I really like the idea of a WAW setup. I'm new to DIY and have yet to build anything so excuse me if I'm being naive, but could someone explain the reasoning behind using something like the RS225-8, with a frequency response of 28 - 2400 Hz? There's a lot of wasted frequency range at the top. wouldn't it be better to find a subwoofer with a narrower range that will go down closer to 20hz like the RSS265hf with its 22 - 1000 Hz range?

Can you find the differences in frequency response?

RSS225-8: https://doc.soundimports.nl/pdf/brands/Dayton Audio/RS225-8/pdf_dayton audio_RS225-8_1.pdf

RSS265HF: https://doc.soundimports.nl/pdf/brands/Dayton Audio/RSS265HF-4/pdf_dayton audio_RSS265HF-4_1.pdf

One of them clearly is meant as a subwoofer, there's no 'wasted' frequency response here, to get away with a first order crossover you need well behaved drivers way past the crossover point...

RSS225-8: https://doc.soundimports.nl/pdf/brands/Dayton Audio/RS225-8/pdf_dayton audio_RS225-8_1.pdf

RSS265HF: https://doc.soundimports.nl/pdf/brands/Dayton Audio/RSS265HF-4/pdf_dayton audio_RSS265HF-4_1.pdf

One of them clearly is meant as a subwoofer, there's no 'wasted' frequency response here, to get away with a first order crossover you need well behaved drivers way past the crossover point...

Isn't that what you need in a waw setup, a subwoofer? You just want something flat from 500hz and go as low as possible right?Can you find the differences in frequency response?

RSS225-8: https://doc.soundimports.nl/pdf/brands/Dayton Audio/RS225-8/pdf_dayton audio_RS225-8_1.pdf

RSS265HF: https://doc.soundimports.nl/pdf/brands/Dayton Audio/RSS265HF-4/pdf_dayton audio_RSS265HF-4_1.pdf

One of them clearly is meant as a subwoofer, there's no 'wasted' frequency response here, to get away with a first order crossover you need well behaved drivers way past the crossover point...

Not if you want to have a first order crossover. That sub has a huge peak at ~2300 Hz, with a first order crossover you'd want to have a much more smooth driver.

A first order crossover isn't used that often for a reason. It requires well behaved drivers. Not everyone cares about the order of crossover used, but this design is meant to have a very good transient behavior, thus it needed a smooth enough driver to get that job done.

A first order crossover isn't used that often for a reason. It requires well behaved drivers. Not everyone cares about the order of crossover used, but this design is meant to have a very good transient behavior, thus it needed a smooth enough driver to get that job done.

OK, I've got you. Thank you for explaining this.Not if you want to have a first order crossover. That sub has a huge peak at ~2300 Hz, with a first order crossover you'd want to have a much more smooth driver.

A first order crossover isn't used that often for a reason. It requires well behaved drivers. Not everyone cares about the order of crossover used, but this design is meant to have a very good transient behavior, thus it needed a smooth enough driver to get that job done.

A first order filter is reducing the output by 6 dB per octave. In a second order it would be 12 dB... etc.

If the drivers have a wide and overlapping bandwidth, like the drivers used in this design, a very simple crossover can be used, like a single coil on a woofer like this.

But, there's more to it...

The full range driver needs more components, as it was louder than the woofer to begin with. What you'd really want is to have that ideal 6 dB per octave slope acoustically, not electrically. Meaning one can't just look up the crossover value needed in an online crossover calculator. The impedance of a driver never is a straight line, so that too might need some help with parts to make sure the crossover really crosses the driver at the right spot.

