You lost me in the first sentence!That's the beauty of good damping, that it effects all frequencies in a good way. Undamped panels have a strong preference to vibrate at particular frequencies, but not at the frequencies in between. Damping reduces the amplitude of vibration of a panel at its natural frequencies and increases its amplitude of vibration at the frequencies in between resonances.

Here is a comparison of a "close mic" measurement of two identical panels, one hanging freely with no added damping, and the other attached to a frame around the entire perimeter with an effective damping foam. The "close mic" measurement gives a result that approximates the measurement you would get from an accelerometer and gives you an idea of how the vibration amplitude of the panel varies with frequency at the location of the mic. In these particular measurements, the mic was placed directly opposite the exciter, but other locations give results with the same basic character. That is, with an undamped panel (red curve), the vibration amplitude varies wildly with frequency. In contrast, the vibration amplitude of the damped panel (green) varies much less as a function of frequency. Basically, damping reduces the sensitivity of the panel to frequency, reducing its amplitude at resonances, and increasing its amplitude between resonances.

So yes, it affects the panel at all frequencies, and in a good way. With effective damping, there's no need for haphazardly adding weights or cutting angles, hoping (mostly in vain) that it will help reduce a nasty resonance at one frequency without simply moving it to another.

Spectrograms of the same two measurements are show below (undamped above, and damped below). Everyone should decide for themselves which is more likely to faithfully reproduce a recording.

And just to be complete, the final plot below compares the impedance curves for the same panels (again offset for clarity). It should be clear which is which. Both results, (close mic, and impedance) suggest that the impact of damping is strongest at lower frequencies. If you use your panel only for higher frequencies, maybe you can get away without damping. But if you want to use your panel in the lower range, where modal density is low, I suggest to consider added damping,

Eric

View attachment 1260460

View attachment 1260458

View attachment 1260461

View attachment 1260466

I design panels to sound the best that they can sound.

You design panels to measure the best that they can.

As for clamping the bottom of a panel at an angle in a vice to see how it sounds, it only takes a few minutes and does not damage the panel.

So what is the problem?

These are only suggestions, that could be work well.

Sorry if you do not like them.

Steve.

Is it a late Christmas gift? Question which doesn't require an answer...I have just received my new exciters 😎

Welcome with this exciter model. Let us know about your result.

Christian

I see this concept of "self noise" cropping up every now and then. What exactly do you guys all mean by that? Have you taken frequency or distortion measurements?... it has a large amount of harsh self noise at reasonable listening levels... almost like vibrations within the depth of the panel...

The "self-noise" concept implies that the panel reacts very significantly non-linearly to an impulse, and this implies that Youngs Modulus is extremely random over the panel, which implies that common materials are hopelessly too unpredictable to obey the normal laws of physics.

Or it implies that there are parts within the panel material which are rubbing against each other. And this implies that the panel material has somehow been cut through all the way.

Or it means that air velocity somewhere in the panel design is too high and the actual signal causes audible whistling on the panel... most likely from undamped, unsupported edges.

Please explain.

I also have never been clear on what that term means.I see this concept of "self noise" cropping up every now and then. What exactly do you guys all mean by that?

Eric

I have these and find them ok... Not as powerful (force wise) as the DAEX25SHF-4 Steered High Flux 25mm Exciter 20W, but about half the priceI have just received my new exciters 😎

Eucy

Someone here said that they used multi tone signal to test panel for self noise. Different materials will have more or less noise between the peaks.I see this concept of "self noise" cropping up every now and then. What exactly do you guys all mean by that? Have you taken frequency or distortion measurements?

The "self-noise" concept implies that the panel reacts very significantly non-linearly to an impulse, and this implies that Youngs Modulus is extremely random over the panel, which implies that common materials are hopelessly too unpredictable to obey the normal laws of physics.

Or it implies that there are parts within the panel material which are rubbing against each other. And this implies that the panel material has somehow been cut through all the way.

Or it means that air velocity somewhere in the panel design is too high and the actual signal causes audible whistling on the panel... most likely from undamped, unsupported edges.

Please explain.

It makes sense to call panels that generates extra signals between the peaks for noisy, but I don't know if it comes from material that is not completely uniform in some way, ringing causing interference, a combination, or something else.

I don't know what it is, but it is there, is very harsh, and only on EPS for me at least. It sounds like bad breakup noise. More testing needed

Eucy

Eucy

Although it is very early days for my project, I still definitely intend to use my Yamaha stereo analogue 10 band equalizer

+ Spectrum Analyzer to sort-out peaks & dips. As we have seen, most panels exhibit these peaks & dips.

I actually recommend all builders buy a cheap Graphic Equalizer on Ebay, while their still around. It could prove very helpful.

If I have understood correctly, adding damping/suspension on all sides of the panel, you not only decrease efficiency

but also achieve a more 'pistonic' output > more like a conventional driver.

Is this what DML builders aim for ???

+ Spectrum Analyzer to sort-out peaks & dips. As we have seen, most panels exhibit these peaks & dips.

I actually recommend all builders buy a cheap Graphic Equalizer on Ebay, while their still around. It could prove very helpful.

If I have understood correctly, adding damping/suspension on all sides of the panel, you not only decrease efficiency

but also achieve a more 'pistonic' output > more like a conventional driver.

Is this what DML builders aim for ???

Although it is very early days for my project, I still definitely intend to use my Yamaha stereo analogue 10 band equalizer

+ Spectrum Analyzer to sort-out peaks & dips. As we have seen, most panels exhibit these peaks & dips.

I actually recommend all builders buy a cheap Graphic Equalizer on Ebay, while their still around. It could prove very helpful.

If I have understood correctly, adding damping/suspension on all sides of the panel, you not only decrease efficiency

but also achieve a more 'pistonic' output > more like a conventional driver.

Is this what DML builders aim for ???

There is no consensus concerning suspension and damping on this forum. I would argue that it is actually wrong to conflate the two of them, although others commonly do. Suspension around the full perimeter boosts bass response, while damping around the perimeter (or within the panel itself) reduces ringing at resonance frequencies. Both of which are good, IMHO, especially together.

Some believe that damping deceases efficiency. Theoretical papers suggest the opposite, my own experience is that the effect is neutral. That is, adding damping results in no significant change in efficiency, at least for perimeter damping.

The aims of DML builders on this forum vary. I don't think you can say what it is that we all aim for. Sorry, but that's where you have landed!

Eric

It is due to a couple of comments in the above video, that I intend to not only use EQ,

but also use a 12" woofer + Super Tweeter 🙂

but also use a 12" woofer + Super Tweeter 🙂

That would be frequency dependent 😉That is, adding damping results in no significant change in efficiency, at least for perimeter damping.

Hello Leob,Someone here said that they used multi tone signal to test panel for self noise. Different materials will have more or less noise between the peaks.

Yes I did. Keywords are "spectral contamination". If I remember well, you did some tests on your side.

Refer to posts #6131, #4656 and #4651 for links (to the test signal and a patent that mention the self noise).

For the origin of the phenomena, I would simply said that I don't see any reason that a material behave purely linearly as our theories model it. Our material are poor spring in the idea the relation displacement to force is most probably not linear even in the small displacement without speaking of possible hysteresis. In addition material like EPS are not homogeneous.

I don't know if there is a possible general explanation. Anyway, the spectral contamination test is a tool to sort the materials. It is not more what it is done in any intermodulation test of an audio device.

Christian

It amazes me that the so called professionals on this forum do not understand the meaning of self noise.

Does wood sound like wood, does metal sound like metal, does concrete sound like concrete?

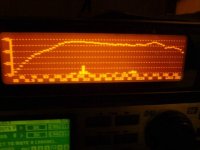

Here is a heavily damped free floating panel frequency measurement i made about 15 years ago , mmmmmmmm is it not wonderfully smooth ?

It is a dream come true 😍

What do you think it sounded like?

😴😴😴😴😴😴😴

Steve.

Does wood sound like wood, does metal sound like metal, does concrete sound like concrete?

Here is a heavily damped free floating panel frequency measurement i made about 15 years ago , mmmmmmmm is it not wonderfully smooth ?

It is a dream come true 😍

What do you think it sounded like?

😴😴😴😴😴😴😴

Steve.

Attachments

Hi mister audio.Although it is very early days for my project, I still definitely intend to use my Yamaha stereo analogue 10 band equalizer

+ Spectrum Analyzer to sort-out peaks & dips. As we have seen, most panels exhibit these peaks & dips.

I actually recommend all builders buy a cheap Graphic Equalizer on Ebay, while their still around. It could prove very helpful.

If I have understood correctly, adding damping/suspension on all sides of the panel, you not only decrease efficiency

but also achieve a more 'pistonic' output > more like a conventional driver.

Is this what DML builders aim for ???

At last someone understands one of the basic theories of dml.

If you try to damp a panel at its edges you are reducing the bending waves reflections that create the dml action.

you end up with something more like a BMR, mostly pistonic and bending wave.

More like a conventional driver 😃

This is what I have been saying for years.

I certainly do not want my panels to sound like an ordinary cone speaker.

This is why I love my panels so much, they sound nothing like ordinary speaker boxes.

I get the impression that some like the sound of speaker boxes, so they try to make their panels sound like speaker boxes.

My concensus is , let the panels sing !!!

Steve.

It should have been titled, how not to build a DML panel. 😱Here is a CONTRA - VIDEO > for the 'heck of it'.

Steve.

I don't think self noise refers to the sound when you strike an object and it resonates, which is what we think of when we think about the sound of wood or iron. The striking sound does not correlate to the DML characteristics. If you tap an EPS plate it does not have much of a sound compared to say a iron anvil, but attach an exciter and the EPS will sound a lot more.It amazes me that the so called professionals on this forum do not understand the meaning of self noise.

Does wood sound like wood, does metal sound like metal, does concrete sound like concrete?

Here is a heavily damped free floating panel frequency measurement i made about 15 years ago , mmmmmmmm is it not wonderfully smooth ?

It is a dream come true 😍

What do you think it sounded like?

😴😴😴😴😴😴😴

Steve.

But I'm also unsure what it actually means. "wood sound like wood" doesn't really tell my anything, and don't know if it is generated by some interference happening, or by the material itself when being bent or vibrated.

Leob.

Are you saying, that the sound that a certain panel material makes is nothing to do with the sound that a dml panel makes?

I am a little dumbfounded by this statement ,if that is what you ment ?

Could you clarify this for me, as i am a little lost for words

Steve.

Are you saying, that the sound that a certain panel material makes is nothing to do with the sound that a dml panel makes?

I am a little dumbfounded by this statement ,if that is what you ment ?

Could you clarify this for me, as i am a little lost for words

Steve.

spedge said:but maybe you should try my idea of only clamping the panel in a vice at the bottom , leaving the rest of the panel to vibrate.

Funny enough, that's pretty much how I had the main birch panel (the 10x48 cutaway piece), I used the frame as a vice sorta; although two contact points instead of one. but after you said that, I had a supporting xps panel that kept falling down so I grabbed my vice for that one.

Then, I think the next day, I came down with food poisoning and some other stuff happened and so my speaker building is on hold until I catch up with drudgery.

Veleric said:Also, however, I do want to clarify that my initial recommendation for a 14x48 panel as a good size applies only in the specific case that I described.

Absolutely. I'd never say anything about your design without first having executed the build to specs. Where I initially got stuck, was on 2 layers of that tape -- I have to somehow cut 100+ inches of the stuff down the center and then layer it? I have a hard time just making a small square that works to stick an exciter to for testing.

Veleric said:also suggest wating until you have your mic and REW running before you commit to a particular design.

I'm a long way away from committing to anything. Yes, all the stuff came. I hate learning new software. And so I will likely take a couple weeks and work on that slowly with my current xps panels and everything else put away.

but yeah, there's definitely stuff I'm not able to put a finger on by ear. with that setup with the "clamped" stereo birch panel, the two small xps panels, the subs, and deskFX to EQ down some of the highs, I had a great sound. Then I got sick, and with everything else torn apart, I was stuck with that setup for a few days watching TV and YouTube etc. After prolonged listening, it's just so fatiguing. So as I felt better, I cleaned everything up and got my main xps panels rebuilt and once again doing general listening duty and I can listen for hours no problem.

It seems to me that small panels just don't work. maybe it's missing frequencies, I guess I should be able to test for that in the coming weeks, but I definitely wouldn't use any of the small panels I've tried (save the xps tweeters when mixed with mains) for a "small" system, say for another room. Probably okay for surround.

In that case they're referring to intermodulation distortion!Someone here said that they used multi tone signal to test panel for self noise.

Then again, "self-noise" could mean third-harmonic distortion, which means that the panel is built incorrectly - one of the biggest advantages of DML panels, when built correctly is the very low level of 3rd harmonic distortion.

Or it could simply be rattling caused by incorrectly mounted drivers, or membranes flapping against mountings, or skins flapping against the substrate. Or, as I eventually discovered after months of heavy abuse, the driver flange itself eventually dismounted from the voice coil.

Last edited:

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker