Hello,

I’m trying to find the blueprints of the original H110 cabinet on net, without any luck…

Does anyone have the plans for the H110 cabinet?

It is an early model of the Altec A5, REF: attached screenshot.

Considering building one.

—I already have the 515 RWB Hollywood woofer and a 288 Gold labeled driver with original diaphragm, and a tar-filled 1005 multi-cell….

I’m trying to find the blueprints of the original H110 cabinet on net, without any luck…

Does anyone have the plans for the H110 cabinet?

It is an early model of the Altec A5, REF: attached screenshot.

Considering building one.

—I already have the 515 RWB Hollywood woofer and a 288 Gold labeled driver with original diaphragm, and a tar-filled 1005 multi-cell….

Last edited by a moderator:

Greets!

Lucky you! 👍 😎

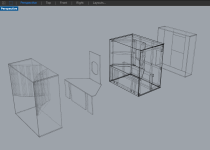

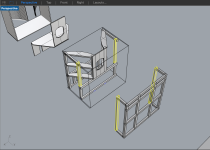

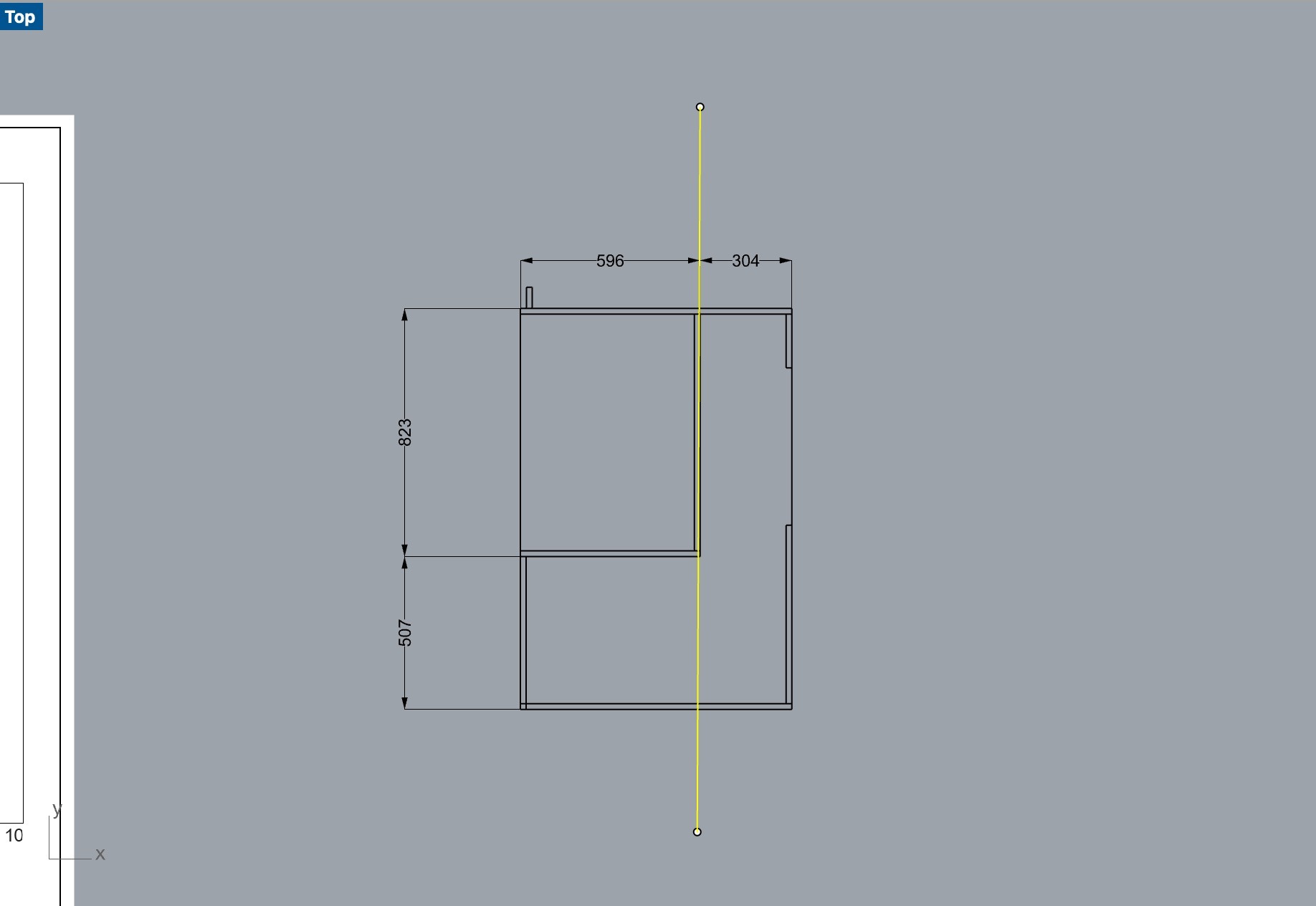

TTBOMK none exist, though attached were done from an original and FWIW having measured one and

lived' with one as an A6 (less riser) at my high school, its basic dimensions are spot on to my sketch, so should perform the same except for the fact that the originals were made from some really cheap packing crate plywood, so 'colored' the performance somewhat depending on the soundtrack, SPL in a nearfield app.

Lucky you! 👍 😎

TTBOMK none exist, though attached were done from an original and FWIW having measured one and

lived' with one as an A6 (less riser) at my high school, its basic dimensions are spot on to my sketch, so should perform the same except for the fact that the originals were made from some really cheap packing crate plywood, so 'colored' the performance somewhat depending on the soundtrack, SPL in a nearfield app.

👍 Thank the Melaudia folks, they've been a cornucopia of help since my earliest days on the net, not to mention introduced me to the late, great Jean Michel LeCleac'h that after a pretty intense 'meeting of the minds' re compression horn design found we both had a lot in common, not the least of which was our love affair with the pioneer's audio design philosophy/W.E./Lansing/Altec systems.

Thanks!

I have one more issue I would like to address…

The cone of my 515 RWB was in such a state that it was not salvageable. It had tears along the basket.

I have the original coil + an after marked paper cone w. correct pressing; bought on eBay.

