my sample request of richlite Black Diamond Bamboo Ply has been acknowledged. i also know a guy who could test its damping properties if thats worth doing ?

ABSOLUTELY!!! THANK YOU!

Richlite's Technical Documents section https://www.ecosupplycenter.com/products/richlite/ (scroll down) has ASTM E90 04 Sound Transmission results for two thicknesses of solid Richlite (.5 in. and .75 in.), but as far as I know, nobody has published results on damping.

Please keep us posted,

john

Richlite's Technical Documents section https://www.ecosupplycenter.com/products/richlite/ (scroll down) has ASTM E90 04 Sound Transmission results for two thicknesses of solid Richlite (.5 in. and .75 in.), but as far as I know, nobody has published results on damping.

Please keep us posted,

john

Belated thanks.No i mean push-push. (90%?) of the energy that would normally be pumped into the enclosure.

Imagine 2 12s loading energy into the cabinet that is likely closer to what a single 3 or 4" driver would impart to the box.

dave

Vivid Audio of South Africa does that with the twin woofers on their Giya models.

https://vividaudio.com/giya/

ciao,

john

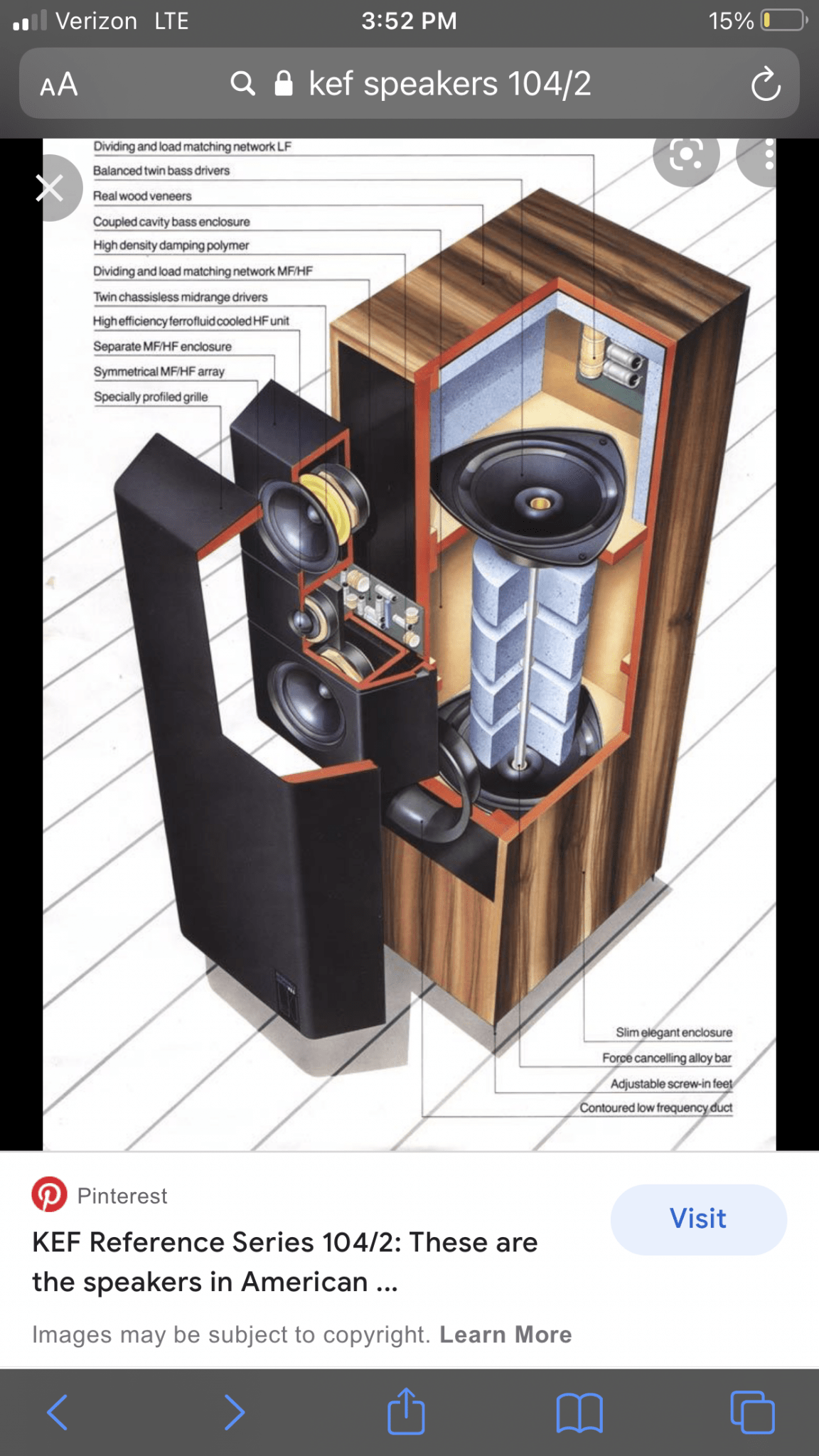

Yes, the first commercail loudspeaker with push-push woofers is the KEF 104/2 series so he inherited the idea (if he wasn’t the KEF designer back then).

dave

dave

Previous to Vivid Audio, Laurence Dickey was at B&W, but it was a small world back then.

ciao,

john

ciao,

john

Interesting option for speaker building. Funny they don't include the Modulus of Elasticity (E) in the Properties sheet.

There is a download "Richlite Cantilever Spans" which gives tables of deflection for various cantilevers and simple spans, presumably for countertops. If we take a 12" wide by 1" thick material as an example, the second moment of inertia is I = b*h^3/12 = 1.0 in^4. Cantilever deflection is FL^3/3EI. The table shows .356" deflection with 150 lb weight on the end of a 24" cantilever, so the E should be (150*24^3)/(3*1*0.356) = 1.94 million psi (13.4 GPa).

That puts the elastic modulus close to high quality birch (per Eric Meier's reference) which is quite good. And presumably Richlite is anisotropic so don't have to worry about weakness across the grain.

With a half inch sheet weighing in at 104.5 lb it's quite heavy! Note the sound transmission test is only for 0.5" thickness. The 0.75" test is for plywood (for comparison?).

I'm curious if there is an agreed upon standard method of testing damping properties of sheet materials? Jamie123 mentions testing, which would be amazing! I've searched through various journal articles and have found several different methods to quantify damping, but not any kind of consensus of a test method. So if somebody could point me to a common test method, it would be much appreciated.

Ben

There is a download "Richlite Cantilever Spans" which gives tables of deflection for various cantilevers and simple spans, presumably for countertops. If we take a 12" wide by 1" thick material as an example, the second moment of inertia is I = b*h^3/12 = 1.0 in^4. Cantilever deflection is FL^3/3EI. The table shows .356" deflection with 150 lb weight on the end of a 24" cantilever, so the E should be (150*24^3)/(3*1*0.356) = 1.94 million psi (13.4 GPa).

That puts the elastic modulus close to high quality birch (per Eric Meier's reference) which is quite good. And presumably Richlite is anisotropic so don't have to worry about weakness across the grain.

With a half inch sheet weighing in at 104.5 lb it's quite heavy! Note the sound transmission test is only for 0.5" thickness. The 0.75" test is for plywood (for comparison?).

I'm curious if there is an agreed upon standard method of testing damping properties of sheet materials? Jamie123 mentions testing, which would be amazing! I've searched through various journal articles and have found several different methods to quantify damping, but not any kind of consensus of a test method. So if somebody could point me to a common test method, it would be much appreciated.

Ben

It would be great to have only one standard for damping coefficient, but a quick glance at the various standards to which you can relate a materials damping shows, that one common standard is not common practice. We have:

ASTM E756, BS AU125, dIN 53440, MIL P22581, SAE J671 and ISO 2856. In Japan there are further JIS K6394, JASO M306, M329m. I found scientific papers suggesting new methods as late as 2020, so the race is definitely not over.

A larger sampling of data with regards to audio (speakers) related materials was made some ten years ago.

In the first link there is description of chosen method for comparison. Second link includes updates and revisions.

https://www.tapatalk.com/groups/audioqualia/damping-factor-values-t20.html

https://qualia.webs.com/newdampingfactors.htm

ASTM E756, BS AU125, dIN 53440, MIL P22581, SAE J671 and ISO 2856. In Japan there are further JIS K6394, JASO M306, M329m. I found scientific papers suggesting new methods as late as 2020, so the race is definitely not over.

A larger sampling of data with regards to audio (speakers) related materials was made some ten years ago.

In the first link there is description of chosen method for comparison. Second link includes updates and revisions.

https://www.tapatalk.com/groups/audioqualia/damping-factor-values-t20.html

https://qualia.webs.com/newdampingfactors.htm

Thanks for the links! Great data to have. Interesting description of test "damping factor values have been determined by suspending a sample of the material (usually 100 x100mm) in air, and striking with a suitable implement".

I have used the log decrement to find the damping and natural frequency of floor structures (in my day job), but doesn't the 100mm x 100mm size sound like it is going to strongly influence the natural frequency if nothing else? I'm thinking of a xylophone with different sized chunks of the same type of wood producing different tones. Hopefully the damping at least is more independent of sample size.

Does Plasticene really have a natural frequency of 77 Hz? It's basically play-doh, right? My experience with highly damped materials is that the "waveform" decay is so short that there is no way to tell the natural frequency. Which is why I was hoping there was some kind of commonly-used forced vibration test method where damping was determined by forced vibration response.

I have used the log decrement to find the damping and natural frequency of floor structures (in my day job), but doesn't the 100mm x 100mm size sound like it is going to strongly influence the natural frequency if nothing else? I'm thinking of a xylophone with different sized chunks of the same type of wood producing different tones. Hopefully the damping at least is more independent of sample size.

Does Plasticene really have a natural frequency of 77 Hz? It's basically play-doh, right? My experience with highly damped materials is that the "waveform" decay is so short that there is no way to tell the natural frequency. Which is why I was hoping there was some kind of commonly-used forced vibration test method where damping was determined by forced vibration response.

WOW, thank you for that work.Interesting option for speaker building. Funny they don't include the Modulus of Elasticity (E) in the Properties sheet.

There is a download "Richlite Cantilever Spans" which gives tables of deflection for various cantilevers and simple spans, presumably for countertops. If we take a 12" wide by 1" thick material as an example, the second moment of inertia is I = b*h^3/12 = 1.0 in^4. Cantilever deflection is FL^3/3EI. The table shows .356" deflection with 150 lb weight on the end of a 24" cantilever, so the E should be (150*24^3)/(3*1*0.356) = 1.94 million psi (13.4 GPa).

That puts the elastic modulus close to high quality birch (per Eric Meier's reference) which is quite good. And presumably Richlite is anisotropic so don't have to worry about weakness across the grain.

With a half inch sheet weighing in at 104.5 lb it's quite heavy! Note the sound transmission test is only for 0.5" thickness. The 0.75" test is for plywood (for comparison?).

I'm curious if there is an agreed upon standard method of testing damping properties of sheet materials? Jamie123 mentions testing, which would be amazing! I've searched through various journal articles and have found several different methods to quantify damping, but not any kind of consensus of a test method. So if somebody could point me to a common test method, it would be much appreciated.

Ben

Yes, it appears that the .75 Marine Plywood was chosen for a Reference.

Yes... solid Richlite is heavy.

In case you missed the reference, there is a "Panel Tap Test" video up on YT:

Richlite is what Gibson Guitars now uses for the fretboards on most of their guitars, and there are loads of YT demo videos about that. Richlite is so tough it is certified as Kosher for food-cutting boards.

I think the idea of making a Xylophone or even a Vibraphone with Richlite keys is a gas!

I first became aware of Richlite from an article in the architecture magazine DWELL about a home that was designed with Richlite panels as the "rain screen." A rain screen is a floating exterior-wall construction detail where the siding stands off from the moisture-resistant surface of an air/water barrier applied to the sheathing to create a capillary break and to allow drainage and evaporation. (wiki) My immediate reactions were, wow, that is such an elegant solution for a low-maintenance exterior cladding; but then I did a little research and said, OMG, that sure cost a young fortune.

I don't remember where that house was, but, say, if one were rich enough to build a house on the Block Island shore, that would be a great way to go.

amb,

john marks

Attachments

Thanx for that video. Given how mist people interpret such a test i was curious. But as i expected, MDF was worst, BB next (almost certainly 18mm BTW, not ¾”).

I was surprised at how much higher in frequency the richlite was. A good thing.

But there is a confounding element to the test. Without all the panel shapes being the same size the test is not valid. Larger sheets will hve lower frequency resonance, so the larger size of the BB sets it at an immediate disadvantage.

Now it would be interesting to see teh results with stranded bamboo vrs the various richlite materials.

dave

I was surprised at how much higher in frequency the richlite was. A good thing.

But there is a confounding element to the test. Without all the panel shapes being the same size the test is not valid. Larger sheets will hve lower frequency resonance, so the larger size of the BB sets it at an immediate disadvantage.

Now it would be interesting to see teh results with stranded bamboo vrs the various richlite materials.

dave

Thanks for your comments. I did an informal tap test on the 12 x 12 inch "partial sheet" of the Richlite-clad/PlyBoo-core Bamboo Stratum product I bought to make one BBC-Shoebox sized monitor front panel from. It seemed nice and high, but... it was also only one square foot.

I should note that I asked my cabinet maker to get the Rockler router bit for cutting picture-hanging "key slots" in picture frames. I asked him to cut keys in the panel back and fill the voids with Saint-Gobain Green Glue. I can't find a photo that shows that in the Bamboo Stratum front panel but here is a photo that shows the same technique in a Stratum Birch Plywood front panel. I don't claim to have done rigorous scientific testing, but the "anecdotal results" are very good, and not just in my own opinion--I have a "Golden Ears" panel of friends who stop by to listen.

I should note that I asked my cabinet maker to get the Rockler router bit for cutting picture-hanging "key slots" in picture frames. I asked him to cut keys in the panel back and fill the voids with Saint-Gobain Green Glue. I can't find a photo that shows that in the Bamboo Stratum front panel but here is a photo that shows the same technique in a Stratum Birch Plywood front panel. I don't claim to have done rigorous scientific testing, but the "anecdotal results" are very good, and not just in my own opinion--I have a "Golden Ears" panel of friends who stop by to listen.

Attachments

Last edited by a moderator:

This is pretty funny... I was reading this thread and I was going to post something about using material called "Skatelite" for cabinets because it seems very similar to you were talking about. But one of the main issues with Skatelite is that it's only 1/4" thick. Then I looked deeper into this and is actually made by Richlite lol. I actually have a bunch and thought about using a 1/2" baltic birch layer, then figure out how to glue this to the inside of the cabinet, but I've never actually tried that.

Speaking of gluing it, one of the other issues is gluing this, @johnmarianmarks, not sure what you glued yours with, but I was under the impression that wood glue will not work. But I absolutely agree, this stuff is crazy dense- a 4x8 sheet of 1/4" Skatelite weighs about as much as a 3/4" sheet of MDF. FWIW, it's also fireproof.

Just FYI, for anyone that doesn't know, Skatelite is what's used for skateboard ramp sheeting. It's used because it's virtually indestructible so when a skateboard goes flying 10' in the air and the metal truck bounces off a half pipe, it doesn't damage the ramp. But also VERY expensive, a 4x8 sheet of 1/4" thick Skatelite is $190 😳.

https://www.skatelite.com/

Speaking of gluing it, one of the other issues is gluing this, @johnmarianmarks, not sure what you glued yours with, but I was under the impression that wood glue will not work. But I absolutely agree, this stuff is crazy dense- a 4x8 sheet of 1/4" Skatelite weighs about as much as a 3/4" sheet of MDF. FWIW, it's also fireproof.

Just FYI, for anyone that doesn't know, Skatelite is what's used for skateboard ramp sheeting. It's used because it's virtually indestructible so when a skateboard goes flying 10' in the air and the metal truck bounces off a half pipe, it doesn't damage the ramp. But also VERY expensive, a 4x8 sheet of 1/4" thick Skatelite is $190 😳.

https://www.skatelite.com/

this stuff is crazy dense

That is not an asset. If it was as stiff and less dense it would be better.

An example is western red cedar which is, surprisingly, a VERY good cabinet material as it is quite stiff. It does suffer from easy bruising, workin to figure that out. Proposed fix should further improve the material.

dave

Interesting, I've never used western red cedar in a cabinet. I did use this ply, it's an MDF ply core sandwich and found it to be very dead. Not sure offhand what the ply core is but I could find out.That is not an asset. If it was as stiff and less dense it would be better.

An example is western red cedar which is, surprisingly, a VERY good cabinet material as it is quite stiff. It does suffer from easy bruising, workin to figure that out. Proposed fix should further improve the material.

dave

Yes. Fountek's NeoCD3.0, a 3-inch laminated aluminum ribbon. US Street Price circa $100.ea. Mms 18 milligrams; extension to 40kHz. A modified version of that driver is used in the UK company Falcon Acoustics' $27,000/pr. "statement" loudspeaker with Graphene woofers. Fountek's larger 5-inch ribbon, the 2.0, is used as front and rear super-tweeters in von Schweikert Audio's $250,000 and $350,000/pr. super-speakers. I actually know a guy who owns the $250,000 pair.

ciao,

john

ciao,

john

Last edited by a moderator:

I'm curious what the differences between these 2 materials is, I think they're very similar, if not the same just different colors. The Skatelite I mentioned earlier is the Richlite r50 (the same stuff), what the OP used is the Rainier. Are you saying this Richlite is not good cabinet material because it's too dense? Or that the r50 is different than the Rainier?...That is not an asset. If it was as stiff and less dense it would be better.

An example is western red cedar which is, surprisingly, a VERY good cabinet material as it is quite stiff. It does suffer from easy bruising, workin to figure that out. Proposed fix should further improve the material.

dave

https://www.richlite.com/collections/partial-sheets/products/partial-sheets-r50

https://www.richlite.com/collections/partial-sheets/products/partial-sheets-rainier

- Home

- Loudspeakers

- Multi-Way

- An Under-Appreciated Cabinet Material