Welcome to the can of worms of audio.

Audio falls under various personal preferences that are even changing in time, so there is no best for you to dictate really.

B&C Speakers 18DS100 is very nice driver that should work in various designs.

Hornresp has steep learning curve, but is not THAT difficult. Just more fiddles then usual simulation program.

Choice of the Tapped horn is not bad at all. Hopefully someone can pop in and do more informed recommendation.

Cheers!

Audio falls under various personal preferences that are even changing in time, so there is no best for you to dictate really.

B&C Speakers 18DS100 is very nice driver that should work in various designs.

Hornresp has steep learning curve, but is not THAT difficult. Just more fiddles then usual simulation program.

Choice of the Tapped horn is not bad at all. Hopefully someone can pop in and do more informed recommendation.

Cheers!

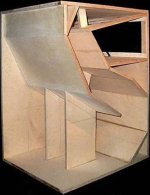

If you are referring to this model found there. Air opposes resistance at a certain speed/pressure, to understand for yourself take a sheet of paper and push half in the open air and the other half to an obstacle and you will notice imbalance and this imbalance is felt in the speaker excursion at high power, this can be felt in the ring next to the magnet and not the outer membrane more or less likely. and about the mouth of the enclosure it is different being flat and not inclined which offers different sound wave propagation.Hello

Im really new to to the pa sektion and want to build some subs for my rcf art945.

I want to build the lonely th18 from Victor https://www.lautsprecherforum.eu/viewtopic.php?t=9487

And to compare the xoc1 sub.

Just to know what sounds bitter to me because yeah im new and dont know wich sound will be the best for me

But i only have 2 of the bc ds 100 8 ohm and a lot of 15mm ply.

Anybody tryed to Use the ds100?

I never used hornresp so i dont know and also no computer is avaible at the moment..

Mabey somebody can tell me about that.

And really sorry about my bad english🙂

I hope the link is ok in the forum here..

Attachments

Thats why i want to try different stuff to find out what im looking for 🙂Audio falls under various personal preferences that are even changing in time, so there is no best for you to dictate really.

So you wanna say that is not good for the speaker?i dont get your post completly.imbalance and this imbalance is felt in the speaker excursion at high power, this can be felt in the ring next to the magnet and not the outer membrane more or less likely. and about the mouth of the enclosure it is different being flat and not inclined which offers different sound wave propagation.

this difference cannot be a valid reason because it does not affect so much but it exists. the sound is probably the same and you can not figure out what this is. If you ask me I prefer the xoc version it is much more viable. To observe these aspects you must check every detail in blood. any horn propagates depending on the shape it has in the entire frequency range.

so you want to build 2 different models ? and compare ?I want to build the lonely th18 from Victor https://www.lautsprecherforum.eu/viewtopic.php?t=9487

And to compare the xoc1 sub.

then from the 2 you will pick the one you like most

and duplicate it so you will end with a pair of those cabinets ?

To be honest, I don't understand what you're trying to say with your post either! Or what are you getting at?this difference cannot be a valid reason because it does not affect so much but it exists. the sound is probably the same and you can not figure out what this is. If you ask me I prefer the xoc version it is much more viable. To observe these aspects you must check every detail in blood. any horn propagates depending on the shape it has in the entire frequency range.

Kind Regards Viktor

You wants to know the diffrence of enclosure but are similar horn and couple of details what i said above.

Yes this was my planso you want to build 2 different models ? and compare ?

then from the 2 you will pick the one you like most

and duplicate it so you will end with a pair of those cabinets ?

Here too, I unfortunately didn't understand the intention behind your post. If you have any criticisms or something isn't clear, then feel free to say so. I have no problem with that.If you are referring to this model found there. Air opposes resistance at a certain speed/pressure, to understand for yourself take a sheet of paper and push half in the open air and the other half to an obstacle and you will notice imbalance and this imbalance is felt in the speaker excursion at high power, this can be felt in the ring next to the magnet and not the outer membrane more or less likely. and about the mouth of the enclosure it is different being flat and not inclined which offers different sound wave propagation.

Yes like that. Because im really a newbie i want to collect experience.so you want to build 2 different models ? and compare ?

then from the 2 you will pick the one you like most

and duplicate it so you will end with a pair of those cabinets ?

And also want to find out what im like.and the best thing I have a good connection for cheap wood🙂 so not a problem with costs. So if the ds100 fit i will try it. At this moment I will say thank you Viktor!

He helped me a lot and also did a simulation for the xoc1 for me. You are the best!

Attachments

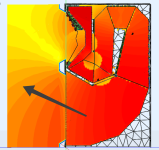

well, the shape mouth of horn can spread the wave sound in different angle. if you can build hog scoop, lonely.th18 pro and xoc come back here with review, will be very interesting. use the same driver for measuring.

Attachments

Is this simulation now for xoc1 ? Because i found some other parameters in this forum.

If it is for the xoc1 what you think about it?

If it is for the xoc1 what you think about it?

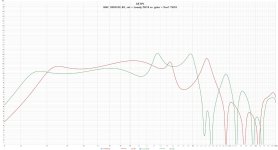

The sim above is for the Boxplan - MTH fold above It definitely looks impressive for the system volume. The TH18 sim parameters give more efficiency but not quite as deep response.

But both designs look fairly compromised if the lossy inductance switch is used.

TH18 grey MTH black

But both designs look fairly compromised if the lossy inductance switch is used.

TH18 grey MTH black

on post 3,199Does anybody have 3D model of enclosure with cone correction? (latest version preferably?)

deman made fusion 360 3d models and DXF files

he built em also

LINK TO FILES:

FUSION 360 models and DXF

DEMAN POST :

Finally got around to tidying up the files. There's a 3d model in Fusion 360 and drawing files for cutting in Rhino 3d and DXF. It all fits on 2 sheets of 18mm 2440X1220 ply.

All the files for cutting have layers for CNC operations and bevel cuts as needed. And there are layers for the pole mounts (Penn-Elcom M1562) are flagged as optional so you can delete them if you don't need them.

There is a third sheet saved in the folder called TH18 Sub Extras - this isnt needed but has template jigs to cut the rebates with a hand router for the pole mounts and skids (on the flip side of all the other rebates that will be CNC'd) there's also skids and a few spaces to help when assembling the bracing.

I'm not sure the way i did rebates on the bracing was optimal and it needs to be assembles in a specific order so make sure you dry fit everything and work it out. I'm getting a second one cut so will try and make a better build log.

Thank you @maxolini

I am wondering about this part, made my version and made it about 15mm shorter as it looks too large in posted version?

BTW did anyone actually compare results with and without cone correction? I have some tapped horns build with original plan for Xoc1 TH18 (no cone correction) and I am curious if there are any noticeable differences.

I am wondering about this part, made my version and made it about 15mm shorter as it looks too large in posted version?

BTW did anyone actually compare results with and without cone correction? I have some tapped horns build with original plan for Xoc1 TH18 (no cone correction) and I am curious if there are any noticeable differences.

Last edited:

I guess that topic have been touched many times in different threads , can't recall where are the measurements with and without cone correction but according to some definitions:

Designing a tapped horn subwoofer with cone correction has several advantages over a design without it. Cone correction refers to adjusting the horn's expansion or shape near the driver to account for the physical displacement and acoustic impedance mismatch caused by the driver's cone. Here’s how it benefits the design:

Advantages of Cone Correction in Tapped Horns:

- Improved Efficiency

- Cone correction helps match the acoustic impedance of the driver to the horn, reducing energy loss and increasing overall efficiency. This means more sound output per watt of input power.

- Smoother Frequency Response

- Without cone correction, irregularities in the horn's throat region can cause dips or peaks in the frequency response. Correcting for the cone’s shape helps smooth out these inconsistencies, leading to better overall sound quality.

- Reduced Distortion

- A well-matched transition between the driver and horn reduces turbulence and unwanted resonances, lowering harmonic distortion and improving clarity.

- Extended Low-Frequency Performance

- A properly implemented cone correction can help maintain efficiency at the lowest frequencies by ensuring better coupling between the driver and the horn.

- More Accurate Simulation Results

- Many horn simulation programs assume a point source driver, but in reality, the cone has a physical presence that affects the loading. Accounting for this leads to more accurate real-world performance compared to predictions.

What Happens Without Cone Correction?

- The driver might experience improper loading, leading to dips in response.

- There may be higher distortion due to reflections and turbulence at the throat.

- The system could be less efficient, requiring more power for the same output.

- There could be unexpected peaks and nulls in the response, making tuning more difficult.

Conclusion

While a tapped horn can function without cone correction, adding it refines the design by improving efficiency, reducing distortion, and ensuring a more accurate frequency response. This is especially beneficial in high-performance subwoofer applications where smooth and controlled bass output is crucial.

but at the end.... looks like without REW or SMAART and a measuring mic... you cant tell the difference between cone corrected and no cone corrected cabinets, so it is not a a matter of life and death.

soo many cabinets built without cone correction not just the TH18 but many others plans, and people love their cabinets

specially in groups of 4 or more.

cabinet count plus proper amplification and processing makes the difference

unless you have OCD i guess you are pretty fine.

😀

soo many cabinets built without cone correction not just the TH18 but many others plans, and people love their cabinets

specially in groups of 4 or more.

cabinet count plus proper amplification and processing makes the difference

unless you have OCD i guess you are pretty fine.

😀

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)