Stuff like

https://www.madisoundspeakerstore.com/coaxial/seas-excel-c18en002/a-e0060-6.5-coaxial-each/

https://www.madisoundspeakerstore.com/coaxial/seas-excel-5-magnesium-cone-coax-c16n001/f-e0051/

https://www.madisoundspeakerstore.com/coaxial/satori-mt19cp-8-coaxial-with-papyrus-cone-8-ohm/

etc etc etc

OK many woofers in this life are not so smooth on top.These tweeters though are ragged, some with huge response holes, and dying above 10k or even less. I'm sure folks are using these and saying they sound lovely blah blah...but who would ever buy loose tweeters measuring like this?!?

What am I missing?

https://www.madisoundspeakerstore.com/coaxial/seas-excel-c18en002/a-e0060-6.5-coaxial-each/

https://www.madisoundspeakerstore.com/coaxial/seas-excel-5-magnesium-cone-coax-c16n001/f-e0051/

https://www.madisoundspeakerstore.com/coaxial/satori-mt19cp-8-coaxial-with-papyrus-cone-8-ohm/

etc etc etc

OK many woofers in this life are not so smooth on top.These tweeters though are ragged, some with huge response holes, and dying above 10k or even less. I'm sure folks are using these and saying they sound lovely blah blah...but who would ever buy loose tweeters measuring like this?!?

What am I missing?

Well, the first link implied "this is the best we can do". So there must be some other aspect which - to their customers - exceeds the generic requirement for ruler flat response. Could it be phase-coherence?

Amusing to me, I once tried to make a coax out of a 12" and a 1", which I mounted on a threaded pipe somehow held in place through the pole piece vent. This was maybe 35 years ago. I had full lunch break access to the anechoic and B&K equipment at DEC, where I was working.

No matter where I positioned the tweeter, relative to the woofer cone, I could not get a flat response. Unless it was sticking out so far as to completely remove the woofer cone from proximity. Since I wanted the phase-coherence primarily - and couldnt get it w/o lots of FR anomaly - I gave up. I chalked it up to choosing a woofer with a conical cone, versus a "curvilinear"; or one that is bent like a horn.

They had a Cambridge Soundworks portable "suitcase" system, when I tested the speaker from that I got the ruler flat response, which I could not come near with the two drivers I was experimenting with.

Even had some communication with Ed Dell from Speakerbuilder about the project, but it was such a unmitigated flop I pulled my interest on it. I finally blew them up using them for vocal duty at this band rehearsal I was having at my place for one of the DECjams; put dust caps back on and sold the woofers...

Interesting designers are still "struggling" to make this work - if the FR plots in your links are any indication. Bouncy-bouncy-bouncy!

Amusing to me, I once tried to make a coax out of a 12" and a 1", which I mounted on a threaded pipe somehow held in place through the pole piece vent. This was maybe 35 years ago. I had full lunch break access to the anechoic and B&K equipment at DEC, where I was working.

No matter where I positioned the tweeter, relative to the woofer cone, I could not get a flat response. Unless it was sticking out so far as to completely remove the woofer cone from proximity. Since I wanted the phase-coherence primarily - and couldnt get it w/o lots of FR anomaly - I gave up. I chalked it up to choosing a woofer with a conical cone, versus a "curvilinear"; or one that is bent like a horn.

They had a Cambridge Soundworks portable "suitcase" system, when I tested the speaker from that I got the ruler flat response, which I could not come near with the two drivers I was experimenting with.

Even had some communication with Ed Dell from Speakerbuilder about the project, but it was such a unmitigated flop I pulled my interest on it. I finally blew them up using them for vocal duty at this band rehearsal I was having at my place for one of the DECjams; put dust caps back on and sold the woofers...

Interesting designers are still "struggling" to make this work - if the FR plots in your links are any indication. Bouncy-bouncy-bouncy!

One of the topics that comes to mind in your basic question here is this: are all of those dips in response due to minimum phase driver properties, or are there internal reflections that are causing it? I'm used to EQing all drivers in my setup, and the entire setup is horn-loaded, so non-flat amplitude response (SPL) isn't a big deal (but ragged response is a big deal--if it can't be smoothed easily with DSP).

