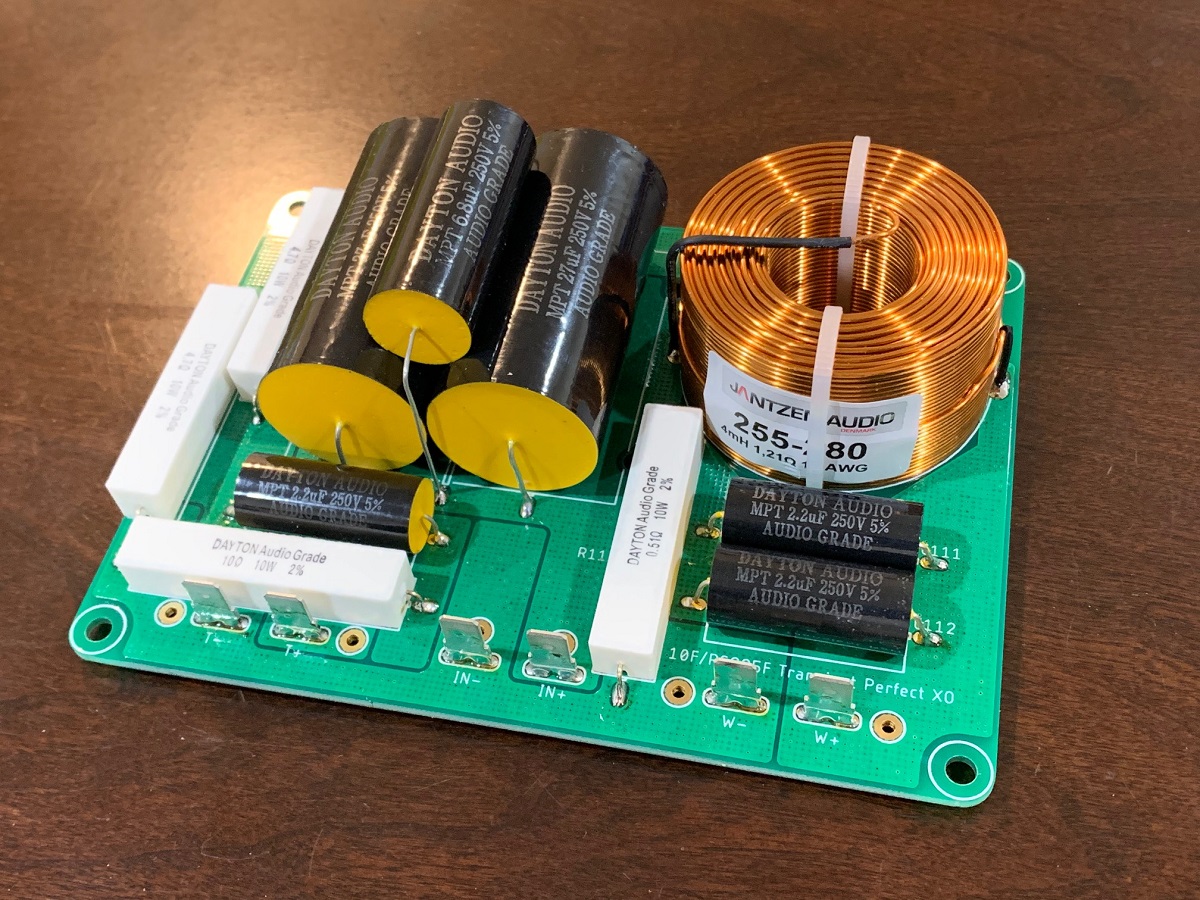

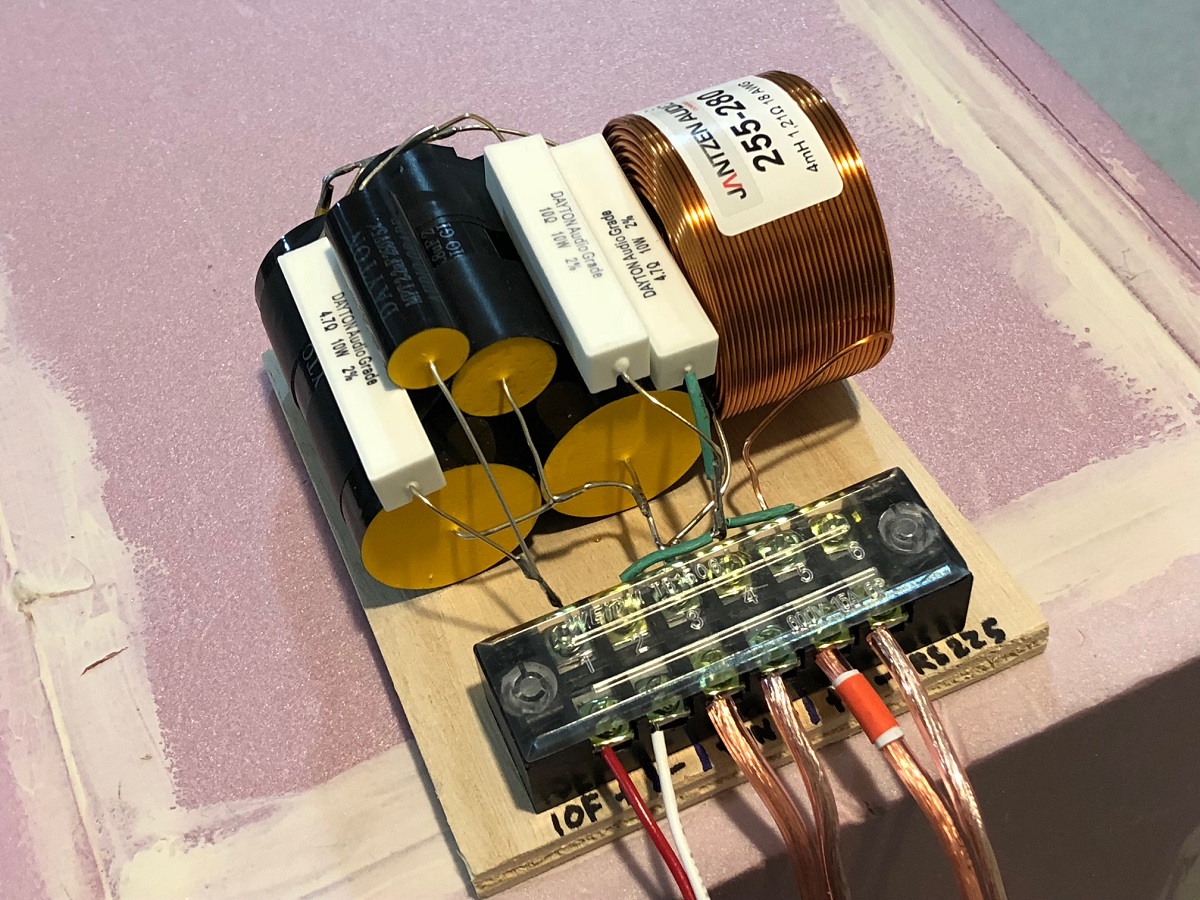

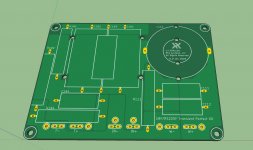

Edit Feb 9, 2020: XO PCB all built up with components from BOM

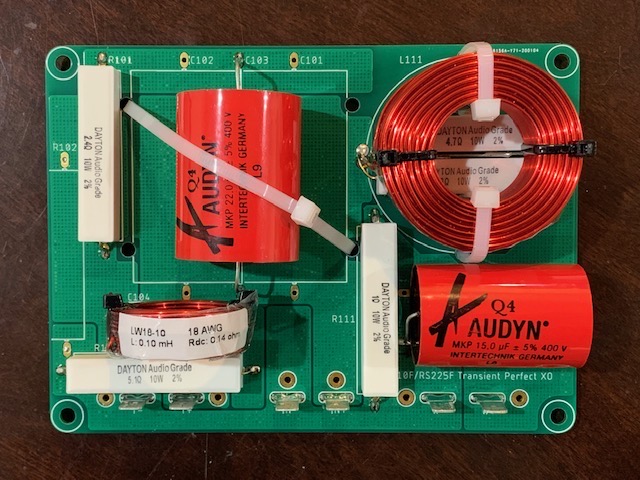

Works well as 2nd order passive XO for MTM speaker too:

This is the Group Buy thread for the PCB for the XO for the speaker described here:

10F/8424 & RS225-8 FAST / WAW Ref Monitor

After making the XO using P2P for years, and at the request of members wanting to try this speaker, I have asked JPS64 to design a layout for this 1st order transient perfect crossover.

