What are you basing this on?I think there will always be some reflection at the driver/throat interface.

It was shown in this thread many times.

With Ath & ABEC it's a simple exercise.

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6248583

With Ath & ABEC it's a simple exercise.

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6248583

Ok, I see you've changed your earlier post to indicate it's probably not a good idea. Yes, the idea of managing HOMs at the signal level didn't seem right.

That's not what I said. The zero-mode reflection can be managed. It's being done all the time.

- What's still not very clear to me, however, is how it relates to an area expansion rate. Since there probably can be a reflection even without an area change (like in a bended tube or similar), I guess it's not really the same thing.

- What's still not very clear to me, however, is how it relates to an area expansion rate. Since there probably can be a reflection even without an area change (like in a bended tube or similar), I guess it's not really the same thing.

Last edited:

No, it's a regular print. It's just an OS-based shape, there's really no reason to use anything else I think. The continuously decreasing curvature being an advantage, it's almost zero at the exit.

View attachment 1091731

That print quality is unreal. What size nozzle and filament?

So it was one perimeter print, but not vase mode? In my opinion, 0.6 mm nozzle is the best compromise between speed and quality.

The trick is in bad photo quality 🙂

- That was an easy (one-perimeter) print, 0.6 mm nozzle, 0.25 (0.2?) mm layer height. Standard PLA stuff.

How do you plan to connect the print to the board? Add a lip on the print to help?

Yea, I should have explained it better. There's a seam (so not a vase mode) but it's one perimeter.So it was one perimeter print, but not vase mode?

- This was the fastest and easiest way to see&touch the actual shape in its scale. It's not the final form of course - that will have a mouting lip, etc.

As it is it could be already used as a mold basis I guess.

Last edited:

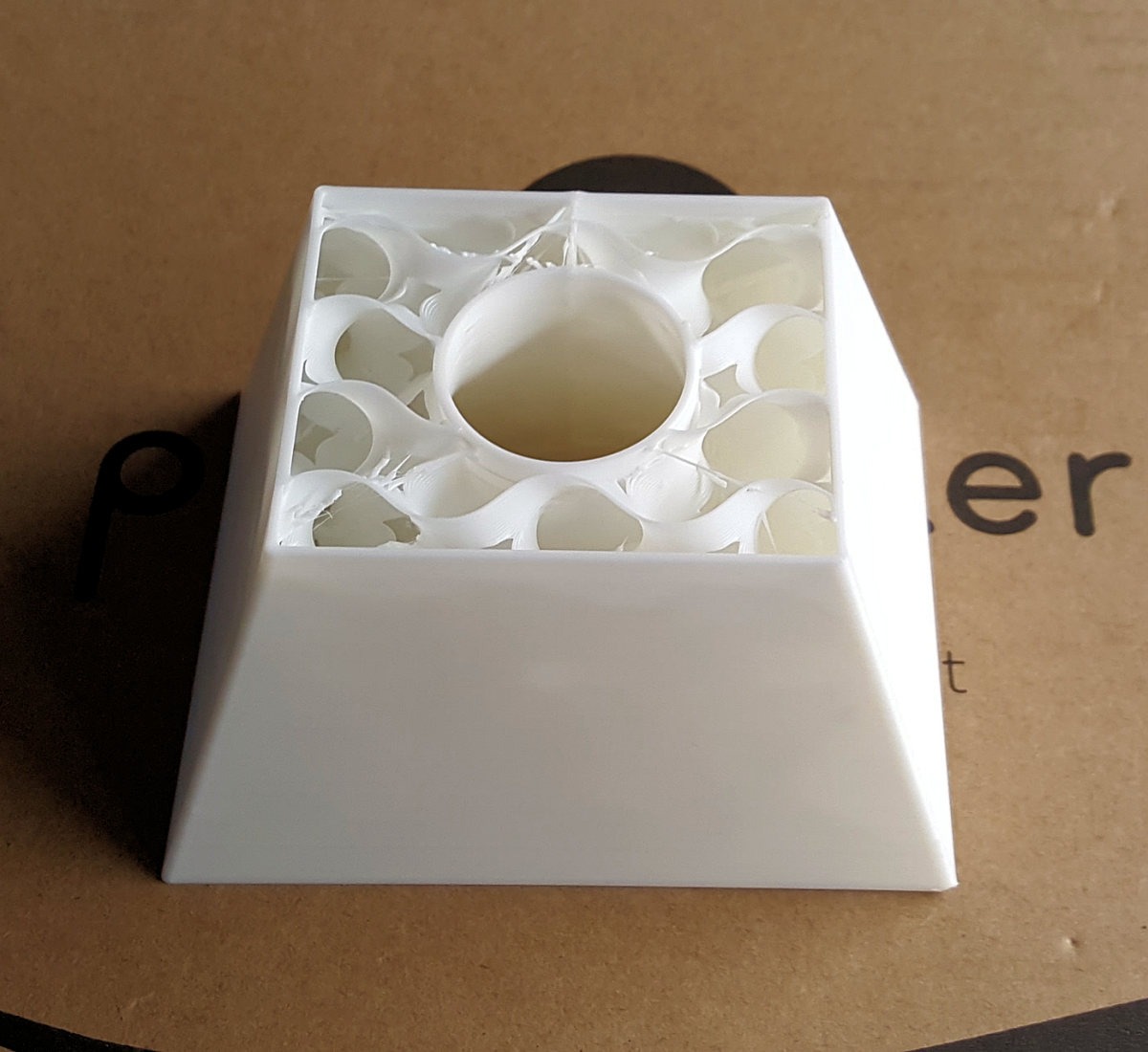

This is another test. After filling it's like a stone, I really like this approach. Again, not a final form, just a quick test.

The sparse infill prevents deformation.

The sparse infill prevents deformation.

Nice. What is the infill type and amount? It looks like it should be easy to fill. Maybe I missed it - is that still PLA?

It's the "gyroid" infill (maybe 5%?) in Prusa slicer, PLA. Yeah, it's easy to fill.

Re filling - https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7063674

You can use anything that gets not too hot during curing... otherwise about anything will work I guess.

Re filling - https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7063674

You can use anything that gets not too hot during curing... otherwise about anything will work I guess.

Hi Marcel

I am trying around with the rectangular horn demo. Could you give me an example with a non-conical section? Few posts before you had one with the st260 parameters I remember!? Somehow I am doing something wrong as it does not run through…

I am trying around with the rectangular horn demo. Could you give me an example with a non-conical section? Few posts before you had one with the st260 parameters I remember!? Somehow I am doing something wrong as it does not run through…

This is the structure. I'm not willing to share the actual numbers, sorry - too much work, too little reward.

You only may need to download the latest update: http://www.at-horns.eu/release/ath-4.9.0-pre-release-220919.zip

You only may need to download the latest update: http://www.at-horns.eu/release/ath-4.9.0-pre-release-220919.zip

Code:

HornGeometry = 2

Length = 90

Throat.Diameter = 25.4

Throat.Angle = 0

Horn.Adapter = {

L = 40

Width = 40

Height = 40

Segments = 8

ZMap = 0.5,0.3,0.5,0.3

}

Horn.Part:1 = {

L = 1

Segments = 20

H = {

r0 = 25.4

a0 = 20

k = 4.0

s = 1.0

a = 45

n = 5

q = 0.996

}

V = {

r0 = 25.4

a0 = 20

k = 4.0

s = 1.0

a = 45

n = 5

q = 0.996

}

ZMap = 0.5,0.5,0.5,0.9

}

; -------------------------------------------------------

Mesh.AngularSegments = 64

Mesh.ThroatResolution = 4

Mesh.MouthResolution = 10

Mesh.InterfaceResolution = 7

Mesh.RearResolution = 15

Mesh.SubdomainSlices = -3

Mesh.InterfaceOffset = 0

; -------------------------------------------------------

ABEC.SimType = 2

ABEC.f1 = 200 ; [Hz]

ABEC.f2 = 15000 ; [Hz]

ABEC.NumFrequencies = 40

ABEC.MeshFrequency = 1000 ; [Hz]

ABEC.Polars:SPL_H = {

MapAngleRange = 0,180,37

Distance = 2

}

ABEC.Polars:SPL_D = {

MapAngleRange = 0,180,37

Distance = 2

Inclination = 45

}

; -------------------------------------------------------

Report = {

Title = "DS3"

NormAngle = 0

DrvImp_Range = 40

Width = 1000

Height = 1200

}

Output.STL = 1

Output.ABECProject = 1It does.The acoustic impedance doesn't care if the shape is a square or a circle or a transitioning form...

May we remind you to ensure that any dialogue and any following replies are kept respectful and in accordance with the forum rules.

The simplest and shortest answer is: "The acoustic impedance Z is the property of a particular geometry and medium."But how?

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)