Again a small modification.

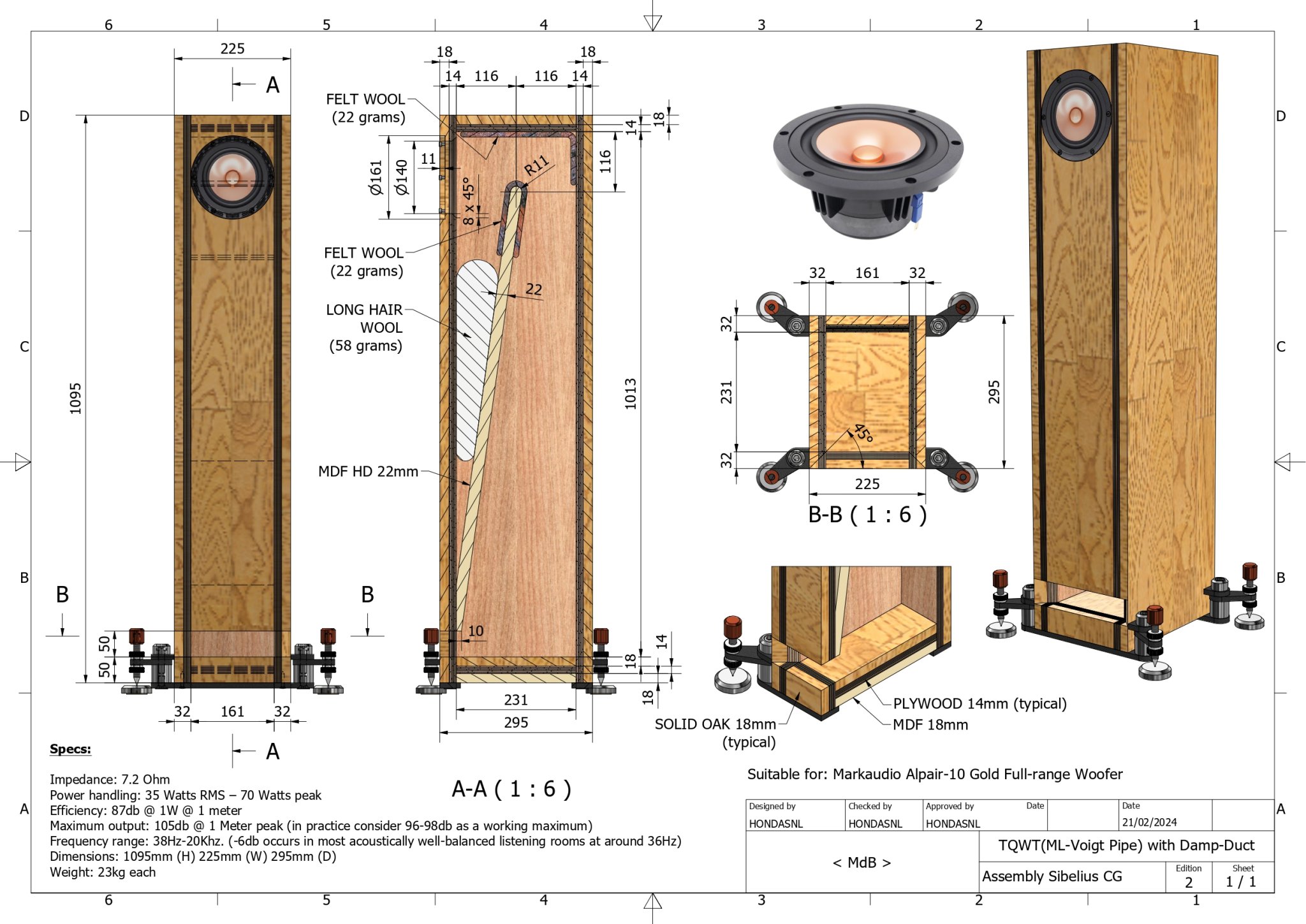

I'll use sandwich panel consist of 18mm solid oak wood and 14mm plywood all properly glued together.

Because 32mm solid oak wood is hard to find.

Sandwich panels are very good to use, very strong and dimensionally stable.

Also a nice effect the plywood in combination with the solid oak panels.

I'll use sandwich panel consist of 18mm solid oak wood and 14mm plywood all properly glued together.

Because 32mm solid oak wood is hard to find.

Sandwich panels are very good to use, very strong and dimensionally stable.