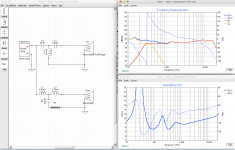

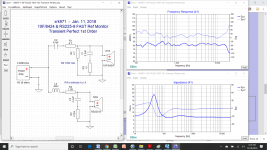

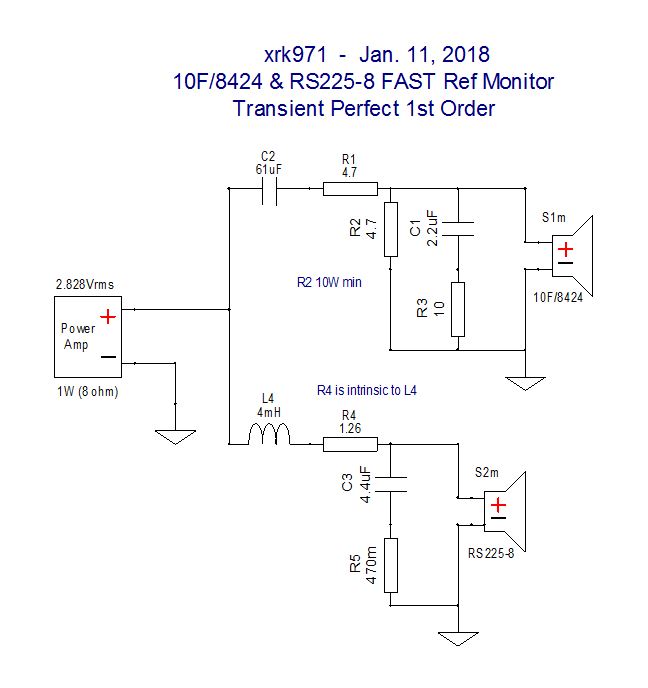

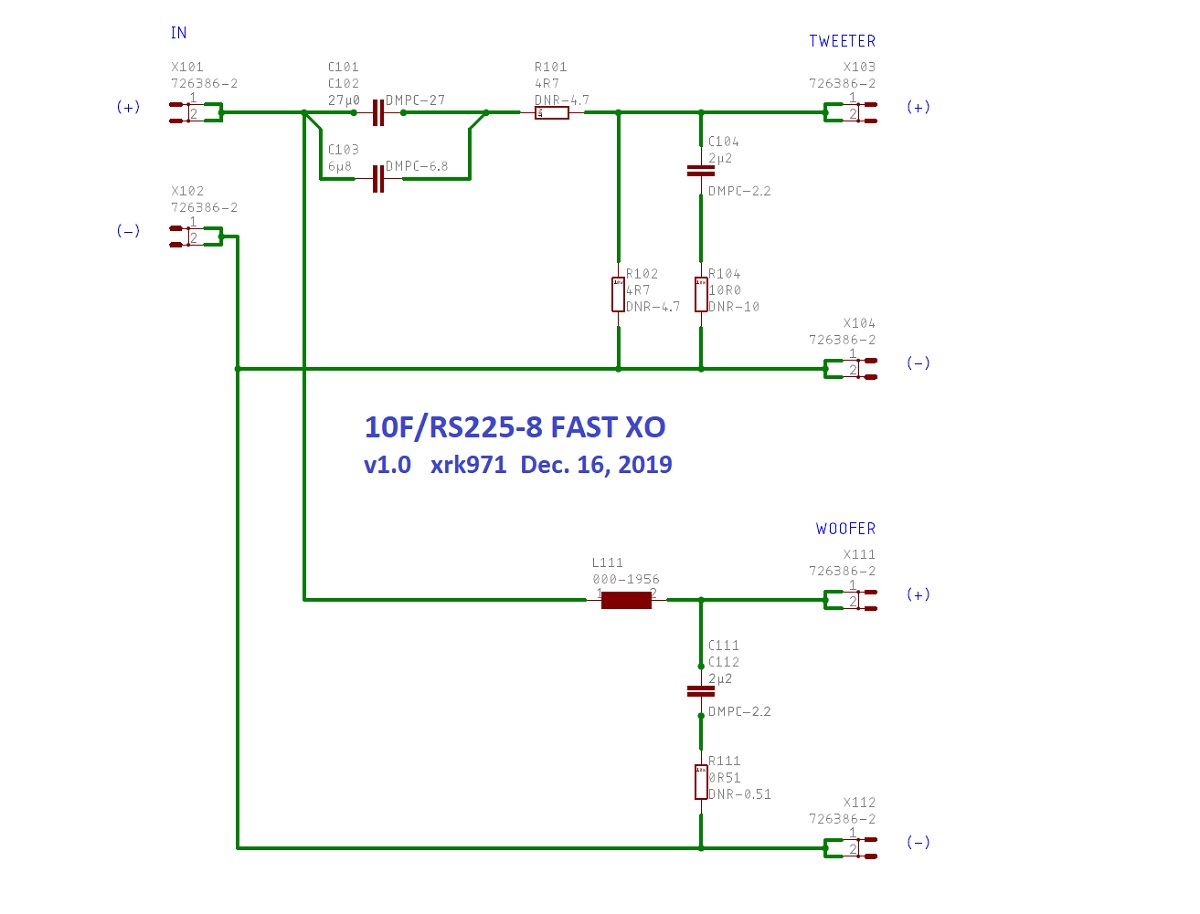

Here is the schematic from Xsim:

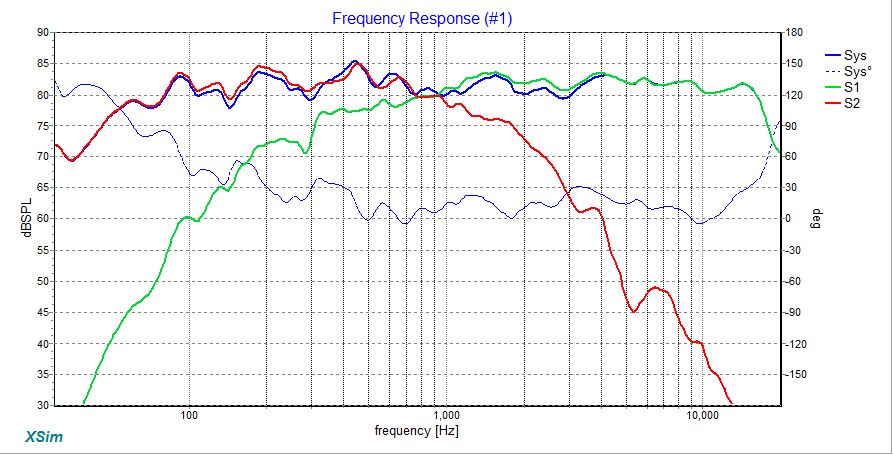

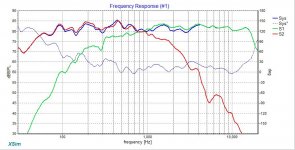

Here is the predicted response and phase using measured response:

