look at Vostro's link, you will find that the whole of Europe uses the 230Vac harmonised voltage.what country has that high supply voltage?.........

The wiki quotes 216Va to 253Vac, but it is actually 216Vac to 254Vac.

This is the range of voltage that can be supplied by the power distribution companies.

It is the responsibility of manufacturers to ensure that equipment they supply via retailers can operate safely over the full harmonised voltage range.

If we as Builders assume a similar role and the responsibilities that go with "manufacturing" one off prototypes, then we Builders must ensure that our equipment is safe for the full range of harmonised voltage.

In the UK since our supplies are still basically the 240Vac system we can expect a normal range of supply voltage to be 226 to 254Vac.

In Mainland Europe I suspect the voltage range is 216Vac to ~234Vac, but this is only based on my guess at what a 220Vac system could supply.

It would be useful if our European Members would post accurate details of the actual delivered voltage tolerances.

Tin,..........also says 220V mains

so if you have 230V mains, it should still be the same trafo voltage.......

this is misleading.

A 220:66Vac transformer will have a different turns ratio from a 230:66Vac transformer. And different again from a 240:66Vac transformer.

The rated input voltage is important to the specification of the transformer.

Similarly the transformer regulation is a very necessary spec when selecting a transformer.

Tin,

this is misleading.

Similarly the transformer regulation is a very necessary spec when selecting a transformer.

anything can be misleading if you want it to be

transformer regulation can be different, but also often follow wattage rating, you know that

for this high power trafo, it might be only 5%... max

but smaller trafo, more regulation, ofcourse

but will also have more power sag...so...what ?

Similarly the transformer regulation is a very necessary spec when selecting a transformer.

yes...and?

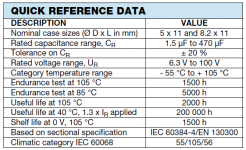

but yes, I would suggest that the first smoothing caps close the bridge are tough types with high ripple ampere rating

and that possible smaller 'on-board' caps with lower ripple ampere rating better have higher voltage safety margin instead

(as well as if having multiple smaller caps)

well that was at least my own intention

and that possible smaller 'on-board' caps with lower ripple ampere rating better have higher voltage safety margin instead

(as well as if having multiple smaller caps)

well that was at least my own intention

Since you seem to be unaware of the physics.

I will again take the Members and you if you want to read through the arithmetic.

The output of a transformer is: Sec Vac = Primary supply voltage / Primary Rated voltage * Secondary Rated voltage, when loaded with the Rated resistor.

Sec Vac = Primary supply voltage / Primary Rated voltage * Rated secondary voltage * {Transformer Regulation+1} when the secondary is measured open circuit.

The DC voltage after the rectifier varies with load current and the type of loading.

The maximum DC voltage after the rectifier for a dual secondary transformer feeding a single bridge rectifier into a capacitor input filter is:

Vdc = [Primary supply voltage / Primary Rated voltage * Rated Secondary voltage * {Transformer Regulation + 1} * sqrt(2)] - one diode drop, when the output is open circuit.

I'll put in some example values for this last equation.

Mains supply voltage 235Vac.

Rated Primary voltage 230Vac

Rated Secondary voltage 66+66Vac

Transformer regulation 5%

Silicon bridge rectifier.

Vdc = [235 / 230 * 66 * {0.05+1} * 1.414] - ~0.5Vdc = 100.1 - ~0.5 ~= +-99.6Vdc

If the mains voltage is different from the 235Vac in this example, then the output will be different.

If the Turns Ratio is different, then the output will be different.

If the regulation is different, then the output will be different.

If the loading is increased, then the output will be lower.

The voltage applied to a capacitor is the steady voltage + any spike type transient. If this combined voltage (continuous+spike) exceeds the rated voltage then some life is used.

If we choose to run a 100Vdc capacitor at ~99Vdc then the overhead to ameliorate the transient spikes is only 1Vpk. If a 2Vspike comes along, it reduces the life of the capacitor.

If one were to rely on a particular manufacturer's safety margin of 20V (i.e. 120V ref rated 100Vdc) which includes for the transient spiking, then one is using up the life of the capacitor.

I will again take the Members and you if you want to read through the arithmetic.

The output of a transformer is: Sec Vac = Primary supply voltage / Primary Rated voltage * Secondary Rated voltage, when loaded with the Rated resistor.

Sec Vac = Primary supply voltage / Primary Rated voltage * Rated secondary voltage * {Transformer Regulation+1} when the secondary is measured open circuit.

The DC voltage after the rectifier varies with load current and the type of loading.

The maximum DC voltage after the rectifier for a dual secondary transformer feeding a single bridge rectifier into a capacitor input filter is:

Vdc = [Primary supply voltage / Primary Rated voltage * Rated Secondary voltage * {Transformer Regulation + 1} * sqrt(2)] - one diode drop, when the output is open circuit.

I'll put in some example values for this last equation.

Mains supply voltage 235Vac.

Rated Primary voltage 230Vac

Rated Secondary voltage 66+66Vac

Transformer regulation 5%

Silicon bridge rectifier.

Vdc = [235 / 230 * 66 * {0.05+1} * 1.414] - ~0.5Vdc = 100.1 - ~0.5 ~= +-99.6Vdc

If the mains voltage is different from the 235Vac in this example, then the output will be different.

If the Turns Ratio is different, then the output will be different.

If the regulation is different, then the output will be different.

If the loading is increased, then the output will be lower.

The voltage applied to a capacitor is the steady voltage + any spike type transient. If this combined voltage (continuous+spike) exceeds the rated voltage then some life is used.

If we choose to run a 100Vdc capacitor at ~99Vdc then the overhead to ameliorate the transient spikes is only 1Vpk. If a 2Vspike comes along, it reduces the life of the capacitor.

If one were to rely on a particular manufacturer's safety margin of 20V (i.e. 120V ref rated 100Vdc) which includes for the transient spiking, then one is using up the life of the capacitor.

Last edited:

looking at Cornell Dubilier 100V SLPX...says 125Vdc surge

hard to believe it will even notice a short 2V spike

maybe you are overdoing it

btw Andrew, any chance we will see some of your own amps ?

since you buy transistors I suppose you also build amps ?

hard to believe it will even notice a short 2V spike

maybe you are overdoing it

btw Andrew, any chance we will see some of your own amps ?

since you buy transistors I suppose you also build amps ?

looking at Cornell Dubilier 100V SLPX...says 125Vdc surge

hard to believe it will even notice a short 2V spike

maybe you are overdoing it

A surge is allowed, but reduces lifetime. For power supply planning we have to respect the maximum continued voltage and many other parameters like ripple voltage, ripple current etc. to reach the minimum guaranteed lifetime of the capacitor!

Here is one manufacturers guideline on using eletrolytic capacitors:

http://industrial.panasonic.com/www-data/pdf/ABA0000/ABA0000PE26.pdf

Other manufacturer guidelines are easy to find on their respective homepages.

Voted thread 5 stars.

Can't wait to see the results of those that are building this amp.

Thread Rating: 12 votes, 3.42 average 🙂

Last edited:

A surge is allowed, but reduces lifetime.

lifetime is reduced every day, no matter what you do

anyway, the specced lifetime is the expected time it will work and meet the general specs after it have been abused, overloaded, and cooked

(safety guidelines and demands for special dangerous environment)

I don't think that is what the manufacturer tells you................after it have been abused, overloaded, and cooked............

yes it is

its the whole reason for the lifetime specs

to know how long time there is left after accidental malfunction

its got nothing to do with 'nursered' hifi gear

if never pushed to its limits, a cap with specced shorter lifetime might live as long as a long life cap

but not in general

ofcourse longlife caps are likely to last longer in any case

but yes, it might appear like different manufacturers have different opinions about how to use life time specs

I guess there is something like a 'sales strategy' too

btw, you really dont think a quality cap with just 3000hours lifetime will last that short ?

its the whole reason for the lifetime specs

to know how long time there is left after accidental malfunction

its got nothing to do with 'nursered' hifi gear

if never pushed to its limits, a cap with specced shorter lifetime might live as long as a long life cap

but not in general

ofcourse longlife caps are likely to last longer in any case

but yes, it might appear like different manufacturers have different opinions about how to use life time specs

I guess there is something like a 'sales strategy' too

btw, you really dont think a quality cap with just 3000hours lifetime will last that short ?

Sorry but no.

Lifetime specs are derived statistically by the Manufacturer after testing lots of samples, under "working conditions" as specified in the datasheet.

It's not "pampering" but proper design.

So if a manufacturer says (as an example)

If you abuse it, which would be using it beyond 50V or 85ºC .... you are on your own.

Lifetime specs are derived statistically by the Manufacturer after testing lots of samples, under "working conditions" as specified in the datasheet.

It's not "pampering" but proper design.

So if a manufacturer says (as an example)

mans exactly that: if you use it at 50V or less and 85ºC or less it will 99.5 % probability of lasting 10000 hours . Period."this 50V, 85ºC rated capacitor is guaranteed to have less than 0.5% failure rate within 10000 hours"

If you abuse it, which would be using it beyond 50V or 85ºC .... you are on your own.

DonnyAb: If you are interested in some transformers for this project to get between 93-96vdc rails, PM me. I am cleaning out 10-12 high power toroids in the 900va to 1000va range.

Also for 100vdc rails, I have 700va Metal encapsulated toroids that give about 70-0-70vac.

Also for 100vdc rails, I have 700va Metal encapsulated toroids that give about 70-0-70vac.

Sorry but no.

believe it or not, I read the test procedure, its well described

again, do you really think a cap with specced 3000hours lifetime will last that short

who would be interested in 3000hours lifetime ....its 125days pal

You must read the full spec:

As an example:

There it's clearly stated:

So what?

What they are telling you is " it won't *explode* at 105ºC but it will have very poor life"

They also tell you that even if *stored* at 105ºC, it will also degrade (even if "unused")

But if you use it in a more sensible way, at, say, 85ºC (which is still very hot):

By the way, you made your calculations based on 24 H continuous use, at continuous max. temperature (105ºC or whatever is specified) , which is not a realistic use expectation.

For a real world example, let's consider a grueling but possible job, as, say, the power amps in a Disco which are used full power, in a very poorly ventilated rack, 8 hours per night, 3 nights a week.

In that case you would have 24 abuse hours a week, so 1500 hours would give you 1500/24=62.5 weeks, or a year and a few months, which is consistent with my experience installing and repairing Disco and Live PA equipment.

But if the installation was not *that* bad, meaning no fans but at least the rack enclosure has some ventilation holes (so no surpassing 85ºC) , that amp can count on its PSU caps for: 5000/24= 208 Weeks, over 3 years and a half.

Not bad.

And if you want to use those caps properly , as in Home Hi Fi or even , say, a Mall/Railway_station system providing background music/announcements , and you allow ventilation so they don't surpass 40ºC (which is a reasonable spec), they will last:

In this case I calculated with 24 hours continuous work 7 days a week, all year long.

Which is consistent with the datasheet, and everybody's experience.

So in a nutshell: if you want long life (who does not 😉 ? ), follow datasheet recommendations from a serious manufacturer.

Good luck.

As an example:

116 RLL Aluminum Capacitors Radial Long Life - Vishay

There it's clearly stated:

Yes, that's even less: 62.5 days. 😱Endurance test at 105 °C 1500 h

So what?

What they are telling you is " it won't *explode* at 105ºC but it will have very poor life"

They also tell you that even if *stored* at 105ºC, it will also degrade (even if "unused")

Still 62.5 days.Shelf life at 0 V, 105 °C 1500 h

But if you use it in a more sensible way, at, say, 85ºC (which is still very hot):

Endurance test at 85 °C 5000 h

By the way, you made your calculations based on 24 H continuous use, at continuous max. temperature (105ºC or whatever is specified) , which is not a realistic use expectation.

For a real world example, let's consider a grueling but possible job, as, say, the power amps in a Disco which are used full power, in a very poorly ventilated rack, 8 hours per night, 3 nights a week.

In that case you would have 24 abuse hours a week, so 1500 hours would give you 1500/24=62.5 weeks, or a year and a few months, which is consistent with my experience installing and repairing Disco and Live PA equipment.

But if the installation was not *that* bad, meaning no fans but at least the rack enclosure has some ventilation holes (so no surpassing 85ºC) , that amp can count on its PSU caps for: 5000/24= 208 Weeks, over 3 years and a half.

Not bad.

And if you want to use those caps properly , as in Home Hi Fi or even , say, a Mall/Railway_station system providing background music/announcements , and you allow ventilation so they don't surpass 40ºC (which is a reasonable spec), they will last:

or [200000/24]/365= 23 years 😱Useful life at 40 °C, 1.3 x IR applied 200 000 h

In this case I calculated with 24 hours continuous work 7 days a week, all year long.

Which is consistent with the datasheet, and everybody's experience.

So in a nutshell: if you want long life (who does not 😉 ? ), follow datasheet recommendations from a serious manufacturer.

Good luck.

Attachments

look at Vostro's link, you will find that the whole of Europe uses the 230Vac harmonised voltage.

The wiki quotes 216Va to 253Vac, but it is actually 216Vac to 254Vac.

This is the range of voltage that can be supplied by the power distribution companies.

It is the responsibility of manufacturers to ensure that equipment they supply via retailers can operate safely over the full harmonised voltage range.

If we as Builders assume a similar role and the responsibilities that go with "manufacturing" one off prototypes, then we Builders must ensure that our equipment is safe for the full range of harmonised voltage.

In the UK since our supplies are still basically the 240Vac system we can expect a normal range of supply voltage to be 226 to 254Vac.

In Mainland Europe I suspect the voltage range is 216Vac to ~234Vac, but this is only based on my guess at what a 220Vac system could supply.

It would be useful if our European Members would post accurate details of the actual delivered voltage tolerances.

this is way too high tolerance for supply voltage. when we here in Serbia have 210Vac or 237Vac that is something that we consider needed to be alarmed at EPS (Elektro Privreda Srbije,our state electric power supplier).

at all other cases (under 210V or higher than 237) the power supply is being disconnected because something is wrong.

we also have three phased system where we have 235Vac between any phase and neutral or 360Vac between any phases.

we mostly do our single phase transformers at 235Vac primary ratings so 2Vac doesn´t mean much trouble. less primary voltage leads to lower secondary voltage so there is not much risk of voltage overload at capacitors.

there are cases when the voltage drops under 210Vac but that is mostly due to long power supply lines at distanced houses or low cross surface of copper leads in house grid and/or line overloaded by some high power devices.

i have seen now in wikipedia that there are countries with 240Vac supply,i haven´t known that before this night...

By the way, you made your calculations based on 24 H continuous use..... which is not a realistic use expectation.

The plates of the caps needs to be covered in the electrolyte and oxygen has to be kept outside, otherwise corrosion will ruin all. Heat is a problem and the cap needs to vent. The vent valve does never seal probably.That causes degeneration as well. I have read that a 100uf cap must not be used in a circuit that does not charge it less say at lease than 60% of its capacity, otherwise it will never keep its capacity. A cap is closely related to a battery, you have to keep it at its working capacity.

- Home

- Amplifiers

- Solid State

- 1000W Simple PA Amplifier