I've also been working on honeycombed cardboard... Honeycombed, not corrugated. So it's similar to Nidaplast, construction-wise.

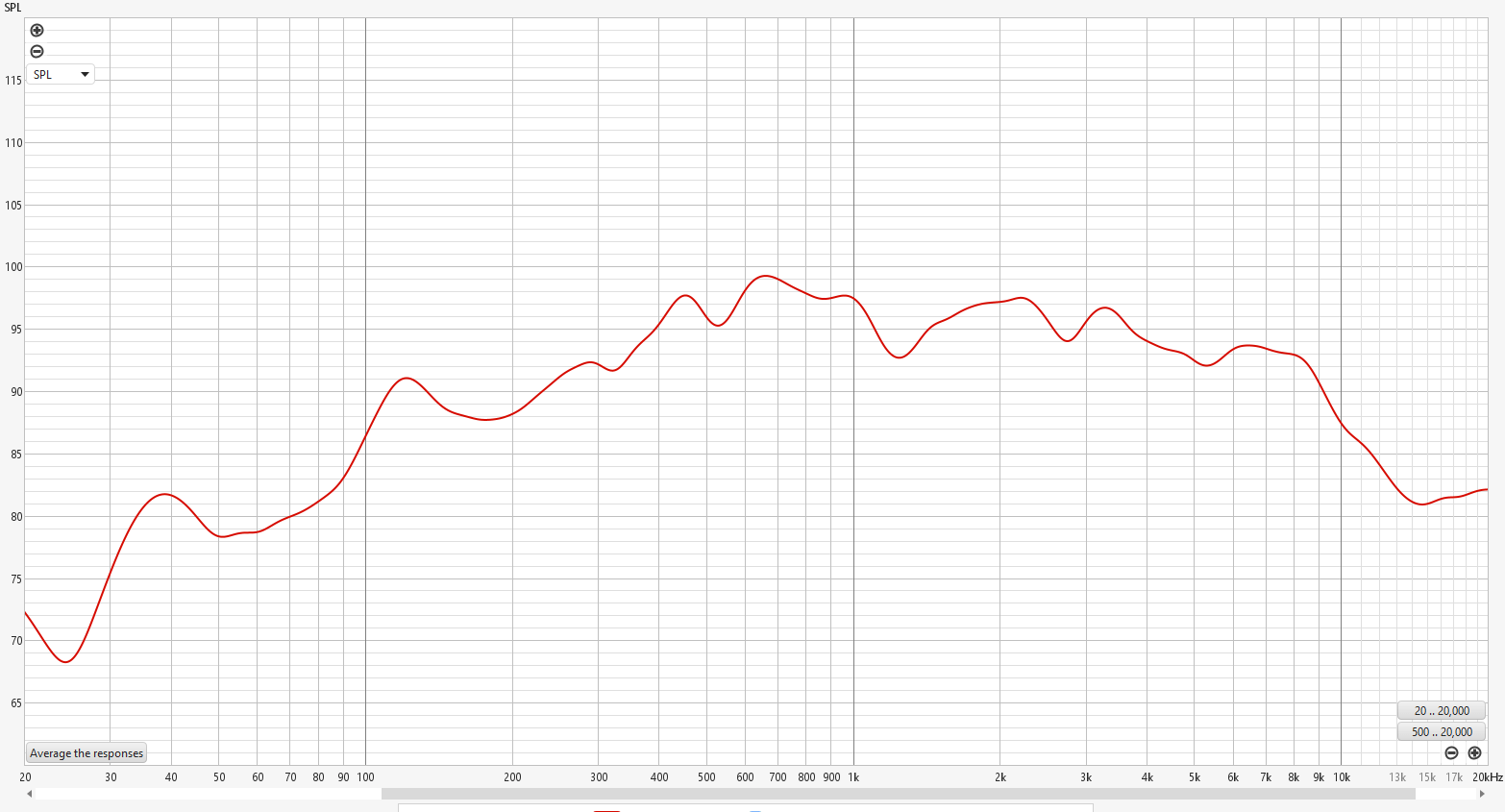

This is a 10mm cardboard panel, 300mm x 400mm. No frame, no damping, no edge termination. Driven with an XT32-4.