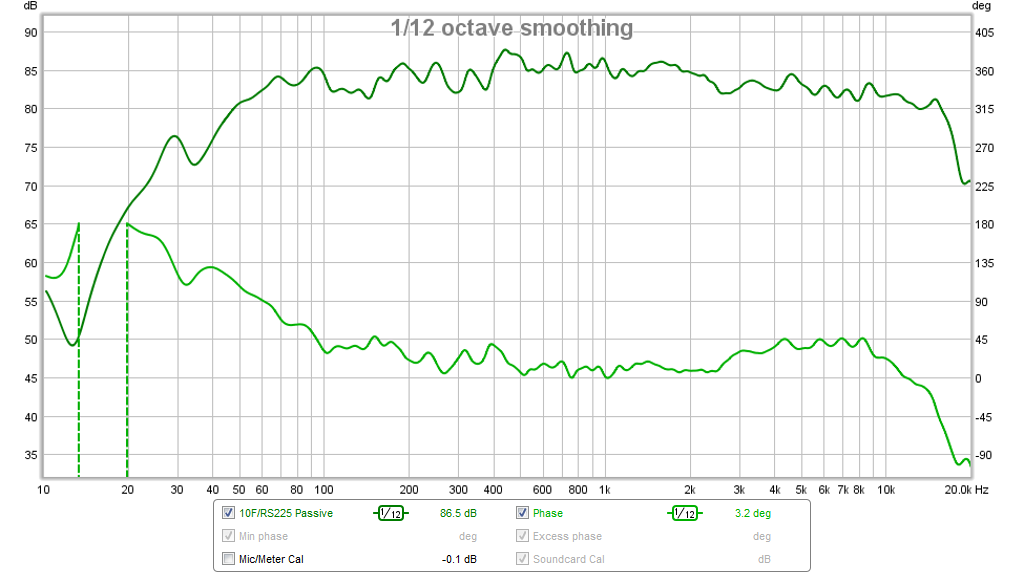

Here is the measured response - note the flat phase from 100Hz through 10kHz - essential for reproducing the transient dynamics correctly:

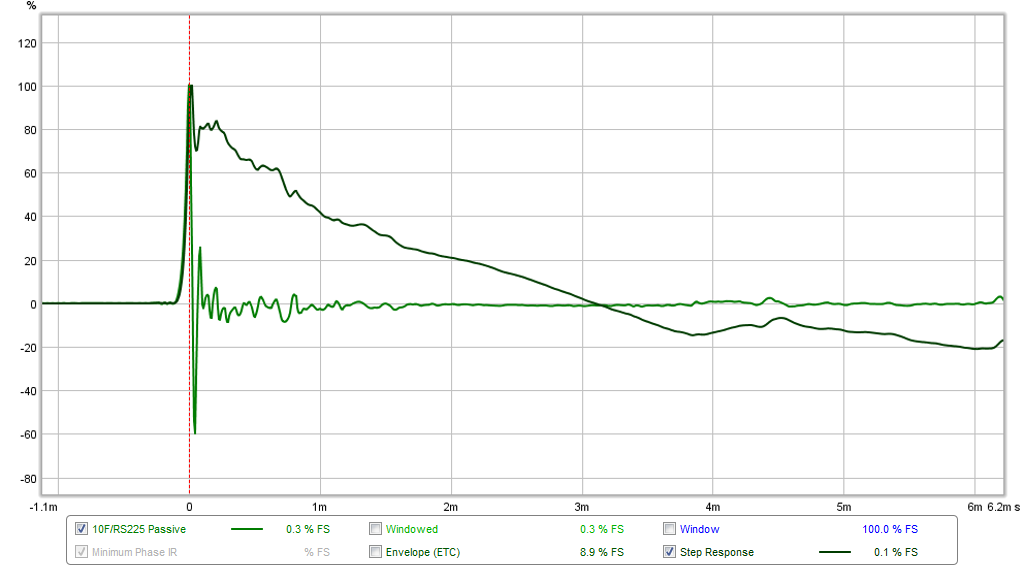

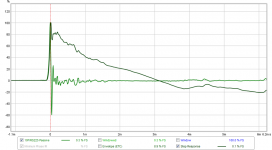

Here is the measured step response (right triangle is idea transient perfect response):

Here is what the P2P XO used to look like:

Here is the PCB schematic:

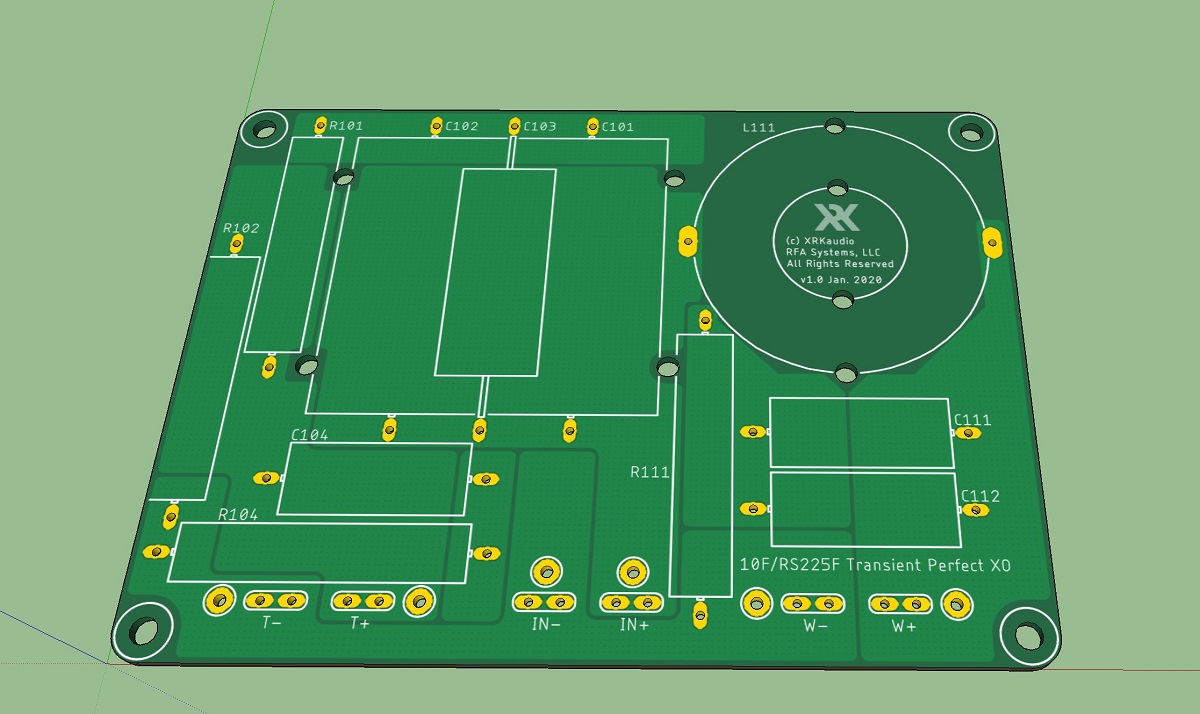

Here is the layout (board is 150mm x 110mm, 4mm dia holes are 140mm x 100mm). Connectors will be Faston spades with optional flying lead solder pads for 16ga wire. Holes will be provided to zip tie the inductor and heavy large capacitors to the board:

Thank you to JPS64 for another outstanding design!

Here is the list of components (all from Parts Express) for a stereo pair:

Boards will be thick 2mm thick FRP, 2oz copper with thousands of via stitched holes to tie identical planes on both sides for low impedance), ENIG finish, green solder mask. Pricing will be $38 ea. Shipping will be the usual tracked first class parcel, auto-calculated in Etsy (about $6 in US, $14 CAN, $23 everywhere else).

If you are interested please add your name, quantity of boards, country below:

Works well as 2nd order passive XO for MTM speaker too:

This is the Group Buy thread for the PCB for the XO for the speaker described here:

10F/8424 & RS225-8 FAST / WAW Ref Monitor

After making the XO using P2P for years, and at the request of members wanting to try this speaker, I have asked JPS64 to design a layout for this 1st order transient perfect crossover.

Here is the schematic from Xsim:

Here is the predicted response and phase using measured response:

Here is the measured response - note the flat phase from 100Hz through 10kHz - essential for reproducing the transient dynamics correctly:

Here is the measured step response (right triangle is idea transient perfect response):

Here is what the P2P XO used to look like:

Here is the PCB schematic:

Here is the layout (board is 150mm x 110mm, 4mm dia holes are 140mm x 100mm). Connectors will be Faston spades with optional flying lead solder pads for 16ga wire. Holes will be provided to zip tie the inductor and heavy large capacitors to the board:

Thank you to JPS64 for another outstanding design!

Here is the list of components (all from Parts Express) for a stereo pair:

Code:

Product Name Sku Qty Price Total

Dayton Audio DNR-4.7 4.7 Ohm 10W Precision Audio Res 004-4.7 4 $1.09 $4.36

Dayton Audio DMPC-27 27uF 250V Polypropylene Capacitor 027-439 4 $8.58 $34.32

Dayton Audio DNR-0.51 0.51 Ohm 10W Precision Audio Res 004-.51 2 $1.38 $2.76

Dayton Audio DNR-10 10 Ohm 10W Precision Audio Res 004-10 2 $1.38 $2.76

Dayton Audio DMPC-2.2 2.2uF 250V Polypropylene Capacitor 027-415 6 $1.87 $11.22

Dayton Audio DMPC-6.8 6.8uF 250V Polypropylene Capacitor 027-424 2 $2.75 $5.50

Jantzen Audio 4.0mH 18 AWG Air Core Inductor Crossover Coil 255-280 2 $20.91 $41.82Boards will be thick 2mm thick FRP, 2oz copper with thousands of via stitched holes to tie identical planes on both sides for low impedance), ENIG finish, green solder mask. Pricing will be $38 ea. Shipping will be the usual tracked first class parcel, auto-calculated in Etsy (about $6 in US, $14 CAN, $23 everywhere else).

If you are interested please add your name, quantity of boards, country below:

