A MLTL is just a long bass reflex speaker that takes advantage of the fundamental quarter-wave mode to enhance the bass output. It uses a constricted (small cross sectional area) vent. The constriction is the so-called “mass” loading analogous to adding a mass at the end of a tuning fork to lower its resonant frequency.

The 10F/RS225 FAST TL was designed using a tapered transmission line, which although tends to be larger in volume than a MLTL, achieves a much higher efficiency of the bass output because the vent cross section is much larger. Maybe 4x to 5x larger and hence, the speaker output is less compressed and more dynamic. The other reason I chose a tapered TL is the fact that the group delay can be made lower through proper use of damping and this improves the transient response and time coherency of the bass relative to the other notes.

Sure, a MLTL variant of this speaker can work, but the sound quality will not be as good. Have you ever heard a well designed tapered TL speaker? In my opinion, it sounds better than a MLTL.

You can design a MLTL using the Accidental MLTL (AMLTL) method described here. If you have a moderate QTs driver, no simulation is necessary.

The 10F/RS225 FAST TL was designed using a tapered transmission line, which although tends to be larger in volume than a MLTL, achieves a much higher efficiency of the bass output because the vent cross section is much larger. Maybe 4x to 5x larger and hence, the speaker output is less compressed and more dynamic. The other reason I chose a tapered TL is the fact that the group delay can be made lower through proper use of damping and this improves the transient response and time coherency of the bass relative to the other notes.

Sure, a MLTL variant of this speaker can work, but the sound quality will not be as good. Have you ever heard a well designed tapered TL speaker? In my opinion, it sounds better than a MLTL.

You can design a MLTL using the Accidental MLTL (AMLTL) method described here. If you have a moderate QTs driver, no simulation is necessary.

Last edited:

Thank you for yout reply,

i'll draw the plan in cm or someone have already done one ? and i think i'll begin with the loudspeakers next week with normal plywood.

i'll go with 10f8424 for the 10f/rs225 FAST TL

for the Rockville, do i have to take the shielded version of the dc130?

i'll probably have some questions but now it's on the way !

thank you again

i'll draw the plan in cm or someone have already done one ? and i think i'll begin with the loudspeakers next week with normal plywood.

i'll go with 10f8424 for the 10f/rs225 FAST TL

for the Rockville, do i have to take the shielded version of the dc130?

i'll probably have some questions but now it's on the way !

thank you again

Hi Moutik,

You only need shielded if you plan to put the center channel close to your cathode ray tube (CRT) style TV 😉

LCD TVs are unaffected by the magnetic field typical driver motor assemblies have - as far as I know.

Glad you are going to do the works and have a complete Xrk speaker system! Both of these speakers have received unanimous praise by all who have built them so your risk of them not sounding great is very low.

Cheers,

X

You only need shielded if you plan to put the center channel close to your cathode ray tube (CRT) style TV 😉

LCD TVs are unaffected by the magnetic field typical driver motor assemblies have - as far as I know.

Glad you are going to do the works and have a complete Xrk speaker system! Both of these speakers have received unanimous praise by all who have built them so your risk of them not sounding great is very low.

Cheers,

X

Last edited:

A MLTL is just a long bass reflex speaker that takes advantage of the fundamental quarter-wave mode to enhance the bass output. It uses a constricted (small cross sectional area) vent. The constriction is the so-called “mass” loading analogous to adding a mass at the end of a tuning fork to lower its resonant frequency.

The 10F/RS225 FAST TL was designed using a tapered transmission line, which although tends to be larger in volume than a MLTL, achieves a much higher efficiency of the bass output because the vent cross section is much larger. Maybe 4x to 5x larger and hence, the speaker output is less compressed and more dynamic. The other reason I chose a tapered TL is the fact that the group delay can be made lower through proper use of damping and this improves the transient response and time coherency of the bass relative to the other notes.

Sure, a MLTL variant of this speaker can work, but the sound quality will not be as good. Have you ever heard a well designed tapered TL speaker? In my opinion, it sounds better than a MLTL.

dear xrk, yes, I do know how MLTL works, probably the only type of speaker which I do understand. I have read pretty much everything there is on the web about MLTL.

To stay short. No, I haven't heard proper TL speaker. Or I have heard, but did not knew it was TL... But I read many of your threads and value your opinion very much. If you say, that tapered TL in this case will sound better and have lower group delay - I am sold. Lower than 35Hz F3 is more than enough for me.

Another question about stuffing: lets say that the speaker will be made in such way that there is no way to put stuffing into it before cabinet is done - that is only through the hole for speaker. Will that work to use volume stuffing like in Tabaq?

On this TL, stuffing can be adjusted from the driver cutout. However, you need to line the walls with felt or eggcrate foam. That cannot be done after the panels are all glued up.

nas3000,

Here you go with an earlier post of mine where the internal lining is shown. I lined the inside wall of my RS225 FAST TL with natural jute felt.

https://www.diyaudio.com/forums/ful...5-8-fast-waw-ref-monitor-265.html#post6317187

Here you go with an earlier post of mine where the internal lining is shown. I lined the inside wall of my RS225 FAST TL with natural jute felt.

https://www.diyaudio.com/forums/ful...5-8-fast-waw-ref-monitor-265.html#post6317187

On this TL, stuffing can be adjusted from the driver cutout. However, you need to line the walls with felt or eggcrate foam. That cannot be done after the panels are all glued up.

nas3000,

Here you go with an earlier post of mine where the internal lining is shown. I lined the inside wall of my RS225 FAST TL with natural jute felt.

https://www.diyaudio.com/forums/ful...5-8-fast-waw-ref-monitor-265.html#post6317187

Thanx for quick replies.

...The way of building will be such, that there is NO way to put internal lining beyond the reach through speaker hole. Sorry not to give more details as this is in experiment stage, but the method is not similar to gluing plywood panels.

The most I can ask if someone can say theoretically if the volume stuffing will work in this exact speaker case. Will it?

Stuffing is from closed end to about where the top 180deg turn is. Loosely stuffed about the volume of two number 5 soccer balls. If you find that more stuffing is needed, add more at the 180deg turn while looking at impedance sweeps and watch for the two peaks flattening. Too much and there is no bass left. A very small loose amount in the exit vent has a huge effect. You can also use blocks of reticulated open cell fish aquarium filter foam here (the dark grey 15ppi bio filter). It can be used at the terminus to prevent bugs and other critters from entering the speaker to make a home in there. Use sparingly.

Last edited:

Stuffing is from closed end to about where the top 180deg turn is. Loosely stuffed about the volume of two number 5 soccer balls. If you find that more stuffing is needed, add more at the 180deg turn while looking at impedance sweeps and watch for the two peaks flattening. Too much and there is no bass left. A very small loose amount in the exit vent has a huge effect. You can also use blocks of reticulated open cell fish aquarium filter foam here (the dark grey 15ppi bio filter). It can be used at the terminus to prevent bugs and other critters from entering the speaker to make a home in there. Use sparingly.

Thanks for tips.

So the effect to the quality of sound will be more or less the same as lining walls? In other words: will the quality be the same?

nas3000,

The lining and stuffing both need to be done, it is not one or the other.

I think if you can access the inside of the speaker through the hole cut out for the woofer, you will still be able to line the inside walls

The lining and stuffing both need to be done, it is not one or the other.

I think if you can access the inside of the speaker through the hole cut out for the woofer, you will still be able to line the inside walls

Last edited:

nas3000,

The lining and stuffing both need to be done, it is not one or the other.

I think if you can access the inside of the speaker through the hole cut out for the woofer, you will still be able to line the inside walls

Yes, through the hole cut out it will be possible to access ~1/4-1/3 of the line length to line walls and to stuff also ~1/2 of the length (until the 180 degrees bend in the bottom).

The exact question is: will the quality of the sound be the same, if I can reach ~1/3 for lining and ~1/2 for stuffing?

So you have already assembled the box without lining the walls?

I don't have box, but lets assume, that I have a box where you can access inside of it ONLY through the speaker cut out.

So... YES.

nas3000,

If you have properly sized cut pieces of the lining material you should be able to apply it on the inside walls of the cabinet through the woofer cut-out hole.

Same goes to the poly-fill material.

I am curious - how do you intend to fit the smaller sealed enclosure for the wideband driver on the inside of the baffle?

If you have properly sized cut pieces of the lining material you should be able to apply it on the inside walls of the cabinet through the woofer cut-out hole.

Same goes to the poly-fill material.

I am curious - how do you intend to fit the smaller sealed enclosure for the wideband driver on the inside of the baffle?

nas3000,

If you have properly sized cut pieces of the lining material you should be able to apply it on the inside walls of the cabinet through the woofer cut-out hole.

Same goes to the poly-fill material.

I am curious - how do you intend to fit the smaller sealed enclosure for the wideband driver on the inside of the baffle?

It will be "cast". And it will not be the exact shape only similar volume. Of course I will try to replicate drop/triangle as much as I can.

Think as the same limitations as 3d printing: you get the final shape as is and have to deal with stuffing after production.

You could add via the molding process, a secondary “access” cutout on the back wall similar to what Zman01 did towards the bottom where the XO board was placed (to be covered with a small door later). This will give you access almost everywhere.

You could add via the molding process, a secondary “access” cutout on the back wall (to be covered with a small door later). This will give you access almost everywhere.

I am especially against latches, doors, temporary panels etc etc in speaker building. You design, build, spend hundreds hours and Euros on project, with quality drivers, quality materials, thinking about reducing vibrations, air tightness, beauty, finish and then... you ad huuuuuge point, actually perimeter of failure.

IMHO access doors only for prototyping. Avoid such things as plague.

They sure are handy for installing dampening felt on the walls when no access is afforded before hand. It's also on the back of the speaker and a good place to put your XO board and binding posts.

I have mentioned this in another thread: if your 3D print a speaker cabinet, you can 3D print the mesh/matrix in the internal cavities or along the wall to serve as the damping. So-called Voronoi reticulated organic looking mesh patterns, or even simple zigzag or rectilinear meshes.

Layer by Layer - How To Make Voronoi Patterns in MeshMixer - YouTube

I have mentioned this in another thread: if your 3D print a speaker cabinet, you can 3D print the mesh/matrix in the internal cavities or along the wall to serve as the damping. So-called Voronoi reticulated organic looking mesh patterns, or even simple zigzag or rectilinear meshes.

Layer by Layer - How To Make Voronoi Patterns in MeshMixer - YouTube

Last edited:

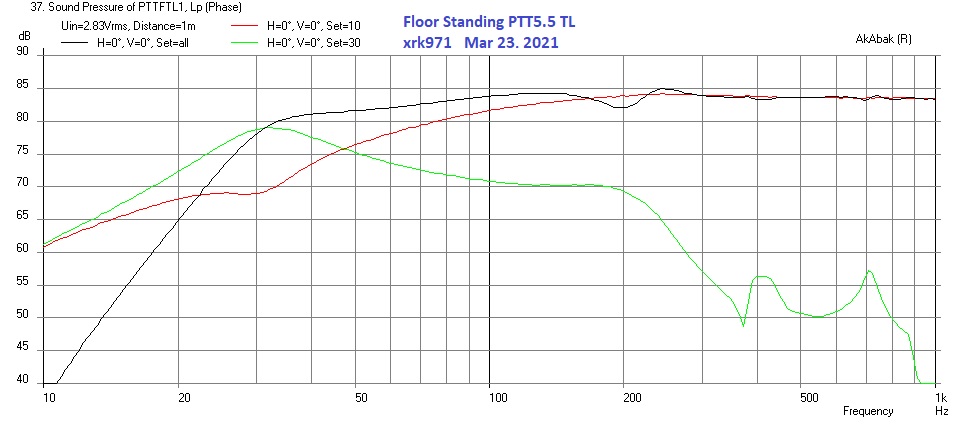

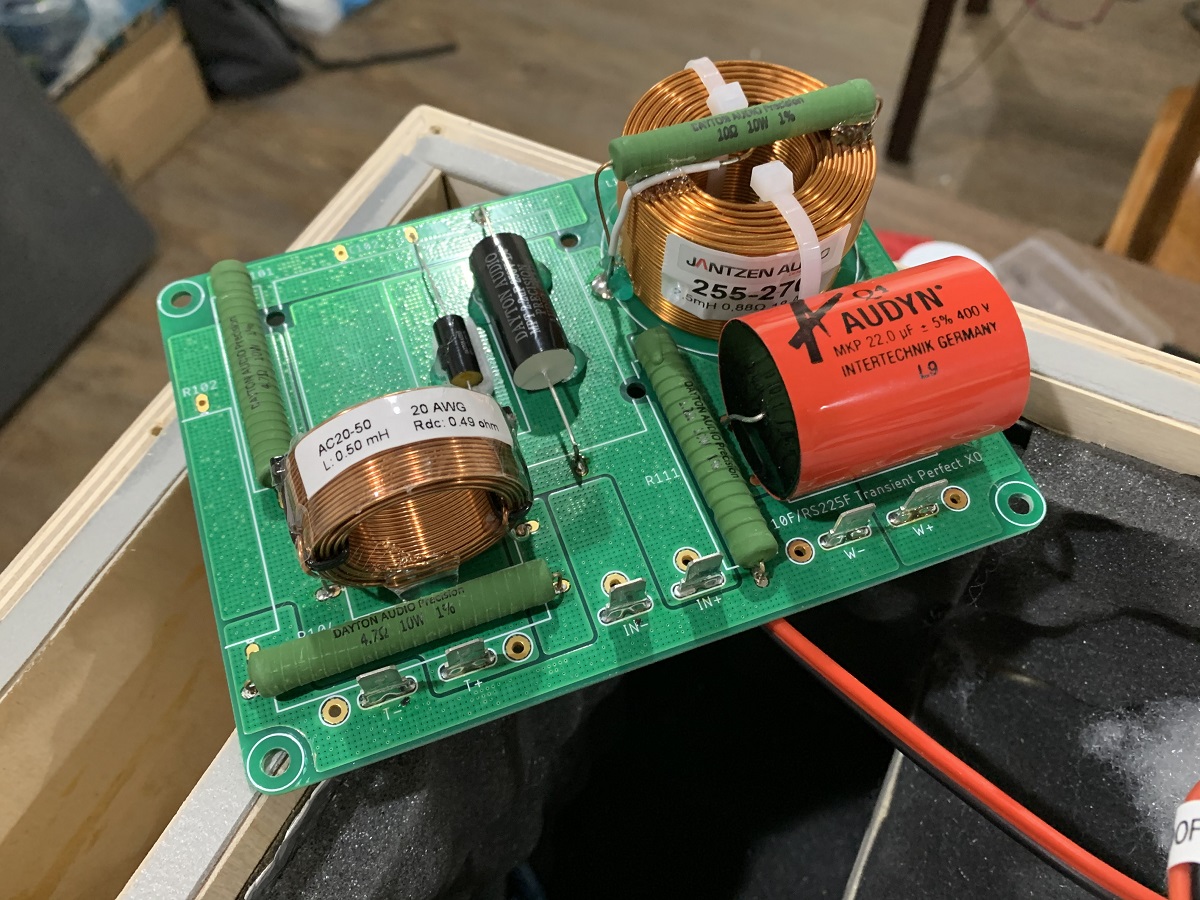

For fans of this style of TL, I have designed another one for the Purifi PTT6.5 driver to be used with an RST28F dome tweeter in a WG300 waveguide. It has a passive Harsch crossover that is quasi-transient perfect.

Simple Passive Harsch XO Using PTT6.5 and RS28F in a Waveguide

40in tall x 9in wide x 14.25in deep, all 3/4in BB ply construction. Woofer goes above tweeter.

The Purifi woofer is one of the lowest distortion and flattest response drivers ever made and it is operating almost like a full range with XO point at 3.5kHz.

84dB nominal sensitivity after baffle step loss in 4pi space. Bass extension is -3dB at 40Hz and -6dB at 29Hz. With room gain, response down to 30Hz should be nice. This 6.5in sounds like an 8in in terms of bass capability but at the same time can handle nuanced mids very well.

Passive XO is already developed and tested:

Simple Passive Harsch XO Using PTT6.5 and RS28F in a Waveguide

40in tall x 9in wide x 14.25in deep, all 3/4in BB ply construction. Woofer goes above tweeter.

The Purifi woofer is one of the lowest distortion and flattest response drivers ever made and it is operating almost like a full range with XO point at 3.5kHz.

84dB nominal sensitivity after baffle step loss in 4pi space. Bass extension is -3dB at 40Hz and -6dB at 29Hz. With room gain, response down to 30Hz should be nice. This 6.5in sounds like an 8in in terms of bass capability but at the same time can handle nuanced mids very well.

Passive XO is already developed and tested:

Last edited:

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor