Hi @ItsAllInMyHead , we are here in the "do it yourself forum" and here you can already sell kits that require some knowledge of electrics. And everyone can decide whether they have the confidence to assemble the components.

You will still get a balanced output even if you use a single-ended source with the Modulus-686. You can drive the amp to clipping even with a single-ended source.In case of SE output connected to Modulus-686. Then only half of amp is working? One should not expect much of heat on negative side of the amp?

Tom

Wow. Am I the only one who’s left a little shell shocked after all this drama? I hope we can now restore normality and get back to the regular scheduled program. When a thread goes through the spin cycle like this, I often take the opportunity to take a step back and re-evaluate things, and that’s what I did this time around as well.

Electrical safety is paramount, and it is also important to me that my circuits play well with others. This is why I paid extra to have ModuShop remove the anodization from the inside of the bottom panel of the Modulus-686 I show in the build video, for example. It is also why I spent time explaining how to make a solid safety earth connection to the chassis in the video. And it is why I incorporate EMI/RFI filters in my products.

Having double-checked and verified my previous understanding I’m certain that I have implemented my products according to the best engineering practices regarding electrical safety and EMC compliance. In case you’re curious about the requirements, here’s a starting point. I’ve focused on three markets: Canada, USA, and EU as that’s where most of my customers are from.

Canada:

Marking:

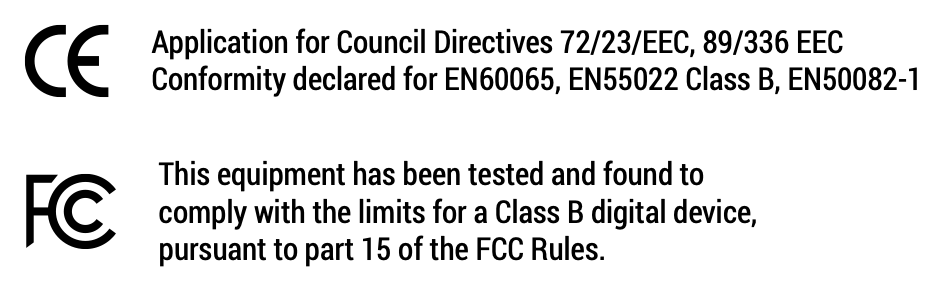

If a manufacturer applies the FCC mark or CE mark, the manufacturer, thereby, states that the product meets the relevant standards for that equipment. I pulled the example below from the manual to the Schiit Ragnarok 2 integrated amp:

Now, let’s unpack this a bit. They refer to two EU – or rather EEC – directives dating back to 1973. That’s hard to take seriously. “72/23/ECC” is actually 73/23/EEC. It’s the low-voltage directive. It’s been updated a few times since 1973. Most recently in 2014 with 2014/35/EC. 89/336/ECC is the EMC directive from 1989. That was also updated in 2014 (2014/30/EC).

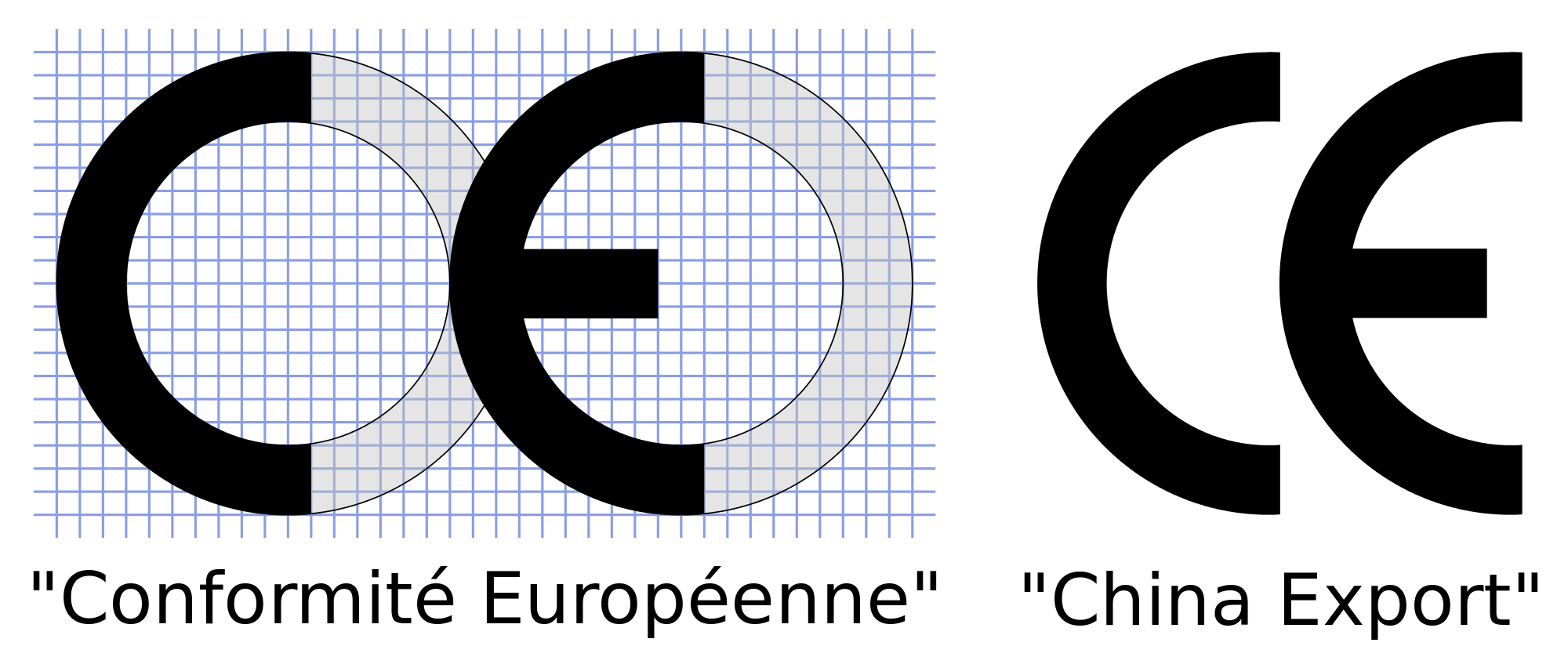

It’s also a bit funny that they managed to get CE mark wrong. Instead of the correct mark, it’s the “China Export” mark. Pretty 'special' for a Proudly made in the US of A product.

At least they seem to have gotten the FCC mark right, though EN50082-1 is rather outdated. It’s been updated twice since 1998, most recently in 2019 in the form of IEC 61000-6-1. You can buy the .pdf for “only” $250 if you want to read it.

Let’s look at another example. This time from our beloved Nelson Pass. This is his flagship preamp, the XP-32.

You will notice the CE mark but no FCC mark even though the power supply and control unit (top box) clearly contains a display and supports remote control which would require either a micro controller or some digital logic operating at or beyond 9 kHz clock frequency to work and, thereby, require FCC certification. There’s also no mention of which standards the equipment has been certified to, so we are left to guess which EU directives this power supply/controller was tested to. Also note that the equipment is not cUL or CSA marked. Nor is it ISED certified, yet, it is available for purchase in Canada. Go figure…

I’m not here to knock Schiit or Pass. I’m just pointing out that even those who sell hundreds or thousands of products yearly and have been doing so for decades get lost in the standards and marking requirements at times.

So what about Neurochrome?

So how will all this impact me? The most compelling course of action for the few fully built amps I have available is to restrict sales to the US where I can meet the requirements without making changes to the builds.

I have no intention of starting a mass production of fully assembled products. My products are much better set up for the DIY market. I’m willing to undertake custom builds of bespoke amps. I will continue to do my absolute best to ensure that these products are safe to use and will play well with others. I will continue to employ the best engineering practices in the construction of these products. But I may have to require that buyers outside the US accept that while every effort has been made to ensure compliance with the relevant safety and EMC standards, the products have not been compliance tested.

I did take a quick look at what it would take for me to be able to perform the EMC certification myself. It’s roughly $5-6k in equipment and standards. That’s a good chunk of money but not an overwhelming amount. Some of the testing will need to be done in a quiet area. “Quiet” in an RF sense. So away from cellphone towers, wifi access points, and other intentional emitters of RF signals. So … hey … maybe this could be a way for me to write off my summer camping trips as business expenses. It would certainly make for a cool YouTube video. 🙂 OTOH $5-6k is insanely expensive compared to the value it adds (practically none).

Do note that this $5-6k investment would not guarantee that my products would pass compliance testing. The $5-6k ‘toys’ are specifically marketed as a way to increase the likelihood of passing the compliance testing the first time. Not as a certified method of compliance testing.

Tom

Electrical safety is paramount, and it is also important to me that my circuits play well with others. This is why I paid extra to have ModuShop remove the anodization from the inside of the bottom panel of the Modulus-686 I show in the build video, for example. It is also why I spent time explaining how to make a solid safety earth connection to the chassis in the video. And it is why I incorporate EMI/RFI filters in my products.

Having double-checked and verified my previous understanding I’m certain that I have implemented my products according to the best engineering practices regarding electrical safety and EMC compliance. In case you’re curious about the requirements, here’s a starting point. I’ve focused on three markets: Canada, USA, and EU as that’s where most of my customers are from.

Canada:

- Electrical safety is handled by cUL and CSA and a third-party safety inspection of products sold is mandatory. The inspection costs a few hundred dollars. The testing standard is CAN/CSA C22 62368, which appears to basically be a Canadian version of UL 62368-1, which, in turn, appears to be IEC 62368-1.

- EMC compliance is governed by ISED. Testing is optional but the equipment must meet the standards for unintentional radiators. Third-party compliance testing is a few $k per product.

- Electrical safety is handled by OSHA and Underwriters Lab (UL). Compliance testing is optional.

- EMC is handled by the FCC. Compliance testing used to be mandatory for unintentional radiators operating at ≥9 kHz. This requirement was removed in 2017 and compliance testing is now optional. Manufactures can self-certify to ensure that their products meet the FCC requirements. Note that home-built devices are exempt from FCC compliance testing as long as you don’t make more than five of them.

- Electrical safety is governed by the low-voltage EU directive: 2014/35/EC

- EMC is governed by a the EMC directive 2014/30/EC.

- Third-party compliance testing is not required for any product that I would make. Manufacturers can self-certify their products.

Marking:

If a manufacturer applies the FCC mark or CE mark, the manufacturer, thereby, states that the product meets the relevant standards for that equipment. I pulled the example below from the manual to the Schiit Ragnarok 2 integrated amp:

Now, let’s unpack this a bit. They refer to two EU – or rather EEC – directives dating back to 1973. That’s hard to take seriously. “72/23/ECC” is actually 73/23/EEC. It’s the low-voltage directive. It’s been updated a few times since 1973. Most recently in 2014 with 2014/35/EC. 89/336/ECC is the EMC directive from 1989. That was also updated in 2014 (2014/30/EC).

It’s also a bit funny that they managed to get CE mark wrong. Instead of the correct mark, it’s the “China Export” mark. Pretty 'special' for a Proudly made in the US of A product.

At least they seem to have gotten the FCC mark right, though EN50082-1 is rather outdated. It’s been updated twice since 1998, most recently in 2019 in the form of IEC 61000-6-1. You can buy the .pdf for “only” $250 if you want to read it.

Let’s look at another example. This time from our beloved Nelson Pass. This is his flagship preamp, the XP-32.

You will notice the CE mark but no FCC mark even though the power supply and control unit (top box) clearly contains a display and supports remote control which would require either a micro controller or some digital logic operating at or beyond 9 kHz clock frequency to work and, thereby, require FCC certification. There’s also no mention of which standards the equipment has been certified to, so we are left to guess which EU directives this power supply/controller was tested to. Also note that the equipment is not cUL or CSA marked. Nor is it ISED certified, yet, it is available for purchase in Canada. Go figure…

I’m not here to knock Schiit or Pass. I’m just pointing out that even those who sell hundreds or thousands of products yearly and have been doing so for decades get lost in the standards and marking requirements at times.

So what about Neurochrome?

So how will all this impact me? The most compelling course of action for the few fully built amps I have available is to restrict sales to the US where I can meet the requirements without making changes to the builds.

I have no intention of starting a mass production of fully assembled products. My products are much better set up for the DIY market. I’m willing to undertake custom builds of bespoke amps. I will continue to do my absolute best to ensure that these products are safe to use and will play well with others. I will continue to employ the best engineering practices in the construction of these products. But I may have to require that buyers outside the US accept that while every effort has been made to ensure compliance with the relevant safety and EMC standards, the products have not been compliance tested.

I did take a quick look at what it would take for me to be able to perform the EMC certification myself. It’s roughly $5-6k in equipment and standards. That’s a good chunk of money but not an overwhelming amount. Some of the testing will need to be done in a quiet area. “Quiet” in an RF sense. So away from cellphone towers, wifi access points, and other intentional emitters of RF signals. So … hey … maybe this could be a way for me to write off my summer camping trips as business expenses. It would certainly make for a cool YouTube video. 🙂 OTOH $5-6k is insanely expensive compared to the value it adds (practically none).

Do note that this $5-6k investment would not guarantee that my products would pass compliance testing. The $5-6k ‘toys’ are specifically marketed as a way to increase the likelihood of passing the compliance testing the first time. Not as a certified method of compliance testing.

Tom

It was brought to my attention that actually it's the CPSC that's the governing body for safety of consumer products. Not UL or OSHA. OSHA cares about occupational safety. UL is probably the best known compliance testing lab. My bad.

Those interested in FCC's rules should have a look at 47 CFR Part 15. Specifically, Subpart A 15.23, which covers DIY builds, and Subpart B, which covers unintentional radiators.

Tom

Those interested in FCC's rules should have a look at 47 CFR Part 15. Specifically, Subpart A 15.23, which covers DIY builds, and Subpart B, which covers unintentional radiators.

Tom

Thank you Tom for taking the time to double check the standards and summarizing how they relate to your offerings. It's very educational.

The idea was mentioned on the last page to sell kits like Hypex does. They sell complete kits including a chassis through diyclassd.com. Everything has been prepared to the point that you just need a screwdriver, no need to solder anything. Might be the next best thing to fully built amps. This could lower the barrier to entry for some folks too.

I enjoy a bit higher degree of control over my builds than that though. I was looking at the Nilai kit but don't like the case. It comes with flat cables with connectors pre-crimped for the control stuff, which makes it annoying to use your own LED's and switches for example.

The idea was mentioned on the last page to sell kits like Hypex does. They sell complete kits including a chassis through diyclassd.com. Everything has been prepared to the point that you just need a screwdriver, no need to solder anything. Might be the next best thing to fully built amps. This could lower the barrier to entry for some folks too.

I enjoy a bit higher degree of control over my builds than that though. I was looking at the Nilai kit but don't like the case. It comes with flat cables with connectors pre-crimped for the control stuff, which makes it annoying to use your own LED's and switches for example.

Odd. I made sure to drop off the package at UPS well before the normal pick-up time at the UPS Store last Friday, but it looks like the package wasn't picked up until Monday. I have no idea why. At least it's cleared customs on both ends and is reaching your end of the country pretty quickly.Now if UPS would actually deliver it

3-Day UPS is often delivered early, but with the holiday season upon us I'm sure they'll stretch that to the max, so with Thursday being a holiday in the US, Friday delivery seems reasonable. As long as it arrives in one piece life is good. It should... It's not my first time shipping such things. 🙂

Tom

Last edited:

I could do that. For sh!ts & grins here's the rear panel of the Hypex preamp. I grabbed it from the manual but you can just barely see the markings in the official product photos.The idea was mentioned on the last page to sell kits like Hypex does.

Once again we note the CE mark but not much else. Don't throw the product in the trash. Don't electrocute yourself by opening it. Don't use above 2000 m altitude. I think the latter has to do with electrical safety. There're some changes in creepage and isolation distances at higher altitude. I find it ironic that a DIY kit has a warning on the back, "DO NOT OPEN - RISK OF ELECTRIC SHOCK". But maybe that's just me... 🙂

I'm willing to bet money that Hypex self-certifies wrt. electrical safety and EMC. That's a bit risky in my view. After all, they have no control over how the product is assembled. But, hey... It has a CE mark so the customs officers are happy.

I've been kinda/sorta tempted to make a wiring kit available for the Hypex/Purifi amps. That would make it very plug-n-play, especially with the chassis that I offer. I could also make a Modulus power amp available that way.

I'm not sure making a kit available solves anything as far as the regulations go, though. In fact, 47 CFR Part 15 Subpart A 15.23 specifically excludes kits, i.e., if you build a piece of hifi gear from a kit, the kit needs to be FCC certified if it contains an oscillator ≥ 9 kHz. Maybe $5-6k in toys and a few camping/business trips are back on the table. 🙂 Product development during the winter, EMC testing during the summer.

Tom

I ended up managing an ESA, 2 week space compliance test program here https://www.3ctest.co.uk/ . The kit was in a sealed EM anechoic chamber (where the wedges are electrically absorbing). At one stage the guy who was running a particular test said "Anyone using a mobile?", And sure enough one of the team was using her phone along the corridor. And sure enough there was a peak (admittedly a weak one) in the spectrum analyser at the typical frequency of a mobile phone.Some of the testing will need to be done in a quiet area. “Quiet” in an RF sense. So away from cellphone towers, wifi access points, and other intentional emitters of RF signals.

Tom

So in terms of compliance testing even a super expensive EMC test facility is not immune to even a mobile phone!

Craig

Now, if one would like to avoid the certification - would leaving one out of two (3) wires for mains inside a box to be connected by the customer, be a way to claim that it is a self built amp (albeit little work), and no certification is needed. I would assume all responsibility would end up with the final builder? I'm basically pro certification but wondered about the legal aspects of this...

//

//

I imported quite some parts from China to Germany and had to explain at the customs office what it was. If it was not working as is, there was no problem. They looked for a way to connect it to 230 Volt or to install a battery. If this was impossible, it passed. Could have been a nuclear bomb.

As far as I know, if you declare it "electronic parts for assembly, no working unit" and for example do not install the mains connector at the rear, this is all it needs to get into the EU without any approvement. You can include the connector in plasic bag, no problem, as long as it is not connected. So having it in the case and not connecting it won't work. You have to be pysically unable to connect it to mains.

Also, if you are a registered importer (of electronics, best) you can receive samples for certification. They are even tax free in this case.

On the other side, in the EU, even if you use certified (often called pre-certified) components and combine them to a working unit for sale, you still have to certify the product!

Like an Hypex amp module and a Hypex power supply connected in a case, this does not make a legal unit. Same with ICE amps.

If you ask, they will assist in the process and supply documents, but you still have to get it tested. It is not about safety, but the allmighty TÜV organization doing constant lobby work in the EU and calling for more and new, even more expensive testing. The Industry is on their side, as small developer can not get new products on the market, because of the huge cost involved. So they are keept out of the market.

Even a software update makes a product illegal until a new certification has been done.

Some German suppliers of DIYS kits do or did offer a certification if you return the finished product to them for testing. Another way to stay legal.

As far as I know, if you declare it "electronic parts for assembly, no working unit" and for example do not install the mains connector at the rear, this is all it needs to get into the EU without any approvement. You can include the connector in plasic bag, no problem, as long as it is not connected. So having it in the case and not connecting it won't work. You have to be pysically unable to connect it to mains.

Also, if you are a registered importer (of electronics, best) you can receive samples for certification. They are even tax free in this case.

On the other side, in the EU, even if you use certified (often called pre-certified) components and combine them to a working unit for sale, you still have to certify the product!

Like an Hypex amp module and a Hypex power supply connected in a case, this does not make a legal unit. Same with ICE amps.

If you ask, they will assist in the process and supply documents, but you still have to get it tested. It is not about safety, but the allmighty TÜV organization doing constant lobby work in the EU and calling for more and new, even more expensive testing. The Industry is on their side, as small developer can not get new products on the market, because of the huge cost involved. So they are keept out of the market.

Even a software update makes a product illegal until a new certification has been done.

Some German suppliers of DIYS kits do or did offer a certification if you return the finished product to them for testing. Another way to stay legal.

@tomchr, the question is (and never was) if you did everything to make your product as safe as it gets. I am sure your did. However, I'd suggest you to look at the marking/labels from a different angle. Who is responsible to demonstrate liability if something bad happens?

Here's how my lawyer tried to explain the situation a few years ago, when I asked about the safety markings. Let's say something bad happens with one of your fully built amp, for example it causes a fire that destroys a house. The lawyers will inspect your product and...

...find the relevant safety mark on your product. The responsibility to demonstrate that your product was not safe (and that you may be liable for the damage) is with the victim.

...do not find the relevant safety mark on your product. The responsibility to demonstrate that your product was safe (and that you are not liable for the damage) is with you.

I'd say it's a lot easier for you to mark your fully built amps ("self certification") than to take the risk for being responsible to demonstrate that your product was safe, and that it was not your fault.

Here's how my lawyer tried to explain the situation a few years ago, when I asked about the safety markings. Let's say something bad happens with one of your fully built amp, for example it causes a fire that destroys a house. The lawyers will inspect your product and...

...find the relevant safety mark on your product. The responsibility to demonstrate that your product was not safe (and that you may be liable for the damage) is with the victim.

...do not find the relevant safety mark on your product. The responsibility to demonstrate that your product was safe (and that you are not liable for the damage) is with you.

I'd say it's a lot easier for you to mark your fully built amps ("self certification") than to take the risk for being responsible to demonstrate that your product was safe, and that it was not your fault.

We had a couple of screen rooms where I worked at TI. They were sizeable and had a large door with copper leaf springs to ensure a good RF-tight seal. It was remarkable how little one could leave the door cracked open and still have a strong cellphone signal. We also had to have the wifi access point mounted outside the lab to prevent wifi from getting into our phase noise measurements. Our frequency of interest was right next to the 2.4 GHz wifi band.So in terms of compliance testing even a super expensive EMC test facility is not immune to even a mobile phone!

Do you know for a fact that no certification is needed for a DIY build or are you basing this on the assumption that certification is not needed? If you do know this for a fact, would you point me to the relevant section of the directives so I can see for myself? I'm not trying to argue with you. I've had enough drama to last me quite a while. 🙂 I'm just trying to tease apart fact from assumptions. I thought too that DIY builds (of unintentional radiators) were exempt from the FCC certification only to read 47 CFR Part 15 Subpart A 15.23 and find that the exemption only applies if you build from scratch and not from a kit. But FCC and CE (or rather the EU commission) are two different animals.Now, if one would like to avoid the certification - would leaving one out of two (3) wires for mains inside a box to be connected by the customer, be a way to claim that it is a self built amp (albeit little work), and no certification is needed.

I bristle at the use of the word 'legal' here. Let's be 200 % clear on this. There is nothing criminal about what I'm doing. I'm not selling cocaine here. These standards are about product liability (both for safety and EMC).Some German suppliers of DIYS kits do or did offer a certification if you return the finished product to them for testing. Another way to stay legal.

That is a very good point. Just so I can sleep better at night I would want to perform at self-certification of the circuits before I slap any marks on them, though.I'd say it's a lot easier for you to mark your fully built amps ("self certification") than to take the risk for being responsible to demonstrate that your product was safe, and that it was not your fault.

As I pointed out yesterday, I have made every effort to ensure that my products are safe and play well with others. But having made every effort is no guarantee that the products will pass the compliance test. That said, I am very confident that I at least have the electrical safety aspects covered, so the only uncertainty is around EMC. RF behaves in mysterious ways at times. That said, my products have very little circuitry that would trigger testing, so I'm not overly worried. It's mostly my desire for precision and my unrelenting high standards that drive me to want to actually measure the EM emissions and susceptibility of my circuits before slapping on a CE mark. Everybody else in the field is clearly just applying the mark and moving on.

Tom

Last edited:

Tom,I bristle at the use of the word 'legal' here. Let's be 200 % clear on this. There is nothing criminal about what I'm doing. I'm not selling cocaine here. These standards are about product liability (both for safety and EMC).

you are far away, not in Germany. This "Legal" here this an approval only neccesary if you do want to sell your self assembeled kit or want to give it to someone else.

So you selling a populated PCB "done right" here, have no problem at all. Only if you sold a working amp ie Plug&Play.

We are some kind of lucky, as we are only procecuted if our self build device is causing problems. So if the measuring gang knocks on your door, you still have time to pull the plug. They can not simply enter your home and search for the emitter of the problem. The Gestapo was abolished a few years ago. Even as this might change soon... They still have to get a search warrant to do that.

If the cause, for example, was a defective Wlan Router, you have no problems anyway, as long as there are some CE markings on it. I don't know of anyone ever being fined for any DIYS thingy. Maximum fine was 50.000€ a while ago iirr.

There are so many people I know of, which are using D-amps just screwed on a piece of wood, there can be no one really hunting for EMI emitter.

If I plan to use it permanently, I put any SMPS or D-amp in a metal case and hope for the best. Not 100%, I know, but this should cure the worst problems. Of course I know quite well how to wire up the mains in different cases.

Anyway, because of a possible rest risk, I'm carefull what I post online. Too stupid to deliver evidence of your "crimes" to anyone searching.

That's one of the reasons I will not just slap a sticker on my products and hope for the best. If I claim the product is certified then I will want data to back that up. Self-certification is one way to ensure compliance with the standards. That's allowed both in the US and in the EU.

I'm not overly worried that my products will cause trouble with EMI. I use certified switching power supplies and exercise due diligence in the builds. But then again, measuring and knowing would make me sleep even better at night.

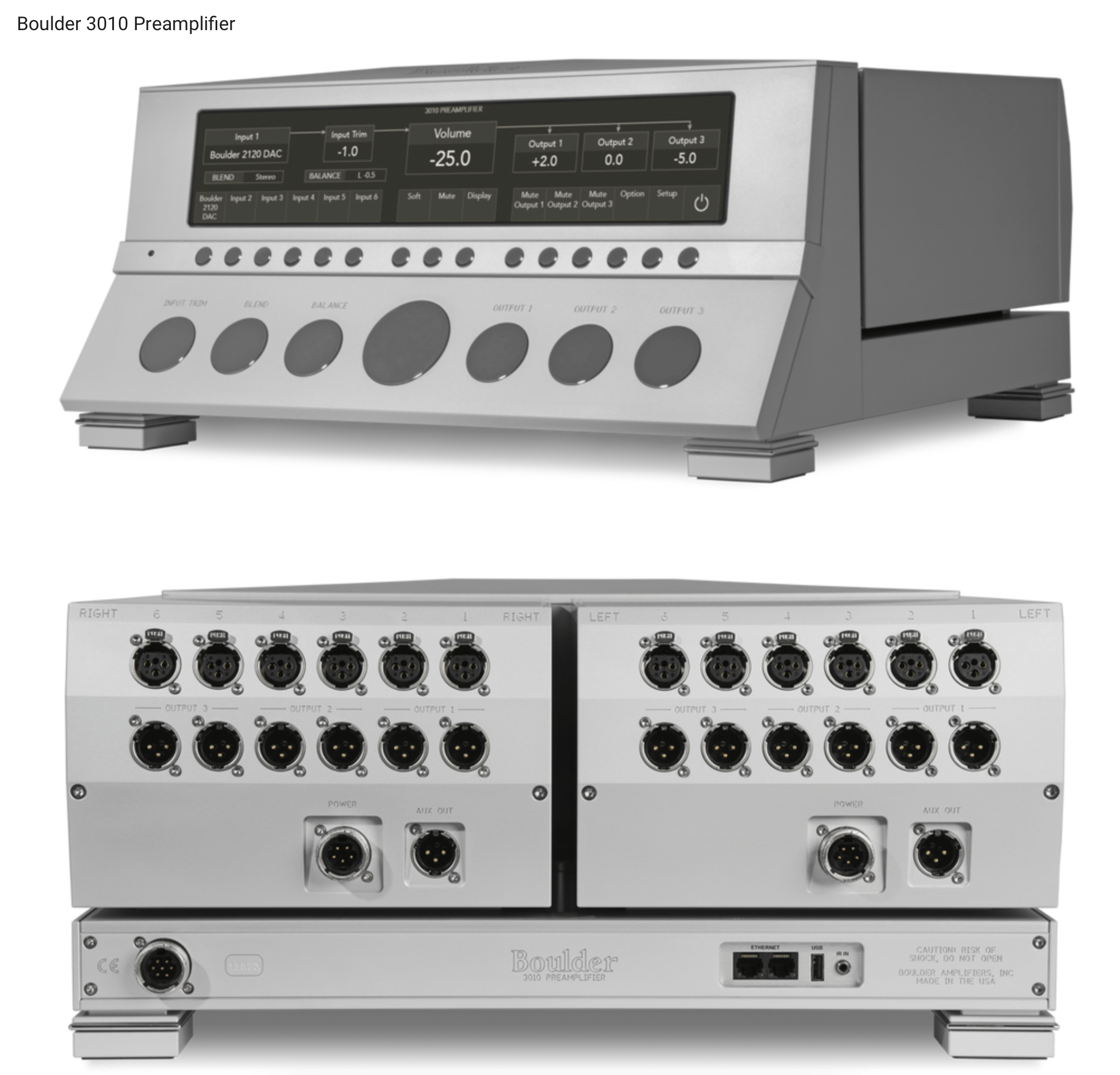

Once you start looking it's remarkable how few products are certified. Here's Boulder's 3010 preamp for example.

It clearly contains some processing power to drive that display. It also features a built-in web server so you can configure it through HTTP. I would be surprised if the micro controller that handles that doesn't contain an oscillator running at or above 9 kHz. And it would need to talk to an ethernet PHY so there's certainly opportunity for emissions. Yet, all it sports is the CE mark. No FCC...

I did check the manual. At it says is:

There is no mention of which standards they've tested to. But ... hey ... it sounds wonderful. That's good...

Am I the only one who's left a bit underwhelmed? This is a $130k preamp for F's sake! One hundred and thirty THOUSAND dollars!! For a preamp. One could buy a house in some parts of North America for that. Or a pretty nice luxury car. Surely they could find a few $k in the budget to get the gear tested ... or do it themselves (as they say they do) and mention the standards in the manual.

Tom

I'm not overly worried that my products will cause trouble with EMI. I use certified switching power supplies and exercise due diligence in the builds. But then again, measuring and knowing would make me sleep even better at night.

Once you start looking it's remarkable how few products are certified. Here's Boulder's 3010 preamp for example.

It clearly contains some processing power to drive that display. It also features a built-in web server so you can configure it through HTTP. I would be surprised if the micro controller that handles that doesn't contain an oscillator running at or above 9 kHz. And it would need to talk to an ethernet PHY so there's certainly opportunity for emissions. Yet, all it sports is the CE mark. No FCC...

I did check the manual. At it says is:

There is no mention of which standards they've tested to. But ... hey ... it sounds wonderful. That's good...

Am I the only one who's left a bit underwhelmed? This is a $130k preamp for F's sake! One hundred and thirty THOUSAND dollars!! For a preamp. One could buy a house in some parts of North America for that. Or a pretty nice luxury car. Surely they could find a few $k in the budget to get the gear tested ... or do it themselves (as they say they do) and mention the standards in the manual.

Tom

- Home

- Vendor's Bazaar

- Modulus-686: 380W (4Ω); 220W (8Ω) Balanced Composite Power Amp with extremely low THD