Name Quantity Boards Country

xrk971 4 USA

Attachments

-

AB5FAEB4-E6FD-4C24-A2FF-D3165DA6BA74.jpeg45 KB · Views: 1,982

AB5FAEB4-E6FD-4C24-A2FF-D3165DA6BA74.jpeg45 KB · Views: 1,982 -

D2385983-F9BD-48CD-B213-656503D855D3.jpeg171.8 KB · Views: 2,009

D2385983-F9BD-48CD-B213-656503D855D3.jpeg171.8 KB · Views: 2,009 -

34934B34-511A-47C6-AF69-944D8B33940E.jpeg107.9 KB · Views: 1,651

34934B34-511A-47C6-AF69-944D8B33940E.jpeg107.9 KB · Views: 1,651 -

3DBD58E4-5B93-4EBE-A245-BE941D6476AC.jpeg422.7 KB · Views: 1,627

3DBD58E4-5B93-4EBE-A245-BE941D6476AC.jpeg422.7 KB · Views: 1,627 -

EBEDF9AD-094C-44FF-B4AC-931BD13D405C.png55.5 KB · Views: 1,551

EBEDF9AD-094C-44FF-B4AC-931BD13D405C.png55.5 KB · Views: 1,551 -

7309759B-62D2-437C-BCBA-D69529FE47D4.png80.1 KB · Views: 1,610

7309759B-62D2-437C-BCBA-D69529FE47D4.png80.1 KB · Views: 1,610 -

66F2B891-D8BB-4172-9C01-531C8F40636B.jpeg95.4 KB · Views: 1,669

66F2B891-D8BB-4172-9C01-531C8F40636B.jpeg95.4 KB · Views: 1,669

Last edited:

Btw, there is currently a pretty good sale on the drivers for this speaker.

The RS225-8 is on sale for $50:

Dayton Audio RS225-8 8" Reference Woofer

The ScanSpeak 10F, available in a truncated blue bezel (custom Thiel driver) is available for $53:

THIEL 10F/8424G02 4" Fiberglass Midrange 8 ohm (DRVM-060-01)

Or you could get the 10F/8414 for $73 and it has a nice round black bezel:

Scanspeak Discovery 10F/8414G-10 4" Full Range: Madisound Speaker Components

Anyhow, all the drivers for this speaker could be obtained for $206 to $246 for a stereo pair. The XO items can be obtained from PE for about $100.

The cabinet is simple to make, and you can have one of the nicest sounding speakers around.

Here is the Xsim project file in case you want to play around with the XO yourself.

https://www.diyaudio.com/forums/att...rk971-10f-rs225-fast-xo-transient-perfect-zip

The RS225-8 is on sale for $50:

Dayton Audio RS225-8 8" Reference Woofer

The ScanSpeak 10F, available in a truncated blue bezel (custom Thiel driver) is available for $53:

THIEL 10F/8424G02 4" Fiberglass Midrange 8 ohm (DRVM-060-01)

Or you could get the 10F/8414 for $73 and it has a nice round black bezel:

Scanspeak Discovery 10F/8414G-10 4" Full Range: Madisound Speaker Components

Anyhow, all the drivers for this speaker could be obtained for $206 to $246 for a stereo pair. The XO items can be obtained from PE for about $100.

The cabinet is simple to make, and you can have one of the nicest sounding speakers around.

Here is the Xsim project file in case you want to play around with the XO yourself.

https://www.diyaudio.com/forums/att...rk971-10f-rs225-fast-xo-transient-perfect-zip

Attachments

Last edited:

GB Status Update.

Thanks, Jwjarch!

I have enough to order boards now since I am getting 8 🙂

Name Quantity Boards Country

xrk971 8 USA

Jwjarch 2 USA

Thanks, Jwjarch!

I have enough to order boards now since I am getting 8 🙂

Hi xrk, I think you may have posted a different Xsim file than you intended.

I got a pair of the Thiel 10f drivers a month ago and they are truly fantastic! Since then I have ordered two more pairs. 😀 I think they are unrivaled for the price.

I'd like to get a set of the PCBs.

Ray21 2 USA

I got a pair of the Thiel 10f drivers a month ago and they are truly fantastic! Since then I have ordered two more pairs. 😀 I think they are unrivaled for the price.

I'd like to get a set of the PCBs.

Ray21 2 USA

Here is the Xsim project file in case you want to play around with the XO yourself.

https://www.diyaudio.com/forums/att...rk971-10f-rs225-fast-xo-transient-perfect-zip

Attachments

Hi Ray,

Oops, sorry - wrong file. Let me fix that.

Thanks,

X

Oops, sorry - wrong file. Let me fix that.