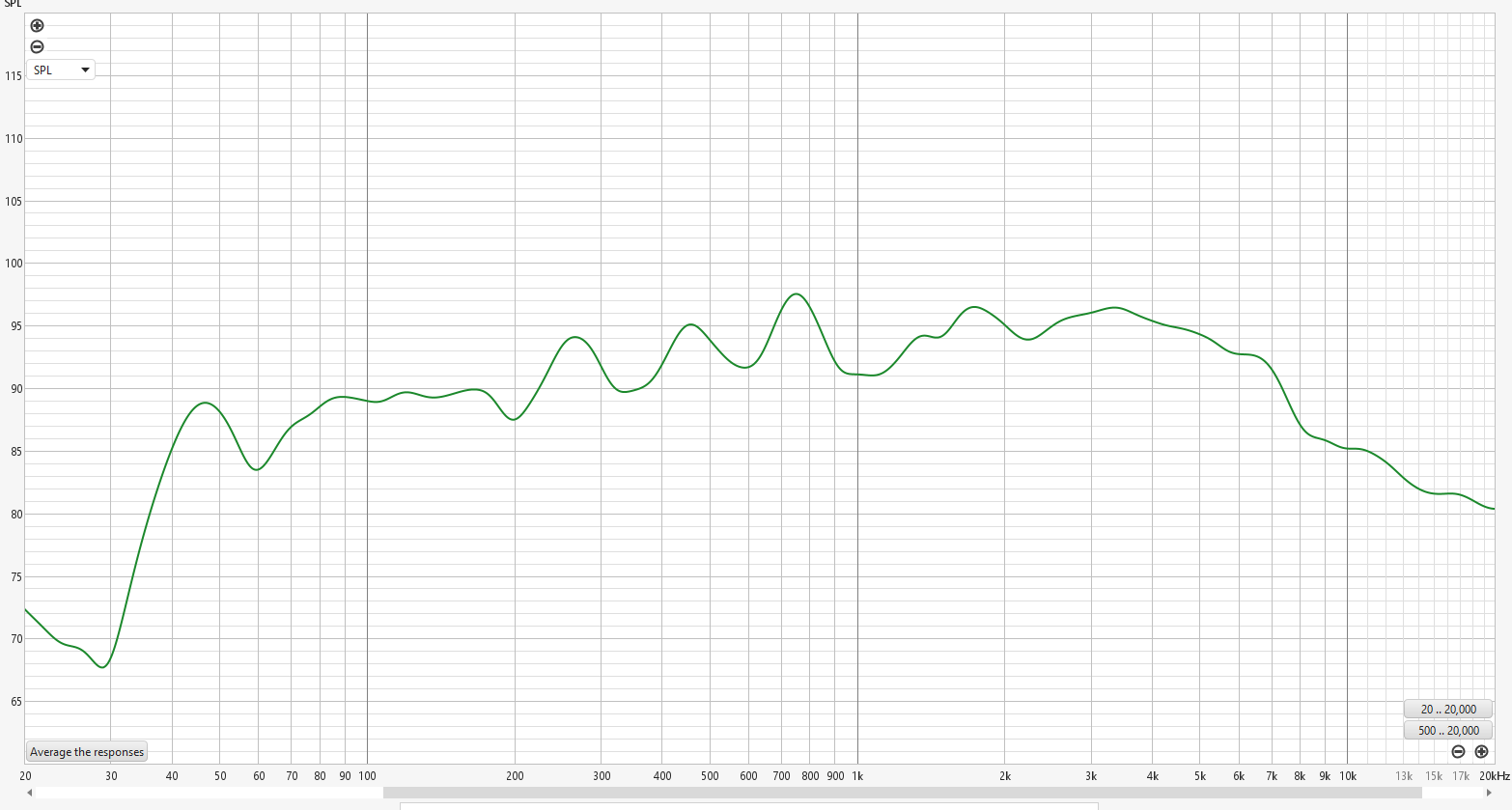

Here's the same panel after being mounted with PVA in a 400mm x 500mm canvas frame. The canvas is tightened (I think I over-tightened it too much, hence the bass being a little attenuated). I've used a 34g weight to iron out the ubiquitous 600hz peak.

The next version will have slightly looser canvas, and careful damping to increase the bass dB slightly; and epoxy resin in front of the driver to increase the tops.

This is a 10mm cardboard panel, 300mm x 400mm. No frame, no damping, no edge termination. Driven with an XT32-4.

Here's the same panel after being mounted with PVA in a 400mm x 500mm canvas frame. The canvas is tightened (I think I over-tightened it too much, hence the bass being a little attenuated). I've used a 34g weight to iron out the ubiquitous 600hz peak.

The next version will have slightly looser canvas, and careful damping to increase the bass dB slightly; and epoxy resin in front of the driver to increase the tops.

Looks like the hole has an opposite effect? So, something to do with the VC area? And damping the VC cavity with felt or foam did not help either?identical plate with a 25mm hole drilled through the Albasia, centred on the XT32 driver VC

Will be out today, but will get back to you with the drawings.Leob.

I was referring to this recording of two exciters situated next to each other.

As can be seen in the video, one exciter is having problems, while the other is rock solid.

These exciters in these positions are unable to work in tandem.

Are there any positions that will allow them to work together in harmony, which is essential for low end performance.

What are the exact positions of your exciters on your panels, so that I can test them on my eps panels.

