Hi all,

I'm just in the process of designing a one-off scratch built belt drive turntable, however the current hurdle is selecting a suitable motor system. I have plenty of mechanical/machining knowledge but little motor control experience so hopefully this will be a good learning opportunity.

Initially I was looking at the SG4 with MA-3D driving a BLWS231S-24V-2000 as suggested by Pyramid, and was hoping to order from Radwell ( https://www.radwell.co.uk/Buy/ANAHEIM AUTOMATION/ANAHEIM AUTOMATION/BLWS231S-24V-2000 ). However from speaking to them it looks like even though they list it on the website they no longer sell them, and there doesn't seem to be any other source for Anaheim Automation this side of the pond.

I would greatly appreciate any opinions on what the best route would be for me to go - has anyone got a UK source/spares for reasonably beefy motor which would drive a ~12kg platter? Ideally I would stay with AC but could go the DC route if that's the consensus (I have looked at the Maxon offerings, but am slightly put-off by the price tag and a few mentions of QC issues). The Papst motors sound enticing but there don't seem to be many lying around on ebay etc.

Any help would be massively appreciated!

Herbie

I'm just in the process of designing a one-off scratch built belt drive turntable, however the current hurdle is selecting a suitable motor system. I have plenty of mechanical/machining knowledge but little motor control experience so hopefully this will be a good learning opportunity.

Initially I was looking at the SG4 with MA-3D driving a BLWS231S-24V-2000 as suggested by Pyramid, and was hoping to order from Radwell ( https://www.radwell.co.uk/Buy/ANAHEIM AUTOMATION/ANAHEIM AUTOMATION/BLWS231S-24V-2000 ). However from speaking to them it looks like even though they list it on the website they no longer sell them, and there doesn't seem to be any other source for Anaheim Automation this side of the pond.

I would greatly appreciate any opinions on what the best route would be for me to go - has anyone got a UK source/spares for reasonably beefy motor which would drive a ~12kg platter? Ideally I would stay with AC but could go the DC route if that's the consensus (I have looked at the Maxon offerings, but am slightly put-off by the price tag and a few mentions of QC issues). The Papst motors sound enticing but there don't seem to be many lying around on ebay etc.

Any help would be massively appreciated!

Herbie

Try RS or their competitors.

Electric motor merchants?

My solution would be to buy an old table or two, see how they work, and read up.

Then start your project.

Why 12 kilos platter?

Bearings and so on will be complex.

Electric motor merchants?

My solution would be to buy an old table or two, see how they work, and read up.

Then start your project.

Why 12 kilos platter?

Bearings and so on will be complex.

https://www.ebay.com/itm/1537675933...vVP2v|tkp:Bk9SR5qpoNOwYw&shqty=1&isGTR=1#shId

Check the spec before ordering.

Shipping costs more than the motor but gets cheaper if you buy more than 1.

Check the spec before ordering.

Shipping costs more than the motor but gets cheaper if you buy more than 1.

Seems like a good motor option. 3ohms phase resistance as well, so easy to drive. I would assume 4 poles?[URL='https://www.ebay.com/itm/153767593349[/URL]