Thanks,

X

Name Quantity Boards Country

xrk971 8 USA

Jwjarch 2 USA

Ray21 2 USA

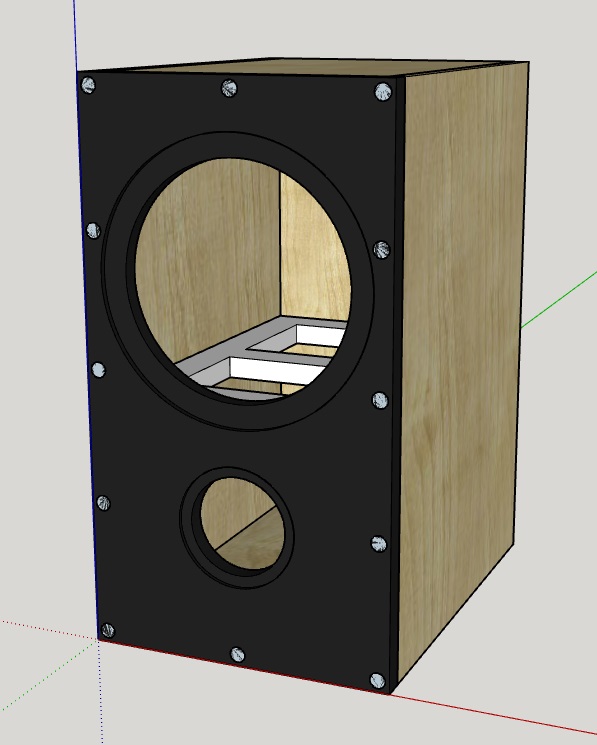

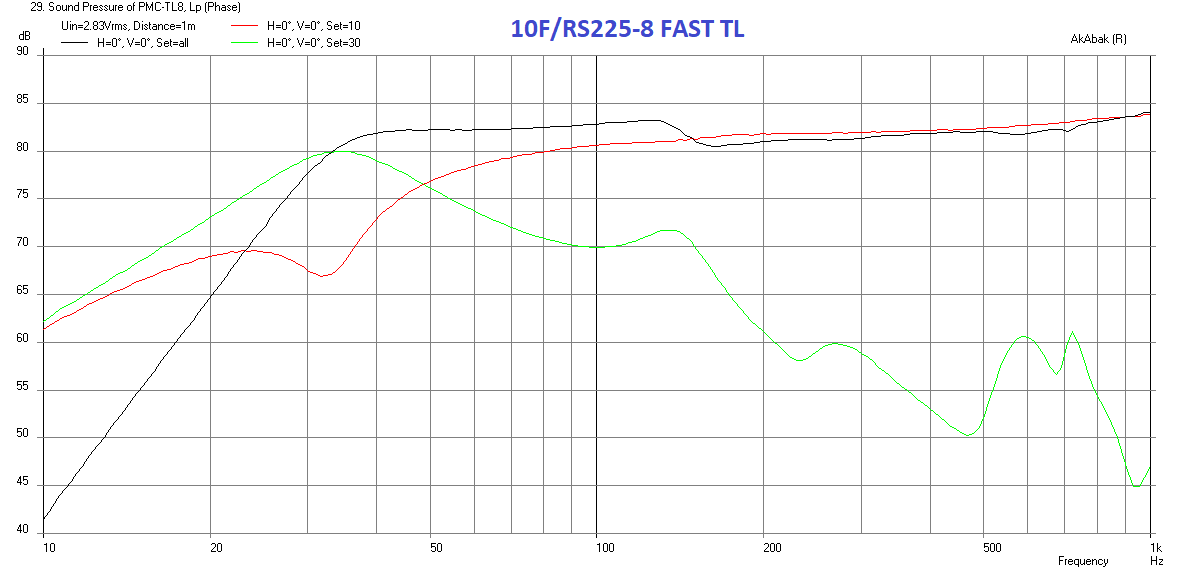

Nice to see some interest in this project. I was trying to design a floorstanding version of this speaker today for Vunce. That gives a lot more volume and so I decided to make a tapered TL sort of like a PMC monitor. I was able to get a -3dB point of 32Hz with the same sensitivity as the sealed alignment. The TL should be a lot higher quality tighter bass than a bass reflex. Here is the Akabak sim so far for a TL:

I like the idea of a floor standing transmission line, the rs225 really does good bass. I was lucky enough to score 4- of the Thiel 10f's on eBay for around $40 each shipped.

Mordikai,

That's a great deaal on some 10F's. It looks like you are aiming to build 4 of these boxes then?

That's a great deaal on some 10F's. It looks like you are aiming to build 4 of these boxes then?

Hi Ray,

I think my Xsim file looks fine - I just downloaded it and opened it up. Looks to be the correct one from jan 11, 2018. Here is my screenshot. Maybe you are opening a cached file?

Cheers,

X

OK, that was weird. I must have goofed up and loaded the wrong file. 😱

It shows up as correct to me, now. Thanks Xrk.

Last edited:

X, I'm also interested in the possibility of a floor standing TL for these. Care to share any more details? I'm happy to be a guinea pig of sorts. 🙂

Hi Jwjarch,

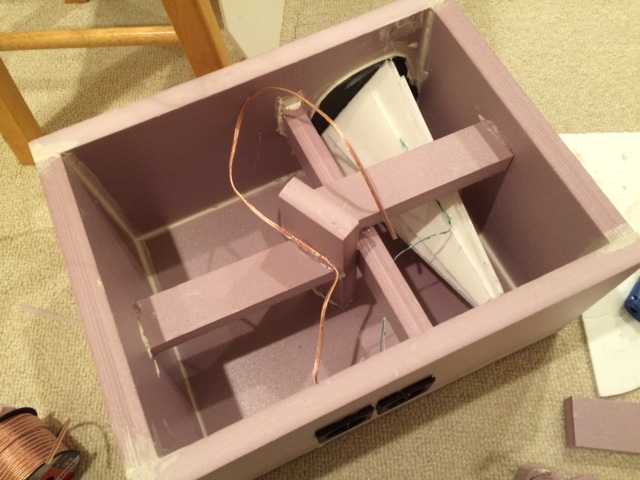

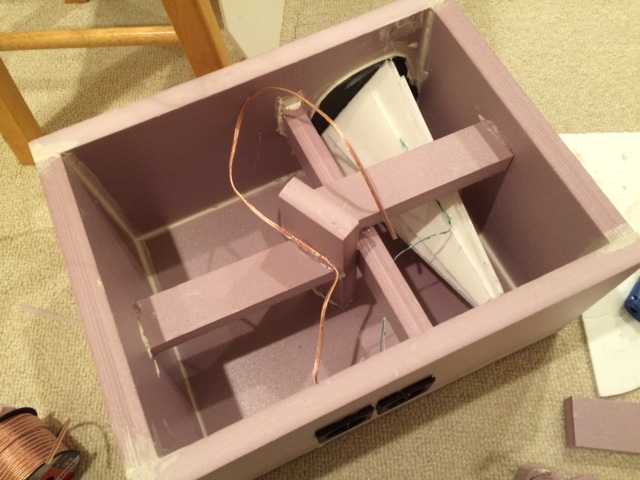

That's great - thanks for offering! Give me a few more days to fold the TL. Right now it exists as a tweaked and scaled up TL based on my 5in PMC clone. I have to redo it because the full range chamber blocks the TL in the standard config. I would recommend being a guinea pig with XPS foam first before making out of plywood. I think Vunce might be doing this too.