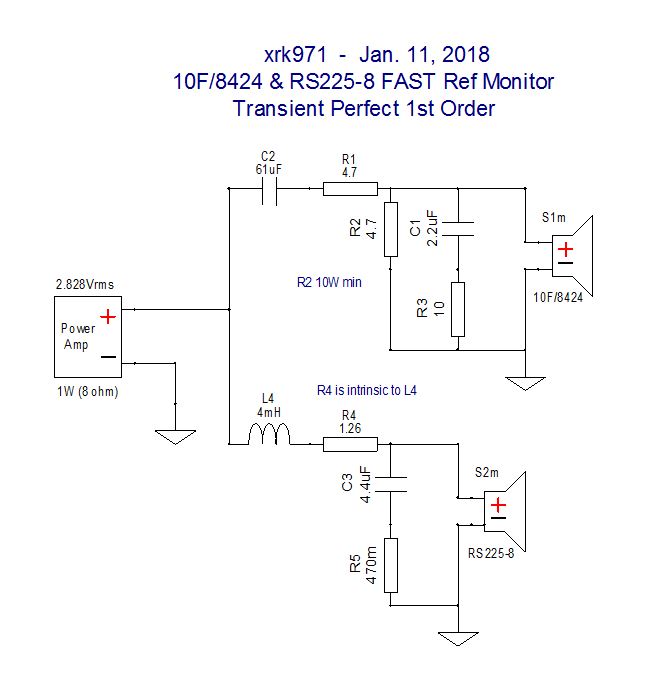

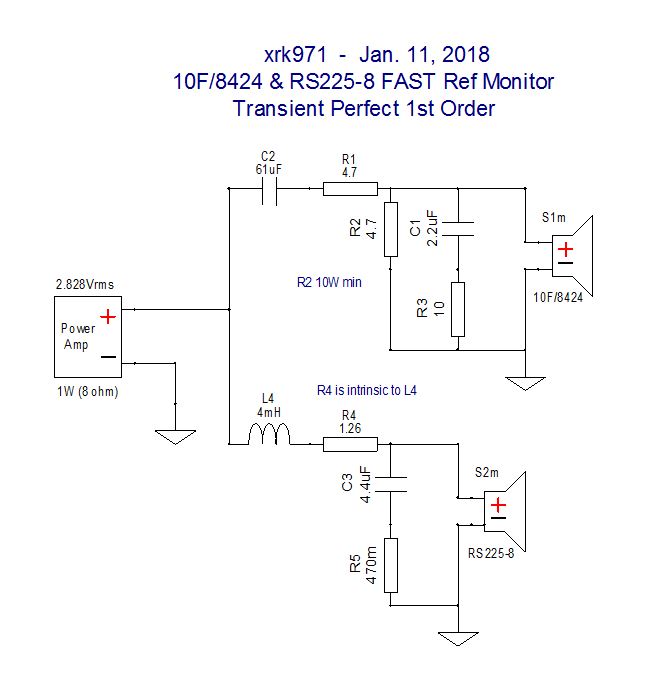

See this schematic stolen from the first post:

It is clear to see that multiple components were used to achieve the goal of that first order crossover. It still resembles a first order crossover past the crossover point, which is higher than your mentioned 500 Hz to have enough smooth bandwidth in both drivers to get it done.

We'd want to get as close as possible to that 6 dB/octave slope, and that's where the well behaved drivers make sense. They need less help to achieve that. The first post in this thread contains lots more measurements that show how the crossover was developed. First order crossovers usually are some of the hardest crossovers to achieve, acoustically. At times it may take more components to "get it right" than a second order crossover. Does that make sense?

If the drivers have a wide and overlapping bandwidth, like the drivers used in this design, a very simple crossover can be used, like a single coil on a woofer like this.

But, there's more to it...

The full range driver needs more components, as it was louder than the woofer to begin with. What you'd really want is to have that ideal 6 dB per octave slope acoustically, not electrically. Meaning one can't just look up the crossover value needed in an online crossover calculator. The impedance of a driver never is a straight line, so that too might need some help with parts to make sure the crossover really crosses the driver at the right spot.

See this schematic stolen from the first post:

It is clear to see that multiple components were used to achieve the goal of that first order crossover. It still resembles a first order crossover past the crossover point, which is higher than your mentioned 500 Hz to have enough smooth bandwidth in both drivers to get it done.

We'd want to get as close as possible to that 6 dB/octave slope, and that's where the well behaved drivers make sense. They need less help to achieve that. The first post in this thread contains lots more measurements that show how the crossover was developed. First order crossovers usually are some of the hardest crossovers to achieve, acoustically. At times it may take more components to "get it right" than a second order crossover. Does that make sense?

Thanks again. I've got a lot to learn 🙂A first order filter is reducing the output by 6 dB per octave. In a second order it would be 12 dB... etc.

If the drivers have a wide and overlapping bandwidth, like the drivers used in this design, a very simple crossover can be used, like a single coil on a woofer like this.

But, there's more to it...

The full range driver needs more components, as it was louder than the woofer to begin with. What you'd really want is to have that ideal 6 dB per octave slope acoustically, not electrically. Meaning one can't just look up the crossover value needed in an online crossover calculator. The impedance of a driver never is a straight line, so that too might need some help with parts to make sure the crossover really crosses the driver at the right spot.

See this schematic stolen from the first post:

It is clear to see that multiple components were used to achieve the goal of that first order crossover. It still resembles a first order crossover past the crossover point, which is higher than your mentioned 500 Hz to have enough smooth bandwidth in both drivers to get it done.

We'd want to get as close as possible to that 6 dB/octave slope, and that's where the well behaved drivers make sense. They need less help to achieve that. The first post in this thread contains lots more measurements that show how the crossover was developed. First order crossovers usually are some of the hardest crossovers to achieve, acoustically. At times it may take more components to "get it right" than a second order crossover. Does that make sense?

Thanks for explaining the technical details, Wesayso.

The RS225-8 is a unique driver - I have not found an equivalent in another model or brand that has wide bandwidth, low breakup, low distortion, and 7mm Xmax.

The RS225-8 is a unique driver - I have not found an equivalent in another model or brand that has wide bandwidth, low breakup, low distortion, and 7mm Xmax.

Is xmax something you have to match when picking drivers to be in phase?Thanks for explaining the technical details, Wesayso.

The RS225-8 is a unique driver - I have not found an equivalent in another model or brand that has wide bandwidth, low breakup, low distortion, and 7mm Xmax.

Nice words Wesayo.

Speaking of first order, and the nay sayers of crossing 8" to a dome tweeter.....

I was finding my PS95s lacking a little bit of life and a recent purchase of some Morel CAT378, I decided to try them in my XRK speakers. Looking at the DS for the Morel it seems feasible to use 5uf for a 1st order. I simmed it in Xsim and the result wasn't ruler flat but acceptable. And to avoid taking the baffle off to get to the XO, the Morel is seeing the whole network designed for the 3"fr, I just added a 4.7uf in series. Tweeter is reverse phase wired.

Listening now and its really very good. Moderate levels at the moment as not to blow them up! Playing via Google Chromecast, Miro AD1862, Salad DCG3 and an Aleph 30....well more a 20 until I sort the heat out !

Speaking of first order, and the nay sayers of crossing 8" to a dome tweeter.....

I was finding my PS95s lacking a little bit of life and a recent purchase of some Morel CAT378, I decided to try them in my XRK speakers. Looking at the DS for the Morel it seems feasible to use 5uf for a 1st order. I simmed it in Xsim and the result wasn't ruler flat but acceptable. And to avoid taking the baffle off to get to the XO, the Morel is seeing the whole network designed for the 3"fr, I just added a 4.7uf in series. Tweeter is reverse phase wired.

Listening now and its really very good. Moderate levels at the moment as not to blow them up! Playing via Google Chromecast, Miro AD1862, Salad DCG3 and an Aleph 30....well more a 20 until I sort the heat out !

@rjbell no, the lower you go in frequency, the more volume displacement you need. The 10F used in this design has about 2.6 mm of what is called x-max. It can move more than that mechanically (up to 7 mm) but it won't be as linear in it's movement anymore, so it would also produce more distortion. The 10F is small, so it's volume displacement is the area of the cone X (times) x-max. The RS225's cone is much larger, plus it has more movement within it's linear range. In other words: it has more volume displacement, so it can move more air. (exactly what is needed to produce low frequencies)

For both to produce the same SPL at say 750 Hz, the 10F's cone has to move a larger distance than the RS225.

Phase is related to the frequency response. So, in theory, if the frequency response is a straight line, phase is flat too. It doesn't depend on the amount of movement of the drivers.

With a first order crossover, both the drivers are connected "in phase" at the crossover and sum much like "one driver", as long as the proper bandwidth is available to reach that acoustic 6 dB/octave roll off on each end, the high pass on the 10F, the low pass on the RS225.

At a higher order crossover, due to the crossover having more phase rotation, as the frequency roll off is faster, the resulting phase isn't summing flat anymore. You'd see the 10F leading the RS225 by a very small margin. That means the frequency curve will still be flat, but the phase will have a partial rotation, depending on the specific order used.

With a second order filter, one driver should be inverted (or delayed) to have the proper phase overlap at the crossover point, for the drivers to sum.

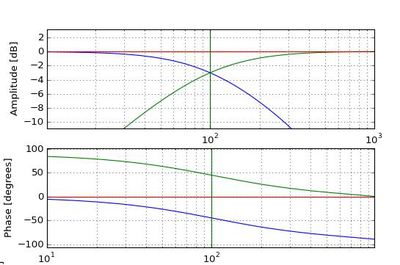

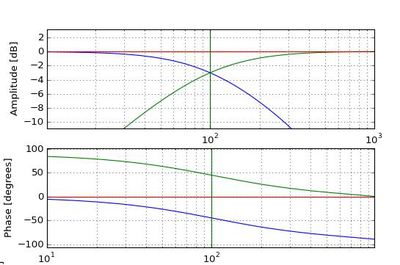

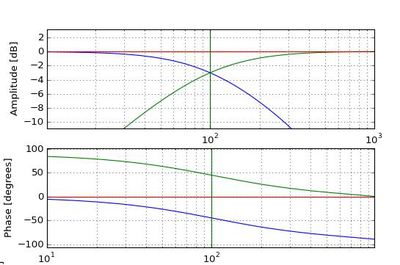

See how the phase of each driver rotates? Source of picture...

That makes a first order crossover quite unique, but most of the time difficult to achieve. I hope that helps you a bit, it's quite the topic to explain in a few sentences.

Here's some good information on crossovers in general (except the first order crossover) by the designer of the B&O Beolab 90. Mr. Geoff Martin.

For both to produce the same SPL at say 750 Hz, the 10F's cone has to move a larger distance than the RS225.

Phase is related to the frequency response. So, in theory, if the frequency response is a straight line, phase is flat too. It doesn't depend on the amount of movement of the drivers.

With a first order crossover, both the drivers are connected "in phase" at the crossover and sum much like "one driver", as long as the proper bandwidth is available to reach that acoustic 6 dB/octave roll off on each end, the high pass on the 10F, the low pass on the RS225.

At a higher order crossover, due to the crossover having more phase rotation, as the frequency roll off is faster, the resulting phase isn't summing flat anymore. You'd see the 10F leading the RS225 by a very small margin. That means the frequency curve will still be flat, but the phase will have a partial rotation, depending on the specific order used.

With a second order filter, one driver should be inverted (or delayed) to have the proper phase overlap at the crossover point, for the drivers to sum.

See how the phase of each driver rotates? Source of picture...

That makes a first order crossover quite unique, but most of the time difficult to achieve. I hope that helps you a bit, it's quite the topic to explain in a few sentences.

Here's some good information on crossovers in general (except the first order crossover) by the designer of the B&O Beolab 90. Mr. Geoff Martin.

Last edited:

Too late to edit, but to clarify, the graph above is for a first order crossover...With a second order filter, one driver should be inverted (or delayed) to have the proper phase overlap at the crossover point, for the drivers to sum.

See how the phase of each driver rotates? Source of picture...

I tried to add a bunch of stuff and ran out of time.

The graph could be seen as the green line representing the 10F, the blue line as the RS225.

Many more types here: https://www.ranecommercial.com/kb_article.php?article=2134

Thank you for such a detailed explanation. I think i've got my head around this now.@rjbell no, the lower you go in frequency, the more volume displacement you need. The 10F used in this design has about 2.6 mm of what is called x-max. It can move more than that mechanically (up to 7 mm) but it won't be as linear in it's movement anymore, so it would also produce more distortion. The 10F is small, so it's volume displacement is the area of the cone X (times) x-max. The RS225's cone is much larger, plus it has more movement within it's linear range. In other words: it has more volume displacement, so it can move more air. (exactly what is needed to produce low frequencies)

For both to produce the same SPL at say 750 Hz, the 10F's cone has to move a larger distance than the RS225.

Phase is related to the frequency response. So, in theory, if the frequency response is a straight line, phase is flat too. It doesn't depend on the amount of movement of the drivers.

With a first order crossover, both the drivers are connected "in phase" at the crossover and sum much like "one driver", as long as the proper bandwidth is available to reach that acoustic 6 dB/octave roll off on each end, the high pass on the 10F, the low pass on the RS225.

At a higher order crossover, due to the crossover having more phase rotation, as the frequency roll off is faster, the resulting phase isn't summing flat anymore. You'd see the 10F leading the RS225 by a very small margin. That means the frequency curve will still be flat, but the phase will have a partial rotation, depending on the specific order used.

With a second order filter, one driver should be inverted (or delayed) to have the proper phase overlap at the crossover point, for the drivers to sum.

See how the phase of each driver rotates? Source of picture...

That makes a first order crossover quite unique, but most of the time difficult to achieve. I hope that helps you a bit, it's quite the topic to explain in a few sentences.

Here's some good information on crossovers in general (except the first order crossover) by the designer of the B&O Beolab 90. Mr. Geoff Martin.

Hello XRK,

You might perhaps consider asking Dayton what is the minimum oem quantity to buy, based on a minimal change to this 8" Dayton woofer (preferably the 4 ohm version due to higher sensitivity). As for me this change would be a glasfiber (or titanium) instead of the existing aluminium former. Perhaps a foamed rubber surround as well (I don't know about the existing surround btw). If then there's enough fans here to buy those woofers from you (which they have to due to slightly different specs) you earn a penny for your work and risk and we are better served.

Aluminum voice coil formers introduce damping of cone movement by shorting eddy current around the magnet gap. The result is lower mechanical Q and higher rms. One thing that can characterise vintage drivers (with a paper former) is low mechanical loss and a more vivid and dynamic presentation.

Foam surround used to be one of the best surround materials available when it comes to low-loss suspensions. This primarily due to low mass and excellent elastic properties, and when applied a suitable coating it would also have a reasonable life-span. What was not available back then was foamed rubber surrounds as an alternative to coated foam. Foamed rubber provides lower mass compared to the standard rubber used for bass drivers and in many ways properties similar to foam surround. Foamed rubber is rubber, only added compressed air during molding to make a more porous structure and reduce weight.

Due to such new voice coil and low-loss suspension you will notice an improvement in transient response, transparency and low-level detail in that driver.

Probably the minimum quantity to buy would be like 50 or a 100 units?

I don't know what would be the demand for this woofer, but you can add me up for 2 such drivers after approval of samples.

Meanwhile I've given your question a thought what would be an even 'better' woofer for this project. As for me I'd like a PA like (somewhere between home and pa) midwoofer with admittedly a -3db point of about 70 hz sealed or even somewhat higher. I care less too for 7 mm linear instead of 5 mm if the end result is more satisfying. I value a small enclosure, better dynamics, playing louder with less distortion and hopefully no need for resistors for the fullrange. Add a sub (not really necessary when placed near a wall) and you're (even more) in heaven. I would have to do an extended search though for such midwoofer that suits your needs.

You might perhaps consider asking Dayton what is the minimum oem quantity to buy, based on a minimal change to this 8" Dayton woofer (preferably the 4 ohm version due to higher sensitivity). As for me this change would be a glasfiber (or titanium) instead of the existing aluminium former. Perhaps a foamed rubber surround as well (I don't know about the existing surround btw). If then there's enough fans here to buy those woofers from you (which they have to due to slightly different specs) you earn a penny for your work and risk and we are better served.

Aluminum voice coil formers introduce damping of cone movement by shorting eddy current around the magnet gap. The result is lower mechanical Q and higher rms. One thing that can characterise vintage drivers (with a paper former) is low mechanical loss and a more vivid and dynamic presentation.

Foam surround used to be one of the best surround materials available when it comes to low-loss suspensions. This primarily due to low mass and excellent elastic properties, and when applied a suitable coating it would also have a reasonable life-span. What was not available back then was foamed rubber surrounds as an alternative to coated foam. Foamed rubber provides lower mass compared to the standard rubber used for bass drivers and in many ways properties similar to foam surround. Foamed rubber is rubber, only added compressed air during molding to make a more porous structure and reduce weight.

Due to such new voice coil and low-loss suspension you will notice an improvement in transient response, transparency and low-level detail in that driver.

Probably the minimum quantity to buy would be like 50 or a 100 units?

I don't know what would be the demand for this woofer, but you can add me up for 2 such drivers after approval of samples.

Meanwhile I've given your question a thought what would be an even 'better' woofer for this project. As for me I'd like a PA like (somewhere between home and pa) midwoofer with admittedly a -3db point of about 70 hz sealed or even somewhat higher. I care less too for 7 mm linear instead of 5 mm if the end result is more satisfying. I value a small enclosure, better dynamics, playing louder with less distortion and hopefully no need for resistors for the fullrange. Add a sub (not really necessary when placed near a wall) and you're (even more) in heaven. I would have to do an extended search though for such midwoofer that suits your needs.

Hi Lucas,

I think I know the type of driver you speak of, but the choice of an aluminum former is indeed used to dampen the motion. Foam surrounds are soft and don’t dampen and rot after 10 or 15 years (polyurethane). I suspect that the driver would have more breakup modes. The key to RS225 is one of the best flat smooth wide bandwidth woofers available. We need this behavior for a 1st order crossover since it must be well behaved for an octave+ above and below the XO point.

I have manufacturers who are able to make me custom drivers - specified to anything I can imagine. I have several custom drivers in order as a matter of fact.

The number of drivers is not the issue but the unique tooling is the high cost. It can be in the $2k to $7k for one time cost. Depending on what is available commercially premade (formers, spiders, surrounds, etc) one may be able to get away with minimal tooling.

I think you might look at pro audio drivers from Fane, B&C, Faital Pro, etc. they indeed sound lively and are circa 95dB. But have big breakup peaks.

I think I know the type of driver you speak of, but the choice of an aluminum former is indeed used to dampen the motion. Foam surrounds are soft and don’t dampen and rot after 10 or 15 years (polyurethane). I suspect that the driver would have more breakup modes. The key to RS225 is one of the best flat smooth wide bandwidth woofers available. We need this behavior for a 1st order crossover since it must be well behaved for an octave+ above and below the XO point.

I have manufacturers who are able to make me custom drivers - specified to anything I can imagine. I have several custom drivers in order as a matter of fact.

The number of drivers is not the issue but the unique tooling is the high cost. It can be in the $2k to $7k for one time cost. Depending on what is available commercially premade (formers, spiders, surrounds, etc) one may be able to get away with minimal tooling.

I think you might look at pro audio drivers from Fane, B&C, Faital Pro, etc. they indeed sound lively and are circa 95dB. But have big breakup peaks.

Is there any benefit to going with the 4ohm rs225 compared to the 8ohm?

Does it bring the overall sensitivity of the system up the 3dB?

Does it bring the overall sensitivity of the system up the 3dB?

The 4ohm RS225 woofer is rated 91dB at 2.83v and accounting for 5dB baffle step loss it will be 86dB at 2.83v. This is 3dB better but the impedance is 4ohms and the crossover needs to be redesigned. Also, many amps cannot handle 4ohm loads well.

"I think I know the type of driver you speak of, but the choice of an aluminum former is indeed used to dampen the motion."

Usually aluminium is used as it is a cheap material that can take quite a lot of heat. If damping the motion (what it does indeed) is a good thing, why are the more expensive drivers usually not equipped with an alu former? I guess the reason is like described in my post? I'm not a fan of those formers as well.

"Foam surrounds are soft and don’t dampen and rot after 10 or 15 years (polyurethane). I suspect that the driver would have more breakup modes."

That is why I mentioned foamed rubber as a replacement for the old foam. Why on earth would you expect more breakup modes?

"I have manufacturers who are able to make me custom drivers - specified to anything I can imagine. I have several custom drivers in order as a matter of fact.

The number of drivers is not the issue but the unique tooling is the high cost."

Basically any manufacturer will make you custom drivers, but indeed like you say it, to what price? Another former or another surround are simple modifications for a manufacturer. In my opinion (well not just mine) these two mods likely give you a better driver. Isn't that what you more or less ask for in post 3809? Get yourself a set of samples and you'll see.

"I think you might look at pro audio drivers from Fane, B&C, Faital Pro, etc. they indeed sound lively and are circa 95dB. But have big breakup peaks."

Indeed, nearly all, But if you're interested I might do a search for exceptions. But if that's not of your interest I save myself the trouble of course.

Usually aluminium is used as it is a cheap material that can take quite a lot of heat. If damping the motion (what it does indeed) is a good thing, why are the more expensive drivers usually not equipped with an alu former? I guess the reason is like described in my post? I'm not a fan of those formers as well.

"Foam surrounds are soft and don’t dampen and rot after 10 or 15 years (polyurethane). I suspect that the driver would have more breakup modes."

That is why I mentioned foamed rubber as a replacement for the old foam. Why on earth would you expect more breakup modes?

"I have manufacturers who are able to make me custom drivers - specified to anything I can imagine. I have several custom drivers in order as a matter of fact.

The number of drivers is not the issue but the unique tooling is the high cost."

Basically any manufacturer will make you custom drivers, but indeed like you say it, to what price? Another former or another surround are simple modifications for a manufacturer. In my opinion (well not just mine) these two mods likely give you a better driver. Isn't that what you more or less ask for in post 3809? Get yourself a set of samples and you'll see.

"I think you might look at pro audio drivers from Fane, B&C, Faital Pro, etc. they indeed sound lively and are circa 95dB. But have big breakup peaks."

Indeed, nearly all, But if you're interested I might do a search for exceptions. But if that's not of your interest I save myself the trouble of course.

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor