Yep will upload some tonight. Matching the area expansion of the conical horn throat to the exponential expansion seems to reduce throat impedance ripple but this is a tradeoff against good low frequency performance. I found the patent on the EV vanes: https://patentimages.storage.googleapis.com/55/eb/f9/ec53d8972d1ede/US4685532.pdf hope to try this out soon.

Wouldn't it make sense to limit the radiation downward? For example instead of a 90x40 where it is 90 wide and 20up-20down, why not 90x30 and make it 20up-10down? Wouldn't that reduce the floor bounce?

https://www.diyaudio.com/community/...per-scripts-and-m200-fun.385493/#post-7003214 here is the data I have so far on some exponetial-conic-conic horns and scripts to generate them.

If you don't plan to use the horn very high, the simplification with the rectangular driving is probably sufficient (but it will cause the throat impedance to appear higher in the sim). I certainly want to include a smooth circle-to-rectangle transition segment in my implementation.

I would be curious to see the effect of making a circular driving in a rectangular throat though. That's probably something you could already try without much of an effort.

I would be curious to see the effect of making a circular driving in a rectangular throat though. That's probably something you could already try without much of an effort.

Last edited:

Good point about the throat impedance. I have a script for generating point clouds of simple round to square throat adapters that preserve the area expansion for which I would just need to write a new meshing algorithm (I tried meshlab but could not generate a satisfactory quality mesh from the point clouds). I think a separate throat adapter is sufficient for 4kHz but I would like to incorporate the round to rectangular transition into the whole first exponential part of the horn if I developed a higher frequency version. The construction plan is currently to 3D print the first exponential section with carbon fiber reinforced plastic and to build the conical sections out of ply, this does restrict me in that I can't have curves in the ply sections.

^You could do kerf bending or laminate multiple thin layers plywood to get curved profiles 😉

we did that for the midbass horn but it takes a long time to make all the jigs etc.

"Cone" in VCAD is circular rigid flat piston calculated to infinity. DI increases towards HF with quite constant slope no matter size and shape of the baffle/box - just like simulation shows. Cones in practice are not flat & rigid, and common user does not have any changes to know parameters required for directivity simulation of vibrating & flexible radiating areas. Diffraction tool is designed primarily for simulation of baffle loss and directivity at LF...low MF, and measurements with actual driver+box are valid for high MF...HF. Just like all versions of measurement instructions tell.I also wanted to ask @kimmosto, ... What to rely on?

Do you mean to say that the enclosure has no effect on the directivity? Or just that the DI will always increase with frequency regardless of the enclosure?"Cone" in VCAD is circular rigid flat piston calculated to infinity. DI increases towards HF with quite constant slope no matter size and shape of the baffle/box

He is still telling us how DI is and under which limitations it is being calculated in VCad. DI may very well change due to enclosure dimensions, but with VCad, we must rely on gated measurements down to the usual frequencies and learn about more complex DI from spins of prototypes.

No. Just that above certain frequency (ka~2) ideal flat rigid piston (as closed direct radiator) starts to rule directivity. DI increases quite linearly (does not drop close to 0 dB for sure). Box plays much bigger / significant role below that point. Anyway, all this is just theory because ideal flat rigid pistons are not common IRL.Do you mean to say that the enclosure has no effect on the directivity? Or just that the DI will always increase with frequency regardless of the enclosure?

@mabat

Can ATH be used to design a waveguide for a BMR (balanced mode radiator)?

I am thinking a 4" or 5" waveguide for a 1-1/2" or 2" BMR.

According to some measurements, BMR have very good performance between 400hz and 20kHz, so maybe these could be optimized with a WG and leave the lower and sub bass to standard woofer (2-way with no crossover in the most crucial frequency range).

https://www.erinsaudiocorner.com/driveunits/tectonic-elements-tebm35c10-4-miniature-bmr-driver/

https://diy.midwestaudio.club/discussion/1447/tectonic-tebm46c20n-4b-bmr

Can ATH be used to design a waveguide for a BMR (balanced mode radiator)?

I am thinking a 4" or 5" waveguide for a 1-1/2" or 2" BMR.

According to some measurements, BMR have very good performance between 400hz and 20kHz, so maybe these could be optimized with a WG and leave the lower and sub bass to standard woofer (2-way with no crossover in the most crucial frequency range).

https://www.erinsaudiocorner.com/driveunits/tectonic-elements-tebm35c10-4-miniature-bmr-driver/

https://diy.midwestaudio.club/discussion/1447/tectonic-tebm46c20n-4b-bmr

Do you know how to express the BMR wavefront? One could easily simulate any axisymmetric source (like I did for the higher order duct modes) but first we need to know what it is.

BMRs only bend down to a couple of kHz - that would be one kind of wave front. Below it tries to be a pistong - thats an other.

Tricky...

//

Tricky...

//

Creating a smooth solid in Fusion is surprisingly easy, could be printed right away -Here's an example with the 'k' varied around the horn

https://a360.co/3vcObMW

Only acoustically there's nothing to be much proud of.

- This was just a small sample, ⌀240 x 120 mm, 1" throat.

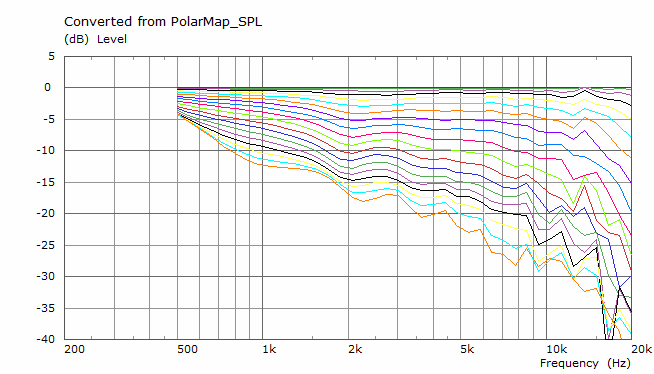

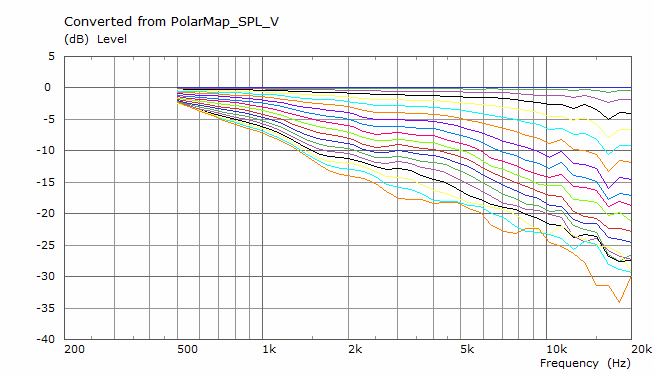

Horizontal, vertical, 0-90/5:

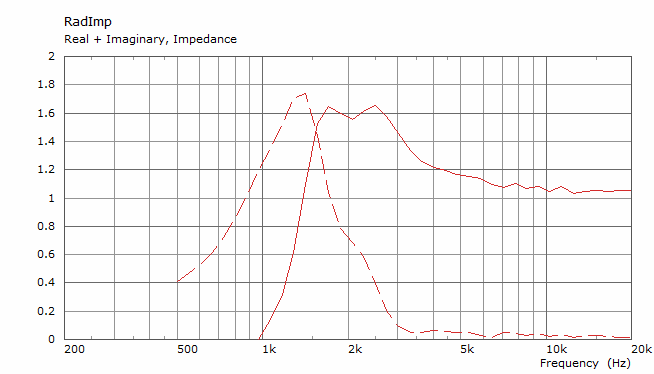

- What about the negative real part of the throat impedance? Does it make any sense? It keeps being negative below 1 kHz repeatedly with these shapes. What would that mean, is that an error?

- This was just a small sample, ⌀240 x 120 mm, 1" throat.

Horizontal, vertical, 0-90/5:

- What about the negative real part of the throat impedance? Does it make any sense? It keeps being negative below 1 kHz repeatedly with these shapes. What would that mean, is that an error?

Last edited:

Obvisouly it's an error. With a subdomain added the impedance is very different and reasonable -is that an error?

( I just hate how tricky this 3D modeling can be.)

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)