One of the most eye-opening experiences that I can remember was when another person that I know was building his own bass bin, and he asked the resident expert (a lead engineer for a large U.S. loudspeaker manufacturer) about a certain woofer that looked good in its specifications, but had a very uneven on-axis amplitude response (and if you've noticed--driver manufacturers don't post their phase response to understand what their driver's full transfer function response looks like).

What the engineer said next caused me to completely change my paradigm on driver manufacturers: he mentioned that the dip in response could likely be a cancellation of the backwave of the cone with its own spider(...!...).

Now, what manufacturer would put out a driver that cancels its own output, and can't really be EQed back to flat response? (You'd be surprised in this case--but I will decline reveal just who it was.)

So one of the things that I'd recommend looking at is a plot of the driver's output on-axis (at least, and off-axis, too if you can do it) of its group delay, specifically its excess group delay. Any non-flat, non smooth areas of this curve will tell you that those are regions of internal reflections that cannot be fixed.

So if you see ragged response in a coaxial driver (especially at the prices they command), first think about whether or not those dips in response are caused by hardware that's providing internal reflections that cause either complete cancellations, partial cancellations, cone modes to be kicked into gear, or just higher order modes (in horn-loaded HF portions of the driver). Those make the driver DOA for hi-fi applications.

JMTC.

Chris

One of the most eye-opening experiences that I can remember was when another person that I know was building his own bass bin, and he asked the resident expert (a lead engineer for a large U.S. loudspeaker manufacturer) about a certain woofer that looked good in its specifications, but had a very uneven on-axis amplitude response (and if you've noticed--driver manufacturers don't post their phase response to understand what their driver's full transfer function response looks like).

What the engineer said next caused me to completely change my paradigm on driver manufacturers: he mentioned that the dip in response could likely be a cancellation of the backwave of the cone with its own spider(...!...).

Now, what manufacturer would put out a driver that cancels its own output, and can't really be EQed back to flat response? (You'd be surprised in this case--but I will decline reveal just who it was.)

So one of the things that I'd recommend looking at is a plot of the driver's output on-axis (at least, and off-axis, too if you can do it) of its group delay, specifically its excess group delay. Any non-flat, non smooth areas of this curve will tell you that those are regions of internal reflections that cannot be fixed.

So if you see ragged response in a coaxial driver (especially at the prices they command), first think about whether or not those dips in response are caused by hardware that's providing internal reflections that cause either complete cancellations, partial cancellations, cone modes to be kicked into gear, or just higher order modes (in horn-loaded HF portions of the driver). Those make the driver DOA for hi-fi applications.

JMTC.

Chris

Last edited:

Depends on the designers focus on performance and areas worth compromising. The point source presentation and near perfect phase quadrature is not to be underestimated as performance value IMO. That, and just how ragged are we talking with what cant be managed in the crossover........2db, 3db, 5? Is the ragged response above 12khz where most folks couldn't identify it or care?

From a monitoring perspective in the recording profession, phase coherence is a huge plus as it allows the engineer to easily distinguish phasing from mics on the same source as opposed to a two or three way where it's often masked by the existing fwd lobes. Folks are truly giddy for Genelecs for a reason.

Unsighted, i would challenge any golden eared self proclaimed superstar to identify a 3db response wiggle.....and if the speaker is designed for off axis listening?.......4/5db becomes the more realistic threshold.

From a monitoring perspective in the recording profession, phase coherence is a huge plus as it allows the engineer to easily distinguish phasing from mics on the same source as opposed to a two or three way where it's often masked by the existing fwd lobes. Folks are truly giddy for Genelecs for a reason.

Unsighted, i would challenge any golden eared self proclaimed superstar to identify a 3db response wiggle.....and if the speaker is designed for off axis listening?.......4/5db becomes the more realistic threshold.

It'a actually a very common thing, and no, it can not be EQ'd back.What the engineer said next caused me to completely change my paradigm on driver manufacturers: he mentioned that the dip in response could likely be a cancellation of the backwave of the cone with its own spider(...!...).

Now, what manufacturer would put out a driver that cancels its own output, and can't really be EQed back to flat response? (You'd be surprised in this case--but I will decline reveal just who it was.)

Most modern woofer cones are thick and made out of a relatively "loose/"spongy" paste, which overdamps any radially moving wave, meaning voice coil (he mentioned "spider" 🙄) to edge and back.

Edges are also soft which again minimizes "bounce back".

But modern guitar speaker cones are still made the old way: thin stiff cones, steam dried under high pressure in metallic dies, hard undamped edges, so much so that "undoped" is a feature, go figure, and they much show that strong backwave out of phase cancellation.

In 12" speakers, always around 1500 Hz or so.

It is a transversal wave, think shaking a taut string or wire, or waves on a lake after you throw a pebble.

Out of phase cancellation is so strong and perfect as to beat any EQ attempt.

Here's a typical guitar speaker curve, all of them show that same strong and narrow ~1500Hz notch.

Doping lowers it because it lowers reflection.

Different brands, very different speakers, and yet .....

So your Engineer comment was right, that particular woofer must have been built similar to these.

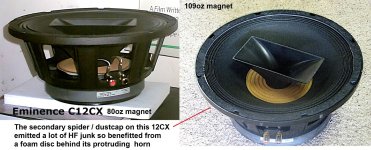

I still love the things - my lone 604B/E and various cast frame Eminence CX in 12" and 15" sizes. Another problem

I saw with my Eminence was that they had a spider dustcap which acted as a crude tweeter so a felt or foam disc

laying basically against that spider took out a lot of garbage. The cast frame Eminence coax were produced with 54-109oz ferrite magnet slugs. Some had no protruding horn - many had a rectangular horn very much like the little front horn in the ancient E-V CDP ("Compound Diffraction Projector". I got one to snap into better focus with an LCLC allpass on the woofer - but could have been something else going on.

I saw with my Eminence was that they had a spider dustcap which acted as a crude tweeter so a felt or foam disc

laying basically against that spider took out a lot of garbage. The cast frame Eminence coax were produced with 54-109oz ferrite magnet slugs. Some had no protruding horn - many had a rectangular horn very much like the little front horn in the ancient E-V CDP ("Compound Diffraction Projector". I got one to snap into better focus with an LCLC allpass on the woofer - but could have been something else going on.

Attachments

EQ.... Linear EQ.what is the point of expensive coaxials with ragged response?

For me, flat frequency response is pretty low on my priority list. Coaxial drivers have many other benefits which frequently equate to good sound. And good sound is pretty much on the top of my priority list. So, I tend to like coaxial drivers no matter what their graphs visually reveal.

I think there are several things to consider here. A coaxial driver has some benefits that other configurations can not match, but it also comes with a set of challenges, at least if maximum fidelity is what we are after. But to dive a bit into the problem highlighted here, there are some things that could also be improved.

Two very obvious aspects about the integration of a tweeter in a coax is the interface between the tweeter dome and the midrange cone, and between the midrange cone and the cabinet. Interestingly, the OP contains links to two drivers from the same manufacturer. Most of the parts on the two tweeters are very similar to each other. One is a soft dome and the other is some kind of an aluminium/magnesium alloy dome. But if we look closely, the black plastic ring that is glued on top of the outer edge of the dome surround, one is tall (C16) and the other one (C18) is not as tall. The C18 also has a narrow inverted surround while the C16 has a fat positive roll surround.

If we take a close look at the frequency response of both, we will see that both have some rough edges, but especially the C18 cleans up really well once you listen slightly off axis. If you can disregard the on axis response, it is really not rugged at all. The C16 does not clean up as well, and it is likely partly to the higher plastic ring, and the fat suspension. I expect to see the effects of the plastic ring at higher frequencies (6-7kHz and up) and the surround closer to 2-2,5kHz.

