear in mind that this is not a crossover network.

In a crossover network, you are typically using low-value bypass caps to ensure high frequencies pass through to the speaker drivers - to maximise treble response.

But here, we are attempting to block frequencies from passing through to the DC motor - for a smooth ride - so a bypass cap may be unhelpful.

Just my 10-cents worth. Others may disagree.

I don't think it would cause any real harm to bypass the big EL cap with a low-value cap, but bear in mind that this is not a crossover network.

In a crossover network, you are typically using low-value bypass caps to ensure high frequencies pass through to the speaker drivers - to maximise treble response.

But here, we are attempting to block frequencies from passing through to the DC motor - for a smooth ride - so a bypass cap may be unhelpful.

Just my 10-cents worth. Others may disagree.

Sondeknz,

based on your feedback, a bypass capacitor may do more harm than good in the particular application. So, probably it's wiser to follow your approach, simply with one or two bigger capacitors than the existing 1000uF one. By the way, why did you pick that particular capacitance value and not something else (smaller / bigger)?

Cheers,

P.

based on your feedback, a bypass capacitor may do more harm than good in the particular application. So, probably it's wiser to follow your approach, simply with one or two bigger capacitors than the existing 1000uF one. By the way, why did you pick that particular capacitance value and not something else (smaller / bigger)?

Cheers,

P.

Hey Panos!

When it comes to filtering noise from circuits, bigger uF capacitors almost always do it better.

There are complex formulas for calculating such filter capacitance values - plenty on YouTube about that - but as a learner myself, I'm not the right person to step you through that.

For every dollar they spend, manufacturers need to add (rule of thumb) at least $10 to the final sell price, so understandably most manufacturers install the smallest and cheapest capacitor to get the job done. We understand - they need to work to a budget and turn a buck.

I don't need to multiply my investment, so I am happy to spend a bit more.

But there are a couple of other considerations other than buying a giant capacitor with adequate power handling.

Firstly, physical size and form-factor. It's got to fit the project!

Secondly, going overboard with a gigantic uF value cap could be very difficult to charge-up - especially with the DC-9V feed that I am currently working with! At worst - depending upon the project - this charge difficulty could potentially blow fuses or trigger protection circuitry to kick-in. Nobody is looking for those fun and games.

The NICHICON 4700uF / 63V EL caps I found offer a great compromise between capacitance value, power handling and form factor - in a brand renown for long life and durability.

Also, because of the size of these NICHICON caps, I knew that I could potentially fit 2 or more of them on the PCB, if I wanted to. This meant I could progressively install them and check the resulting impact on sound quality after each increase.

Two (paralleled) sounds better than one IMHO, so two it is!

It will be interesting to see how they perform when the OL SCU is fed with 24V - instead of 9V. As you know, I have up-rated all my resistors on the PCB for 2W power handling, just as a precautionary measure.

Again, I leave the platter to spin overnight, in order for the caps to form - and make friends. It really makes a difference.

My new LHY AUDIO 160W / DC-24V / 5A Linear Power Supply will probably arrive tomorrow.

Let's see... 😉

When it comes to filtering noise from circuits, bigger uF capacitors almost always do it better.

There are complex formulas for calculating such filter capacitance values - plenty on YouTube about that - but as a learner myself, I'm not the right person to step you through that.

For every dollar they spend, manufacturers need to add (rule of thumb) at least $10 to the final sell price, so understandably most manufacturers install the smallest and cheapest capacitor to get the job done. We understand - they need to work to a budget and turn a buck.

I don't need to multiply my investment, so I am happy to spend a bit more.

But there are a couple of other considerations other than buying a giant capacitor with adequate power handling.

Firstly, physical size and form-factor. It's got to fit the project!

Secondly, going overboard with a gigantic uF value cap could be very difficult to charge-up - especially with the DC-9V feed that I am currently working with! At worst - depending upon the project - this charge difficulty could potentially blow fuses or trigger protection circuitry to kick-in. Nobody is looking for those fun and games.

The NICHICON 4700uF / 63V EL caps I found offer a great compromise between capacitance value, power handling and form factor - in a brand renown for long life and durability.

Also, because of the size of these NICHICON caps, I knew that I could potentially fit 2 or more of them on the PCB, if I wanted to. This meant I could progressively install them and check the resulting impact on sound quality after each increase.

Two (paralleled) sounds better than one IMHO, so two it is!

It will be interesting to see how they perform when the OL SCU is fed with 24V - instead of 9V. As you know, I have up-rated all my resistors on the PCB for 2W power handling, just as a precautionary measure.

Again, I leave the platter to spin overnight, in order for the caps to form - and make friends. It really makes a difference.

My new LHY AUDIO 160W / DC-24V / 5A Linear Power Supply will probably arrive tomorrow.

Let's see... 😉

Hi Sondeknz,

thanks for the info about the caps. It appears to be a quite straightforward mod. And as long as the sound is improved, then I will may as well go ahead and do it.

I am eagerly waiting for your feedback about the linear power supply that you may have received by now.

Thanks.

thanks for the info about the caps. It appears to be a quite straightforward mod. And as long as the sound is improved, then I will may as well go ahead and do it.

I am eagerly waiting for your feedback about the linear power supply that you may have received by now.

Thanks.

Hi Panos,

The LHY AUDIO PSU is a very nice piece of kit, but applying 24V has had mixed results.

The speed is now ROCK SOLID - and never moves. A very BIG win!

I now understand what Niffy said earlier, about the 9V platter-speed being a bit vague, by comparison.

So, goal No. 1 - cure the speed-drift - has now been convincingly achieved. Under 24V supply, I have been able to stop worrying about platter-speed drift. It simply never moves.

Under the 9V supply, our LP12 rig has always sounded really natural and relaxed - perhaps slightly erring on the smooth and warm side of life. The "new" 24V supply sound is very detailed, dynamic, revealing and (almost) a bit too much. WILLY NELSON's usually rich, syrupy vocals on STARDUST now sound just ever-so-slightly hard and croaky. Not like the WILLY we have come to know and love.

My wife made the comment this morning that "...it sounds like it's not warmed-up properly yet". I think her comment was right on the money and strongly suggests that hours or perhaps days of burn-in - actually spinning the platter - need to take place to allow the new capacitors in the 24V PSU to fully form and make friends, before serious critical listening and meaningful comparisons can begin.

Another issue with the 24V supply: The OL SCU R4 (360R) gets dangerously hot - remembering too that I have already up-rated from a 1/4W to a 2W resistor in that position. As an interim safety measure, I have paralleled a 12W 33K resistor with R4, just to absorb any excess heat - but of course the smaller resistor is still getting pretty hot. So, I am about to order a much bigger resistor in true 360R value, to do the job properly.

That's the update. Given that you are not (yet) planning to move to 24V supply, I believe you can upgrade your 1,000uF 63V EL cap with confidence - and enjoy the benefits it delivers - without any of the above concerns.

The LHY AUDIO PSU is a very nice piece of kit, but applying 24V has had mixed results.

The speed is now ROCK SOLID - and never moves. A very BIG win!

I now understand what Niffy said earlier, about the 9V platter-speed being a bit vague, by comparison.

So, goal No. 1 - cure the speed-drift - has now been convincingly achieved. Under 24V supply, I have been able to stop worrying about platter-speed drift. It simply never moves.

Under the 9V supply, our LP12 rig has always sounded really natural and relaxed - perhaps slightly erring on the smooth and warm side of life. The "new" 24V supply sound is very detailed, dynamic, revealing and (almost) a bit too much. WILLY NELSON's usually rich, syrupy vocals on STARDUST now sound just ever-so-slightly hard and croaky. Not like the WILLY we have come to know and love.

My wife made the comment this morning that "...it sounds like it's not warmed-up properly yet". I think her comment was right on the money and strongly suggests that hours or perhaps days of burn-in - actually spinning the platter - need to take place to allow the new capacitors in the 24V PSU to fully form and make friends, before serious critical listening and meaningful comparisons can begin.

Another issue with the 24V supply: The OL SCU R4 (360R) gets dangerously hot - remembering too that I have already up-rated from a 1/4W to a 2W resistor in that position. As an interim safety measure, I have paralleled a 12W 33K resistor with R4, just to absorb any excess heat - but of course the smaller resistor is still getting pretty hot. So, I am about to order a much bigger resistor in true 360R value, to do the job properly.

That's the update. Given that you are not (yet) planning to move to 24V supply, I believe you can upgrade your 1,000uF 63V EL cap with confidence - and enjoy the benefits it delivers - without any of the above concerns.

Hi Sondeknz,

thanks for the very interesting feedback. Correct me if I am wrong, but I think that when the voltage is increased, the current flowing through the circuit is lower (for a given resistance). Hence, based on the lower current, I would expect the produced heat to be lower, too. Obviously, I am missing something. Again, apologies for my lack of electronics knowledge.

With respect to my OL controller, I can go ahead and order two 4700uF capacitors, that I can solder in parallel.

Thanks again.

thanks for the very interesting feedback. Correct me if I am wrong, but I think that when the voltage is increased, the current flowing through the circuit is lower (for a given resistance). Hence, based on the lower current, I would expect the produced heat to be lower, too. Obviously, I am missing something. Again, apologies for my lack of electronics knowledge.

With respect to my OL controller, I can go ahead and order two 4700uF capacitors, that I can solder in parallel.

Thanks again.

Hi SondekNZ,

Glad to hear that your speed problems have been remedied with the new power supply.

I found that dynamics, detail, transparency and soundstage all improved with the higher voltage power supply. With my deck I would say it was more a case of the lower voltage supply sounding soft rather than the higher voltage lacking warmth.

My latest power supply upgrade, which was basically just higher grade components, did result in a fuller tone.

Although both of our supplies are similar in output voltage and maximum continuous current they will have a couple of big differences. Your supply is more "refined" and should have lower noise and ripple. My supply is a much simpler design but will have much higher instantaneous peek current, probably in the 30A-50A range. Which supply will result in higher sound quality? Without having them side by side I wouldn't want to hazard a guess.

When initially switching from the Advanced to Ultra controller I actually preferred the Advanced. It took a couple of days for the Ultra to fully come on line, it being left spinning the platter overnight. Once warmed up the Ultra showed itself to be smoother and more transparent. A big enough difference to make making the upgrade an easy choice. Hopefully your new supply will improve similarly with a bit of time.

The most significant upgrade was swapping the motor for the Maxon. This gave big improvements in all areas. By far the biggest was tonality. Much richer and fuller.

I was having a conversation with a friend discussing what we thought was the "click" moment in each others systems when an upgrade just seemed to pull everything together, the big upgrade. In his system I thought it was a tonearm upgrade. He thought it was the motor swap in mine. The motor really did make that much difference.

Niffy

Glad to hear that your speed problems have been remedied with the new power supply.

I found that dynamics, detail, transparency and soundstage all improved with the higher voltage power supply. With my deck I would say it was more a case of the lower voltage supply sounding soft rather than the higher voltage lacking warmth.

My latest power supply upgrade, which was basically just higher grade components, did result in a fuller tone.

Although both of our supplies are similar in output voltage and maximum continuous current they will have a couple of big differences. Your supply is more "refined" and should have lower noise and ripple. My supply is a much simpler design but will have much higher instantaneous peek current, probably in the 30A-50A range. Which supply will result in higher sound quality? Without having them side by side I wouldn't want to hazard a guess.

When initially switching from the Advanced to Ultra controller I actually preferred the Advanced. It took a couple of days for the Ultra to fully come on line, it being left spinning the platter overnight. Once warmed up the Ultra showed itself to be smoother and more transparent. A big enough difference to make making the upgrade an easy choice. Hopefully your new supply will improve similarly with a bit of time.

The most significant upgrade was swapping the motor for the Maxon. This gave big improvements in all areas. By far the biggest was tonality. Much richer and fuller.

I was having a conversation with a friend discussing what we thought was the "click" moment in each others systems when an upgrade just seemed to pull everything together, the big upgrade. In his system I thought it was a tonearm upgrade. He thought it was the motor swap in mine. The motor really did make that much difference.

Niffy

Hi Panos,

As I understand it, the additional 15V are not actually required, so the first stage of voltage stabilisation components get the job of burning up the extra energy before it enters the circuit proper; hence the additional heat generated from 24V supply.

That said, it is very hard to understand exactly how the additional voltage impacts platter-speed stability, when the additional voltage is being burned-off before reaching the circuit proper.

Frankly, I’m still trying to understand all that is happening in this OL SCU circuit.

When you fit your new caps, be sure to fit the first cap - and have a good listen - before fitting the second cap. You may prefer the sound of one over two.

As I understand it, the additional 15V are not actually required, so the first stage of voltage stabilisation components get the job of burning up the extra energy before it enters the circuit proper; hence the additional heat generated from 24V supply.

That said, it is very hard to understand exactly how the additional voltage impacts platter-speed stability, when the additional voltage is being burned-off before reaching the circuit proper.

Frankly, I’m still trying to understand all that is happening in this OL SCU circuit.

When you fit your new caps, be sure to fit the first cap - and have a good listen - before fitting the second cap. You may prefer the sound of one over two.

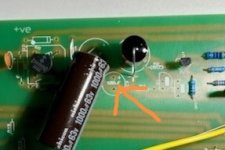

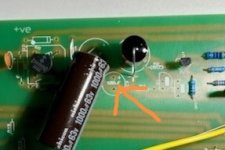

The free space on the board, labelled with the arrow, is paralleled to the main 1000μf capacitor. This would be the ideal place to mount the second cap.

I think that the component above and to the right of this is a bypass cap so you won't need to be adding another one. I haven't looked inside of my controller so I'm not sure what the value of it is.

Niffy

I think that the component above and to the right of this is a bypass cap so you won't need to be adding another one. I haven't looked inside of my controller so I'm not sure what the value of it is.

Niffy

- Home

- Source & Line

- Analogue Source

- 12VDC motor for the turntable. Power, torque, PCB questions