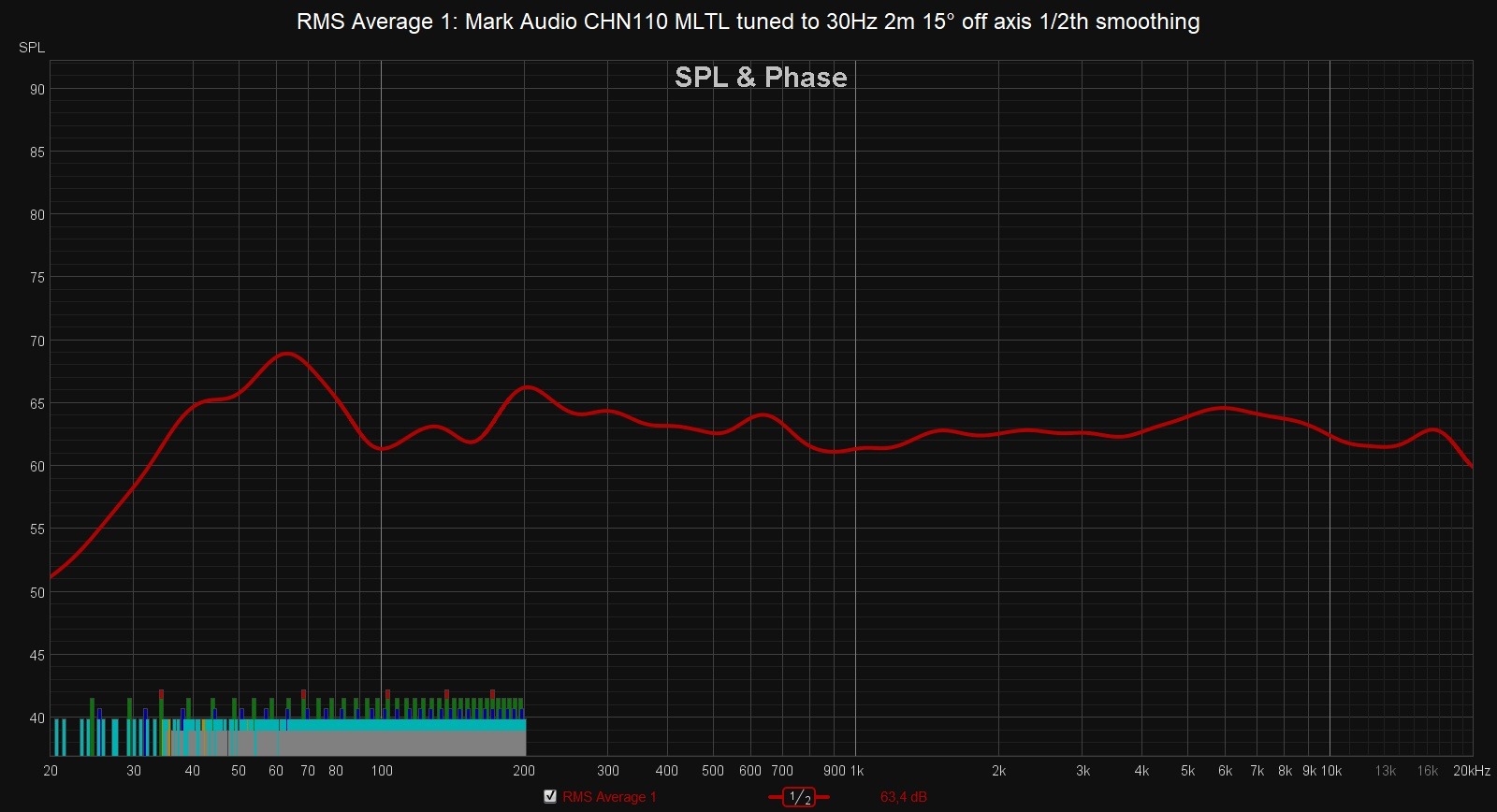

It seems i even have the mdat file on this computer also. This is the 1/2th smoothing. But 1/2th smoothing takes out a lot of info i'll use for the dsp programming i want to try. But to compare to commercial speaker spec sheets (where it's often used this can be usefull.

But it gives a better general idea. Remarkable smooth for such a largw driver. A real standout.

dave

dave

When simulating the St helens in winisd I get a f3@38hz ??Interesting indeed? Smaller than the Kewel yet goes some 10hz lower? I'm sure Planet10 or Scottmoose can help as they have produced several designs for the CHN110.

There's probably some quarter wave action going on in the line that can't be accounted for in WinIsd.When simulating the St helens in winisd I get a f3@38hz ??

jeff

Yes Scott def seem to know how to design speakers. And I don't really know how to use the advanced features of winisd...

The dimensions of the st. Helens speakers fit my application perfectly, except the top vent. Would it totally break the design if I move the port to the front?

( I actually just finished cutting the plywood -but top venting will not work for my speaker location :-(

The dimensions of the st. Helens speakers fit my application perfectly, except the top vent. Would it totally break the design if I move the port to the front?

( I actually just finished cutting the plywood -but top venting will not work for my speaker location :-(

advanced features of winisd

winISD is incapable of simulating TLs.

dave

Many would disagree with that. However, as Dave said, WinISD can't accurately model this enclosure as it relies purely on Helmholtz assumptions and takes no account of anything else.Yes Scott def seem to know how to design speakers. And I don't really know how to use the advanced features of winisd...

Mostly. The raison d'etre of that design was the top-firing vent, so if you don't want that, I recommend building an alternative.The dimensions of the st. Helens speakers fit my application perfectly, except the top vent. Would it totally break the design if I move the port to the front?

I'm going to flush mount the speakers in sort of a 2cm thick "false/double wall" (sorry my English is probably as bad as my speaker building)

But available height is only approximately 95cm.

I guess I could place the port at top if I make it external and bend it 90° -But porting through the wall would require a longer port...

Would it be OK to use 22cm long port if I also increase the diameter to keep the port tuning at 36-37hz ?

But available height is only approximately 95cm.

I guess I could place the port at top if I make it external and bend it 90° -But porting through the wall would require a longer port...

Would it be OK to use 22cm long port if I also increase the diameter to keep the port tuning at 36-37hz ?

So I build the St Helens according to Scotts plan. But I can not find any OC-703 bonded acoustic fiberglass and wool felt is crazy expensive.

Could I use wool blankets?

Could I use wool blankets?

No, that does not work. Use polyfill then. Acoustica stuffing or visaton stuffing is the same. You need to tease it so it's equal density. I also used Rockwhool sono in a sealed pillow sleeve for a build with good result. And teased longhair sheepwool also works very well, but make sure it's treated against mots or your speaker will have little squatters...

Scotts drawings say 2.5mm bonded fibreglass on all internal faces. And the illustrated linning does not look teased. So I am a little confused you want me to tease the stuffing??

I do have two old sheep furs I could use, but I wonder if 1 fur in each speaker would be to much or to little damping...?

I do have two old sheep furs I could use, but I wonder if 1 fur in each speaker would be to much or to little damping...?

Yesterday I measured a few different alternative damping materials I had laing around.

For reference I first measured the speaker without any damping. As expected the response was very jagged.

I then tested with a wool shirt in bottom and 4 old wool socks placed low on the speaker sides. The wool smoothed the responce significantly, but still a fair amount of dips and cliffs.

Next test was bonded woodfibre isolation.

40mm on 3 sides, 80mm on top and 120mm bottom.

Result was smooth response from 30 to 17000hz but output at 35hz was a bit lower compared with the wool.

I then tested with isover glasswool isolation Batts.

Approximately 25mm on 3 sides, triple in bottom and double in top.

Result was almost identical to the woodfibre.

Looking at the measurements I am wondering if covering a larger area with wool could outperform both woodfibre and glassfibre.

Guess I will just have to try it...

For reference I first measured the speaker without any damping. As expected the response was very jagged.

I then tested with a wool shirt in bottom and 4 old wool socks placed low on the speaker sides. The wool smoothed the responce significantly, but still a fair amount of dips and cliffs.

Next test was bonded woodfibre isolation.

40mm on 3 sides, 80mm on top and 120mm bottom.

Result was smooth response from 30 to 17000hz but output at 35hz was a bit lower compared with the wool.

I then tested with isover glasswool isolation Batts.

Approximately 25mm on 3 sides, triple in bottom and double in top.

Result was almost identical to the woodfibre.

Looking at the measurements I am wondering if covering a larger area with wool could outperform both woodfibre and glassfibre.

Guess I will just have to try it...

Fiberglass insulation? A cheap but effective damping material. Wear gloves.

Scott most often just lines his ML-TLs using other techniques to suppress the most critical unwanted harmonics.

Stuffing will increase the damping of the alignment, we stuffed both of the ML-TLs based on Woden lines, then converted the vet to a higher resistance slot.

So many compromise, these work best for the situation these speakers find themselves in.

dave

Scott most often just lines his ML-TLs using other techniques to suppress the most critical unwanted harmonics.

Stuffing will increase the damping of the alignment, we stuffed both of the ML-TLs based on Woden lines, then converted the vet to a higher resistance slot.

So many compromise, these work best for the situation these speakers find themselves in.

dave

I useually work with my hands in fiberglass insulation so my hands are pretty immune to that stuff -other body parts are more sensitive...

I'm concerned fibreglass particles might damage the driver?

The spectographs from my tests indicate wool is a tiny bit better at high frequencies, so I have removed the fibreglass insulation and lined with wool fabric.

It's almost midnight here, so I guess my naibors probably wouldn't appreciate outdoor speaker tests. Even though it is Friday...

I'm concerned fibreglass particles might damage the driver?

The spectographs from my tests indicate wool is a tiny bit better at high frequencies, so I have removed the fibreglass insulation and lined with wool fabric.

It's almost midnight here, so I guess my naibors probably wouldn't appreciate outdoor speaker tests. Even though it is Friday...

Attachments

I'm concerned fibreglass particles might damage the driver?

I’ve disassembled 100s of commercail loudspeakers that have shown no issues. If you are worried stretch som cheescloth, strechy licra or similar over the back of the driver. Often seen in older Britsh loudspeakers.

dave

Wool fabric does seem to dampen high frequencies better than fibreglass insulation.

It's a little windy today so outside background noise screws my low frequency measurements somewhat. But it seems low frequencies could use just a bit more damping.

Currently the cabinet is damped by two layers of wool blanket on 3 sides, half a wool shirt on the bottom and two sock in top.

I'm unsure where to place additional damping material for optimal result.

I'm guessing it's best to avoid to much damping in the top near vent and driver?

It's a little windy today so outside background noise screws my low frequency measurements somewhat. But it seems low frequencies could use just a bit more damping.

Currently the cabinet is damped by two layers of wool blanket on 3 sides, half a wool shirt on the bottom and two sock in top.

I'm unsure where to place additional damping material for optimal result.

I'm guessing it's best to avoid to much damping in the top near vent and driver?

- Home

- Loudspeakers

- Full Range

- The new Mark Audio CHN-110 6" driver