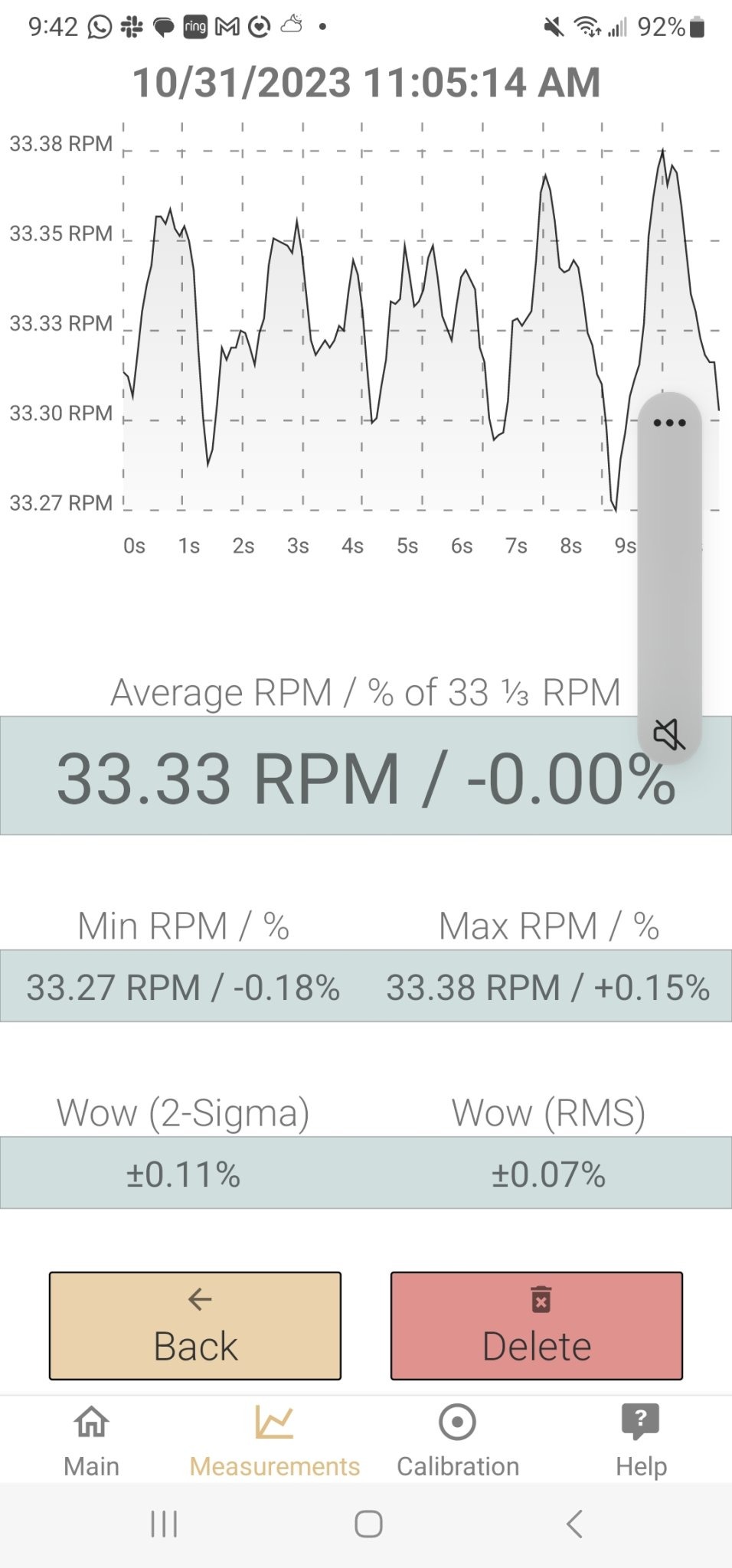

I use a 4 pole Anaheim Nema23 motor in my TT, with an Arduino-compatible controller setup: ST Micro Nucleo G474 as microcontroller, a motor controller shield, and the Arduino code loaded via the Arduino IDE and the SimpleFOC library. I run 3 phase FOC sinusoidal/space vector waves to my BDLC, and get amazingly stable performance.

I would be interested to know more details of your setup.

Both hardware and software.

I am sort of in limbo with Arduino programming.

I can do the basic stuff but struggling to make the leap to more advanced programming.

Current turntable setup is 2 phase sine (using Arduino & D-Spin driver) driving a stepper but it does vibrate.

I have the ACT/Longs BLDC motor and have driven on a test bed with 3 phase generated by Arduino & class D amps between motor & Arduino.

It is absolutely silent and vibration free.

Up to now I have not implemented any control - speed and acceleration/deceleration.

Both hardware and software.

I am sort of in limbo with Arduino programming.

I can do the basic stuff but struggling to make the leap to more advanced programming.

Current turntable setup is 2 phase sine (using Arduino & D-Spin driver) driving a stepper but it does vibrate.

I have the ACT/Longs BLDC motor and have driven on a test bed with 3 phase generated by Arduino & class D amps between motor & Arduino.

It is absolutely silent and vibration free.

Up to now I have not implemented any control - speed and acceleration/deceleration.

Check out SimpleFOC.com. Great Arduino library for running FOC based 3 phase sign waves with easy to drive motors (aka gimbal motors, or motors with high resistance aka 5ohm and low voltage aka under 24v).

The Arduino code becomes super simple. Approx 50 lines of code to run at a single speed (aka 33.333). Bit more complex to add a button/trigger to switch between preset speeds (33.3 vs 45).

I used a SimpleFOCShield 2.0.4 available on ebay, but now moving to an ST Micro Nucleo IHM07M1 as the motor controller.

I currently just run open loop, and it is super smooth.

The Arduino code becomes super simple. Approx 50 lines of code to run at a single speed (aka 33.333). Bit more complex to add a button/trigger to switch between preset speeds (33.3 vs 45).

I used a SimpleFOCShield 2.0.4 available on ebay, but now moving to an ST Micro Nucleo IHM07M1 as the motor controller.

I currently just run open loop, and it is super smooth.

Anybody tried a BLDC cieling fan motor for this purpose?

22W, should be enough, and you can control the speed in fine steps.

22W, should be enough, and you can control the speed in fine steps.

Hi all,

I'm just in the process of designing a one-off scratch built belt drive turntable, however the current hurdle is selecting a suitable motor system. - has anyone got a UK source/spares for reasonably beefy motor which would drive a ~12kg platter?

I happen to have a Hurst 24v AC motor - Model PASP Instrument Motor, Part No. 3201-004, speed 300rpm, 60Hz.

I bought it as an upgrade to the Rega 24v (Premotec) motor I'm currently using (as it has more torque) - but the guy who designed my motor speed controller "left the building" shortly after he sold me the motor - so it was never used. 🙁

Try the solution above. I use ST Micro Nucleo boards, but you can also use straight up Arduino to make it easy.it was never used.

Buy:

1) Arduino Uno R3 (must be R3, because it has a crystal occilator. The newer R4 does not.)

2) SimpleFOCShield 2.0.4. (can buy on Ebay or AliExpress)

Those two should run you $40 USD total. You just plug the shield into the Arduino, connect a DC power source to the shield, and connect the 3 phases of the motor to the appropriate phase screw on the shield.

Then, you just need the Arduino IDE running on a Windows or Mac, and the SimpleFOC library (the IDE can automate that download for you easily).

You dont even need sensors. Open loop speed is fine for this, since there is very little resistance applied when operating.

Here is my build:

https://www.diyaudio.com/community/threads/cat-mouse-i-built-a-turntable.401612/#post-7410902

I get pretty solid performance for a belt drive. My pulley is my weak link right now. Finding a flat belt pulley that fits on a 1/4" is hard. (Round belts are easy, but I did not like the performance from round belts).

https://www.diyaudio.com/community/threads/cat-mouse-i-built-a-turntable.401612/#post-7410902

I get pretty solid performance for a belt drive. My pulley is my weak link right now. Finding a flat belt pulley that fits on a 1/4" is hard. (Round belts are easy, but I did not like the performance from round belts).

See model robot stores for small pulleys, or 3-D print one in a proper grade of plastic.

3-D services are getting common now.

3-D services are getting common now.

Technics quartz-locked DD motors can be overclocked to as high as 120rpm or so, with a crystal change (or DDO), and run off a simple 12VDC power supply. Motor circuit and platter under $100 on Ebay all day long. Very stable and reliable, and all you have to do is get the clock frequency right.Hi all,

I'm just in the process of designing a one-off scratch built belt drive turntable, however the current hurdle is selecting a suitable motor system. I have plenty of mechanical/machining knowledge but little motor control experience so hopefully this will be a good learning opportunity.

Initially I was looking at the SG4 with MA-3D driving a BLWS231S-24V-2000 as suggested by Pyramid, and was hoping to order from Radwell ( https://www.radwell.co.uk/Buy/ANAHEIM AUTOMATION/ANAHEIM AUTOMATION/BLWS231S-24V-2000 ). However from speaking to them it looks like even though they list it on the website they no longer sell them, and there doesn't seem to be any other source for Anaheim Automation this side of the pond.

I would greatly appreciate any opinions on what the best route would be for me to go - has anyone got a UK source/spares for reasonably beefy motor which would drive a ~12kg platter? Ideally I would stay with AC but could go the DC route if that's the consensus (I have looked at the Maxon offerings, but am slightly put-off by the price tag and a few mentions of QC issues). The Papst motors sound enticing but there don't seem to be many lying around on ebay etc.

Any help would be massively appreciated!

Herbie

I use one with a modified LP12 inner platter working as a 165mm dia. drive pulley, to drive my Micro Seiki turntable (10kg platter). Works great.

Cheers, Mike

Thanks everyone for the input, it sounds like 3 phase BLDC with and Arduino Uno running the simpleFOC code would be a good route to go down. Looking at the SimpleFOC site they suggest this JK42BLS01 motor

https://www.aliexpress.com/item/1005001858931568.html?gatewayAdapt=glo2fra

and DRV8302 board

https://www.aliexpress.com/item/100...ad5be524fec84e0f407a599da7d&afSmartRedirect=y

https://www.aliexpress.com/item/1005001858931568.html?gatewayAdapt=glo2fra

and DRV8302 board

https://www.aliexpress.com/item/100...ad5be524fec84e0f407a599da7d&afSmartRedirect=y

From what I can tell the SimpleFOCShield is mainly for lower power applications - am I correct in thinking to drive something like the motor linked above or even larger (such as JK42BLS02 https://www.aliexpress.com/item/100....new_all_items_2007523695353.1005001873278578 ) I would be able to use the DRV8302 board. Do I need to worry about rated speeds - the ACT/Longs motor that russc mentioned is rated for 2500RPM whereas these ones I've found are 3200RPM. From what I can tell BLDC have quite a flat torque/RPM curve?1) Arduino Uno R3 (must be R3, because it has a crystal oscilator. The newer R4 does not.)

2) SimpleFOCShield 2.0.4. (can buy on Ebay or AliExpress)

These aliexpress motors apparently have 8 poles - does that mean they might have smoother rotation than the 4 pole 57BL01?https://www.ebay.com/itm/153767593349?hash=item23cd434585:g:tXwAAOSw5cRZJpm7&amdata=enc:AQAIAAAA4D/1yS0dsfB2PjODYuURxVzw23mp87kBtsrzPJiF9583sPFcl4zBgF6NTiRIEfTMKnIwJrwM6UBHTxuYAvvJ/9ZL7I/yuXKC14/f/FTS/N5M2w6xhp1KoqiRNcHgijvj+yIepWpHdxsrHXgkyLR93MLZD73r7mxdEznF/7IF8x47P00sKACTbN8mYDBcAmfCZZLWtkGzQ6HcMAH1jFyf5ZtS7Fr+Etvaon5L0C7FMlQ+9kP1K+2Vg+3sxBoSeJO7GJB43grEMQpsa0qV99yLWLs5ysV7ySQxpYzvmwlvVP2v|tkp:Bk9SR5qpoNOwYw&shqty=1&isGTR=1#shId

Check the spec before ordering.

Shipping costs more than the motor but gets cheaper if you buy more than 1.

I'll be turning the pulley on my lathe, I would rather use my 3d printer for prototyping. The high mass platter is intended to help dissipate vibration from the stylus and reduce speed variations (which might not be a problem if I get the motor right). Also I think big platters look cool! I had checked RS components for motors but as expected they are quite overpriced and have fewer options than ebay/aliexpress. I also own a few small inexpensive tables so have a decent idea of how they run, however with this project am aiming to build something very overkill!See model robot stores for small pulleys, or 3-D print one in a proper grade of plastic.

3-D services are getting common now.

Typically yes, but not always.aliexpress motors apparently have 8 poles - does that mean they might have smoother rotation than the 4 pole 57BL01?

Also, either motor board should work. Just make sure the motors have at least a couple ohms of phase resistance. Phase resistance lower than 1 ohm (in drone propeller motors for example) is really problematic with these controllers.

Hi Herbmeister!

the 12 kg plate is easy to fold

SG4 and MK154 on the "richb" thread, in design. It can provide a printed circuit board.

It requires 3 class D amplifiers approx. 100W and 3 torroid transformers. Papst 3-phase asynchronous motor.

Like this on my record player.

Andrew

the 12 kg plate is easy to fold

SG4 and MK154 on the "richb" thread, in design. It can provide a printed circuit board.

It requires 3 class D amplifiers approx. 100W and 3 torroid transformers. Papst 3-phase asynchronous motor.

Like this on my record player.

Andrew

A BLDC motor would need a lot of pole pairs to provide negligible torque ripple. A permanent magnet synchronous motor (PMSM) is more suitable for the said purpose. The PMSM also has sinusoidal flux distribution in its stator (like an induction machine) which makes it a quieter motor when compared to the BLDC.

There's no reason you can't drive a BLDC with sinusoidal current, the best motor controllers do this anyway. Physically a PMSM and a BLDC are basically the same, its just whether you drive it with discrete commutation steps, trapezoidal or sinusoidal waveforms that determines how smooth the rotation is. A BLDC pole shape is less likely to be optimized for low torque ripple compared to a PMSM, since the expectation would be trapezoidal drive, but these motor types are converging over time as DC motor controls become more sophisticated (using sinusoidal waveforms and FOC). For best smoothness a three-phase induction motor with field-oriented control (FOC) is perhaps the way to go. Not as energy efficient though, and precise speed control won't be as good unless a good tacho or encoder are added to the control system.

From what I understand, the difference is that BLDC stator uses concentrated winding vs. distributed winding of the PMSM / WFSM / IM / SynRM, that have a sinusoidal flux variation (in space). The BLDC maybe driven with sinusoidal current but the cogging and torque ripple would remain.There's no reason you can't drive a BLDC with sinusoidal current, the best motor controllers do this anyway. Physically a PMSM and a BLDC are basically the same, its just whether you drive it with discrete commutation steps, trapezoidal or sinusoidal waveforms that determines how smooth the rotation is. A BLDC pole shape is less likely to be optimized for low torque ripple compared to a PMSM, since the expectation would be trapezoidal drive, but these motor types are converging over time as DC motor controls become more sophisticated (using sinusoidal waveforms and FOC).

In my opinion, the induction machine is mechanically simpler but more difficult to control electrically, due to the differences in speed between various quantities:For best smoothness a three-phase induction motor with field-oriented control (FOC) is perhaps the way to go. Not as energy efficient though, and precise speed control won't be as good unless a good tacho or encoder are added to the control system.

Rotor - mech speed)

Rotor EMF/currents - slip speed

Stator EMF/current/flux and rotor flux - synchronous speed.

It is also prone to parameter variations that affect slip estimation etc. that affect the FOC performance. However, synchronous machines have no slip and the all EMFs, currents and fluxes of both the rotor and stator are all at the same (syncronous) speed, making it easier to control, even when closed loop.

Nevertheless, if the performance of a simple open loop V/f control of the induction machine would suffice, that would be easier to do. But, again the synchronous machine has a definite speed relationship with the frequency of the applied voltage / current.

The car alternator is perhaps the easiest 3-phase synchronous motor one could get.

Last edited:

- Home

- Source & Line

- Analogue Source

- UK AC motor source (DIY Turntable)