I currently don’t use crossover between DML and tweeters either.This will be a 2 way DML panel using the Tectonics frog exciter ran full range while using a tweeter with a single capacitor for the HF

At high frequencies, there is also a capacitor

But I adjusted the EQ on Full frequencies

I also have tests that I can accept without using EQ.

But I prefer to use a little EQ to adjust

Didn't pay attention this morning

I found that @Andre Bellwood cannot be opened either.

Is there anyone else who can upload it?

Because I can't open it either...XD

Thank you very much for sharing

Hello Audiofrenzy,Started working on my new project last week. These are large panels around 15inches width and around 3ft. height. At first it was just going to be a all DML panel but all this talk about combining conventional cone drivers with DML made me rethink this project. Yesterday I've been experimenting with using a tweeter with these large panels because like I've mentioned before large panels seem to lack the high frequencies when compared to smaller ones. Also this is not my first rodeo in adding a tweeter as I've done it many times in the past as I have gone through 10 different types of tweeters.

This will be a 2 way DML panel using the Tectonics frog exciter ran full range while using a tweeter with a single capacitor for the HF. I've been playing around with tweeter placement by researching other planar speakers and where they place there HF driver and most of them like Diptyque and others place the HF driver on the side of the panel instead of the top like most conventional cone speakers. So I tried placing the tweeter on the side of each panel. The first track I played by Sarah Mclachlan's Angel and it just floored me. Now I know why those planar speakers place the HF tweeter on the side instead of the top of the panel. When placed on the top of the panel the HF sounds like its mostly coming from the top. When placed on the side of the panel it sounds like its coming from the whole panel which in turn blends better with the DML panel. This new technique will be added to my list of what works. As usual if I have time I will make a carpet video of them playing.

I hope you will accept to answer few questions... if not showing the details of those panels 😉

- Which material is the panel?

- What is the cut off frequency (or capacitor value) of the tweeter?

First, I won't push the DML to cone comparison very far. A cone speaker is a mass loaded device. This is a first important limitation in its bandwidth so in its cone diameter. In addition the diameter of the cone as a direct consequence on the directivity.

In DML, the voice coil is loaded by the mechanical impedance of the membrane. The HF limitation is no more linked to the diaphragm mass. The mechanism in HF limitation might be different.

About the link between the HF and the dimensions of the panel, I have the feeling through what I have experimented, it might be more complex.

I have 2 quite large plywood panels for which I don't have the feeling neither the evidence with measurements of a lack of HF.

At the opposite, while experimenting with polypropylene, the lack of HF is here with small dimensions piece of this material.

I am wondering about material in between, with an HF absorption such as this effect of lack of HF becomes visible. EPS? Unfortunately, I haven't managed to find high density enough to experiment with.

Christian

Christian,The recommendation in the paper you linked (not this last one, the one before) is to have this transition frequency as low as possible.

As it is directly linked to how the modes are located over the frequency range, the drivers (design parameters) are the panel dimensions, the panel ratio, the material choice, the boundary conditions (suspension).

For a room, there is a relation between the reverberation time which is quite easy to mesure and the Schroeder frequency. For a panel, I don't know...

Yes, that's what I understood their idea to be, that is, that the transition frequency should be as low as possible, most ideally below the audible range (or at least below the frequency range of application). That's actually quite consistent with what I have been trying to achieve with high aspect ratio panels combined with strong perimeter damping.

I too would be interested in a method to measure the transition frequency. A scanning laser vibrometer would help but I don't have access to one! I've been giving a little thought to what measurement(s) I could make using the tools I have (FEM, tap testing, close-micing, impedance testing) that might provide an elegant alternative to the laser vibrometer but I don't have the answer yet. If you have any ideas let me know.

Eric

Eric,Thanks for providing a working link Christian.

That paper led me to this one by the same authors:

https://pubs.aip.org/asa/poma/artic...Measures-of-vibrational-localization-on-point

This paper is one of the most intriguing (and mercifully short!) papers I've come across in a long time. This figure is central to the paper:

View attachment 1216554

And they end up splitting the frequency response into two regions (figure below), "modal" below a crossover frequency and "statistical" above the crossover frequency.

View attachment 1216672

It reminds me of a discussion we had on this thread some time back concerning the different frequency regimes of a DML. I wanted to look back at that but couldn't figure out how to find it. Any body think they can? (Christian??).

I enjoyed that the paper is so short, but one thing I wish the authors wrote more about was the implications of this crossover frequency on the characteristics of the sound produced in each regime, say in terms of directionality, phase (correlated/uncorrelated), etc.

Eric

I read the paper...

The explanation about the Modal Overlap, the comparison to the Schroeder frequency makes sense to me.

The paper seems too limited in the relation between the membrane material and the named transition frequency. At least with not enough evidence (in my opinion of a person with limited knowledge in such topic) Only results for acrylic are shown; what about others? It was shared here that HF, in some materials (plywood?) can go far no? OK the only sensor we have is a mic...

About the post, you are looking for... difficult. I have in mind exchanges with Steve about the different modes the DML works but I have not specific enough keywords to find it...

Christian

Christian

^ this reminds me of:

View attachment 1216835

from a PDF you posted here:

https://www.diyaudio.com/community/...s-as-a-full-range-speaker.272576/post-7458376

deanznz,

I read that too and thought it a bit curious. I am frankly a bit confused about what they are trying to say there. They single out "rectangular panels with constrained edges" but as far as I can tell, panels of any shape and unconstrained edges also display sharp peaks in their frequency response. And often sharper peaks, as there is less opportunity for introducing damping with free edges.

Later in the same section they add to my confusion when they cite Heron's patent as an example of a "highly compliant panel with free edges". Heron's patent indeed describes a panel with free edges, but the panel itself is a 40 mm thick (!) panel with aluminum honeycomb core and skins, and hence is about as far from "highly compliant" as I can imagine!

From Heron's patent:

That's probably the least compliant panel I've ever heard of used for a "DML"!

All that said, I do see how there could be merit to using truly compliant panels, as such would shift all the natural frequencies down, and thereby increase the density of natural frequencies in the audible range.

Eric

An idea I have (I don't remember if I already shared it) is the use of a cartridge (this old thing for vinyl disc). What I don't know is the transfer function. This will sense only one point not giving a full membrane view in one shot.Christian,

Yes, that's what I understood their idea to be, that is, that the transition frequency should be as low as possible, most ideally below the audible range (or at least below the frequency range of application). That's actually quite consistent with what I have been trying to achieve with high aspect ratio panels combined with strong perimeter damping.

I too would be interested in a method to measure the transition frequency. A scanning laser vibrometer would help but I don't have access to one! I've been giving a little thought to what measurement(s) I could make using the tools I have (FEM, tap testing, close-micing, impedance testing) that might provide an elegant alternative to the laser vibrometer but I don't have the answer yet. If you have any ideas let me know.

Eric

Christian,Eric,

I read the paper...

The explanation about the Modal Overlap, the comparison to the Schroeder frequency makes sense to me.

The paper seems too limited in the relation between the membrane material and the named transition frequency. At least with not enough evidence (in my opinion of a person with limited knowledge in such topic) Only results for acrylic are shown; what about others? It was shared here that HF, in some materials (plywood?) can go far no? OK the only sensor we have is a mic...

About the post, you are looking for... difficult. I have in mind exchanges with Steve about the different modes the DML works but I have not specific enough keywords to find it...

Christian

Yes, I agree, validation across other materials and/or other levels of damping would have made the work more convincing.

No worries about not finding the old posts. I was just curious, but probably there's no real value in it.

Eric

Christian,An idea I have (I don't remember if I already shared it) is the use of a cartridge (this old thing for vinyl disc). What I don't know is the transfer function. This will sense only one point not giving a full membrane view in one shot.

Can you explain more what you are suggesting? I'm not following.

Concerning the use of a mic as a alternative to a vibrometer, as you may suspect, I think it has great potential value. I'm pretty sure one could create similar graphics to the vibrometer results by driving the panel using an exciter at a fixed location and frequency (as they did in the paper) and measuring the SPL using a close mic (say 2 mm) at locations across the entire surface of the panel, and using SPL as a proxy for displacement amplitude. Of course, it would take forever, so it would not be practical.

But is there a more elegant way? That through judicious selection of the driving point and measuring points, and using white or pink noise instead of a single frequency, that the transition frequency could be estimated? That's how I'm leaning now...

Eric

Hi Eric, would the chladni plate test be useful ?I too would be interested in a method to measure the transition frequency.

Do watch it for 6-7 minutes if you can.

The video link should jump to the correct part.

Last edited:

This song is so familiarHigh density EPS.

But I can’t remember what song it is

In theory, yes, I think it would. If you ramped the frequency, at some point you would stop seeing patterns, and that should be the transition frequency.Hi Eric, would the chladni plate test be useful ?

Last time I tried a Chladni plate demo I got some cool figures but burned up an exciter, as you may recall.

https://www.diyaudio.com/community/...s-as-a-full-range-speaker.272576/post-7198955

Hello Eric,Christian,

Can you explain more what you are suggesting? I'm not following.

Concerning the use of a mic as a alternative to a vibrometer, as you may suspect, I think it has great potential value. I'm pretty sure one could create similar graphics to the vibrometer results by driving the panel using an exciter at a fixed location and frequency (as they did in the paper) and measuring the SPL using a close mic (say 2 mm) at locations across the entire surface of the panel, and using SPL as a proxy for displacement amplitude. Of course, it would take forever, so it would not be practical.

But is there a more elegant way? That through judicious selection of the driving point and measuring points, and using white or pink noise instead of a single frequency, that the transition frequency could be estimated? That's how I'm leaning now...

Eric

The idea is to use a phono cartridge. Have a look here for some illustrations : Equivalent circuit of the dynamic system of a phono cartridge. A phono cartridge transforms the speed of the stylus in volt. The difficulty is to have an idea of this transfer function according to the frequency.

With a mic, there is no reason to proceed with a single frequency in my opinion. My favorite test is the IR with a logsweep. Depending of the sweep duration, the frequency resolution is good. Treatment like smoothing are possible afterwards. It is more difficult with a noise where the frequency resolution is defined at the measure by the RTA or spectrum analyser. setup.

Christian

I can't help but think..... was there a time when we could see sound 🙄

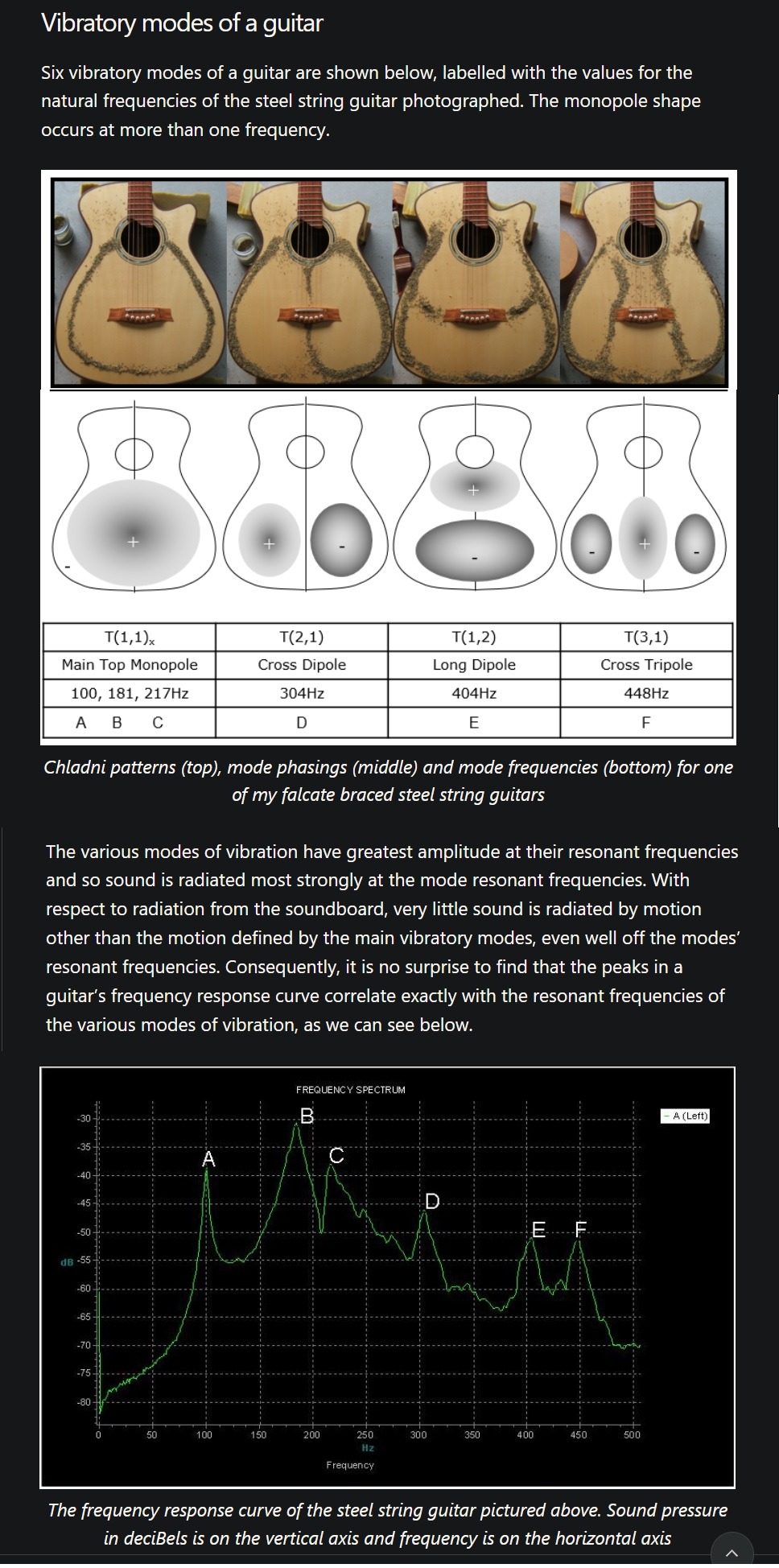

from:

https://goreguitars.com.au/design/#Modal_Tuning

from:

https://goreguitars.com.au/design/#Modal_Tuning

Hmm, that would be cool.I can't help but think..... was there a time when we could see sound 🙄

I must admit that I'm initially a bit skeptical of this claim:

I would really like to hear the explanation of that. The only thing I can think of offhand is the possibility that at each of the different frequencies with the monopole shape on the face, the sides and back are doing something different.

Eric

Not just strings either. Pretty much all instruments produce a series of harmonics (i.e overtones that are integer multiples of the fundamental). Even percussion instruments produce a series of overtones, though they are typically not harmonic overtones.String instruments are designed to produce tones not some pure frequencies. Much more a mix of them.

Eric

Ah, I see. The idea is to use a phono stylus/cartridge as a displacement sensor. Makes sense.The idea is to use a phono cartridge.

Concerning the single frequency test, I mentioned it only as the simplest (least elegant) example of a "brute force" method to try and qualitatively replicate the laser vibrometer result.

I like the frequency sweep test best for most applications too. The "noise" method is nice for some special applications though. For example, in the test I did some time ago when I continuously moved the mic across the surface of the panel to look for comb filtering. In that case the "noise" method was much quicker.

I'm not sure yet which approach would be best for investigating the modal/statistical crossover frequency, however. Perhaps neither.

Eric

Yes, the noise + RTA is excellent to find the exciter best place. I did it in my last panel (polypro version) built. The place I choose is totaly different the one I thought.I like the frequency sweep test best for most applications too. The "noise" method is nice for some special applications though. For example, in the test I did some time ago when I continuously moved the mic across the surface of the panel to look for comb filtering. In that case the "noise" method was much quicker.

A sweep keep the time information, not the noise test. I just read a paper about the auditory system saying we are able of accurate evaluation in frequency and in time. What an FFT can't do. One day or later, the time aspect will appear.

I don't have it in mind for now but as you mentioned, the impendance curve should remain in the game.I'm not sure yet which approach would be best for investigating the modal/statistical crossover frequency, however. Perhaps neither.

Eric

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker