Hi Moray... Seems like the technology has some issues ??.. The hybrid 6 and the Melior 2 weren't given very favourable reviews ... Can you give some insight into the experience you have with these?, and maybe what could be/ should be done in hindsight to improve the performance

Also, how much thicker do you think the membrane should be...Drafting film is at least twice as thick as the material you used (.003 to .005 in). It is also relatively heat stable (IE non shrink)

Thanks

Eucy

Also, how much thicker do you think the membrane should be...Drafting film is at least twice as thick as the material you used (.003 to .005 in). It is also relatively heat stable (IE non shrink)

Thanks

Eucy

Last edited:

the hybrid products were produced for very little time and were conceived by Ed Meitner. By the time the Melior 2 came about Ed was experimenting with the panel design and it is what it is close but no cigar, We did later make improvements to the Melior 2 but I don't remember if those ever were reviewed. The initial issues with the Melior 2 was bad motor brace design with an X brace that did not work. Vertical or horizontal braces both woked well.

I would say that a diaphragm of at least 2.5 mil or 3 mil would be a good place to start and play with the tension but I would try diaphragms up to 4 or 5 mil thick just to see. For an exciter I would experiment with polyester silk screed mesh. I hope this helps.

I would say that a diaphragm of at least 2.5 mil or 3 mil would be a good place to start and play with the tension but I would try diaphragms up to 4 or 5 mil thick just to see. For an exciter I would experiment with polyester silk screed mesh. I hope this helps.

Last edited:

how many excites are used and what wattage is the exciter? I would love to have enough information to replicate these panels when I get back home. I also want to experiment with smaller satellite panel to see how they sound. Thank you.Pete,

As it turns out, the 5 mm Revolution Ply is quite well suited to the "high aspect ratio" approach that I have been investigating. The dashed green line below is the frequency response I got using a 14.25" x 50" revply panel. This is among the best (if not the best) response of all the hundreds of DML responses I have measured.

Revply is unusual in that it is stiffer in the direction perpendicular to the face grain than it is in the direction parallel to the face grain. That results in a particularly high density of natural frequencies when used as a high aspect ratio panel with the face grain running in the long direction of the panel.

The panel is mounted to a frame with 1/2" wide 3M 411 tape around most of the perimeter.

I'd be happy to share more details if you are interested in building something like it. The image below is of a similar construction, but using a different but similarly sized panel.

Eric

View attachment 1072287

View attachment 1072279light size panels

Thanks Moraythe hybrid products were produced for very little time and were conceived by Ed Meitner. By the time the Melior 2 came about Ed was experimenting with the panel design and it is what it is close but no cigar, We did later make improvements to the Melior 2 but I don't remember if those ever were reviewed. The initial issues with the Melior 2 was bad motor brace design with an X brace that did not work. Vertical or horizontal braces both woked well.

I would say that a diaphragm of at least 2.5 mil or 3 mil would be a good place to start and play with the tension but I would try diaphragms up to 4 or 5 mil thick just to see. For an exciter I would experiment with polyester silk screed mesh. I hope this helps.

Those thicknesses would bang straight into a thick acrylic dml panel which has been covered here previously, and which would be utterly different to the thin skin Mylar/exciter interaction.

I don't understand what you mean by your second last sentence : "For an exciter I would experiment with polyester silk screed (screen) mesh. "

Eucy

not mm but Mil which is 1/1000 of an inch, these are thin films. I was suggesting that if I was going to use an exciter to drive a thin film DML panel my choice would be to first experiment with using silk screen mesh rather than a Mylar film. The mesh has very much more internal loss (compared to a film) so modes might be better controlled. Of course this necessitates having a stretching jig. One of my favourite early panels was a line source dimension was about 12"x48" it had a 1 mil (1/1000") Mylar diaphragm tension was just short of its breaking point and used a vertical 4 ohm copper voice coil in the centre of the diaphragm and a matching magnet structure with ceramic magnets and steel pole pieces. The winding of the voice coil were all going in one direction by means of a wiring harness so signal entered vertical wire number one of the coil travelled up the panel connected to the harness which returned the signal via the frame well out of the magnetic gap to the next wire in the coil and so on so that signal flow of all the wires in the VC were all in the same direction. I hope this is of interest.

my take away from watching the IT video regarding corner rounding was that while it did little to the actual response of the panel it did shift the response upward. That meant that peaks and dips in the response were then no longer matching from one panel to the other so their effect on the sound was not doubled up with a pair of matching. The suggestion was to have a pair of panels one with rounded corners the other without. A small but nice touch (attention to detail) so long as you can live with the look.Leob.

There are patents describing the use of rounding the corners and why.

But I must admit I have never really heard much difference in sound?

I do round my small card panels though as this stops the corners flapping around uncontrollably.

Steve.

could you tell me how the aluminum panel was made and details about the aluminum used thickness and is it annealed or stiff? I think this would be a good reference to have around. Thanks Steve.Christian.

If you like a smooth response, the first picture is of a thin Ali sheet ply , this was a near field response.

The second picture shows the green very flexible sheet on the floor with the grey stain in the middle.

The third picture is my bog standard 25mm eps large panel using my TLs below 250hz at a distance of 3m , with a very flat response from 250hz up to 10k.

All pictures taken from the nxt RUBBISH forum ,which were posted 10 years ago.

The thin sheet aluminium sounded smooth ,some might call it boring 😄

But then a lot of high end audio does sound smooth, some find this desirable?

Not me.

Steve.

do you like the sound of the 5 ply poplar more than the underlay (revply)versions you built? I suspect the ply is more efficient?More details:

Panels are 12" x 48" 5-ply poplar plywood, 0.23" thick.

Frame is 1" x 6" poplar, and includes a brace on the backside.

Panel is mounted to frame with 3M Extreme double sided mounting tape, 3/8" wide, around the entire perimeter (except about 1 inch from each corner)

Exciter is DAEX25VT-4 (one each panel).

Exciter is offset from the panel center by 1.25" across the width and 6" along the length. A piece of EPDM foam is placed between the exciter support and the back of the exciter.

View attachment 1090230

Hello moray.

The Ali panel is built very similar to the card and veneer panels.

Except you can't use a water based glue on the Ali sheets ,as they will not dry.

The glue heavily damps and controls the thin sheets.

The Ali sheets are made from printing plates, so are not 100% Ali.

They are very thin.

The plates are quite heavy, so i would not recommend them , myself.

The problem is , you are asking me about projects I made a long time ago, which hopefully I sorted out.

But you have to read to the end to find out.

The card panel is a good starter project as it is easy and cheap, or free if you use an old cornflakes or pizza box.

You can also add a dome in the central area to improve things, if it goes wrong all you have to do is throw it in the bin ,and eat another pizza 🍕 😉 😀

This can be used as a near field monitor or desktop speaker.

But for serious listening you really need low frequency drivers in an open baffle or a box that allows the low frequency drivers to go up quite high , preferably at least 250hz, in my case.

The panels can be allowed to go down to nearly 100hz depending on music material you like to listen to.

The sound of these panels is excellent when built correctly .

I have made recordings to prove this, for all those that can be bothered to listen to them, and I know you do.

Hope you enjoy them.

Thanks for your feedback.

Steve.

The Ali panel is built very similar to the card and veneer panels.

Except you can't use a water based glue on the Ali sheets ,as they will not dry.

The glue heavily damps and controls the thin sheets.

The Ali sheets are made from printing plates, so are not 100% Ali.

They are very thin.

The plates are quite heavy, so i would not recommend them , myself.

The problem is , you are asking me about projects I made a long time ago, which hopefully I sorted out.

But you have to read to the end to find out.

The card panel is a good starter project as it is easy and cheap, or free if you use an old cornflakes or pizza box.

You can also add a dome in the central area to improve things, if it goes wrong all you have to do is throw it in the bin ,and eat another pizza 🍕 😉 😀

This can be used as a near field monitor or desktop speaker.

But for serious listening you really need low frequency drivers in an open baffle or a box that allows the low frequency drivers to go up quite high , preferably at least 250hz, in my case.

The panels can be allowed to go down to nearly 100hz depending on music material you like to listen to.

The sound of these panels is excellent when built correctly .

I have made recordings to prove this, for all those that can be bothered to listen to them, and I know you do.

Hope you enjoy them.

Thanks for your feedback.

Steve.

You can also have different shapes and angles in the corners.my take away from watching the IT video regarding corner rounding was that while it did little to the actual response of the panel it did shift the response upward. That meant that peaks and dips in the response were then no longer matching from one panel to the other so their effect on the sound was not doubled up with a pair of matching. The suggestion was to have a pair of panels one with rounded corners the other without. A small but nice touch (attention to detail) so long as you can live with the look.

This all depends on how badly, or not the corners are affecting your panel type.

Not all panels seem to react the same.

Steven.

Moraydo you like the sound of the 5 ply poplar more than the underlay (revply)versions you built? I suspect the ply is more efficient?

Just thought I'd throw in this remark while it was on my mind.

I coated an area of XPS with UV resin and let it cure with proper lighting. There was no damage to the XPS, it cured with to a hard shell-like coating.

Maybe too hard, I don't know. It may be worth trying an entire panel to see what effect it has on dampening. No one knows the frustrations of R&D better

than you.

Jack

hello Jack thank you. what is the brand of uv cure adhesive that you used and what does it cost to cover say a square foot? trying to get an idea of cost to use.

I bought two 250 gram bottles of JDiction New Formula UV resin Hard Type from Amazon.

The cost of two bottles was $29.99.

This particular type may be too viscous to spread on a panel, but if memory serves, the company makes a version that is considerably thinner.

The product cures crystal clear, does not yellow and has a hard, tough surface.

My light source is small in area. I would imagine some sort of plant growing light would be needed to cover a panel.

I would be making a wild guess to say that one 250 gram bottle can easily cover both sides of a 2X2 piece of XPS.

Jack

The cost of two bottles was $29.99.

This particular type may be too viscous to spread on a panel, but if memory serves, the company makes a version that is considerably thinner.

The product cures crystal clear, does not yellow and has a hard, tough surface.

My light source is small in area. I would imagine some sort of plant growing light would be needed to cover a panel.

I would be making a wild guess to say that one 250 gram bottle can easily cover both sides of a 2X2 piece of XPS.

Jack

Andre,1. How would I model a panel assembled from different materials, for example a polycarb plate with a hole in it, and an aluminium disc inside that hole on which the driver is mounted.

Glad you are having fun with LISA. The easy part of you question is that under "Components and Materials" you can create a second component with different material properties from the first, then select the elements that are the second component and assign the new properties to those elements only. The trickier part is to create the mesh to start with. I have never done it but I think the way to do it would be to first create a model of the rectangular plate with a round hole in it, then create a circular plate of the same diameter as the hole, and with the same number of nodes around the circumference of the plate as you have nodes around the hole. You should be able to make both plates using the "Mesh Tools/Create". Then move the circular plate into the hole, and use the "Mesh Tools/merge nearby nodes" to attach the two together.

I hope that's a decent explanation.

Eric

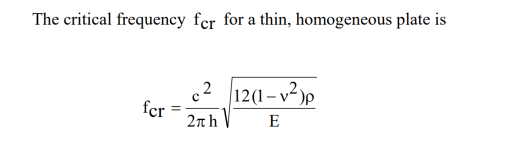

Andre,2. How would I use LISA to find the coincident frequencies of different panels? None of the equations I use give me consistent or believable results. I've been having arguments with ChatGPT regarding this, and we've eventually agreed to disagree....

LISA can't do that AFAIK.

But you can use this:

where c is the speed of sound in air

h is the plate thickness

E is the Elastic Modulus

rho is the density

v is the poisson ratio.

the limitation to be aware of is that this applies to only a thin plate. (how think is thin enough?). For thicker plates the coincidence frequency will be higher than the thin plate approximation, and might not even exist.

Eric

moray,how many excites are used and what wattage is the exciter? I would love to have enough information to replicate these panels when I get back home. I also want to experiment with smaller satellite panel to see how they sound. Thank you.

just a single DEAX25FHE-4 on each panel. 25 watts.

Eric

is there any benefit to making the sides of the 1'x4' panel slightly non parallel or is any difference only minimal?

moray,do you like the sound of the 5 ply poplar more than the underlay (revply)versions you built? I suspect the ply is more efficient?

The 5-ply poplar is lighter and more efficient that the revply.

Eric

I think epoxy resin is too hard, and on styrofoam you want something that will act as a thin skin, not a hard wall.I bought two 250 gram bottles of JDiction New Formula UV resin Hard Type from Amazon.

The cost of two bottles was $29.99.

This particular type may be too viscous to spread on a panel, but if memory serves, the company makes a version that is considerably thinner.

The product cures crystal clear, does not yellow and has a hard, tough surface.

My light source is small in area. I would imagine some sort of plant growing light would be needed to cover a panel.

I would be making a wild guess to say that one 250 gram bottle can easily cover both sides of a 2X2 piece of XPS.

Jack

And since it is so hard, if you could make it thin enough to not overdampen the plate, it is too brittle and would crack.

PVA and hide glue can be easily diluted for a really thin coat, and is soft enough to not crack.

On some plates I attempted covering an area around the exciters with epoxy to see how that would affect HF reproduction, but found that mostly it reduced sensitivity, and the plates I had prepped like that overheated with the same power as plates where I only used a minimal amount of epoxy to fix the exciters.

moray,how many ply is this poplar panel? thank you.

Revolution ply is 5 ply, but non necessarily poplar, according to their patents.

One interesting thing about revply is that the face layers are very, very thin. Like about 0.010 inches (0.25 mm). So thin you can easily sand right through it. Also, the face layers are what's referred to as "recon" (reconstituted) veneers. The grain pattern you see is not an actual grain pattern but rather a simulated grain pattern. They make recon veneer by stacking and gluing a bunch of veneers together, and then slicing them perpendicular to the original layers. It's the layers of glue between each of the original layers that create the simulated grain pattern. Crazy!

Eric

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker