Oops, I suppose I should have mentioned that I'm building a pair of the transmission line version and have the Dayton woofers already.

Has anyone built a TL version with the ps95 and sb23nrx45? Or should I stick to the sealed bookshelf version?

I think SB23nrx45 would work fine in the TL. I probably have an Akabak simulation of it somewhere already.

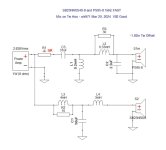

Thank you, sounds good. Looks fun to build and plywood is actually reasonably priced currently, birch is cheaper than mdf in my local area. The SB23 is also much cheaper and available in Canada compared to the RS225. Will be using the crossover below 🙂

Thanks for sharing all this work with us

Thanks for sharing all this work with us

Attachments

Very surprised you say that! 5x5' sheet of 18mm Baltic Birch ply is $140 at the best hardwoods/plywood store on Vancouver Island, while 3/4" MDF is $73 for a 4x8' sheet.... plywood is actually reasonably priced currently, birch is cheaper than mdf in my local area.

Unless you refer to local birch veneer plywood, which is not suitable for a high quality speaker enclosure. Only the outer layers are very thin birch; the rest are softwood and not free of voids. It's ok but not great. MDF isn't really great either, it's dense without being strong & holds energy before releasing.

I guess I was just looking at the cheapest option at RONA. 18mm Birch is 65 dollars for 4x8. Willing to take a chance with it, my hearing might not be good enough to detect softwood inner layers and voids.

Question about the crossover. Which one should I use if I use the RS225 with a PS95-8? The one proposed by XRK in 2018? Or take the bottom half of it and combine it with the top half of the crossover for the PS95-8 and SB23NRXS45 seen in the second schematic.

Question about the crossover. Which one should I use if I use the RS225 with a PS95-8? The one proposed by XRK in 2018? Or take the bottom half of it and combine it with the top half of the crossover for the PS95-8 and SB23NRXS45 seen in the second schematic.

Not so much "hearing" the voids, but you sure will see them in the end grain when you cut your panels. It will look like a layer is missing if your end cuts are visible. I've used wood filler to patch the voids, this is the type of birch veneered plywood sold at my local Home Depot. Definitely not furniture grade wood, hehe.Willing to take a chance with it, my hearing might not be good enough to detect softwood inner layers and voids.

One other type of plywood that's been recommended as good for speaker boxes is Metrie Premium Pine Plywood ACX 3/4 inch x 4 ft. x 8 ft. -- imported from Chile, all plies from a sustainably harvested pine variety. Available at Home Depot stores in/around SW BC for $93.I've used wood filler to patch the voids, this is the type of birch veneered plywood sold at my local Home Depot. Definitely not furniture grade wood,

I haven't used it but based on descriptions, I'd say it has better acoustic properties than MDF, is stronger, but not quite as good as BB. I'd use it over MDF for sure.

https://na.arauco.com/en/p/araucoply-sanded-plywood-araucoply_sanded

Awesome, thanks for the feedback guys. Going plywood shopping tomorrow. Hoping to perform some DIY magic and build something that sounds either different or better than the KEF LS50's that I just smoked for the same price as replacement drivers for the KEFS( all future amps to be fitted with some sort of speaker protection)

The second crossover is only for the SB23 woofer.I guess I was just looking at the cheapest option at RONA. 18mm Birch is 65 dollars for 4x8. Willing to take a chance with it, my hearing might not be good enough to detect softwood inner layers and voids.

Question about the crossover. Which one should I use if I use the RS225 with a PS95-8? The one proposed by XRK in 2018? Or take the bottom half of it and combine it with the top half of the crossover for the PS95-8 and SB23NRXS45 seen in the second schematic. View attachment 1394726View attachment 1394727

Not so much "hearing" the voids, but you sure will see them in the end grain when you cut your panels. It will look like a layer is missing if your end cuts are visible. I've used wood filler to patch the voids, this is the type of birch veneered plywood sold at my local Home Depot. Definitely not furniture grade wood, hehe.

Yeah, our local big box hardware store has what they call AA grade marine plywood (which I guess it is, because the two faces are appearance grade with no knots) but the inner plies are softwood with many voids. I find this misleads the customer to be honest. I'm fine, but some people might not realise they're going to get holes in the end plies.

As an aside, their BC grade plywood (not marine) has much better inner plies with few voids I found this week after close inspection. They don't specify the timber used, calling it oak, but this is the name they give to a species of eucalypt over here - which is actually nice timber.

Is this the right 10f?? May pull the trigger on these on account of I got unexpected bonus!

https://www.madisoundspeakerstore.c...canspeak-discovery-10f/8414g-10-4-full-range/

https://www.madisoundspeakerstore.c...canspeak-discovery-10f/8414g-10-4-full-range/

Questions for the New Year:

I hate to be another one of "those guys" but I want to build these speakers around some vintage front grill covers to keep my mid century modern partner happy.

That said, there has been mention here of making the baffle wider. I want it 11 inches. I understand the risks with the crossover not being designed for this but I think I'm willing to take that risk.

I've seen less chatter with increasing the width with regards to the TL version. The design calls for 8.5" internal width. Should I "absolutely not!" allow this width to increase to 9.5" or is the risk "reasonable"?

I hate to be another one of "those guys" but I want to build these speakers around some vintage front grill covers to keep my mid century modern partner happy.

That said, there has been mention here of making the baffle wider. I want it 11 inches. I understand the risks with the crossover not being designed for this but I think I'm willing to take that risk.

I've seen less chatter with increasing the width with regards to the TL version. The design calls for 8.5" internal width. Should I "absolutely not!" allow this width to increase to 9.5" or is the risk "reasonable"?

It will probably be close enough - just make sure you preserve the internal TL dimensions. Easiest way is to add two 0.5in thick walls to the sides and use sound deadening glue for drywall or even a pliable non hardening construction adhesive. This will give you constrained layer damping for a really low resonance cabinet. I suspect the larger baffle might change the baffle step comp shelf filter a tiny bit.

But if a grill is all you need there is room for a grill frame held by magnets, as is. Why is extra width needed?

But if a grill is all you need there is room for a grill frame held by magnets, as is. Why is extra width needed?

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor

.

.