In my mind I started a long time ago but I am now collecting parts 😀

For now I am going to try to use the board I posted above with the TMC 2209 stepper drivers to see what noise they make. That will determine if the mechanics need a counterweight for the z. I need to finish the ARTA turntable to see if I want to use that for the rotation like you have or try to use a belt driven platform with the 3rd axis of the board.

I think I will start with just having the arm move up and down and round and round. The in and out for dual layers can be done in two measurement steps physically changing the distance for r by sliding a mic mount back. If it is truly necessary to measure top and bottom surfaces then in and out can be motorized later.

The structure will be either aluminium tubes or v-slot. I want to design for 2m of travel vertically. I want it to be as light and minimal as possible but stiff enough to be accurate. I think that will need some trial and error to get right.

I think I will start with just having the arm move up and down and round and round. The in and out for dual layers can be done in two measurement steps physically changing the distance for r by sliding a mic mount back. If it is truly necessary to measure top and bottom surfaces then in and out can be motorized later.

The structure will be either aluminium tubes or v-slot. I want to design for 2m of travel vertically. I want it to be as light and minimal as possible but stiff enough to be accurate. I think that will need some trial and error to get right.

Sort of scanning possible components & suppliers as well when i have some time and not able to work on my speakers.

Also doodling/sketching some concepts also to breakdown into main components. Focus on the mechanical side of the shoestring.

Also doodling/sketching some concepts also to breakdown into main components. Focus on the mechanical side of the shoestring.

Indeed v-slot and/or linear gliders. Also the rotation axle with igidur rotation bearings.

Weight/stiffness is a challenge. Those alu profiles are not particularely stiff.

Need to also brush up my mechanical background. But conceptually triangle shapes are stiff by definition ;-)

Weight/stiffness is a challenge. Those alu profiles are not particularely stiff.

Need to also brush up my mechanical background. But conceptually triangle shapes are stiff by definition ;-)

Question : the dual layers what distance between are you considering?

Is that also related to the measurement distance with the dut?

Is that also related to the measurement distance with the dut?

@JanRSmit : If you want to see it in person and decide what you like and don't like... Let me now, the coffee will be ready.

I really like linear rails or rods from a movement perspective, but I have come to the conclusion that they will be too heavy for what I want to do. As much as I dislike V-Wheels I have a lot of them and they are light.Indeed v-slot and/or linear gliders. Also the rotation axle with igidur rotation bearings.

The V-slot profiles are pretty good at least in 2040 size or larger. I built a torsion box out of 2040 to sit under my CNC and it is very stiff in this configuration. The C-Beam is really stiff, but too heavy without rolling support underneath, which then needs a level floor.Weight/stiffness is a challenge. Those alu profiles are not particularely stiff.

Pm gestuurd ;-)@JanRSmit : If you want to see it in person and decide what you like and don't like... Let me now, the coffee will be ready.

I have the slewing bearing. It will require a preload I am fairly sure. I have yet to decide to I go with T slot or go with Baltic Birch Stressed frame members. I have the BB. I am watching how you are getting along. Literally right now I am completing one woofer prototype that I designed for a client. I need to do the acoustical measurements on an IEC baffle that I need to replace. And an AMT datasheet that also requires some careful measurement on an IEC baffle. After this I am hoping to have enough bucks left over to buy the materials that I don't have. This is my 9 to 5. Not a hobby. And right now I don't have a contract that allows billable hours and steady pay.@fluid Does that mean that you are starting a build also?

So, is it getting built? Yup. Have I started? Yup. Will it be this week? I wish 🙂

Question : the dual layers what distance between are you considering?

Weinreich mentions a quarter wavelength and uses 14.5cm. I used way less in my first attempt. I will try to improve it. I either need to make the scanner smaller (more space efficient) or the room bigger...

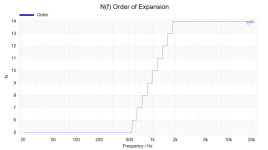

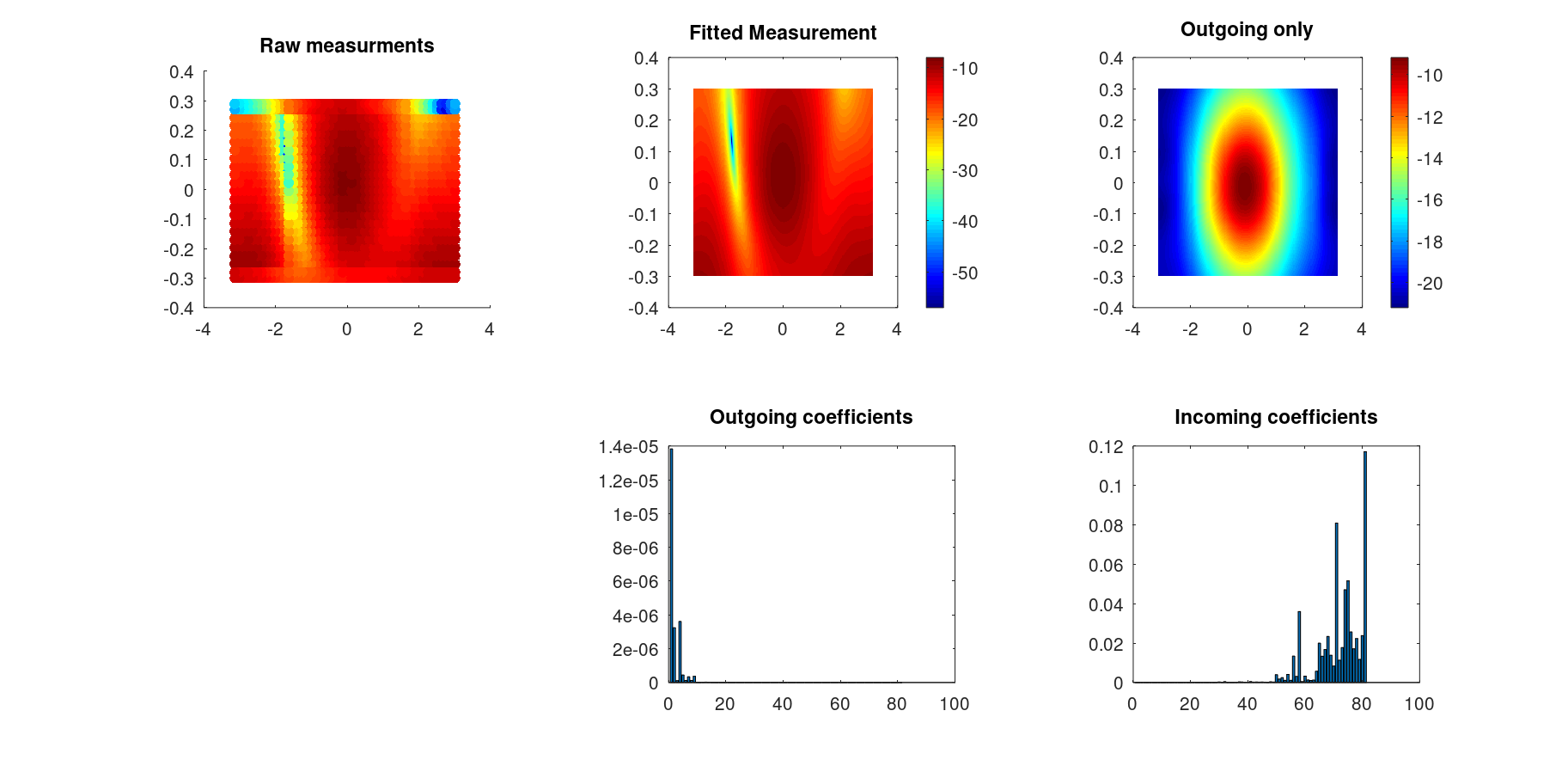

I still have a lot of questions and a lot of frequencies don't fit properly, but this (f = 200Hz) looks promising:

Any idea why the freq do not fit properly?

Can you describe the deviation?

I am not into math anymore, but logical thinking still ok i presume;-)

Can you describe the deviation?

I am not into math anymore, but logical thinking still ok i presume;-)

Are the discontinuities at the top and bottom of the first “image” (Raw measurements) a problem in the data? Are those glitches throwing a wrench in the works?I still have a lot of questions and a lot of frequencies don't fit properly, but this (f = 200Hz) looks promising:

View attachment 1315676

Few

It's a drawing artefact. I didn't bother to throw the top and bottom cap measurements away. You see measurements at different radii. There is no hint of this 'discontinuity' in the fit, because there isn't any to begin with and the evaluation of the fit is done only for the cylinder wall.

Small update:

I've been looking a bit more into the measurements with the guys over on audiosciencereview. Not sure what I've learned this far, but I'm currently performing a dry run with a evenly spaced spherical grid using the raspberry pi. I tried that before, but the scanner pushed the speaker of the stand. I implemented some checks and we'll see how it goes now.

I've been looking a bit more into the measurements with the guys over on audiosciencereview. Not sure what I've learned this far, but I'm currently performing a dry run with a evenly spaced spherical grid using the raspberry pi. I tried that before, but the scanner pushed the speaker of the stand. I implemented some checks and we'll see how it goes now.

- Home

- Design & Build

- Software Tools

- Klippel Near Field Scanner on a Shoestring