At the same time we know of more things that can be issues in a driver like this. Firstly, a hard cone with high speed of sound tends to flatten the wavefront coming out of the driver, reducing dispersion at high frequencies leading to more beaming. A dome made from a similar material will do the oposite, the wavefront will propagate faster to the middle, while a softer, therefore slower dome, will flatten the response. Flattening the response is really not a great idea for any waveguide or coaxial mounted tweeter as they tend not to integrate as well with the waveguide. In general metal domes do have mor air and details as the high end dispersion is more similar to the low end dispersion when mounted in a waveguide. Therefore, a metal dome will allways be the better option in a coaxial driver, unless it is broken or badly designed, or badly integrated (aka sounds "metallic"). To mimic the dispersion pattern while crossing over to the midrange, the mid cone should be of a softer material, like paper. This will slow down the propagation to the edge of the cone, making the wave front more spherical.

Secondly, for maximum sound quality, a coaxial driver should never be made to play any kind of bass. If it moves past maybe 0,5mm, it should be so loud that distortion is becoming hard to hear. Typically, a 6,5 inch coaxial should not be used below say 250Hz without significant asistance. This also paves way for some different strategies when it comes to suspension.

Because making the interfacing between the cones and the surrounding parts is important. When manufacturers do the common thing, taking a woofer, and adding a tweeter to it, then nothing was really made to work well as a coaxial driver to begin with. If we look at the dispersion of the midrange at the cross over point, it depends on the size, shape, material and the position of the voice coil. The voice coil is normally centered, but often larger than ideal. A 39mm voice coil is common with a 26mm dome. This leaves a significant gap that does not produce sound. The angle and profile of the cone really determines how effective it is as a waveguide, but also its own natural dispersion.

As a rule of thumb, to match the dispersion of the dome and the cone, you will need a waveguide that is slightly larger than the cone it is set to match, and there are two reasons for this. One is that the cone shape will beam a bit more, leading to it having less dispersion than the dome using it as a waveguide. The second part is that there is a relationship between the penetration of the cone that makes space for the tweeter, and how far up i frequency the midrange cone will perform well. Looking at coaxials we rarely see any significant overlap like we typically see on midranges and domes in general.

The last thing I would like to point out is that you do not often see a coaxial driver where the midrange cone is actually both optimized as a cone for a midrange driver, and as a waveguide for the tweeter at the same time. The coaxials are typically what we see as a combination of a generic mini tweeter put in the middle of a woofer. And if the woofer is changed to be a midrange, we only rarely see any changes to the surround and cone profile.

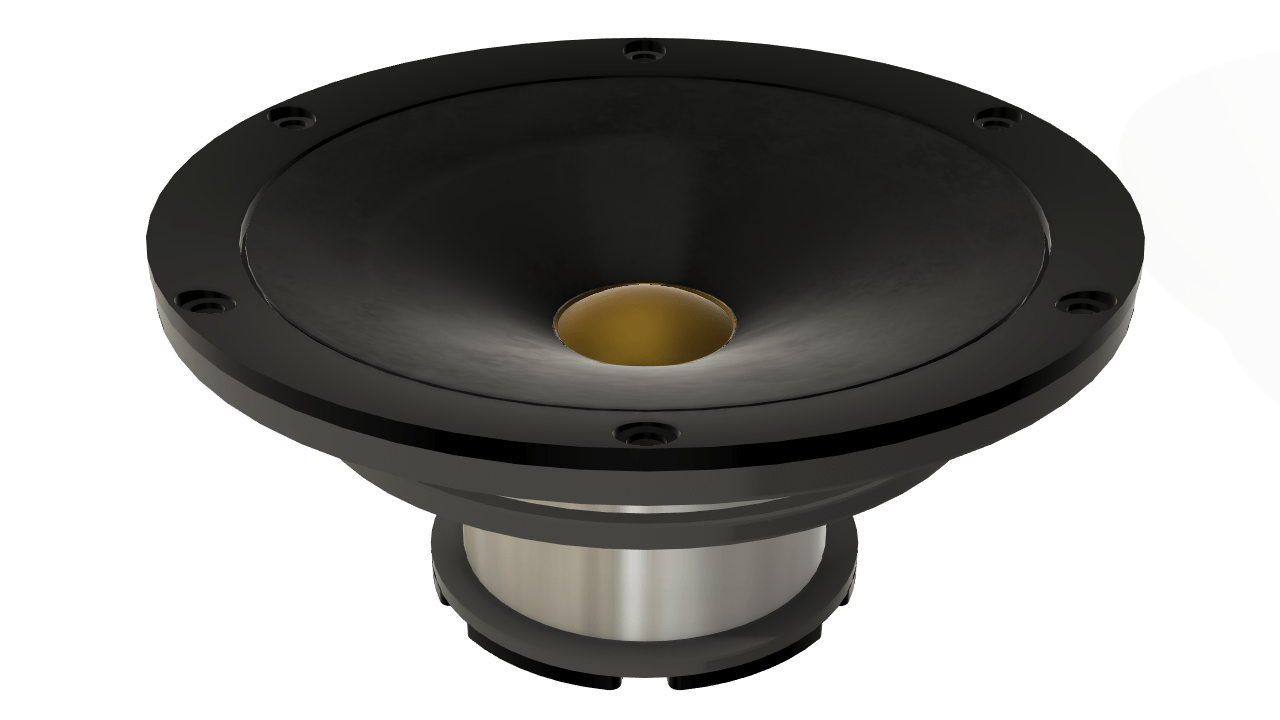

I think an improved coaxial could look something like this:

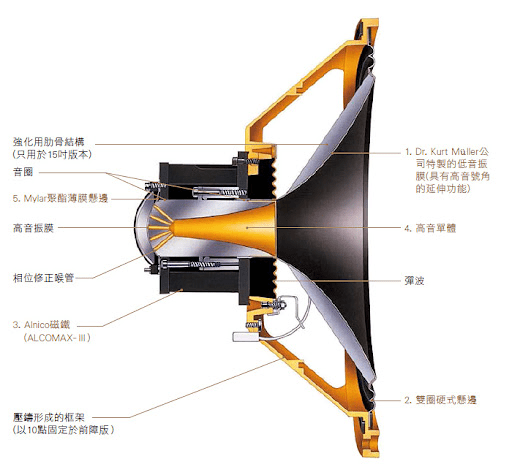

Even if this thread seem to be mostly about direct radiating dome -based coaxials, I wold like to show this cut drawing of the Tannoy Westminster coaxial:

Notice how the interfacing between the compression driver and the cone angle is virtually perfect. And the reinforced cone edge prevents the surround from protruding past the cone edge. They have even combined that with a reinforcement edge of the cone due to the light weight paper cone and the square horn preventing bell modes from forming. I love the attention to detail here.

Two very obvious aspects about the integration of a tweeter in a coax is the interface between the tweeter dome and the midrange cone, and between the midrange cone and the cabinet. Interestingly, the OP contains links to two drivers from the same manufacturer. Most of the parts on the two tweeters are very similar to each other. One is a soft dome and the other is some kind of an aluminium/magnesium alloy dome. But if we look closely, the black plastic ring that is glued on top of the outer edge of the dome surround, one is tall (C16) and the other one (C18) is not as tall. The C18 also has a narrow inverted surround while the C16 has a fat positive roll surround.

If we take a close look at the frequency response of both, we will see that both have some rough edges, but especially the C18 cleans up really well once you listen slightly off axis. If you can disregard the on axis response, it is really not rugged at all. The C16 does not clean up as well, and it is likely partly to the higher plastic ring, and the fat suspension. I expect to see the effects of the plastic ring at higher frequencies (6-7kHz and up) and the surround closer to 2-2,5kHz.

At the same time we know of more things that can be issues in a driver like this. Firstly, a hard cone with high speed of sound tends to flatten the wavefront coming out of the driver, reducing dispersion at high frequencies leading to more beaming. A dome made from a similar material will do the oposite, the wavefront will propagate faster to the middle, while a softer, therefore slower dome, will flatten the response. Flattening the response is really not a great idea for any waveguide or coaxial mounted tweeter as they tend not to integrate as well with the waveguide. In general metal domes do have mor air and details as the high end dispersion is more similar to the low end dispersion when mounted in a waveguide. Therefore, a metal dome will allways be the better option in a coaxial driver, unless it is broken or badly designed, or badly integrated (aka sounds "metallic"). To mimic the dispersion pattern while crossing over to the midrange, the mid cone should be of a softer material, like paper. This will slow down the propagation to the edge of the cone, making the wave front more spherical.

Secondly, for maximum sound quality, a coaxial driver should never be made to play any kind of bass. If it moves past maybe 0,5mm, it should be so loud that distortion is becoming hard to hear. Typically, a 6,5 inch coaxial should not be used below say 250Hz without significant asistance. This also paves way for some different strategies when it comes to suspension.

Because making the interfacing between the cones and the surrounding parts is important. When manufacturers do the common thing, taking a woofer, and adding a tweeter to it, then nothing was really made to work well as a coaxial driver to begin with. If we look at the dispersion of the midrange at the cross over point, it depends on the size, shape, material and the position of the voice coil. The voice coil is normally centered, but often larger than ideal. A 39mm voice coil is common with a 26mm dome. This leaves a significant gap that does not produce sound. The angle and profile of the cone really determines how effective it is as a waveguide, but also its own natural dispersion.

As a rule of thumb, to match the dispersion of the dome and the cone, you will need a waveguide that is slightly larger than the cone it is set to match, and there are two reasons for this. One is that the cone shape will beam a bit more, leading to it having less dispersion than the dome using it as a waveguide. The second part is that there is a relationship between the penetration of the cone that makes space for the tweeter, and how far up i frequency the midrange cone will perform well. Looking at coaxials we rarely see any significant overlap like we typically see on midranges and domes in general.

The last thing I would like to point out is that you do not often see a coaxial driver where the midrange cone is actually both optimized as a cone for a midrange driver, and as a waveguide for the tweeter at the same time. The coaxials are typically what we see as a combination of a generic mini tweeter put in the middle of a woofer. And if the woofer is changed to be a midrange, we only rarely see any changes to the surround and cone profile.

I think an improved coaxial could look something like this:

Even if this thread seem to be mostly about direct radiating dome -based coaxials, I wold like to show this cut drawing of the Tannoy Westminster coaxial:

Notice how the interfacing between the compression driver and the cone angle is virtually perfect. And the reinforced cone edge prevents the surround from protruding past the cone edge. They have even combined that with a reinforcement edge of the cone due to the light weight paper cone and the square horn preventing bell modes from forming. I love the attention to detail here.

They are using some kind of compression driver, which is very different than using an exposed dome in terms of integration in a coaxial driver. However, it does have traces of the things we see on other coaxials.

Here we can see a dip around 2k, which may coincide with the woofer suspension. However, it could also be within the working range of the woofer, and also be caused by the surround, but as a resonance. The deviations we see from around 6k are probably some integration issues. I was not able to find off axis measurements, but I guess they are pretty fine.

https://www.hifinext.com/tannoy-gol...nitors-with-dual-concentric-coaxial-emitters/

It doesn't take that much engineering to build a decent performing coax. I agree, some of the novelty Seas coax drivers are just eye candy IMO, which will never perform as good as a decent separate driver traditional 2 way. The only Seas coax I actually like is the 18REX with the clear poly cone. Even on that one you need to trim the tall collar around the tweeter element to clean up the big dip up top. Once that's done, its a really good driver and works well as a nearfield monitor. The bass is good too.

I tested several cheaper pro coax drivers and really like the Eminence KL3012CX and KL3010CX. They sound very good with a decent screw on CD. The Faital HF108 and Celestion CDX1-1745 work well with it and the FR can be cleaned up very well. They did a good job with the phase plug design too. The only little gripe is the upper lip on the VC former. It should be trimmed for best performance. You have to remove the dust cap to do this, but you'd want to get rid of it anyways so the cone is open without any other reflection or diffraction sources.

Obviously the Tannoy stuff is amazing if you love coax drivers. Their drivers are IMO the best available coax designs. I've heard some very good monitors using these drivers, some of them being used in the best studios around the world.

As for the typical coax with big ugly WGs sticking out, shrouding the cone, these usually sound awful and don't clean up. I'm amazed people actually pay good money for drivers like this which have very bad engineering built into their designs.

The older Eminence with the small rectangular horn sticking out can be helped considerably by covering the outer lip of the horn with dynamat and then gluing 2" foam around the outer perimeter. Once you do that, they are totally different drivers with very high potential. They do require some extensive crossover trickery to make them flat.

I tested several cheaper pro coax drivers and really like the Eminence KL3012CX and KL3010CX. They sound very good with a decent screw on CD. The Faital HF108 and Celestion CDX1-1745 work well with it and the FR can be cleaned up very well. They did a good job with the phase plug design too. The only little gripe is the upper lip on the VC former. It should be trimmed for best performance. You have to remove the dust cap to do this, but you'd want to get rid of it anyways so the cone is open without any other reflection or diffraction sources.

Obviously the Tannoy stuff is amazing if you love coax drivers. Their drivers are IMO the best available coax designs. I've heard some very good monitors using these drivers, some of them being used in the best studios around the world.

As for the typical coax with big ugly WGs sticking out, shrouding the cone, these usually sound awful and don't clean up. I'm amazed people actually pay good money for drivers like this which have very bad engineering built into their designs.

The older Eminence with the small rectangular horn sticking out can be helped considerably by covering the outer lip of the horn with dynamat and then gluing 2" foam around the outer perimeter. Once you do that, they are totally different drivers with very high potential. They do require some extensive crossover trickery to make them flat.

Kef also seem to have gotten fairly close with their UNI Q drivers of different types. Have they not?

https://www.stereophile.com/content/kef-ls50-anniversary-model-loudspeaker-measurements

https://www.stereophile.com/content/kef-ls50-anniversary-model-loudspeaker-measurements

It is really good to see a strong discussion on this. Thank you

Let’s throw another one in the mix that normally wouldn’t be considered on this forum. The Phoenix Gold MX6.5 coaxial unit made for car audio

Zooming on their blowup show a structure between the dome and mesh screen. This appears to be another dome with a slit in the side view

They don’t show a graph but how do I measure one? I’ll pick this up tomorrow as am very intrigued about coaxial drivers

Let’s throw another one in the mix that normally wouldn’t be considered on this forum. The Phoenix Gold MX6.5 coaxial unit made for car audio

Zooming on their blowup show a structure between the dome and mesh screen. This appears to be another dome with a slit in the side view

They don’t show a graph but how do I measure one? I’ll pick this up tomorrow as am very intrigued about coaxial drivers

Nifty! They apparently inverted the traditional phase plug, so likely more slits unless designed to be an oval polar response. 😎

At one time, I think Pioneer made one for car audio also. They didnt sell I assume, as I never found a set I could buy. I assumed they just sounded too different to the car people, all used to the tweeters sticking-out-on-posts alignment's sound, which is 99% of all car coax.The Phoenix Gold MX6.5 coaxial unit made for car audio

I suppose that's what you get for trying something a little different in such a tight market -

Auditioned the Hertz Mile 6.5" coaxial today. $400 AUD for the pair. Probably the worst 6.5" that I have heard in a long time. I went in with thoughts of being more discerning with evaluating the treble and female vocals and such. Ok, these things shrill something crazy and there is a big hole between the bass and treble. I expected more from this brand, but this might be an SPL biased driver. The MX6.5 in stock was on the board and they won't sell them. I found stocks online though

Which one, the Tannoy or Phoenix Gold?Nifty!

I've had a few projects that weren't received with much fanfare, but which worked really great.

My coax design was one:

https://www.diyaudio.com/community/threads/synergy-eggstravaganza.309095/post-5110101

Based on everything I've seen, I really and truly think that tweeters don't really have a place behind the woofer. At least not in a 'true' coaxial, where the woofer and tweeter are one unit.

In a nutshell, it's far easier to get good results if you just put the tweeter on a 'bridge', like cheap car coaxials do.

As you've found in your research, when you put the tweeter inside the voice coil, or even worse, behind the woofer, the response curve just looks awful.

Putting the tweeter in front of the woofer creates an issue, but it's an issue that is fixable. Whereas, the crummy high frequency response of a tweeter in the throat of a woofer is NOT fixable.

So, the issue you get with the tweeter in front of the woofer is that the output of the tweeter will "lead" the woofer by about 0.25-0.5 milliseconds. The actual delay depends on the distance and the crossover, so it's a tricky one to solve. If you go fully active, it's incredibly simple to fix, just use DSP delay on the tweeter. If you're going passive, things get trickier; you want to get the tweeter about one half to one full wavelength ahead of the woofer, and then flip the polarity of one driver in the former case, or keep the polarity the same in the latter case.

That paragraph is probably confusing, but you can sim all of this with Vituixcad.

I imagine that a lot of people think that car coaxials sound bad because they didn't like how they sounded, but the truth is that it's mostly a crossover problem. Fundamentally, you're going to get better frequency response if you take that tweeter out of the woofer's throat and put it on a bridge in front of the woofer. The woofer can't "see" the bridge because it's too small, acoustically. But when the tweeter is in the throat of the woofer, it can definitely see it.

Years ago, the late great Audio Critic magazine heaped praise on a very pedestrian looking speaker that was built like this, and at the time, I remember thinking it looked like a cheap car audio coax in a monkey coffin. But in hindsight, I think the designer had the right idea.

My coax design was one:

https://www.diyaudio.com/community/threads/synergy-eggstravaganza.309095/post-5110101

Based on everything I've seen, I really and truly think that tweeters don't really have a place behind the woofer. At least not in a 'true' coaxial, where the woofer and tweeter are one unit.

In a nutshell, it's far easier to get good results if you just put the tweeter on a 'bridge', like cheap car coaxials do.

As you've found in your research, when you put the tweeter inside the voice coil, or even worse, behind the woofer, the response curve just looks awful.

Putting the tweeter in front of the woofer creates an issue, but it's an issue that is fixable. Whereas, the crummy high frequency response of a tweeter in the throat of a woofer is NOT fixable.

So, the issue you get with the tweeter in front of the woofer is that the output of the tweeter will "lead" the woofer by about 0.25-0.5 milliseconds. The actual delay depends on the distance and the crossover, so it's a tricky one to solve. If you go fully active, it's incredibly simple to fix, just use DSP delay on the tweeter. If you're going passive, things get trickier; you want to get the tweeter about one half to one full wavelength ahead of the woofer, and then flip the polarity of one driver in the former case, or keep the polarity the same in the latter case.

That paragraph is probably confusing, but you can sim all of this with Vituixcad.

I imagine that a lot of people think that car coaxials sound bad because they didn't like how they sounded, but the truth is that it's mostly a crossover problem. Fundamentally, you're going to get better frequency response if you take that tweeter out of the woofer's throat and put it on a bridge in front of the woofer. The woofer can't "see" the bridge because it's too small, acoustically. But when the tweeter is in the throat of the woofer, it can definitely see it.

Years ago, the late great Audio Critic magazine heaped praise on a very pedestrian looking speaker that was built like this, and at the time, I remember thinking it looked like a cheap car audio coax in a monkey coffin. But in hindsight, I think the designer had the right idea.

Specially now with neo magnets reducing size and mounting area of tweeters.

Seem rather easy to just mount traditionally tweeter in front of a woofer

with a mounting bar/bridge

Far as why people buy ragged response.

I assume marketing fluff or brand preference.

Combined with way marked up price.

Might feel high price is high value.

Seem rather easy to just mount traditionally tweeter in front of a woofer

with a mounting bar/bridge

Far as why people buy ragged response.

I assume marketing fluff or brand preference.

Combined with way marked up price.

Might feel high price is high value.

- Home

- Loudspeakers

- Multi-Way

- what is the point of expensive coaxials with ragged response?