Yes you can be pretty sure that the audio runs through a SoC first. As far as I know, Sonos is using mainly chips around NXP i.MX-family, Mediatek and Amlogic.... The audio must be processed in the SoC at first, because every unit can also restream the audio to other speakers in the network. Then they can generate two parallel I2S streams from that (and also speaker-processing, X-over, EQ and so forth is computed there).It looks like this device can accept SPDIF 5.1, so I can't picture how this would work. Is there a chipset that converts 5.1 into multiple I2S data streams to feed the MA12070P amplifiers? Seems it would be easier to use MA12070 amplifiers instead. 🤔

Mkhunt’s figure 15 shows what could be gained if the amp had 3 levels (24, 12 and 6 volts of supply voltage) We se clearly how the efficiency gets better at low watts with lower supply voltage

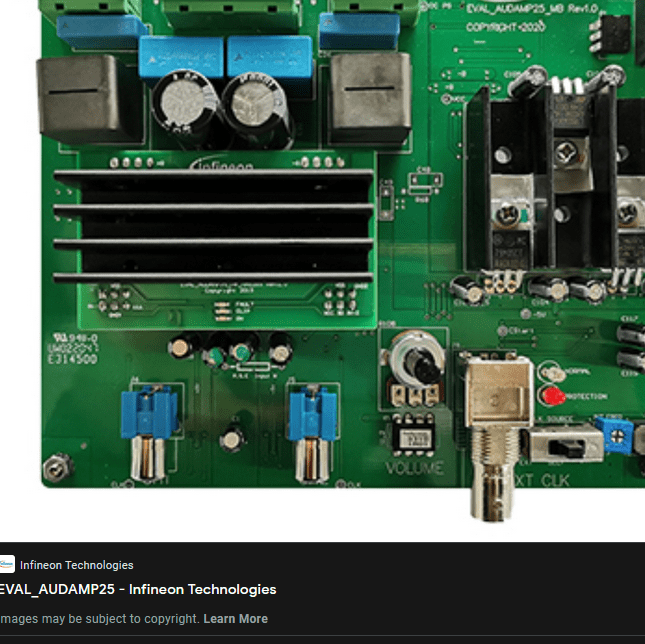

For the new 200w part they even make fun of heatsinks: https://www.infineon.com/cms/en/pro...cs/ma5332ms/#!?videoId=6mUSJP_1Mg1JvPk7MoENJ1

This is really useful, thanks. Gives me some good pointers when comparing with other amps too.To answer your previous question...

I think their marketing seems fairly geared towards this - heatsink-less and no-filter (or rather, just a ferrite bead) output. I was going the opposite way and trying to decide whether it's worth getting one side of a heatsink near the vent of a ported speaker, probably overkill to be fair.For the new 200w part they even make fun of heatsinks: https://www.infineon.com/cms/en/pro...cs/ma5332ms/#!?videoId=6mUSJP_1Mg1JvPk7MoENJ1

Probably because the manufacturer, not the people, tells us "heatsink free operation with Epad-down package" and because it stays relatively cool at moderate sound levels. One could run it at maximum sound levels for a longer time, comparable with driving a car at maximum speed but why?!The TPA3255 is less efficient. This is partly why I am confused about people heatsinking TPA amps and saying the MA12070 does not need to be heatsinked. I guess under 10W neither would need a sink but both will live a whole lot longer and have lower distortion with a proper heat dissipation method.

I paid attention to your emphasis on temperature but my measurements tell me it simply runs relatively cool. It is a non issue when using it normally and also because many cheap amplifiers do have a heatsink besides the epad copper pour. In fact I haven't had one that lacked a heatsink. So in reality they have better cooling than the manufacturer recommends 🙂 I have my doubts about the efficiency comparison when used at moderate sound levels as well but never mind.

The lack of even simple ferrite beads as seen in many amplifiers is an issue.

Last edited:

I think it's about duty cycle for me. In a little portable speaker or for a tweeter channel, I'd try running them heatsink free. If I'm using it for bass I'll use a heatsink. I don't see any point running them at the 10% thd levels, so there'd be less power to dissipate. I should add a disclaimer to all my posts though, I have zero experience with this chip.

Probably because the manufacturer, not the people, tells us "heatsink free operation with Epad-down package" and because it stays relatively cool at moderate sound levels. One could run it at maximum sound levels for a longer time, comparable with driving a car at maximum speed but why?!

I paid attention to your emphasis on temperature but my measurements tell me it simply runs relatively cool. It is a non issue when using it normally and also because many cheap amplifiers do have a heatsink besides the epad copper pour. In fact I haven't had one that lacked a heatsink. So in reality they have better cooling than the manufacturer recommends 🙂

The lack of even simple ferrite beads as seen in many amplifiers is an issue.

I would argue this is true if they typically ever attached the pads. But the pad hardly ever makes decent contact with the PCB so it's just insulated by air gap. Air is a great insulator.

I'm not saying it needs a heatsink. I'm just saying they need to attach the epad. Epad contact > heatsink on top of a highly insulated barrier. I think we are saying the same thing at the end of the day. You are saying "follow the design recommendations" and I am saying "don't cut the same corners as mass market integrators."

because many cheap amplifiers do have a heatsink besides the epad copper pour. In fact I haven't had one that lacked a heatsink.

I was just looking at the Aiyima A8 internals. Looks clean but what do I know. Not the biggest heatsink but I'm sure it's enough.

Thougt epads should always be soldered? https://www.maximintegrated.com/en/design/technical-documents/app-notes/3/3273.htmlI would argue this is true if they typically ever attached the pads. But the pad hardly ever makes decent contact with the PCB so it's just insulated by air gap. Air is a great insulator.

I'm not saying it needs a heatsink. I'm just saying they need to attach the epad. Epad contact > heatsink on top of a highly insulated barrier. I think we are saying the same thing at the end of the day. You are saying "follow the design recommendations" and I am saying "don't cut the same corners as mass market integrators."

YEah, that is the point of them. THey just seem to be mysteriously not attached in most chi-fi. like the soldering of that is more difficult than designing a heatsink mount somehow. It;s just confusing to me.Thougt epads should always be soldered? https://www.maximintegrated.com/en/design/technical-documents/app-notes/3/3273.html

ETA: I think the board styled after the eval module as shown several times in this thread is built to-spec though. It also has at least some ferrite beads which is more than some amps cough*topping*cough. Though for being literally filterless, the topping amps do sound impressive. The MA12070 seems like it is faitly easy to please.

I was just looking at the Aiyima A8 internals. Looks clean but what do I know. Not the biggest heatsink but I'm sure it's enough.

View attachment 1105736

Why are those air-core inductors needed in the output? They filter out high frequencies or what, and why?

According to the data sheet this chip is not really inductor-less but requires >1uH series inductors to make it short-circuit proof. You often find ferrite beads here - but these could saturate at higher currents. Thus an air-coil is not the worst bet. Its disadvantage of a high fringing field could be avoided by chosing a toroidal shape (Rogowski coil) instead. Btw - I wonder if its inductance even comes close to 1uH.Why are those air-core inductors needed in the output? They filter out high frequencies or what, and why?

Last edited:

I saw a discussion about another amp using the same chip and not using any inductor. Someone said it still works because the connected speaker supplies the inductance. So maybe those shiny exposed copper coils are just there for looks n marketing to plebs like me who know very little about audio circuits?According to the data sheet this chip is not really inductor-less but requires >1uH series inductors to make it short-circuit proof. You often find ferrite beads here - but these could saturate at higher currents. Thus an air-coil is not the worst bet. Its disadvantage of a high fringing field could be avoided by chosing a toroidal shape (Rogowski coil) instead. Btw - I wonder if its inductance even comes close to 1uH.

Do you think with or without or depending on size and quality the inductors can make any audible difference to the sound?

Last edited:

Maybe you could read the datasheet? All class D amplifiers till now needed either ferrite beads or coils to form an output filter including the loudspeaker coil. It is not marketing. Saying it is "filterless" is mainly marketing. The Chi-Fi design rule is to make the filters as cheap as possible so underrated parts, minuscule ferrite beads or the usual ... no filter at all. A coil + caps = good. A ferrite bead + caps = adequate. A single air coil = mmmmm but better than nothing. Nothing at all = not OK. Selection criterium for an MA12070 amplifier is to pick one with any form of filtering. No filtering is bad choice.

https://www.infineon.com/dgdl/Infin...N.pdf?fileId=5546d46264a8de7e0164b359d78016f6

The A8 is one of the better cheap MA12070 designs.

https://www.infineon.com/dgdl/Infin...N.pdf?fileId=5546d46264a8de7e0164b359d78016f6

The A8 is one of the better cheap MA12070 designs.

Last edited:

Think this is the cheapest PL-AD-160 board now on Aliexpress.

https://www.aliexpress.com/item/100...store_pc_home.smartJustForYou_6000601971963.0

https://www.aliexpress.com/item/100...store_pc_home.smartJustForYou_6000601971963.0

€ 42,33 for me there. 🙂no, here it is for $32.30 w free shipping https://www.aliexpress.us/item/3256804087518841.html

Either way, that board which I think is a carbon copy of Infineon's eval board actually does a ton of things right. Since it is wired for BAL it;s pretty obvious they meant it for active speakers or something where the wire lengths are super short. A little expensive if you want PBTL, and I guess once you add the PSU it's not particularly inexpensive either but yeah. It;s like a pure datasheet board (which isn;t bad in this case). TI also tends to make some really killer eval boards. I could only do an 8k VR setup over a 50' fiber DP cable due to a TI eval board for a DP1.2x repeater.

Only for 25W though... at 10% distortion. The MA5332 is internally closest to an IRF209x chip. Thermally, the MA12070 is in a whole other league. Infineon also has a whole page (3-5 images) about heatsink mounting on the flip side of the PCB (the chip faces the other PCB).For the new 200w part they even make fun of heatsinks: https://www.infineon.com/cms/en/pro...cs/ma5332ms/#!?videoId=6mUSJP_1Mg1JvPk7MoENJ1

The A8 is one of the better cheap MA12070 designs.

thank you, from someone who doesn't know enough to get anything from reading the datasheet.

If you will, what in particular do you like about the A8 design compared to some others?

For the 12070?.

Only for 25W though... at 10% distortion. The MA5332 is internally closest to an IRF209x chip.

In the video they show ma5332 with 2 x 100w out and less than 220w in. And without heatsink

- Home

- Amplifiers

- Class D

- Infineon MA12070 Class D