I intended to start with the nxt positions first, are your positions similar?

Steve.

Yes, the hole creates a notch instead of a peak. I'm sure it has something to do with the size of the VC area.Looks like the hole has an opposite effect? So, something to do with the VC area? And damping the VC cavity with felt or foam did not help either?

Damping this cavity had no effect, whereas the Dayton Megabass (DAEX 32QMB) which had a 7kHz peak on Twinwall, did benefit greatly from a thick felt plug inside the VC cavity.

I'm not at all surprised by this result...A significant amount of the hf response comes directly from this zone..I was a bit surprised by the subsequent rise in hf until I realised that you drilled a 25 dia hole when the voice coil is 32mm dia. So you have an overhanging edge effect going on in the voice coil zoneYes, the hole creates a notch instead of a peak. I'm sure it has something to do with the size of the VC area.

Yes, the VC is 32mm dia indeed.25 dia hole when the voice coil is 32mm dia.

But the hole in the former is 25mm, the former lip overhangs inside and outside the coil dia.

Last edited:

Ok...I thought after I made that comment that this may be the case. So the extended hf is arising from a zone outside the hole (obviously LOL).. Would be interesting to do a Chandni test at these frequencies...I would take another punt and suggest that maybe it's arising from the former ring area around the hole.Yes, the VC is 32mm dia indeed.

But the hole in the former is 25mm, the former lip overhangs inside and outside the coil dia

In retrospect, it would have been instructive to start with a small hole using a step drill, test, fill it with mastic, test, if no good, go to the next step size etc etc.

20/20 rear vision is a great asset 😁

@Andre Bellwood maybe during the test try holding onto the back of driver, or add a mass to the back of the driver (maybe doubling it's weight), to see if it has any significant effect on that peak.

My first thought when you cut the hole was that the back of the driver is out of phase with the panel and it now has a clear and direct path for that opposite wave to interfere.

Also, just a thought, but maybe that's not a peak at 9kHz, maybe it's a dip from 2kHz - 8kHz 😛

My first thought when you cut the hole was that the back of the driver is out of phase with the panel and it now has a clear and direct path for that opposite wave to interfere.

Also, just a thought, but maybe that's not a peak at 9kHz, maybe it's a dip from 2kHz - 8kHz 😛

I've found honeycomb cardboard to be pretty good too, though it makes the already-not-so-great HF a bit worse in my tests. All those "DIY speaker for $30" videos should probably tell people to use that cardboard instead of XPS because honeycomb cardboard is a lot easier and gives a flatter curve as-is. Elmer's foam board is pretty good too and is available all over the place, including at Staples, which also has the honeycomb cardboard.

I believe that XPS has greater potential than anything else I've tried though because it is so light and rigid. It does need a lot of help though. My goal is to have exceptional dynamic response, minimal distortion, and excellent off-axis response, and I think I can only get that from very light and well controlled DML panels. If directivity wasn't an issue, and if I could justify the expense, then I'd probably just buy some planars and subs and be done with it 😛

I believe that XPS has greater potential than anything else I've tried though because it is so light and rigid. It does need a lot of help though. My goal is to have exceptional dynamic response, minimal distortion, and excellent off-axis response, and I think I can only get that from very light and well controlled DML panels. If directivity wasn't an issue, and if I could justify the expense, then I'd probably just buy some planars and subs and be done with it 😛

I think this is a good test to be donestart with a small hole using a step drill,

This is indeed the case. I have one more test to try boost the top end on this cardboard. If it doesn't work as I would like, then it's back to the Nidaplast.honeycomb cardboard is a lot easier and gives a flatter curve as-is.

I've been trying to find XPS in this country. I've never tested it.

Hello,

if you look closely at the latest podium sound panels you can see a gap around the diaphragm, this is quite obvious at the top, therefore no grill cloth. To me This looks to be black xps foam and the Nomex honeycomb cardboard with a kapton film has been superseded ? You can also see the sound bridges ( 2 on each side ) to tune, and seem to be at the same positions as originally done.

https://www.tllc.london

if you look closely at the latest podium sound panels you can see a gap around the diaphragm, this is quite obvious at the top, therefore no grill cloth. To me This looks to be black xps foam and the Nomex honeycomb cardboard with a kapton film has been superseded ? You can also see the sound bridges ( 2 on each side ) to tune, and seem to be at the same positions as originally done.

https://www.tllc.london

Hi Goldmund

The change must lie in the panel material as the weight of the original 0.5 is stated as 15.6 kg, and the new one is listed at 6 kg

The change must lie in the panel material as the weight of the original 0.5 is stated as 15.6 kg, and the new one is listed at 6 kg

This is indeed the case. I have one more test to try boost the top end on this cardboard. If it doesn't work as I would like, then it's back to the Nidaplast

I've been trying to find XPS in this country. I've never tested it.

If you could route a partial depth circular section out about 50 or 60mm in diameter without destroying the cardboard, you could try an acrylic or ply puck. The edge of the honeycomb hole would need to be reinforced with craft paper glued around the circumference. You could even try cutting the hole full depth. The step junction between the puck and the honeycomb may cause sonic problems however (assuming the puck is thinner than the cardboard)

XPS is abundantly available in Aus, but conversely, I've not been able to find honeycomb cardboard 😖😵💫

Edit..Oops ... Looked again and found some 10mm thick board listed... Not sure where stockists are. Last time I searched I had no luck.

How thick is the board you're using Andre??

Eucy

Last edited:

What ,nearly 10 kg difference in total weight, must be a mistake !Hi Goldmund

The change must lie in the panel material as the weight of the original 0.5 is stated as 15.6 kg, and the new one is listed at 6 kg

Would make more sense if that was for a pairWhat ,nearly 10 kg difference in total weight, must be a mistake !

As a matter of fact adding salt (sodium) to pva adhesive will increase the tackiness and also improve the adhesive's ability to bond.I like the question about the whipped PVA. It is like snow-white with eggs (I like cooking!). A pinch of salt to help?

I have been banging on about the inner ring surface problem for at least a decade, showing the problems in measurements and drawings and how to fix this on various different panel types.@homeswinghome @Veleric @twocents @Leob

Mornin' Gents,

I've done the tests on the XT32-4 on 3mm Albasia to nail down the cause of the 10kHz peak.

The graphs below are all 16k RTA, pink noise, 1/6 smoothing, 500hz - 20kHz.

Here's the original problem, with the peak at approx 10kHz. (I see it's actually 9kHz. Close enough)

View attachment 1316227

The green curve below is an identical plate with a 25mm hole drilled through the Albasia, centred on the XT32 driver VC.

View attachment 1316228

This one is a 3mm Albasia puck, 20mm in dia, stuck to the Albasia panel, centred on the inside of the XT32 VC.

View attachment 1316229

Here's the exact same setup, but 6mm thick. No holes. No pucks.

View attachment 1316230

See how the efficiency drops with the doubling of the panel mass.

Interesting.

But I'm still not fully convinced it's a "drum effect" though. I'm intrigued that the wavelength in air, of 10kHz, is pretty much the same as the diameter of the voice coil...

Comments?

Honeycomb panels are a bit of a problem because of the thickness of the panel and the cavities left when a hole is cut.

The obvious solution would be a phase plug , this would stop the cancellations caused by the deep cavity, but you would still loose the pistonic drive area of the inner coil surface.

The cavity resonance would also be reduced, but this would depend on the treatment of the cut Honeycomb cavities?

Luckily my round flueted panels do not suffer from the 10k peak, from the front of the panel , that is.

I have used various methods to eradicate the problem, such as various dome types, blu-tack, plus small holes with damping in.

Whichever suited the panel type.

Oil can, or tin can effect does not really explain what goes on ,on the centre area surface at high frequencies .

The noises caused by this cental area distortion is fired straight at the listener and also back into the cavity area.

Steve.

The extension in bass is impressive! How is the sensitivity (you get nothing for nothing?)? Does the canvas around the solid panel act as an extension of the panel - like the panel is abruptly thinned out and very flexible?I've also been working on honeycombed cardboard... Honeycombed, not corrugated. So it's similar to Nidaplast, construction-wise.

This is a 10mm cardboard panel, 300mm x 400mm. No frame, no damping, no edge termination. Driven with an XT32-4.

View attachment 1316232

Here's the same panel after being mounted with PVA in a 400mm x 500mm canvas frame. The canvas is tightened (I think I over-tightened it too much, hence the bass being a little attenuated). I've used a 34g weight to iron out the ubiquitous 600hz peak.

View attachment 1316231

The next version will have slightly looser canvas, and careful damping to increase the bass dB slightly; and epoxy resin in front of the driver to increase the tops.

Very interesting but also hard to grasp what could be happening - like everything related to dml panels afaik.

Greetings, Hans

some time back I read some posts here in the thread where members discussed small DML listening positions, specifically listening to the panels on edge and placed in either the front corners or in the rear corners of the room. It was late at the time and I forgot to jot down the page and post number now I cannot find it. Has anyone seen this discussion and do you recall where it was or who poster there? I think there were only three or so posts.

I have spent the last three days looking but manage to get distracted reading other posts or following links. The reading has been worth while but I would like to find the posts on "edge listening" and its impact on the resulting spatial qualities. Thanks for any assistance.

I have spent the last three days looking but manage to get distracted reading other posts or following links. The reading has been worth while but I would like to find the posts on "edge listening" and its impact on the resulting spatial qualities. Thanks for any assistance.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker