Where is your practical experience????? where's the data that proves that assertion Cumbb?

The simplest test: put a wooden plate under your amplifier and listen for a while. Then put a metal plate under your amplifier and listen. You can also put a stone plate under your amplifier and listen. Or put a rubber plate under your amplifier, and listen. Or put something else under your amp. For all I care "double blind", mute, deaf, without sense of smell...-)

I will quote you in the future: You will be my "data that proves"-)

thanks for supplying objective data Cumbb...

in my 40 plus year doing live audio and working as a service technician i've encountered all manner of substrate, orientation, and device operation conditions that i do feel i have a fair understanding of what is relevant and what isn't...by the way i have a Bybee unit i was sent for evaluation and is as yet unclaimed, would you be interested?

in my 40 plus year doing live audio and working as a service technician i've encountered all manner of substrate, orientation, and device operation conditions that i do feel i have a fair understanding of what is relevant and what isn't...by the way i have a Bybee unit i was sent for evaluation and is as yet unclaimed, would you be interested?

Trying to understand this design and not quite sure what they were thinking here..not to confound the topic more but i have to wonder about whether or not something like this would prove more effective....

View attachment 1112330

Most heat sinks are about more surface area but this seems to closed down instead of open

structured.

The size of this might be a clue and maybe smaller than the photos indicate

Is there a mfgr. Info sheet on this ?

Agree. This one seems to have done a great job of maximizing surface area but looks like it would only be effective vertically or with forced air. I would suspect that it is not largeTrying to understand this design and not quite sure what they were thinking here..

Most heat sinks are about more surface area but this seems to closed down instead of open

structured.

very astute gentleman this is not a manufactured product as of yet it comes from an engineering study and is intended to be use with forced air but is an exploration into whether or not increased surface area will achieve better efficiency.

;-)thanks for supplying objective data Cumbb...

in my 40 plus year doing live audio and working as a service technician i've encountered all manner of substrate, orientation, and device operation conditions that i do feel i have a fair understanding of what is relevant and what isn't...by the way i have a Bybee unit i was sent for evaluation and is as yet unclaimed, would you be interested?

Then you know about the influence of material resonances on the "electron flow";-) And also on the function of the "hearing": to perceive differences;-)

When I was working, some of the military airborne equipment that we designed employed short pin fins, similar to above but not tapered (cylindrical pins). This was for applications where we were not permitted a fan and the airflow direction was not well defined.and so as to remove the pigeon hole thinking about orientation this design is intended to work horizontal as well as vertical (but data shows it's performance is degraded when the sink is oriented points down and the heat source is at the top)

View attachment 1112338

I’ve noticed that for some people, the biggest sound change comes from their hollow heads. As they have no gray matter for damping, ridiculous theories freely resonate in their heads, altering what they hear. 😉Aside: We listen to every screw, hood, every material, every mass-stiffness relationship on our equipment. Heat sinks are often large, heavy, vibrate terribly, which modulates the sound.

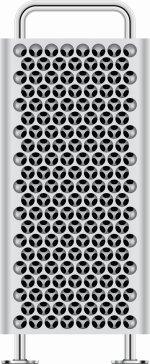

While I really can't imagine how such a structure as in the post above can possibly be made, I think it could be interesting to experiment with a geometry inspired by apple's MacPro front-grille (that disputable lattice-design) — said to be used for a) the touch of techy luxury b) weight management , and I believe, c) maximum airflow... could it possibly act as an efficient heatsink?

(

https://upload.wikimedia.org/wikipe..._Pro_Mockup.svg/1200px-Mac_Pro_Mockup.svg.png

https://saccade.com/blog/2019/06/how-to-make-apples-mac-pro-holes/

)

(

https://upload.wikimedia.org/wikipe..._Pro_Mockup.svg/1200px-Mac_Pro_Mockup.svg.png

https://saccade.com/blog/2019/06/how-to-make-apples-mac-pro-holes/

)

Attachments

Yes. This is actually the front air intake vent on the Mac Pro, not a heat sink per say. There are three large exhaust fans at the rear. The processor has heat pipes to an internal finned heat sink. Having been in the Apple "universe" for 20 years, I can say that thermal design has never been a strong suit for them. It has always taken a seat behind style. The Mac Pros have been the only real exception.That would require a fan to blow air through it for heat transfer.

If I believe that some amplifier or other equipment is running too hot, I place an MCP9808 I2C sensor inside and record temperature for a while. This device is not thermally bonded, it just dangling from a cable. Otherwise, the component temperatures would be TBD higher.

Usually, if the temperature exceeds 50C, I implement some mod to reduce the operating temperature. For example:-

Usually, if the temperature exceeds 50C, I implement some mod to reduce the operating temperature. For example:-

- Schiit Audio Loki Mini+ ..unventilated case feels extremely hot. When I opened the cover, touching the filter caps stung my fingers. It uses SMD 317-337 regulators supplied by a 16vac, 20watt wall-wart. I substituted a 12vac wart which makes the case warm instead of hot.

- Vintage NAD C 320 intermittent because 37vdc discretely regulated to 18vdc with the pass transistor mounted on a vertical PCB heatsink. I added a preregular to drop 37dc to 24dc and also a small CPU fan. The chassis is only partially vented so the fan stirs the air to reduce hot spots.

;-)

A push-pull-amplifier does not have to run in a high class a range. Most pp amplifiers are also adjustable in bias. The sonic difference is not great. A lower quiescent current usually sounds a bit more disembodied, "flatter", seemingly with more "noise": "breath", "livelier", "fresher".

A push-pull-amplifier does not have to run in a high class a range. Most pp amplifiers are also adjustable in bias. The sonic difference is not great. A lower quiescent current usually sounds a bit more disembodied, "flatter", seemingly with more "noise": "breath", "livelier", "fresher".

boy, i wish there was a device like a universal translator that could convert descriptive terms to actual measurements and data....ahhh but that put an end to those Objectivist/Subjectivist debates.

You could use anodized or coated or any painted sinks too. Grinds the transistor contact surface flat, rounds the edges.Back on topic...

If you mount the heatsink(s) inside the enclosure, you can float it(them) to the output device(s)' C or S, so you don't have to isolate the their packages electrically, saving a fair amount of thermal resistance.

Various insulation discs for transistors have different influence on the sound. You could use paper or some foils too.

show me the data....why do i feel like Cuba Gooding Jr. right now????Various insulation discs for transistors have different influence on the sound.

- Home

- Amplifiers

- Solid State

- Internal vs External Heat-Sinks