Hi all

First off...this place is GREAT..

New member with a completed mini that is really impressing... really thought about the F5m ,but thought I'd give the mini a go first.

Anywho...got everything ordered for the '5' ...except the back panel kit which is currently out of stock...gonna try the 2u chassis build as it will fit my space better...don't anticipate issues with the build ...but I do have a coupla questions.

Digikey # for multiturn trimmers instead of the single turns?

I would like a front power switch...using the rear as 'mains on'...like a lot of equipment does...and finally I'd like to use some blue LED's in the front as well...one from each amp board supply as the units 'on' lights.

Any suggestions are most welcome

Jody

First off...this place is GREAT..

New member with a completed mini that is really impressing... really thought about the F5m ,but thought I'd give the mini a go first.

Anywho...got everything ordered for the '5' ...except the back panel kit which is currently out of stock...gonna try the 2u chassis build as it will fit my space better...don't anticipate issues with the build ...but I do have a coupla questions.

Digikey # for multiturn trimmers instead of the single turns?

I would like a front power switch...using the rear as 'mains on'...like a lot of equipment does...and finally I'd like to use some blue LED's in the front as well...one from each amp board supply as the units 'on' lights.

Any suggestions are most welcome

Jody

Not to answer your questions, but just to share my experience with my year old 2U build, which I'm currently listening through. It gets very hot with the lowest level of bias (1 amp), and needs to be raised to aid with cooling. If you can go with 3U then do it.

Thanks for the reply and insight...I was going by the 'lower bias' build guide and of course just got notice from UPS that all is on the way...I will say my Mini seems to be pretty warm to the touch especially after it's been on for quite awhile...and i did use a dab of paste under the outputs....but she shows a steady bias of .300mV and a IR temp gun shows a pretty consistent 52 to 54 C on the sinks..upper 30s to mid 40s on the mosfet cases...still odd to someone not used to class A....'warmth'

Wonder how well a full aluminum chassis that is thick like some of the older car audio amps were would work if appropriately scaled to size for this amp?

Hi all

Quick question...in the build guide it shows the torroid mounted with the wires on the bottom....i would think it would have a flatter , more even pressure mounting if it were flipped so that the wires exit the top...im pretty sure the transformer itself doesn't care which way it faces...

Quick question...in the build guide it shows the torroid mounted with the wires on the bottom....i would think it would have a flatter , more even pressure mounting if it were flipped so that the wires exit the top...im pretty sure the transformer itself doesn't care which way it faces...

Yeah, totally up to you how you want to orient and mount the transformer. Any orientation that works with your chassis geometry and build layout should be fine.

no there is the F3 the M2 , the J2 F8 ,etc.. and all the SIT variations 😆I recently build the F5, does the F5M sound different and is the Aleph J still the best sounding class A amp to built?

yep have a different thd profile...I recently build the F5, does the F5M sound different and is the Aleph J still the best sounding class A amp to built?

"I'd like to use some blue LED's in the front as well...one from each amp board supply as the units 'on' lights"

Ben Mah has a excellent instruction for adding LED's in post #2395 of this thread.

Ben Mah has a excellent instruction for adding LED's in post #2395 of this thread.

Hi,

I did finally see that about the LED's...not surprised I missed it...rabbit hole...lol

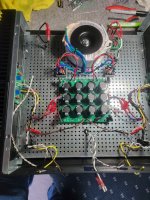

Here are some pics of where I am now, if anyone's interested.

Still waiting on the PEM, Jack's and posts.

I have done some quick and dirty PSU checks....24v both rails. Still needs final checks and what not, but I will wait on PEM before I make any attempt to see if she wakes up happy...or angry...

I did finally see that about the LED's...not surprised I missed it...rabbit hole...lol

Here are some pics of where I am now, if anyone's interested.

Still waiting on the PEM, Jack's and posts.

I have done some quick and dirty PSU checks....24v both rails. Still needs final checks and what not, but I will wait on PEM before I make any attempt to see if she wakes up happy...or angry...

Attachments

Thanks for the kind words

Yes..the...fender.. .washers...my understanding is it promotes better contact with the sink...spreads the load over a larger area...I did use some flat #4 stainless washers and the kit spring washers...what I had...but I don't plan on much over 1 to 1.2 on bias...depending on temps,ect I might add some ...maybe some different insulators..

Jody

.

Yes..the...fender.. .washers...my understanding is it promotes better contact with the sink...spreads the load over a larger area...I did use some flat #4 stainless washers and the kit spring washers...what I had...but I don't plan on much over 1 to 1.2 on bias...depending on temps,ect I might add some ...maybe some different insulators..

Jody

.

Thanks for the kind words

Yes..the...fender.. .washers...my understanding is it promotes better contact with the sink...spreads the load over a larger area...I did use some flat #4 stainless washers and the kit spring washers...what I had...but I don't plan on much over 1 to 1.2 on bias...depending on temps,ect I might add some ...maybe some different insulators..

Jody

.

I think it won't hurt to use a larger diameter washer with solid thickness if you want to crank the bias higher than 1.2A, which is quite easy to do/be tempted to do. Once you start, it is hard to stop...

This is a slightly different FW clone, but they (all FW amps) sound better with high bias settings. I started with smaller and thinner washers and arrived at these - see below. The spring-loading little washer also helps, as JayDee mentioned above. I dissipate 200W at all times... so better to be safe than sorry in the long run.

Might I ask where you found the ones your using...in case I want to pick some up.

Thanks

Jody

Thanks

Jody

Good evening...or rather morning in my case Mr.Pass...I'll be checking them out...a BIG thank you to you...the store...and everyone here. I was just young enough to have missed all the Heath and Dynaco ect. Diy heyday and thought that sort of thing was all but gone...one reason of many why I never plan on parting with my factory assembled ST-35...I do let it out to play on occasion...when I'm feeling...tubey.

Thanks again everyone

Jody

Thanks again everyone

Jody

I guess the primary reasons were that the zinc plated carbon steel is much thicker fender washer, therefore stiffer, and also 1/4 of the price of stainless. Also those ship free from Bezos Bookstore and show up the next day. All my amps operate indoors and the washers do a great job. Is there some reason I'm not aware of that makes the thinner stainless steel option a better choice?

- Home

- Amplifiers

- Pass Labs

- F5m kit