The TubSuMo amps are around 100WPC/8R, I think. I rarely use more than a couple watts, most likely. The design is low-distortion EF3 (I think), with a tube in one of the stages and lateral mosfet outputs. Valery was a brilliant amp designer.

https://www.diyaudio.com/community/...nce-yet-rather-simple-hybrid-and-more.262450/

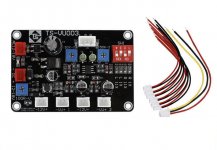

This is the meter board I ordered: https://www.ebay.com/itm/133921989559. I saw it in another thread and others were happy with it.

It has dip switches for line level vs. power out sensitivity, plus trimmer pots for adjustment. I don’t imagine it’s terribly accurate, but I was only interested in some movement.

https://www.diyaudio.com/community/...nce-yet-rather-simple-hybrid-and-more.262450/

This is the meter board I ordered: https://www.ebay.com/itm/133921989559. I saw it in another thread and others were happy with it.

It has dip switches for line level vs. power out sensitivity, plus trimmer pots for adjustment. I don’t imagine it’s terribly accurate, but I was only interested in some movement.

Attachments

I think my meter board may just be faulty. There’s rhythmic 7-15 mV AC going out to the meters at all times. The pot to adjust the lamp voltage does nothing. I can’t get rid of the mains hum with the meter board that was negligent without it. I will try the hand wired passive circuit I used in another amp to get bouncing meters. Gotta find what the values of those diodes, caps, and pots were…

Attachments

Received my modushop chassis today. Everything looks perfect but I cut it really close on the spacing of the furthest right speaker terminal and the back panel mounting screw, fortunately it fits fine but that is what I get for not including the mounting holes in my drawing  . Otherwise just need to order some 30 mm spacers and long M3 screws for mounting the modules to the heatsink and wire everything up.

. Otherwise just need to order some 30 mm spacers and long M3 screws for mounting the modules to the heatsink and wire everything up.

Michael

Michael

Attachments

Awesome. So you had the cutouts done by modushop then? What do they charge for that? Looks like a nice case. You went with the heat sinks I see. So you are going with 2 mods single ended and 2 in BTL? Correct?Received my modushop chassis today. Everything looks perfect but I cut it really close on the spacing of the furthest right speaker terminal and the back panel mounting screw, fortunately it fits fine but that is what I get for not including the mounting holes in my drawing. Otherwise just need to order some 30 mm spacers and long M3 screws for mounting the modules to the heatsink and wire everything up.

The perforated sub-floor that they sell for mounting everything makes it real easy and gives the case a lot more rigidity. Have you thought about getting one for your case? When I ordered mine I got the sub-floor and have no regrets at all. It really helps keep the box square and if it ever gets dropped I think it would help prevent damage.

So you are using DSP right? Is it a finished external unit or are you going to include it inside the amp like I did?

After talking to von I've decided to put a couple VU meters on my amp. I ordered a couple meters and a driver board that I should have around the 18th or shortly there after. They will dress up the front of the amp nicely me thinks.

From what I was reading from the sellers of some of these drivers boards they recommend using separate power supplies for powering up these boards so as not to introduce noise into the audio output. I got one of these to power my DSP unit and it works great. I think it would work for powering the driver board no problem.I think my meter board may just be faulty. There’s rhythmic 7-15 mV AC going out to the meters at all times. The pot to adjust the lamp voltage does nothing. I can’t get rid of the mains hum with the meter board that was negligent without it. I will try the hand wired passive circuit I used in another amp to get bouncing meters. Gotta find what the values of those diodes, caps, and pots were…

https://www.mpja.com/12-Volt-16A-Power-Supply-Module-100-264VAC-Input/productinfo/36674+PS/

Awesome. So you had the cutouts done by modushop then? What do they charge for that? Looks like a nice case. You went with the heat sinks I see. So you are going with 2 mods single ended and 2 in BTL? Correct?

The perforated sub-floor that they sell for mounting everything makes it real easy and gives the case a lot more rigidity. Have you thought about getting one for your case? When I ordered mine I got the sub-floor and have no regrets at all. It really helps keep the box square and if it ever gets dropped I think it would help prevent damage.

So you are using DSP right? Is it a finished external unit or are you going to include it inside the amp like I did?

After talking to von I've decided to put a couple VU meters on my amp. I ordered a couple meters and a driver board that I should have around the 18th or shortly there after. They will dress up the front of the amp nicely me thinks.

Yes, cutouts done by modushop which makes it very easy. It was 45€ for the rear panel cutouts (more than 20 holes) and drilling / tapping the heatsinks was 35€ each. I purchased three of the same chassis which resulted in a discount and they had a 15% off sale. So all said and done it was 710€ shipped which at a 1:1 $ to € conversion rate was not too bad. All chassis will have two modules, one chassis will have modules in BTL for subs, other two will be in stereo mode.

I did order the perforated sub floor to mount the extra capacitors PCB and to provide some additional support for the power supply even though it is fastened to the heatsink. In the test fit up the power supply seems pretty rigid without the sub floor but I don't like the idea of it being cantilevered like that with only two M3 screws for support.

I am using DSP but is external. I have a MOTU Ultralite Mk5 as a 10 channel DAC and do DSP on a RPi4 running CamillaDSP. This setup is described in more detail here -> https://www.audiosciencereview.com/forum/index.php?threads/rpi4-camilladsp-tutorial.29656/ but the RPi4 is mounted in a small aluminum enclosure with an OLED screen and IR receiver.

Michael

That’s an interesting option, thank you. I did try a separate 12V smps to power the VU board and got similar results. I believe there is something incongruent with tapping the amp output as L-GND-R to feed the VU board causing my ground loop noise. I am open to trying the separate power supply like you show, but I also want to try the passive circuit for meter movement. Just gotta order components.From what I was reading from the sellers of some of these drivers boards they recommend using separate power supplies for powering up these boards so as not to introduce noise into the audio output. I got one of these to power my DSP unit and it works great. I think it would work for powering the driver board no problem.

https://www.mpja.com/12-Volt-16A-Power-Supply-Module-100-264VAC-Input/productinfo/36674+PS/

All this talk about meters got me thinking how good they would look on the front of my amp and since the boards allow input from the preamp as well as the amp(s) I decided to put a couple on mine using the preamp inputs. They will be here around the 18th or so. I will be using the separate amp I linked you to to power the driver board as I already have one in the case for the DSP unit. Hopefully no noise.That’s an interesting option, thank you. I did try a separate 12V smps to power the VU board and got similar results. I believe there is something incongruent with tapping the amp output as L-GND-R to feed the VU board causing my ground loop noise. I am open to trying the separate power supply like you show, but I also want to try the passive circuit for meter movement. Just gotta order components.

Have you considered using the low level single ended inputs instead of the output from the amps to drive the meters?

Oh okay. You do have the subfloor then. So you bought three cases? Decided to pull out all of the stops with this build. If you are going to do it do it right. I want to see pics when you get them done.Yes, cutouts done by modushop which makes it very easy. It was 45€ for the rear panel cutouts (more than 20 holes) and drilling / tapping the heatsinks was 35€ each. I purchased three of the same chassis which resulted in a discount and they had a 15% off sale. So all said and done it was 710€ shipped which at a 1:1 $ to € conversion rate was not too bad. All chassis will have two modules, one chassis will have modules in BTL for subs, other two will be in stereo mode.

I did order the perforated sub floor to mount the extra capacitors PCB and to provide some additional support for the power supply even though it is fastened to the heatsink. In the test fit up the power supply seems pretty rigid without the sub floor but I don't like the idea of it being cantilevered like that with only two M3 screws for support.

I am using DSP but is external. I have a MOTU Ultralite Mk5 as a 10 channel DAC and do DSP on a RPi4 running CamillaDSP. This setup is described in more detail here -> https://www.audiosciencereview.com/forum/index.php?threads/rpi4-camilladsp-tutorial.29656/ but the RPi4 is mounted in a small aluminum enclosure with an OLED screen and IR receiver.

Michael

That's a pretty in depth tutorial you put together over there at audio science review. I need to check that forum out it looks like a good source of information. I think I've been over there once before. Those little Raspberry units are pretty powerful these days. I've never used one before but maybe I should take the time and learn how because I can think of a few things that they might be useful for.

Can't wait to see things when they are done.

Cheers

I will try that now!All this talk about meters got me thinking how good they would look on the front of my amp and since the boards allow input from the preamp as well as the amp(s) I decided to put a couple on mine using the preamp inputs. They will be here around the 18th or so. I will be using the separate amp I linked you to to power the driver board as I already have one in the case for the DSP unit. Hopefully no noise.

Have you considered using the low level single ended inputs instead of the output from the amps to drive the meters?

It worked! Everything is operational and the ground loop noise is gone. Thank you, @iamjackalope, for suggesting that test. Easy fix.

It’s going back in the main system tomorrow.

It’s going back in the main system tomorrow.

Oh okay. You do have the subfloor then. So you bought three cases? Decided to pull out all of the stops with this build. If you are going to do it do it right. I want to see pics when you get them done.

That's a pretty in depth tutorial you put together over there at audio science review. I need to check that forum out it looks like a good source of information. I think I've been over there once before. Those little Raspberry units are pretty powerful these days. I've never used one before but maybe I should take the time and learn how because I can think of a few things that they might be useful for.

Can't wait to see things when they are done.

Cheers

Pic of everything fit up. Just need to do the wiring.

Michael

Cool. Glad it worked.It worked! Everything is operational and the ground loop noise is gone. Thank you, @iamjackalope, for suggesting that test. Easy fix.

It’s going back in the main system tomorrow.

Looks great so far. Very nice job. We already know it sounds great. So the most expensive part of this amp is the case right? If you ever want to sell it you shouldn't have any trouble like with many DIY projects that just look to DIY to sell. This looks like a commercial offering. Nice job.

How’s the 4-channel build working out?Pic of everything fit up. Just need to do the wiring.

Michael

How’s the 4-channel build working out?

Very slowly, have all the wiring crimped (which is one of my least favorite tasks), need to solder the speaker, XLR and trigger terminals. Also need to apply some thermal grease to the module heatsinks and power supply. Thought I would get to it this weekend but ended up working instead.

Michael

That seems to be a predicament I find my self in as of late. There is a deck attached to the back side of the house that I live in that I built back about 18 years ago. A good portion of it is in the constant shade from a big White Oak tree and because I live on the coast we get a lot of dew at night plus it rains and for the better part of the year it doesn't completely dry in the shaded area. It is always wet. Plus the tree is always dropping leaves, acorns and pollen all over the deck. So needless to say there is considerable amount of rotten wood that I'm having to repair and replace at the moment. So when I'm not working for paying clients I'm spending all of my time fixing the deck instead of completing my current projects. I really want to finish my speakers but you know how it goes, priorities prevail. Being responsible sucks.Thought I would get to it this weekend but ended up working instead

I also got a couple of nice backlit VU meters that I will be putting on my amp soon. With Von talking about the VU meters on his amp I couldn't resist. I had to have some on mine too. I like the look of a couple big blue back lit VU meters bouncing around on the face of the amp like the Macintosh amps.

Cool factor=high.

Don't work to hard man.

Cheers

Weird, as I have been demolishing the deck on the back of our house, which sit on a bay in NWFL. Built in 1992 and the construction crew seemingly had Miller time on their minds. None of the piers were properly set in concrete, if at all. Oddly enough the deck has weathered two hurricanes in addition to the typical coastal elements. Will be going with a proper cement deck, especially given the cost of lumber these days. Was toying with the idea of pouring it myself until I watched just enough YT videos to appreciate the art and science of constructing a stem-wall foundation.That seems to be a predicament I find my self in as of late. There is a deck attached to the back side of the house that I live in that I built back about 18 years ago. A good portion of it is in the constant shade from a big White Oak tree and because I live on the coast we get a lot of dew at night plus it rains and for the better part of the year it doesn't completely dry in the shaded area. It is always wet. Plus the tree is always dropping leaves, acorns and pollen all over the deck. So needless to say there is considerable amount of rotten wood that I'm having to repair and replace at the moment. So when I'm not working for paying clients I'm spending all of my time fixing the deck instead of completing my current projects. I really want to finish my speakers but you know how it goes, priorities prevail. Being responsible sucks.

I also got a couple of nice backlit VU meters that I will be putting on my amp soon. With Von talking about the VU meters on his amp I couldn't resist. I had to have some on mine too. I like the look of a couple big blue back lit VU meters bouncing around on the face of the amp like the Macintosh amps.

Cool factor=high.

Don't work to hard man.

Cheers

I have to confess, It is mighty fun to do some demo work, even in the high 90s

- Home

- Amplifiers

- Class D

- Why do i have 56v on my vdrive?