Perhaps you already knew, ABEC manual for small "ducts", something to take in account when you get to it:

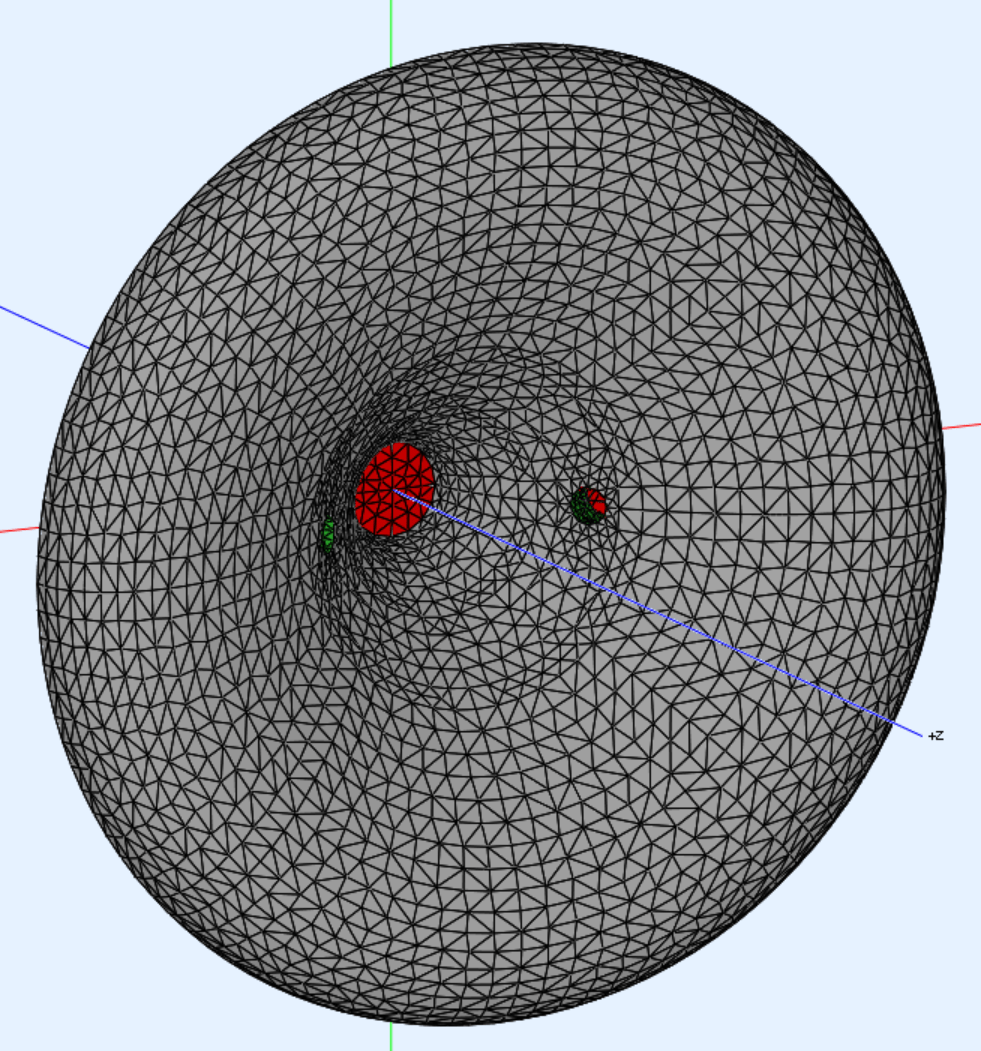

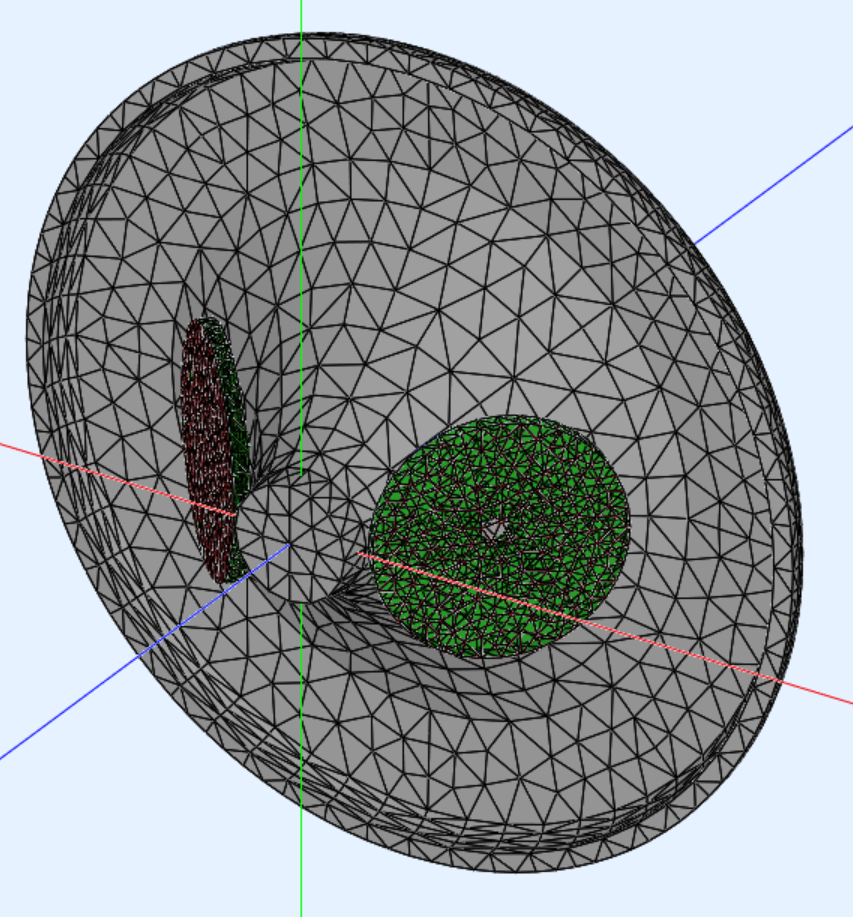

In BEM there is in principal a small exclusion zone around each radiating element within which the sound-field becomes undefined. In theory this zone is infinitesimal small but because we deal with finite elements the size of this zone is finite as well. Normally the auto-mesher makes the elements small enough so that in turn the mutual distance is large enough compared to the wave-length. However, elements can also be too close when, for example, a narrow duct is modeled. Elements of opposite walls may then violate this criterion. Another case is elongated triangles where the distance of the center points is much smaller then the length of the sides. In general, picture a small halo over each triangle having a radius of the inscribed circle. In a good model there is no intersection of these hemi-spheres. Narrow ducts need to be modeled with a higher resolution (see MeshFrequency= or EdgeLength=).

In BEM there is in principal a small exclusion zone around each radiating element within which the sound-field becomes undefined. In theory this zone is infinitesimal small but because we deal with finite elements the size of this zone is finite as well. Normally the auto-mesher makes the elements small enough so that in turn the mutual distance is large enough compared to the wave-length. However, elements can also be too close when, for example, a narrow duct is modeled. Elements of opposite walls may then violate this criterion. Another case is elongated triangles where the distance of the center points is much smaller then the length of the sides. In general, picture a small halo over each triangle having a radius of the inscribed circle. In a good model there is no intersection of these hemi-spheres. Narrow ducts need to be modeled with a higher resolution (see MeshFrequency= or EdgeLength=).

Yes, the taps can be meshed at an arbitrarily high resolution, should this become a problem.

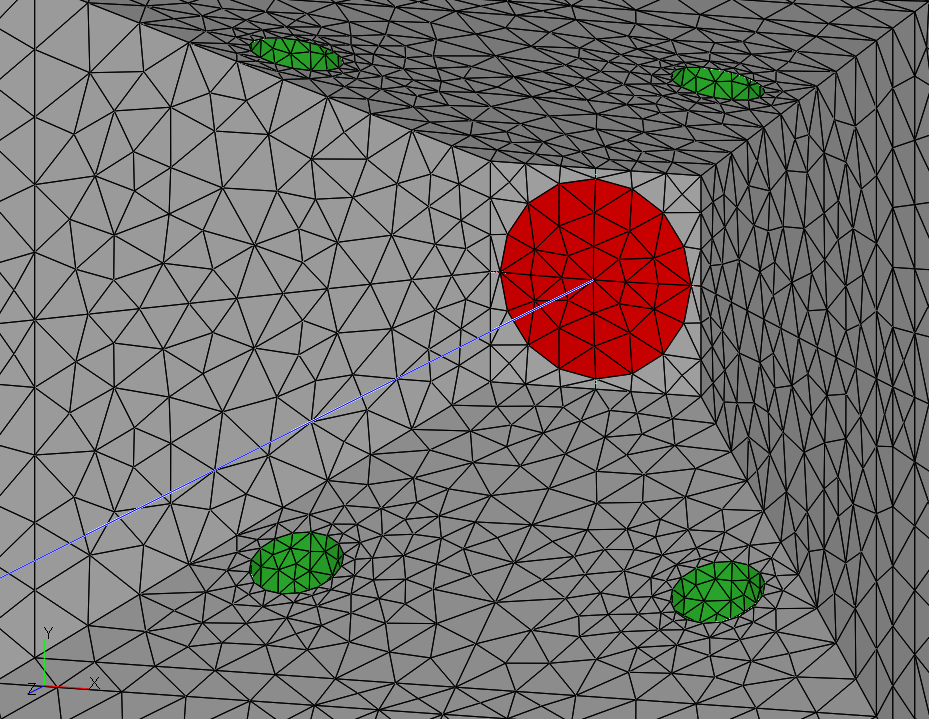

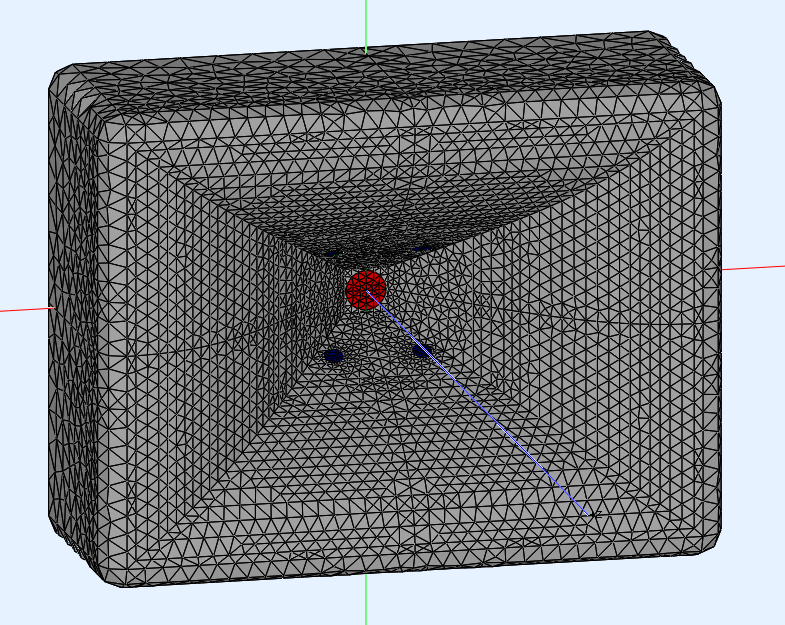

Gmsh does a decent job here -

Gmsh does a decent job here -

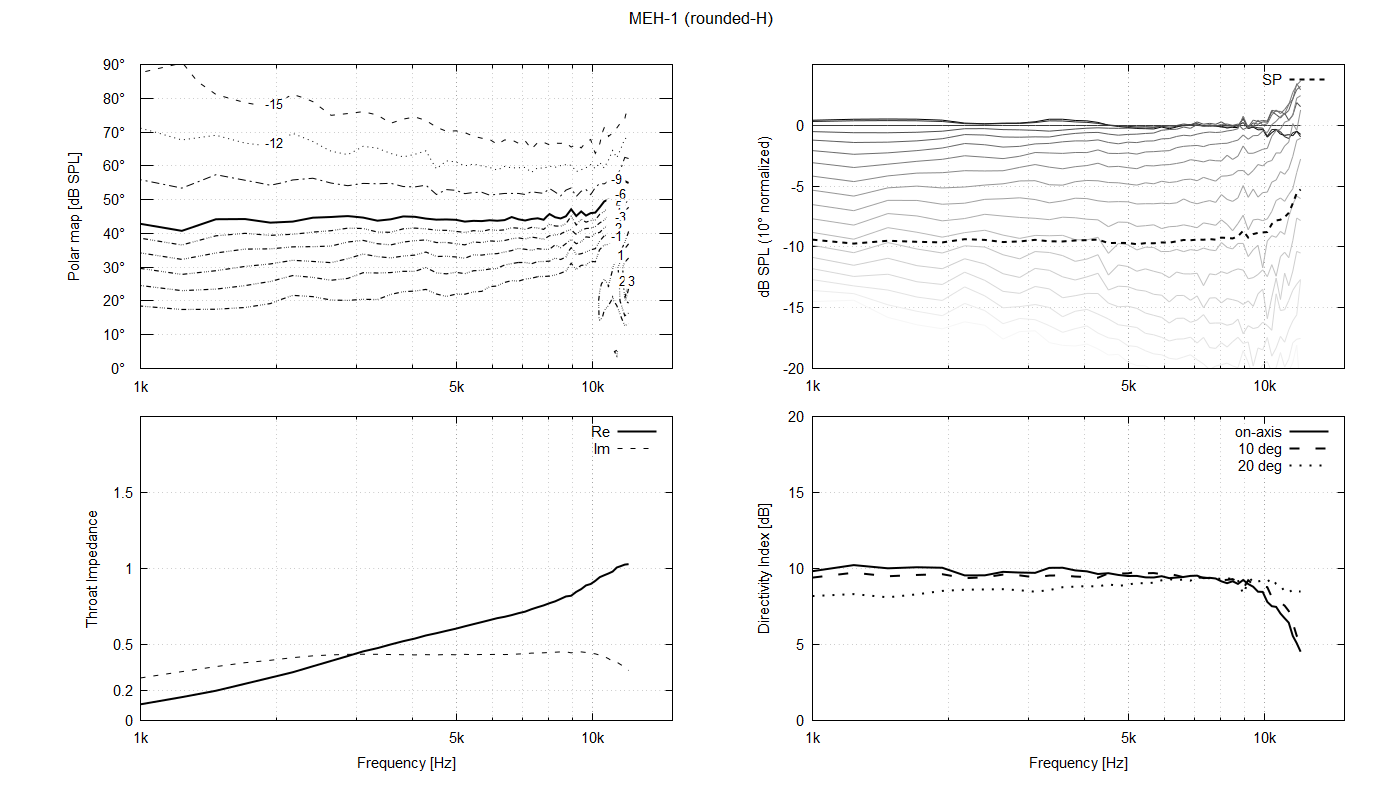

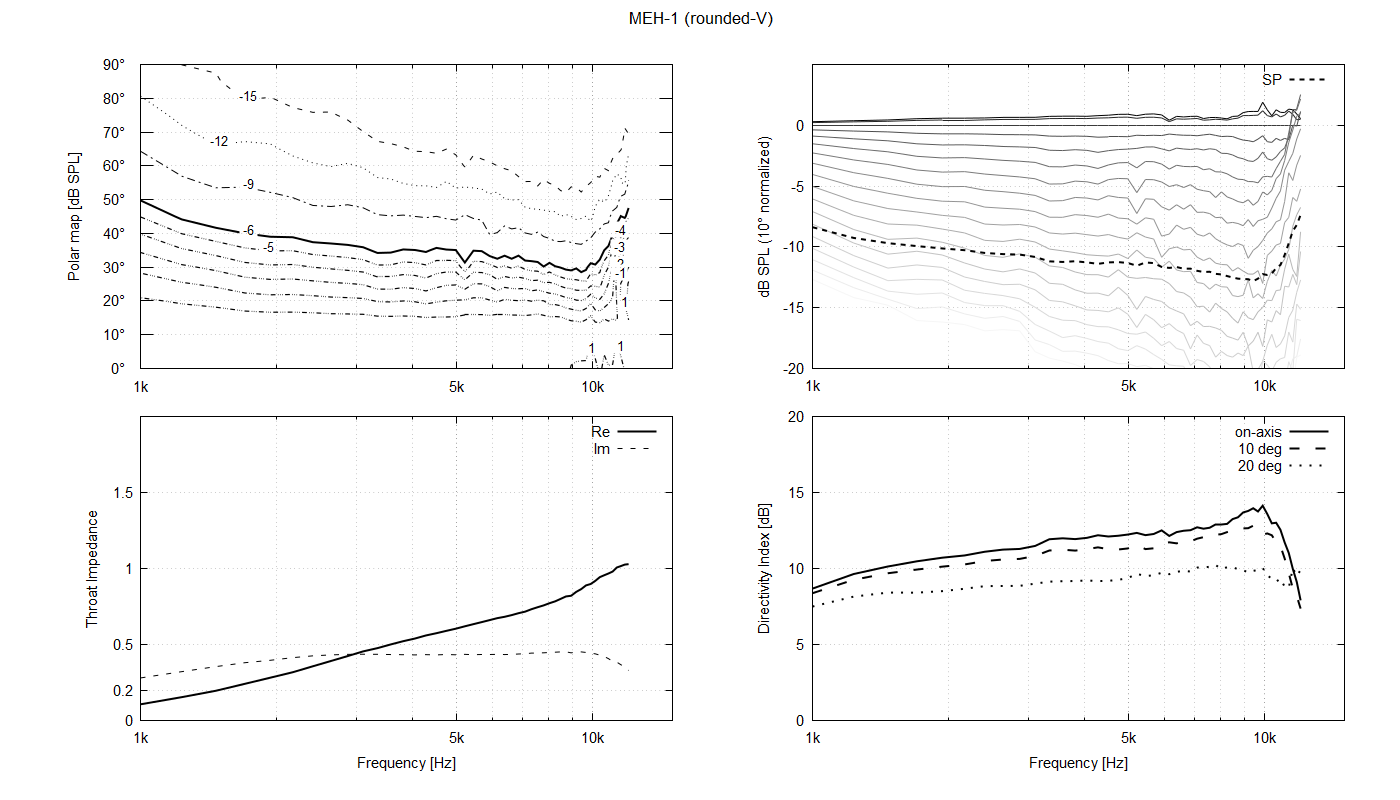

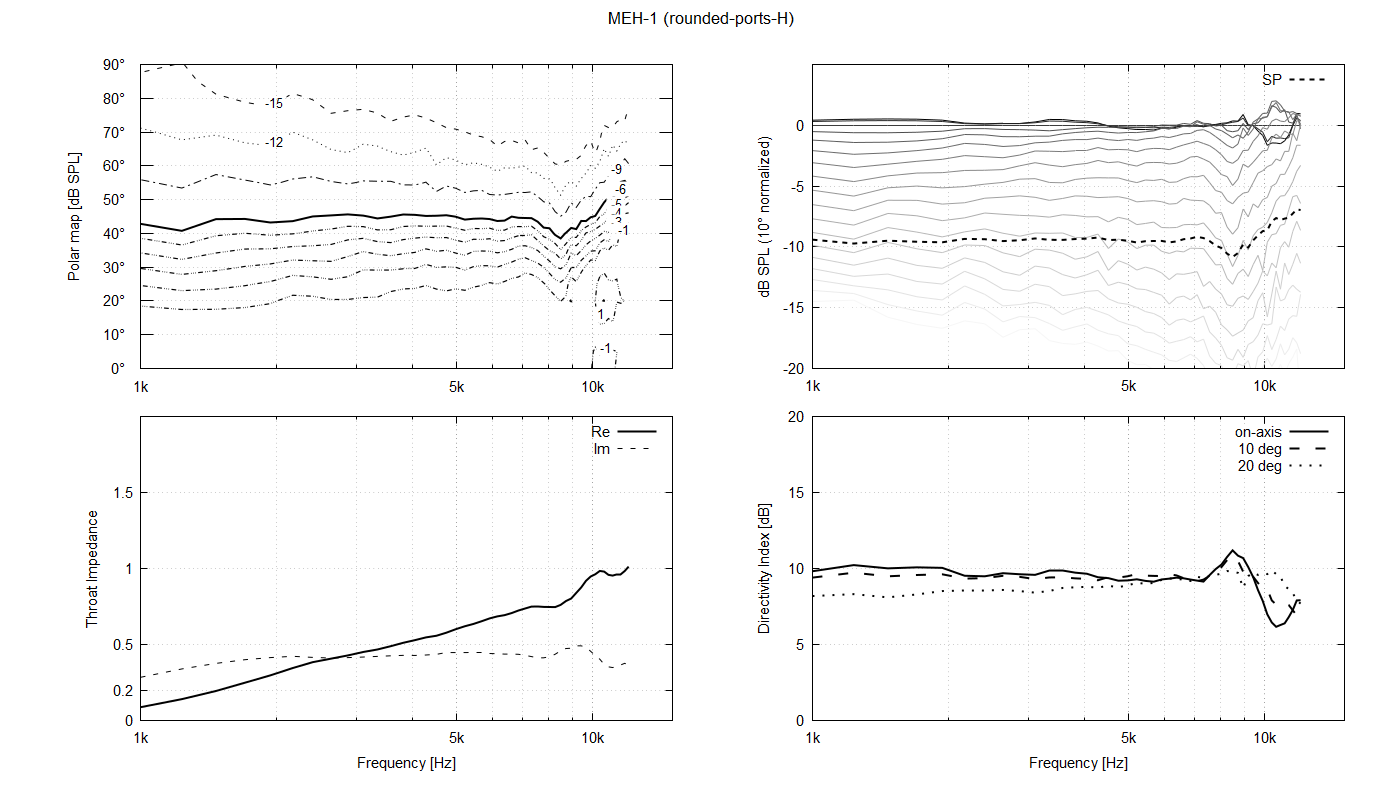

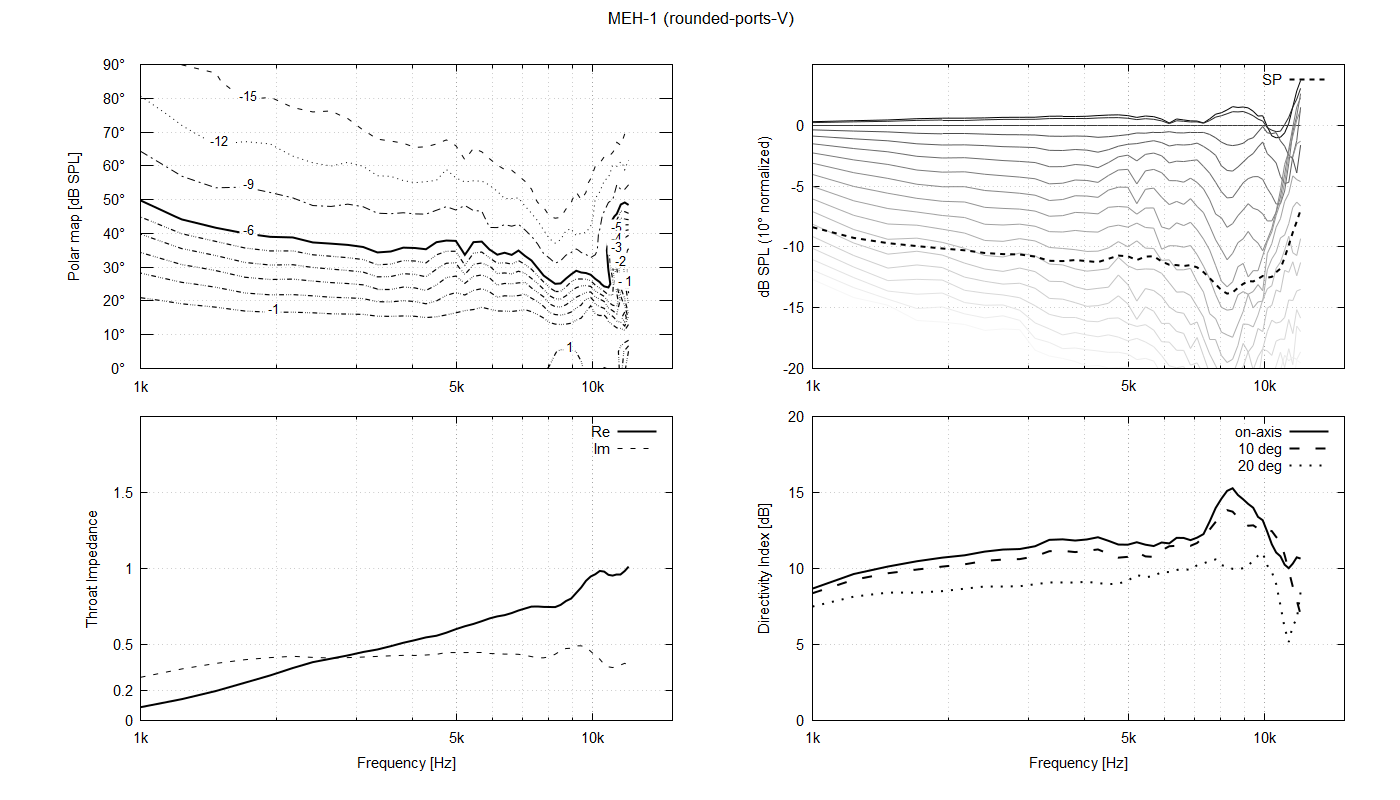

I realized that I mixed up the H/V polars in the previous posts, so here it is again, this time correct (and a rounded enclosure).

Without the ports (horizontal, vertical):

With the ports (horizontal, vertical):

Without the ports (horizontal, vertical):

With the ports (horizontal, vertical):

Awesome mabat !What about a greater number of smaller holes? I even think I've already seen that somewhere. At what diameter of the individual holes would frictional losses become a real issue?

You're about to get me to break down and try to learn ATH.

I've tried a number of perhaps nuts ideas, seeing how to minimize larger low driver ports effect on the compression driver polars.

A cutout from an air-bake pizza pan was one of the most promising....where i could duct tape patterns onto it.

I guess a couple of picts will show what I mean...

This frowny face, as i called it, gave the smoothest response of the many patterns i tried.

A clear effect on the low frequency driver, was how a certain number of holes, a certain area, had to be met not to choke off lower response.

But this was just at low signal level.....never got around to testing at high signal levels to see if additional area is needed.

yeah. And a link to the actual patent:re array of small holes - look at this patent

https://patentimages.storage.googleapis.com/c8/cb/3c/ebd90aeb6f3761/US9894433.pdf

And I quote relevant passages:

"The apertures are angled outwardly...Preferably, the apertures have relatively small diameters, i.e. the diameters are less than the shortest wavelength of the high frequency sound waves... a 20kHz sound wave would have a wavelength of approximately 17mm, meaning that "relatively small" means the aperture is less than 17mm in diameter (or for non-circular apertures, less than 17mm at their widest points... The apertures may be other shapes, including but not limited to ovals, hexagons, squares, and asymmetrical shapes... The apertures are sized and angled such that the difference in distance traveled between the original wave propagation and the redirected wave is less than 1/4 wavelength of the highest frequency wavelength begin generated a(~20kHz)."

Last edited:

17 mm is still not a small aperture in my book 🙂

In the above examples it was 10 - 15 mm. By "smaller" I would imagine say half of that.

In the above examples it was 10 - 15 mm. By "smaller" I would imagine say half of that.

Last edited:

The patent emphasized that the holes must be angled outwardly, so maybe that makes a difference. See the discussion on FIG. 8 (bad) and FIG. 8A (good) (from bottom of column 6 to middle of column 7)

Last edited:

Well, in their case it's an improvement over a midrange diaphragm mounted directly in the wall, which is of course a big NO GO.

re array of small holes - look at this patent

I have no idea if this is an urban legend, but here goes:

I heard that PK Sound got into the subwoofer business largely because they were renting out Danley Labhorns, and they managed to blow up their entire collection of them at the Shambhala music festival one year.

So these guys are definitely aware of Danley's stuff.

It was the success of PK that had me pestering Danley to get into the EDM market, PK is basically ubiquitous at all the festivals that have tons of bass. Datsik and Excision were basically running PK exclusively for a while there. Bassnectar was a big proponent of them too.

two out of three of those DJs got metoo'd, so I'm not sure what the current state of PK is, in the festivals. But they were really ubiquitous for a while there.

Awesome mabat !

You're about to get me to break down and try to learn ATH.

I've tried a number of perhaps nuts ideas, seeing how to minimize larger low driver ports effect on the compression driver polars.

A cutout from an air-bake pizza pan was one of the most promising....where i could duct tape patterns onto it.

I guess a couple of picts will show what I mean...

View attachment 1139464

This frowny face, as i called it, gave the smoothest response of the many patterns i tried.

View attachment 1139465

A clear effect on the low frequency driver, was how a certain number of holes, a certain area, had to be met not to choke off lower response.

But this was just at low signal level.....never got around to testing at high signal levels to see if additional area is needed.

Note that this will change your tuning. You're basically creating a mass loaded transmission line, albeit a very short one.

I heard that PK Sound got into the subwoofer business largely because they were renting out Danley Labhorns, and they managed to blow up their entire collection of them at the Shambhala music festival one year.

So these guys are definitely aware of Danley's stuff.

Jeremy Bridge, CEO of PK Sound had built LAB subwoofers back in 2004, and still had some left in inventory in 2010.

PK also made a horn sub with the same dimensions as the LAB horn sub, the PK- CS212S.

He thanked Danley and PSW (Pro Sound Web, formerly the LAB, Live Audio Board) then stopped posting there.

https://forums.prosoundweb.com/index.php/topic,124929.0.html

A slot mass load 😊 the slot is probably called an offset horn in this case....take a transmission line with an offset driver and make the line a constant csa, now its a slot but if its expanding its a "horn" now.... funNote that this will change your tuning. You're basically creating a mass loaded transmission line, albeit a very short one.

If the port is moved closer to the horn throat does that increase the frequency where the directivity spike happens? In my case, I can't hear above 12kHz. If I move the hole down to where the horn circumference is less than 25mm would the disruption be pushed higher in frequency so it is inaudible to me? And, realistically, it may not have to be that deep into the horn because that is my absolute maximum hearing range. So probably safe at 35mm, 10kHz. And possibly a parabola shaped port where the max width is at 35mm. Downfall is wider bandwidth for DI spike, though maybe softer spike. Or, do a port around the whole circumference of the horn like a coaxial compression driver/woofer (e.g. B&C 12HCX76) that is shorter along the horn length to reduce the bandwidth range. Possibly correcting the DI spike with a Geddes "Tickler" around the circumference?

Why do you think that the ports in the upper/lower wall shouldn't affect horizontal polars?

I guess an overly simplified understanding of directivity control, thanks for clarifying.

Jeremy Bridge, CEO of PK Sound had built LAB subwoofers back in 2004, and still had some left in inventory in 2010.

PK also made a horn sub with the same dimensions as the LAB horn sub, the PK- CS212S.

View attachment 1139638

He thanked Danley and PSW (Pro Sound Web, formerly the LAB, Live Audio Board) then stopped posting there.

https://forums.prosoundweb.com/index.php/topic,124929.0.html

Great stuff, thank you!

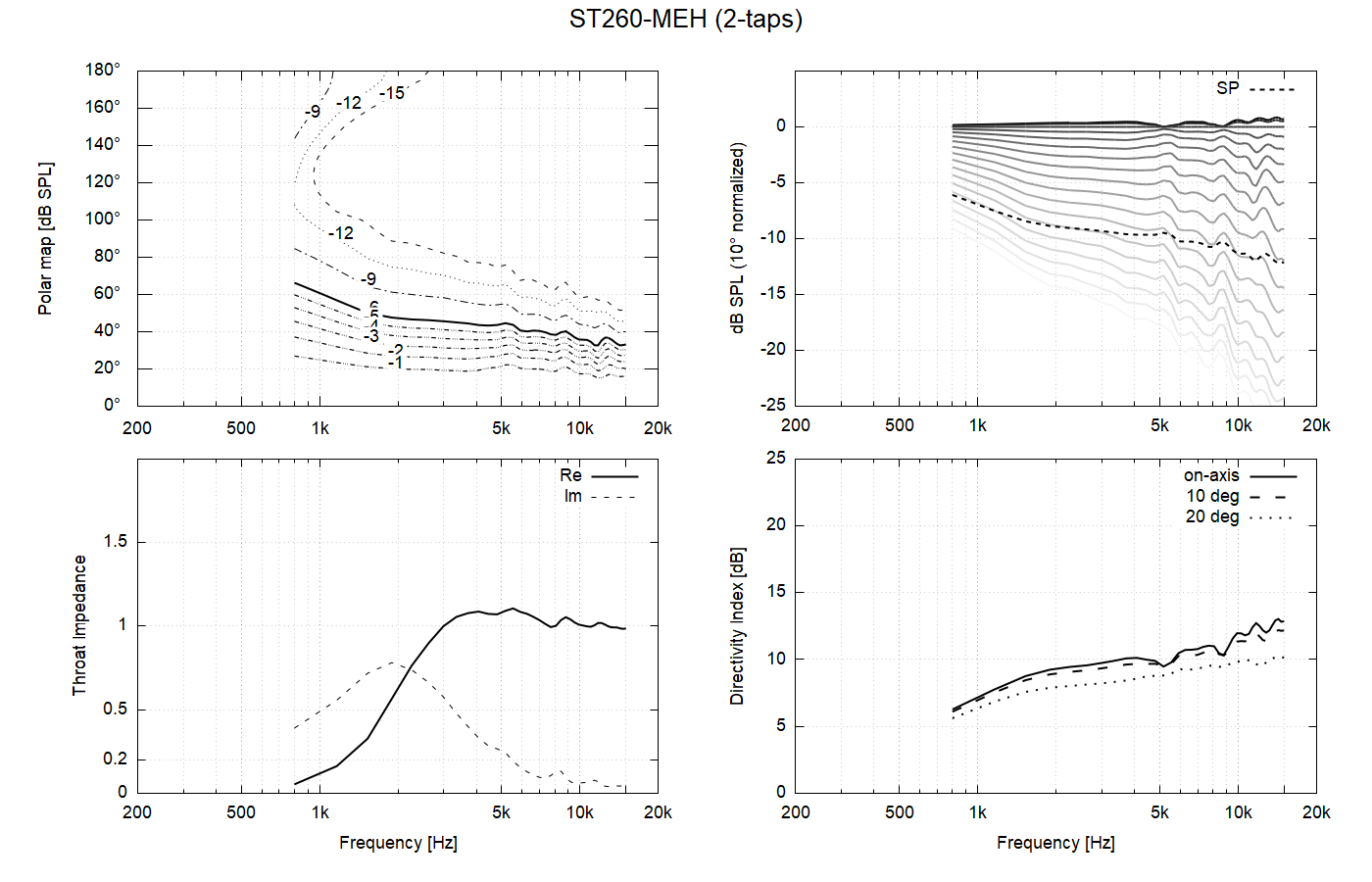

I have to admit this is surprisingly not so bad (ST260 with 2 midrange taps placed 40mm (axially) from the throat):

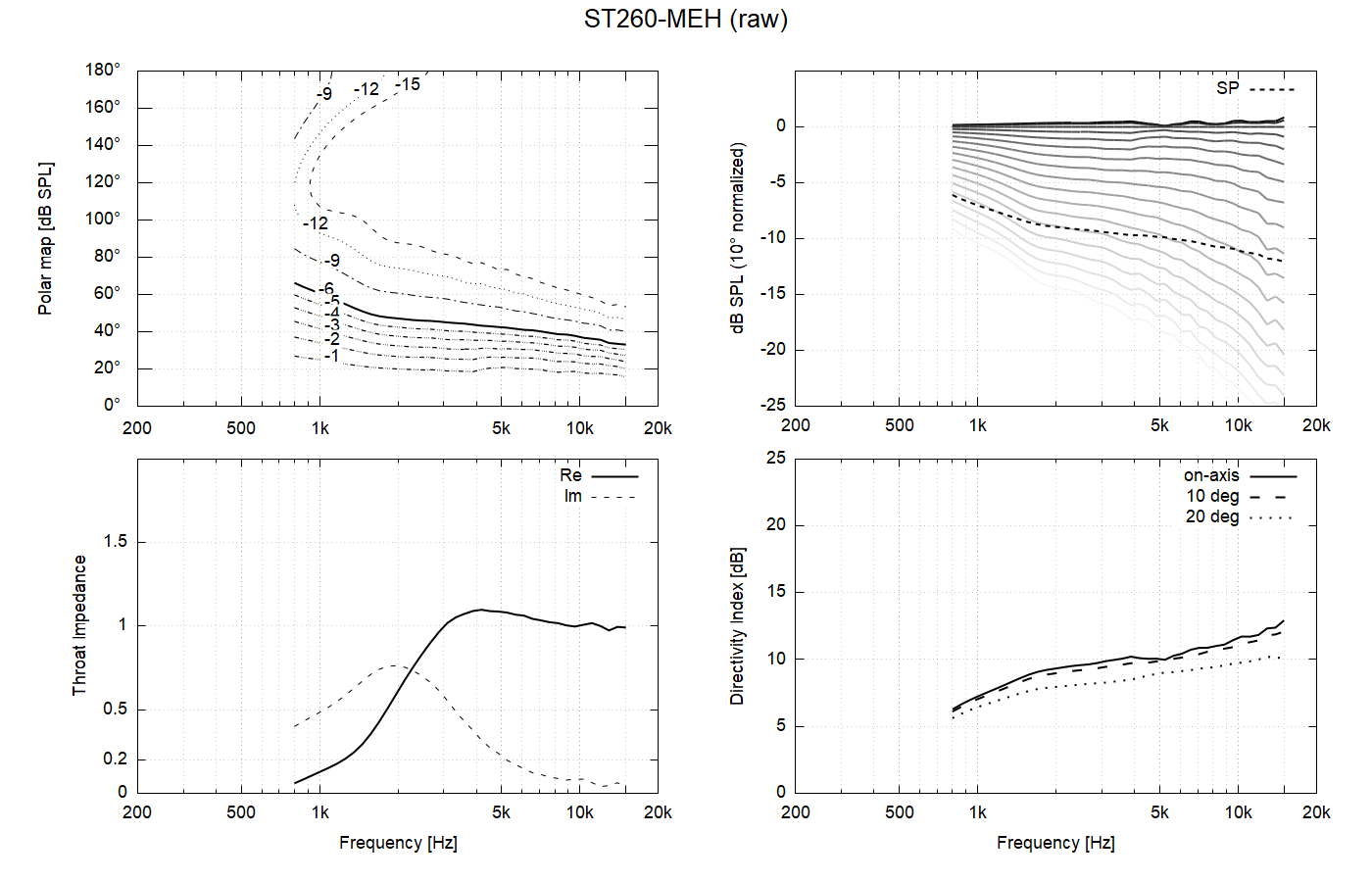

Without the taps (i.e a regular ST260 waveguide):

The MEH version with two midrange drivers (one tap per each):

Without the taps (i.e a regular ST260 waveguide):

The MEH version with two midrange drivers (one tap per each):

A lot of questions I have no answers to (yet).If the port is moved closer to the horn throat does that increase the frequency where the directivity spike happens? ...

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)