Hello Burnt

A free hanging panel is clearly in the situation of no impedance adaptation or damping at the edge.

For a panel with a suspension even all around, it is no so clear for me. Let me explain my thought...

One outcome of our exchange here is to damp or adapt the impedance, a lossy suspension might do the job.

But are all the suspensions lossy?

With the foam I have used for my plywood panel (open cell foam), I have doubt. Seems for me now more a spring than a damper.

A "simple" test of the tape is perhaps simply to pinch it, release it suddenly and see how long it needs to come back to its original shape. A pure spring will do it instantly while a damper needs time; Correct?

I am in the opinion i made a wrong choice of foam.

An electrical impedance measurement should give an idea having a look to the "spike".

I have the idea to go back in the main thread to make a kind of survey of the suspension tapes used. It will be a bit long...

In the mean time, could you remind us Burnt what you used as suspension for your panels?

Christian

PS : I made several tests, not finished panels, with different shapes, surroundings and have been up to now (I mean up to those current posts) disappointed by the poor smoothness of their FR so I agree on the hypothesis an amount of peripheral damping is probably needed. Up to which level is the question. Is there a point where the DML qualities vanished. Among the qualities : the very low directivity, the uncorralated IR in different directions, for a PA application, I would had the low feedback sensitivity. What about also the efficiency?

Hi again Christen @homeswinghome and sorry for the slow response and feedback, I had a family funeral to attend to.

You raise a good point about how we design the suspension-the component that isolates the panel and supports its mass, and the damping. This is something Eric and I discussed briefly a long time back but I agree its well worth think more about and this is the thread to do it in.

"A "simple" test of the tape is perhaps simply to pinch it, release it suddenly and see how long it needs to come back to its original shape. A pure spring will do it instantly while a damper needs time; Correct?" -this is how I understand it too.

"An electrical impedance measurement should give an idea having a look to the "spike"" - again I agree, in principle the ideal response for the 'ripples on a pond' style of DML would be the impulse spike followed by minimal response after that. However I think this would not apply to the chaotic DML mode model as too much damping will reduce the efficiency?

As usual, there is no reliable data, and there is no data I am aware of comparing the two modes so we will have to develop our own.

And to my mind the is a third 'style' of DML that we know produces a good sound, is in part a DML and in part pistonic, the fabric mounted panel in a frame. It would be helpful to have a set of three test panels, each one using the same exciter type and same panel material and dimensions but optimised for the three styles of DML. We can then collect comparable data from these for any performance differences.

On efficiency, Eric reports that somewhat counter intuitively damping increases output, which is a strange but pleasing result.

Burnt

Hi BurntHi Christian,

The first material is a foamed rubber. Here is a link to the Amazon page https://www.amazon.co.uk/Self-Adhesive-Weather-SoundProof-Strength-Anti-Collision/dp/B07P8DT1WR/ref=sr_1_6?crid=CNP3L30ECR0D&keywords=foam+tape&qid=1675254893&sprefix=foam+tape,aps,87&sr=8-6

The second is indeed a Sorbothane

I agree using the metrics from the Sorbothane page is good in principle but I would like to find out how they measure samples so we can standardise measurement of non-Sorbothane samples as well, e.g. the Foowong foamed rubber I am also using. Deflection percentage is a variable that we should be able to measure with a fixed load and probe diameter. We can calibrate any measurement method using the published figures from the Sorbothane Inc website

I remember now you already posted the link to the foamed rubber. Sorry. Thank you

Deflection is one characteristic to evaluate the "spring" effect. What about the damping effect which is time or speed related?

From the limited reading I have done so far it would appear that viscoelasticity determine the time/ frequency determined effect of damping and that is also tested by an impact test.

“Viscoelasticity results in time–frequency dependence of the material (Fig. 1(b) [14,”

https://link.springer.com/article/10.1007/s11340-022-00832-y

“Viscoelasticity results in time–frequency dependence of the material (Fig. 1(b) [14,”

https://link.springer.com/article/10.1007/s11340-022-00832-y

@BurntCoil

Seems an excellent finding for a deeper reading.

Christian

PS : thinking loud, I wonder seeing the drop tower if a simple test where we measure the rebound height of dropping mass would work (or open to smarter idea). Pure spring => rebound high, pure damper => no or low rebound? DIYer thought!

Seems an excellent finding for a deeper reading.

Christian

PS : thinking loud, I wonder seeing the drop tower if a simple test where we measure the rebound height of dropping mass would work (or open to smarter idea). Pure spring => rebound high, pure damper => no or low rebound? DIYer thought!

Last edited:

Hi Christian,

Yes that approach is interesting. Providing the test parameters are standardised for DIY test rigs , e.g. drop height, test mass etc we could gather comparable results. We could also calibrate our results with samples of the materials Sorbothane Inc have tested so we have a baseline.

Burnt

Yes that approach is interesting. Providing the test parameters are standardised for DIY test rigs , e.g. drop height, test mass etc we could gather comparable results. We could also calibrate our results with samples of the materials Sorbothane Inc have tested so we have a baseline.

Burnt

With this thread, I am in the idea collecting the different suspension material. In addition to that , I was wondering the material used by Tectonic... An answer (is the right one?) is in the patent WO2016118341A1

Do you know "Poron"?

Seems a material with high shock resistance, which freezes under high speed impact.

Does it give idea?

Do you know "Poron"?

Seems a material with high shock resistance, which freezes under high speed impact.

Does it give idea?

Helpful Poron data sheet here https://cbfrost-rubber.com/wp-conte...lyurethanes-Product-Availability-Brochure.pdf

It seems there is a wide range of densities and ductility available

It seems there is a wide range of densities and ductility available

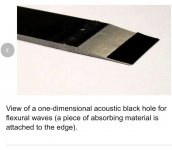

One night i guess i was high, and dreamt about using acoustic blackholes as boundary (make an exponential decrease of the mass in one direction or something like that). Then i ended up thinking if acoustic blackholes are just a marketing academic thing, or a curious sharp way to finish aluminium rods with some mechanical peculiarities. I dreamt about making odd boundary shapes with the help of a twisted hot wire. I mean daydream. I should create the daydreamaudio forum 😛 .

I am not sure to fully understand your post but on my side I wonder what is the effect of the edge shape on a panel, black hole shape or simply a bessel. In my do list. we'll se if can find the time to do it.One night

Christian

Just tested 2 pieces of EPS I have at hand (low grade EPS 13x17cm 7mm thick save from food packaging). red with straight edges, green with a 3cm bezel shape (cut with a knife so a straight cut). Both in free edge conditions (no suspension). Well... it is different. There is an effect around 1kHz, To be continued...

Similar to this, with the damping layer attached to the edge?Just tested 2 pieces of EPS I have at hand (low grade EPS 13x17cm 7mm thick save from food packaging). red with straight edges, green with a 3cm bezel shape (cut with a knife so a straight cut). Both in free edge conditions (no suspension). Well... it is different. There is an effect around 1kHz, To be continued...

Attachments

In the idea yes but in the quick and dirty mode (it tooks me more time to get REW working after my OS update than doing the test!)... The cut is straight (triangular cross section), I think similar to the picture, not 1/x^n shown in the ABH documents and with no damping layer. Proportion seems similar; Mine are 3cm of "ABH" area for 7mm thickness. I will try to find some sand paper in the week end. I would like also to make a test with an elliptical plate.Similar to this, with the damping layer attached to the edge?

If you have experiences, papers on this topic, it would be helpful.

Christian

Quite a comprehensive overview in this paper.

https://www.researchgate.net/publication/354522527_Acoustic_Black_Hole

https://www.researchgate.net/publication/354522527_Acoustic_Black_Hole

"A "simple" test of the tape is perhaps simply to pinch it, release it suddenly and see how long it needs to come back to its original shape. A pure spring will do it instantly while a damper needs time; Correct?" -this is how I understand it too.

Burnt,

This is indeed a good simple test, and one that I use myself as well.

But I want to share for those who might not be familiar with viscoelastic materials the awareness that damping is not a simple material property like say, density, which is pretty constant over a wide range of conditions. I wish it were, but it's not.

Most good damping materials are polymeric materials that have their "glass transition temperature" in the vicinity of room temperature (or whatever the relevant temperature range of operation is). This is the temperature range around which the material goes from a hard state (called glassy) to a soft rubbery state. In both the glassy state and the rubber state on either side of the transition, the material is pretty elastic, and hence not great at damping. However, in the transition region between the two, the polymer becomes very "visco-elastic" and exhibits it's greatest damping properties. In fact, the "glass transition temperture" of a polymer is sometimes defined as the temperature at which it's damping property is at a maximum. I know this because my first task in my first professional job was to make exactly these measurements!

But the thing is, being in a transition region for the material, virtually all the properties of the material, including it's stiffness, and damping, are very sensitive to temperature, AND, deformation frequency. So just at the region where we are most interested in them, their properties are highly variable and frequency dependant! So one caveat to any "damping" test is that it needs to cover or simulate the deformation frequency of interest in order for it to be relevant. This is one reason, I suspect that the pinch and release method can be misleading.

Here's a good introduction.

https://www.roush.com/wp-content/uploads/2015/09/Insight.pdf

Eric

Wooow ! it really seems to be doing something 🙂 . Seems to be shifting the response a couple of hertz down and extending range a little, but certainly is doing something. Thanks for sharing!Just tested 2 pieces of EPS I have at hand (low grade EPS 13x17cm 7mm thick save from food packaging). red with straight edges, green with a 3cm bezel shape (cut with a knife so a straight cut). Both in free edge conditions (no suspension). Well... it is different. There is an effect around 1kHz, To be continued...

Eric, what epoxy resins have you used for your composite panels.I know this because my first task in my first professional job was to make exactly these measurements!

My assumption is a mode shift in the 1kHz area. The change in HF might be simply the difference between the 2 samples. Exciter and mic position were kept but the exciter positions probably not the same on both samples.Wooow ! it really seems to be doing something 🙂 . Seems to be shifting the response a couple of hertz down and extending range a little, but certainly is doing something. Thanks for sharing!

West systems 105/207. Do you have a favorite?Eric, what epoxy resins have you used for your composite panels.

Got it, low TG. Resoltech 1020T/ Resoltech 1029S and 1025S.West systems 105/207. Do you have a favorite?

Hey Lenta,Resoltech 1020T/ Resoltech 1029S and 1025S.

Do you do a 60 C post cure to get the highest Tg?

Eric

- Home

- Loudspeakers

- Full Range

- Effect of Boundary Conditions on the Ringing of DML Speaker Panels