Also a nice effect the plywood in combination with the solid oak panels.

Last edited by a moderator:

Also ordered the Gold Gen. 10.2 version and will compare it with the Gold 10.3.It would be interesting to see some measurments when you finish them, if you dont mind posting them

I can't measure the clone version myself, but I can outsource it.

Edit: Can you show me the measurements of the Sibelius?

This shouldn't be a secret.

Then we can compare these also.

Last edited:

Enabl???I think that this may well be curable with a fairly simple mod

I bought the metal cone version of the 10.3 (for either the FHXL or Pensil something-or-other)

The point of the excercise was spurred by the fact that no one ever complained about the top of the A10.3eN and a quest to see if a much simplier treatment would largely fix the issue.

I have experiemnted with A11ms with seemingly good results. I need to quit procrastinating and get the thread started to se eif my results can be verified by others.

dave

I have experiemnted with A11ms with seemingly good results. I need to quit procrastinating and get the thread started to se eif my results can be verified by others.

dave

Oh yes? That's like hearing that a genius everyone thought had retired has been working productively on the answer to "life, the universe and everything". (and the answer isn't "a suffusion of yellow")I have experiemnted with A11ms with seemingly good results.

I wouldn’t take it that far. Mostly a lot of listening. The fatiging bit at the top seems MIA.

dave

dave

#runthemin!

They really do take about 50 hours to sound ok, and about 150 to sound great. You can just plug them in, in the boxes and play some very quite not too bassy music, if you reverse the polarity they don't even sound very loud. You can even close the lid to drown out the sound.

They really do take about 50 hours to sound ok, and about 150 to sound great. You can just plug them in, in the boxes and play some very quite not too bassy music, if you reverse the polarity they don't even sound very loud. You can even close the lid to drown out the sound.

The first A10.3eN vrs A10PeN comparison had the paper edging out the metal. But the metyal kept improving with time, and we figure 500+ hours to really settle down and became a 6 of one, half dozen of the other kind of choice..

dave

dave

...but if I'm not Enabl-ing and I've picked the metal (had to be one or the other) and there's a simple treatment that's just as good...

the breaking in is a given (unless I give them up)

otherwise it's apples, softballs, bananas and Silly Putty with respect to comparisons.

in any event, with respect to the new idea, I'm all ears (so to speak)

the breaking in is a given (unless I give them up)

otherwise it's apples, softballs, bananas and Silly Putty with respect to comparisons.

in any event, with respect to the new idea, I'm all ears (so to speak)

that's just as good...

It won’t give you the greater DDR EnABL does, it just (seems) to be the part that is suppressing the ringing.

dave

My first speakers I made were from American black walnut engineered floorboards that I bonded to MDF, it was 4mm solid wood on birch ply core that I glued to 6mm MDF, worked very well on small bookshelf's.I'll use sandwich panel consist of 18mm solid oak wood and 14mm plywood all properly glued together.

Can you get 300mm+ wide solid oak? I know Dinesen flooring have some beautiful wide boards (up to 500mm!)

it looks like Pearl use glued up boards, you could just buy full stave oak worktops, they come in 32/40mm as standard. If you can't get solid.

If your not so keen on all the laminating I use oak veneered birch a lot for projects, looks great, finished easy and void free birch, you can get it in 25mm.

Yeah, it's just down the road for me, going tomorrow.Anyone going to be there? Thread and (many) pictures please.

dave

Pearl's set up and new amp...https://www.instagram.com/p/C3qVhgqNoIv/

Hi Vermouth I can easily buy solid 32mm max 200mm Oak here in The Netherlands but I don't want it in one piece. https://www.houthandelvangelder.nl/eiken-plank-32x200-mm-fijnbezaagd.htmlMy first speakers I made were from American black walnut engineered floorboards that I bonded to MDF, it was 4mm solid wood on birch ply core that I glued to 6mm MDF, worked very well on small bookshelf's.

Can you get 300mm+ wide solid oak? I know Dinesen flooring have some beautiful wide boards (up to 500mm!)

it looks like Pearl use glued up boards, you could just buy full stave oak worktops, they come in 32/40mm as standard. If you can't get solid.

If your not so keen on all the laminating I use oak veneered birch a lot for projects, looks great, finished easy and void free birch, you can get it in 25mm.

- Home

- Loudspeakers

- Full Range

- Pearl Acoustic Sibelius