No that is not true. With thinner laminations the permeability drops a lot. That's information Vacuumschmelze gives about there cores.The thinness of the laminations has the benefit of maintaining the effective permeability of the core (and hence primary inductance) to as high a 'low frequency' as practical, with the aim of suppressing low frequency phase shift and roll-off gain in the region where it can complicate GNF stability. This topic come up recently in https://www.diyaudio.com/community/...ncy-dependent-inductance.389901/#post-7118671 . The last reference in that discussion is available via https://ur.booksc.eu/book/39310494/1a2ebb .

Intersting, Can you post a link? ThanksThat's information Vacuumschmelze gives about there cores.

People acting like winding a transformer is tougher than plotting outer space trajectory on a slide rule.

Unfortunately no link, it's from a datasheet i have from Vacuumschmelze "strip wound cut cores"Intersting, Can you post a link? Thanks

You mean like "Only one kid at a time! " , or "No crawling back up !" ?People . . . . . . . . . on a slide rule.

Last edited:

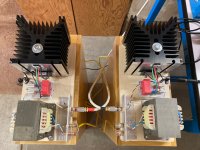

Cheater. That looks very solid state, where impedances tend to be on the low side. It’s realizing high quality high impedance transformers that are difficult. A lot of turns = a lot of problems.

Thanks for posting the graph.Unfortunately no link, it's from a datasheet i have from Vacuumschmelze "strip wound cut cores"

But as I understand it, eddy current losses also go down . How much that influences sound, I don't know, but it's talked about in so many papers that it must be worth some consideration.With thinner laminations the permeability drops a lot.

Sounds like a great starting point as coil winding is a skill. Many years ago part of my job was winding eddy current probes. It was satisfying watching the wire layer perfectly.Cheater. That looks very solid state, where impedances tend to be on the low side. It’s realizing high quality high impedance transformers that are difficult. A lot of turns = a lot of problems.

The eddy currents get down with thinner laminations indeed but with higher frequencies they go up. But, core exitation levels at higher frequencies go down rapidly. Most of the time your speaker has more limitationsThanks for posting the graph.

But as I understand it, eddy current losses also go down . How much that influences sound, I don't know, but it's talked about in so many papers that it must be worth some consideration.

High impedance transformers are not really a problem, even compared to low impedance transformers, this is over exaggerated. In fact, low primary impedance have problems on their own, for example coping with leakage inductance, where in high Z transformers you have watch out for shunt capacitance. There are however some issues with unrealistic expectations, especially for step-up transformers.Cheater. That looks very solid state, where impedances tend to be on the low side. It’s realizing high quality high impedance transformers that are difficult. A lot of turns = a lot of problems.

as step-up for electrostatic speakers?High impedance transformers are not really a problem, even compared to low impedance transformers, this is over exaggerated. In fact, low primary impedance have problems on their own, for example coping with leakage inductance, where in high Z transformers you have watch out for shunt capacitance. There are however some issues with unrealistic expectations, especially for step-up transformers.

Ok, next time I'll use salvaged wire too.Cheater. That looks very solid state, where impedances tend to be on the low side. It’s realizing high quality high impedance transformers that are difficult. A lot of turns = a lot of problems.

Salvaged iron?

No big deal.

Salvaged wire????? 😱

Avoid it like the pest it is.

Main feature of insulated wire (called magnet wire by some) is .... ummmmm ... its insulation , which depends 100% on its enamel integrity.

I do NOT repeat NOT trust it,period.

Hate junking expensive stuff like anybody else, but I do the next best thing: collect it in a bucket (not kidding) and trade it in exchange of new wire at my wire supplier, then it travels the supply chain backwards until it goes to a smelter and wire maker.

High cost of raw copper makes this system run smoothly.

Absolute worst case, sell it by the pound/kilo to your friendly local metals recycler.

No big deal.

Salvaged wire????? 😱

Avoid it like the pest it is.

Main feature of insulated wire (called magnet wire by some) is .... ummmmm ... its insulation , which depends 100% on its enamel integrity.

I do NOT repeat NOT trust it,period.

Hate junking expensive stuff like anybody else, but I do the next best thing: collect it in a bucket (not kidding) and trade it in exchange of new wire at my wire supplier, then it travels the supply chain backwards until it goes to a smelter and wire maker.

High cost of raw copper makes this system run smoothly.

Absolute worst case, sell it by the pound/kilo to your friendly local metals recycler.

ascocomponents.co.ukI've been thinking that it would be fun to go through the process of designing and building a pair of 5k push-pull output transformers, to be driven by a pair of 40W beam tubes. I've read through Patrick Turner's website and I'm sure that there are a more than a few good people here on this forum that I could come to with questions. I think I could get to a workable design and maybe if I'm lucky, a design that even works well.

My main concern is buying parts I would need. Most of the parts don't seem easy to buy in small quantities. Are there places to buy cores and wire in those quantities? I've come across Brideport Magnetics in my searches, anybody ever order from them? Or any other places?

I don't expect that I'd save money over buying a pair of good transformers. I don't care about the money. This is more about having a learning experience.

I have a whole bucket of it - and I use it for making speaker crossover coils, car amp DC-DC converter trafos, and some types of SMPS filter chokes. Nowhere were plug-in power is required or if there is a lot of volts between turns. That lets you save all the expensive virgin wire for making power trafos.Salvaged iron?

No big deal.

Salvaged wire????? 😱

Avoid it like the pest it is.

Main feature of insulated wire (called magnet wire by some) is .... ummmmm ... its insulation , which depends 100% on its enamel integrity.

I do NOT repeat NOT trust it,period.

I don’t think he was being serious there. Those did look like salvaged cores. Works fine for power trafos, or audio at impedances where a little leakage reactance and distributed capacitance aren’t going to bother anything, and where a relatively low primary inductance can be tolerated.

I wasn't 🙂 But I will be serious in suggesting that no one should be daunted by the prospect of winding their own output trafo, whether for electrostatics or some weird tube or for a cheat move like driving it with a MOSFET just to see what your old microwave oven sounds like. It won't be perfect and that's okay, 80/20 rule and all that, this is DIY afterall, not dialysis.I have a whole bucket of it - and I use it for making speaker crossover coils, car amp DC-DC converter trafos, and some types of SMPS filter chokes. Nowhere were plug-in power is required or if there is a lot of volts between turns. That lets you save all the expensive virgin wire for making power trafos.

I don’t think he was being serious there. Those did look like salvaged cores. Works fine for power trafos, or audio at impedances where a little leakage reactance and distributed capacitance aren’t going to bother anything, and where a relatively low primary inductance can be tolerated.

- Home

- Amplifiers

- Tubes / Valves

- Winding my own output transformers...dumb idea?