I have started taking off the last paper cone remains on top of the cardboard cylinder to which the 20 ohm coil is attached.

The phenolic spider I will leave be.

I will need to attach the aftermarket paper cone to the coil.

Q1: I had a bit too much heat on the soldering iron when detaching the two coil wires…needed to take away a lot of epoxy. they now look a bit thin, see attached photo: will I manage to salvage the coil? Should I overlap the two wires with the tinsel leads a bit more than normal?

Q2: It looks like the paper cone, originally, was entered to the cardboard cylinder before the phenolic spider.

I do not want to tamper too much with the spider; is there a possibility to attached the new cone to the top of the coil/cardboard cylinder; if the surface has been grinded down properly? I’m using a Dremel Multitool.

I have one more issue I would like to address…

The cone of my 515 RWB was in such a state that it was not salvageable. It had tears along the basket.

I have the original coil + an after marked paper cone w. correct pressing; bought on eBay.

I have started taking off the last paper cone remains on top of the cardboard cylinder to which the 20 ohm coil is attached.

The phenolic spider I will leave be.

I will need to attach the aftermarket paper cone to the coil.

Q1: I had a bit too much heat on the soldering iron when detaching the two coil wires…needed to take away a lot of epoxy. they now look a bit thin, see attached photo: will I manage to salvage the coil? Should I overlap the two wires with the tinsel leads a bit more than normal?

Q2: It looks like the paper cone, originally, was entered to the cardboard cylinder before the phenolic spider.

I do not want to tamper too much with the spider; is there a possibility to attached the new cone to the top of the coil/cardboard cylinder; if the surface has been grinded down properly? I’m using a Dremel Multitool.

Attachments

Never seen this cabinet before... it looks old, in the color black and with two large vertical vents in front, looks also smaller than the H110, does anyone know the name of the cabinet; or does anyone have the plans for it; if an alternative clone cabinet for the 515 RWB?

Last edited by a moderator:

It's the original A7 and never seen it called anything else except the 825, though don't know if it's technically correct.

Official literature, so physically the same as the 825.

Official literature, so physically the same as the 825.

The very first I think is this one from the 800 system : https://www.lansingheritage.org/images/altec/specs/pro-systems/800/page2.jpg

You can see a sketch of this version of the VOTT in the Revue de l'audiophile, a french magazine that are mostly responsible for the high efficiency speakers craze in that country.

http://6bm8.lab.free.fr/Documentations/Revues/Audiophile/1977-1988/38/JOURNEES/JOURNEES.html

You can see a sketch of this version of the VOTT in the Revue de l'audiophile, a french magazine that are mostly responsible for the high efficiency speakers craze in that country.

http://6bm8.lab.free.fr/Documentations/Revues/Audiophile/1977-1988/38/JOURNEES/JOURNEES.html

For the 825B cab we're most familiar with, yes; but the original A6, A7 mimics the 'A' cinema series and then there's the narrow throat version of the 825 that I've never seen a model # for either, though supposedly was a special order that implies it had one.

Thanks! Forgotten I have all the various articles on an old HD thanks to the late JMMlC.

Thanks! Forgotten I have all the various articles on an old HD thanks to the late JMMlC.

Thanks!

What was the original plywood material for the H110? I got the original top plate, where the brackets for the horn was attached.

To me it looks like pine plywood? I’m considering building th H110 in furniture grade pine plywood, BB/B, not the type you build crates with…

—Never built a cabinet in this size, wondering, if possible to build a cabinet in two parts, that can be put together, when in place; but that can also be possible to get through “normal” door openings….

I was so sure both the A5 and A7 was bass horn constructions, but now understand they are both bassreflex, with large waveguides…. Oh man….

What was the original plywood material for the H110? I got the original top plate, where the brackets for the horn was attached.

To me it looks like pine plywood? I’m considering building th H110 in furniture grade pine plywood, BB/B, not the type you build crates with…

—Never built a cabinet in this size, wondering, if possible to build a cabinet in two parts, that can be put together, when in place; but that can also be possible to get through “normal” door openings….

I was so sure both the A5 and A7 was bass horn constructions, but now understand they are both bassreflex, with large waveguides…. Oh man….

In the 825/828 cabinet, the woofer is reflex load under 150Hz and horn load in frequencies upwards. This feature was designed to improved the transition from the woofer to the compression driver and improved midrange reproduction. That was the main complaint about the Shearer system, the ancestor of the VOTT. For many people, including me, it is that reason that made this cabinet so interesting compare to other high efficency bass enclosure and probably why the product saw little change over 40 years.

plywood material

You wangt to use quality plywood. What it is made of is less critical than the number of plies.

dave

Douglas Fir

A pine. Most of the trees in the forest that surround sme are Douglas Fir.

dave

I mentionned Douglas Fir because it was the material of choice in speaker enclosure in the late 40's to the early 60's : http://www.americanradiohistory.com...54-May-OCR-Page-0026.pdf#search="douglas fir"

I guess this is why we have diyaudio :

The thing is that if I was to build the H110 I will need to build it in two separate parts… the cabinet will need to be cut in two, vertically… and then reassembled in my living room. If not I will not manage to get it through my front door… oh man… haha…

If this is not doable, I will build the A5x, much more easy going this cabinet.

While I’m at it, I would really appreciate if anyone got a high res scan / readable A5x cabinet plan, I only find a low res through Pinterest…., the plans in the French Hifi magazine are not complete…

The thing is that if I was to build the H110 I will need to build it in two separate parts… the cabinet will need to be cut in two, vertically… and then reassembled in my living room. If not I will not manage to get it through my front door… oh man… haha…

If this is not doable, I will build the A5x, much more easy going this cabinet.

While I’m at it, I would really appreciate if anyone got a high res scan / readable A5x cabinet plan, I only find a low res through Pinterest…., the plans in the French Hifi magazine are not complete…

Last edited by a moderator:

When I built my first Altec system (A7-500) in '64 with 3/4" marine grade no void plywood, the manufacturing plant I worked at used what appeared to be the same $%^&* quality pine packing crate plywood as the H110, but then Ga. Pacific used Ga. pine, so assume that whatever the cheap trees used in California shipping was in the mid 1940's.

edit: Sure, no problem, we did it using gasketed 'ship lap' joints to create inexpensive movable concert, trade show arrays.

edit: Sure, no problem, we did it using gasketed 'ship lap' joints to create inexpensive movable concert, trade show arrays.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Altec Lansing H110 (1940s A5) cabinet plans