Have the two 3589 from Norway in the house. One has a damaged cone and surround. The other misses the pepperpot tweeter. As indicated by the seller .The first one connected full range for the woofer and with 2,7 uF for the tweeter. I LIKE THEM. The one with damaged cone has fs of 55 according to my Dats. The other 68. So follow the recipe with isopropyl and hard brush on the cloth surround. Sofar it lowers the fs dramaticaly. See if this improvement is still there tomorrow....

with isopropyl and hard brush on the cloth surround

you need to repeat procedure up to the point where you don't have any tackiness on residue which you're taking with brush to wiping cloth

practically, that's the stage where you did pull all the glue from cloth surround

just take a week for entire procedure, where you'll invest half an hour to each driver, each of 7 days

and, in the end, when alcohol is evaporated, you'll have again almost rock solid cloth surround, but free from original treatment solution

so, when you apply new treatment solution, be it factory made or ZM's recipe, cloth surround goes soft and stays the same for years

I will do that! There is clearly still a lot of sticky stuff left...

Cloth surround repair tips or replace?

Thanks for all the ideas, shared experience and inspiration

Cloth surround repair tips or replace?

Thanks for all the ideas, shared experience and inspiration

Just a heads up.

I contacted Ferrotec today with the purpose of acquiring some ferrofluid for my Tannoy 3833gg.

I figured I’d like to have the proper fluid on hand when they go into new enclosures. As I intend to at least open the tweeters up and inspect them for drying or dirty fluid and wouldn’t want the project to come to a halt unnecessarily if it needs replacement.

I spoke with a very personable and helpful salesperson in the fluids division named Vanessa.

I discovered a few interesting things.

Firstly, the bad news is that the fluid with the designation APGS15N that andynor called out as the proper fluid that Tannoy used in these speakers is no longer available.

The salesperson said something about the surfactant used in the APGS15N formula by their supplier was either no longer available or simply not being used by them anymore.

The good news is they have a replacement fluid with virtually identical properties that they gave the designation of APGS15M to.

The Gooder news is that I can buy it in a reasonable quantity.

The minimum order is $100. However, at $1.80 per cc of fluid I will end up with somewhere around 55cc of fluid.

I think andynor said something about there being only a 30-50 micro-liter requirement per driver?

Vanessa estimated that even at a 100 micro-liter requirement 55cc might be enough to service like 500 drivers?

Anyway, I think I’m gonna shoot them an email and get me some fluid.

I contacted Ferrotec today with the purpose of acquiring some ferrofluid for my Tannoy 3833gg.

I figured I’d like to have the proper fluid on hand when they go into new enclosures. As I intend to at least open the tweeters up and inspect them for drying or dirty fluid and wouldn’t want the project to come to a halt unnecessarily if it needs replacement.

I spoke with a very personable and helpful salesperson in the fluids division named Vanessa.

I discovered a few interesting things.

Firstly, the bad news is that the fluid with the designation APGS15N that andynor called out as the proper fluid that Tannoy used in these speakers is no longer available.

The salesperson said something about the surfactant used in the APGS15N formula by their supplier was either no longer available or simply not being used by them anymore.

The good news is they have a replacement fluid with virtually identical properties that they gave the designation of APGS15M to.

The Gooder news is that I can buy it in a reasonable quantity.

The minimum order is $100. However, at $1.80 per cc of fluid I will end up with somewhere around 55cc of fluid.

I think andynor said something about there being only a 30-50 micro-liter requirement per driver?

Vanessa estimated that even at a 100 micro-liter requirement 55cc might be enough to service like 500 drivers?

Anyway, I think I’m gonna shoot them an email and get me some fluid.

Alternatively: https://mainlytannoy.com/products/high-grade-original-tannoy-ferro-fluid-0-6ml-in-syringe

Enough for 2 biguns.

Yes Ferrotec stopped doing the proper fluid, mine was a one-off

Now it is in Serbia, massaging the prince of Bač’s ears.

Enough for 2 biguns.

Yes Ferrotec stopped doing the proper fluid, mine was a one-off

Now it is in Serbia, massaging the prince of Bač’s ears.

0,3ml per big driver, approx. maybe even less is enough, but I achieved proper fill with that amount.Just a heads up.

I contacted Ferrotec today with the purpose of acquiring some ferrofluid for my Tannoy 3833gg.

I figured I’d like to have the proper fluid on hand when they go into new enclosures. As I intend to at least open the tweeters up and inspect them for drying or dirty fluid and wouldn’t want the project to come to a halt unnecessarily if it needs replacement.

I spoke with a very personable and helpful salesperson in the fluids division named Vanessa.

I discovered a few interesting things.

Firstly, the bad news is that the fluid with the designation APGS15N that andynor called out as the proper fluid that Tannoy used in these speakers is no longer available.

The salesperson said something about the surfactant used in the APGS15N formula by their supplier was either no longer available or simply not being used by them anymore.

The good news is they have a replacement fluid with virtually identical properties that they gave the designation of APGS15M to.

The Gooder news is that I can buy it in a reasonable quantity.

The minimum order is $100. However, at $1.80 per cc of fluid I will end up with somewhere around 55cc of fluid.

I think andynor said something about there being only a 30-50 micro-liter requirement per driver?

Vanessa estimated that even at a 100 micro-liter requirement 55cc might be enough to service like 500 drivers?

Anyway, I think I’m gonna shoot them an email and get me some fluid.

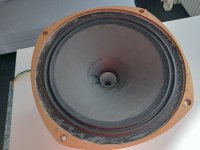

First one with damaged conepics

Attachments

I would recone them, but first confirm the spiders are usable (provide low enough FS). Zen Mod is your friend. Do you have a lead on a new tweeter?

I am not that good in emoji language to get your meaning Zen Mod. But I will first try how far I can go with restoring..

I send a mail to Lockwood for the tweeter. Getting the tweeter is my first priority I think.

Just the fun to see how far this will go with just work plus restoration and limited investment. Going through my bin to see how close I can get to the pepperpot 15" filter with parts I have

I send a mail to Lockwood for the tweeter. Getting the tweeter is my first priority I think.

Just the fun to see how far this will go with just work plus restoration and limited investment. Going through my bin to see how close I can get to the pepperpot 15" filter with parts I have

First one with damaged cone

take white PVA wood glue, cut it with water to 1:1

take white gause, prepare 2 pcs nicely covering size of cone tear

soft brush, apply glue at tear, back side of cone and when soft enough, align cone paper at tear to proper form

put gause across tear, same back side and apply glue across gause and tear, to flatten them together

leave 24 hrs, put 2nd gause across first one, apply glue to flatten

after 24 hrs, water will evaporate and you have it fixed, fully functional

now, if top side of tear is uneven, soak top of it with glue, flatten, leave 24hrs

voila

- Home

- Amplifiers

- Pass Labs

- Tannoy 3134 DC ZM-induced purchase, service and repair