That's great - thanks for offering! Give me a few more days to fold the TL. Right now it exists as a tweaked and scaled up TL based on my 5in PMC clone. I have to redo it because the full range chamber blocks the TL in the standard config. I would recommend being a guinea pig with XPS foam first before making out of plywood. I think Vunce might be doing this too.

Sounds good X. I’ll have to go grab some XPS. No rush on anything though with the holidays and all. Enjoy the time with your family, X!

Hi jwjarch and X,

I have a few questions about XPS, and since there is not a large amount of info about building enclosures using XPS, I thought I would ask here.

Are you working with the 2" XPS which would be common for house construction.

Have you ever tried cutting 2" XPS down to 1", using a fine tooth craft saw. I do not have access to any hot wire foam cutters? I do have sharp craft type cutting blades but they are maybe 1-2" long.

I have only found 1 reference to a speaker made from XPS and the designer commented that the sound was damped and bass was bloaty. Not a lot of info.

I have a lot of this pink type XPS that I would like to experiment with. If you have any comments or links to using XPS for box type enclosures, please let me know. I am following the DML threads also.

Thanks for any help available,

Myles

I have a few questions about XPS, and since there is not a large amount of info about building enclosures using XPS, I thought I would ask here.

Are you working with the 2" XPS which would be common for house construction.

Have you ever tried cutting 2" XPS down to 1", using a fine tooth craft saw. I do not have access to any hot wire foam cutters? I do have sharp craft type cutting blades but they are maybe 1-2" long.

I have only found 1 reference to a speaker made from XPS and the designer commented that the sound was damped and bass was bloaty. Not a lot of info.

I have a lot of this pink type XPS that I would like to experiment with. If you have any comments or links to using XPS for box type enclosures, please let me know. I am following the DML threads also.

Thanks for any help available,

Myles

Hi Myles,

I use the 1in thick which is common in the US at Home Depot and the like. Use lots of bracing - if you look at my thread for the speaker, you can see how it was made. I cut it with a metal straight edge and a brand new utility knife razor blade. Use 8-10 strokes each time going a little deeper. A dull blade will tear and rip it with rough edges. A new razor is a must. I would not bother splitting it to make 2in to 1in. I used non volatile organic compound Liquid Nails to glue it. Give it 2 days to cure before applying load of driver air compression.

Bond a thin 3/16in sub flooring plywood as the baffle face to give strength for the screws to attach the drivers. I used Liquid Nails to do this too although PL Premium would work well also. Or even latex caulking I think.

Hope that helps. The foam will actually absorb some resonances common in wooden boxes. The measured performance of the XPS cabinets was about same as much more time consuming 3/4in BB omg boxes. I had to add mass loaded butyl rubber audio door panel sheets to the inside of the wood cabinets and then line with eggcrate foam. Whereas XPS I just added fiberglass stuffing. Stuffing is needed in wood too of course.

I use the 1in thick which is common in the US at Home Depot and the like. Use lots of bracing - if you look at my thread for the speaker, you can see how it was made. I cut it with a metal straight edge and a brand new utility knife razor blade. Use 8-10 strokes each time going a little deeper. A dull blade will tear and rip it with rough edges. A new razor is a must. I would not bother splitting it to make 2in to 1in. I used non volatile organic compound Liquid Nails to glue it. Give it 2 days to cure before applying load of driver air compression.

Bond a thin 3/16in sub flooring plywood as the baffle face to give strength for the screws to attach the drivers. I used Liquid Nails to do this too although PL Premium would work well also. Or even latex caulking I think.

Hope that helps. The foam will actually absorb some resonances common in wooden boxes. The measured performance of the XPS cabinets was about same as much more time consuming 3/4in BB omg boxes. I had to add mass loaded butyl rubber audio door panel sheets to the inside of the wood cabinets and then line with eggcrate foam. Whereas XPS I just added fiberglass stuffing. Stuffing is needed in wood too of course.

Last edited:

Sounds good X. I’ll have to go grab some XPS. No rush on anything though with the holidays and all. Enjoy the time with your family, X!

I just finished folding the new RS225 TL - then re-entered the new dimensions in Akabak and it is even better than previous estimated sim. Smoother mid bass. Now will put into SolidWorks to make sure the dimensions can physically be built. I am thinking 3/4in BB ply for main walls and 1/2in ply for internal separator walls. Height is 39in and can be elevated higher with unused lower portion. Will post design soon.

Thank you X for your speedy work whipping up this new RS225 TL enclosure. I’m looking forward to build my first set of pink speakers 😀

- Home

- Group Buys

- 10F/RS225 FAST / WAW Speaker XO PCB GB