I have not read much of the tectonic patent yet, but noted in the little bit I did read , they are mentioning exciter wobble and coil damage and how they prevent it.

I even mentioned this in the dml for pro use page, this was back in 2015 !

It's frightening how long I have been making dml panels.

I must stop making them and start listening to them more.

Steve.

I even mentioned this in the dml for pro use page, this was back in 2015 !

It's frightening how long I have been making dml panels.

I must stop making them and start listening to them more.

Steve.

I think it is pretty clear from the animation in Tectonics video (although exaggerated) that the suspension can move quite a bit, and I also recall them discussing the importance of a compliant suspension. How much it affects SPL I'm not sure, but I'm very doubtful that clamping the plate would be optimal in that regard. But if you do find a source for that claim I would be interested to know more.From different papers about the acoustic of plate dealing with their boundary conditions. I am not sure to be able to find the exact source... Too many readings by the time being.

In the Tectonic design, I don't know under which condition they are (see the role of the 4 rubber fixations in addition) really. If the level is an advantage of the clamped edge, the first resonance frequency is also the highest of all the classical conditions. there are probably other reasons... I am not experienced enough about the suspension. some investigation on going.

See my earlier post where I linked to one supplier with figures on thickness and weight of final layer with different materials.You are right that carbon beats glass when it comes to stiffness and weight. But the challenge for a DML panel is that to avoid being too stiff, the carbon needs to be very thin. I think the glass he used was just about the right thickness for a DML (about .08 mm maybe?). For carbon ideally you'd probably want someting even thinner, which is hard to find I think. Or expensive if you do. The closest reasonably priced thin carbon I can get is a 90 gsm spread tow that would finish out at about 0.12 mm.

I think glass just might actually work out better, in this case.

Carbon is available that is both thinner and lighter than glass, but cost €75 instead of €5 per m2. You could get two plates from 1 m2, so not really that expensive per plate.

I did some very hasty experiments when trying printed panels to print the top skin separately and then glue it, but I found it hard to make sure the skin sticks everywhere to the honeycomb. And if you don't get great adhesion everywhere, you get distortion from rattling.You are vacuum bagging? It can be done even without vacuum bagging by doing one side at a time and letting it fully cure. You wet one layer on your release surface then lay the honeycomb on it and then weights and let it cure (I've seen a layer of closed cell and a piece of plywood laid carefully on the honeycomb to give even pressure). As long as you don't overwet the honeycomb won't wick up too much. Then when it's cured repeat for the over side. I think that same guy did this with aluminum honeycomb.

Of course it is very different with a thin plastic sheet and a weave, but my impression than was that without vacuum you end up having to use quite a bit more epoxy if you want to make it stick well.

I guess the glass is cheap enough to experiment with anyway, so I should really give it a go.

Those would be interesting! Especially the first, I think.Carbon should be lighter than glass, and the suppliers I have been looking at do have light carbon weave. Carbix.se has these figures for the weaves:

64g/m2 carbon:

Resin consumption: 46 g/m², laminate thickness: 0.064 mm, laminate weight: 110 g/m²

80g/m² glass:

Resin consumption: 63 g / m², laminate thickness: 0.088 mm, laminate weight: 143 g / m²

They also have 36g/m² aramid weave:

Resin consumption: 51 g/m², laminate thickness: 0,071 mm, laminate weight: 87 g/m²

Eric

I'm not sure I would go as far as Christian to say clamped is loudest, but I do agree that constraining the edges can have a positive effect on both FR and overall output. One of the NXT patents demonstrated this but I'd have to look to find it.+ @spedge

A panel reaching nearly clamped condition is louder than any other suspension modes.

Christian

For me, so far the best constraint seems to be attaching the panel to a rigid frame around most or all of the perimeter using a double sided foam tape. This approaches what engineers refer to as "simple supports" which implies that the edges of the panels can't move (not much, anyway), but can rotate. So the perimeter is mainly like a hinge. I think this is effectively what the Tectonic supports do, although their combination of rigid and compliant supports may be more nuanced.

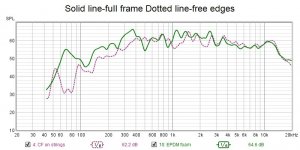

Here are two examples comparing panels with frames and foam, compared to the same panels hanging from strings (free edges). In both cases the biggest difference is at the low frequency end, where the framed panels provide much greater output than the free panels. At higher frequencies, the responses tend to converge. The first is for a 16"x23" CF/balsa panel, and the second is for a 14"x48" plywood panel. In both cases, the same exciter was used for both test, and the amp was set to the same volume, and the mic was placed at 1 meter. I have done this many times and see pretty much the same thing every time.

Eric

Steve wrote... My problem is , knowing how good cone bass drivers are , and the likes of the B139 , is it worth trying to build a sub dml panel (that isn't actually dml anyway ?) With all its problems.

agree 100%

agree 100%

I'm not sure I would go as far as Christian to say clamped is loudest, but I do agree that constraining the edges can have a positive effect on both FR and overall output. One of the NXT patents demonstrated this but I'd have to look to find it.

For me, so far the best constraint seems to be attaching the panel to a rigid frame around most or all of the perimeter using a double sided foam tape. This approaches what engineers refer to as "simple supports" which implies that the edges of the panels can't move (not much, anyway), but can rotate. So the perimeter is mainly like a hinge. I think this is effectively what the Tectonic supports do, although their combination of rigid and compliant supports may be more nuanced.

Here are two examples comparing panels with frames and foam, compared to the same panels hanging from strings (free edges). In both cases the biggest difference is at the low frequency end, where the framed panels provide much greater output than the free panels. At higher frequencies, the responses tend to converge. The first is for a 16"x23" CF/balsa panel, and the second is for a 14"x48" plywood panel. In both cases, the same exciter was used for both test, and the amp was set to the same volume, and the mic was placed at 1 meter. I have done this many times and see pretty much the same thing every time.

Eric

View attachment 1040203

View attachment 1040205

Do you have any photos of your 14"x48" plywood panels mounted in the foam?

Eric.

Your frequency plots show clearly that the foam with frame is louder.

The ply panel is much louder below about 3k.

The cf panel only below about 400hz,

The problem with using foam is that it softens the dynamics .

This old patent used a variable damping (clamping) method ,which allows you to tune or dial in your preferred sound.

https://patents.google.com/patent/U...=priority:19610101&oq=inventor:+A+Cohen++1961

Rigidly mounting my ply panel has the effect of strongly reflecting the waves back into the panel, increasing the dml on the panel.

The 3mm ply is more flexible than the cf so is probably affected more ?

You have to be careful though, reducing the size of the 3mm panel started to make the panel sound more screach -y , like glass ,the panel was getting too rigid !

Holding the panel at the edges gives the panel a more warmer sound as it fills in the dips in the 200hz area , small weights at these points does improve fr, and I used this method on my rigidly clamped panels also.

as I have mentioned before ,in this old patent ,there are hints as to what tectonic are doing to their panel ,that are not in the tectonic patent ?

Steve.

Your frequency plots show clearly that the foam with frame is louder.

The ply panel is much louder below about 3k.

The cf panel only below about 400hz,

The problem with using foam is that it softens the dynamics .

This old patent used a variable damping (clamping) method ,which allows you to tune or dial in your preferred sound.

https://patents.google.com/patent/U...=priority:19610101&oq=inventor:+A+Cohen++1961

Rigidly mounting my ply panel has the effect of strongly reflecting the waves back into the panel, increasing the dml on the panel.

The 3mm ply is more flexible than the cf so is probably affected more ?

You have to be careful though, reducing the size of the 3mm panel started to make the panel sound more screach -y , like glass ,the panel was getting too rigid !

Holding the panel at the edges gives the panel a more warmer sound as it fills in the dips in the 200hz area , small weights at these points does improve fr, and I used this method on my rigidly clamped panels also.

as I have mentioned before ,in this old patent ,there are hints as to what tectonic are doing to their panel ,that are not in the tectonic patent ?

Steve.

It seems to me to be quite a complex subject how to suspend what parts of the panel and that it is really something you have to fine tune....neither fully rigid nor free hanging is optimal, but rigid is better than free.I'm not sure I would go as far as Christian to say clamped is loudest, but I do agree that constraining the edges can have a positive effect on both FR and overall output. One of the NXT patents demonstrated this but I'd have to look to find it.

For me, so far the best constraint seems to be attaching the panel to a rigid frame around most or all of the perimeter using a double sided foam tape. This approaches what engineers refer to as "simple supports" which implies that the edges of the panels can't move (not much, anyway), but can rotate. So the perimeter is mainly like a hinge. I think this is effectively what the Tectonic supports do, although their combination of rigid and compliant supports may be more nuanced.

Here are two examples comparing panels with frames and foam, compared to the same panels hanging from strings (free edges). In both cases the biggest difference is at the low frequency end, where the framed panels provide much greater output than the free panels. At higher frequencies, the responses tend to converge. The first is for a 16"x23" CF/balsa panel, and the second is for a 14"x48" plywood panel. In both cases, the same exciter was used for both test, and the amp was set to the same volume, and the mic was placed at 1 meter. I have done this many times and see pretty much the same thing every time.

Eric

View attachment 1040203

View attachment 1040205

I recall Tim from Tectonic speaking in some interview about plate mounting and bass response, and basically he said that they could have made the panel better at reproducing bass by having a looser suspension, but to the detriment of the rest of the spectrum for which then the suspension would be too loose.

Leob.

If trying to run a panel full range or for PA use ,manipulating a panel is a useful tool, but if for home use you are rolling off the response below 300hz or so , it becomes unnecessary.

when damping the edges with foam or rubber you are restraining the reflections, reducing dml modes and boosting others,

the panel is being pushed more into a bendingwave panel speaker.

the more damping the more into a bendingwave it becomes.

This alters the sound of the rest of the frequencies ,that you don't necessarily want to alter ?

there are many such speakers on the market today, with the exception of the podium of course.

I have found that clamping a dml panel ,tends to make it sound more like a conventional type of speaker.

which is not a problem ,if you like the sound of conventional speakers ?

Dml panels can be manipulated in so many ways, it depends on what you want from them.

Steve.

If trying to run a panel full range or for PA use ,manipulating a panel is a useful tool, but if for home use you are rolling off the response below 300hz or so , it becomes unnecessary.

when damping the edges with foam or rubber you are restraining the reflections, reducing dml modes and boosting others,

the panel is being pushed more into a bendingwave panel speaker.

the more damping the more into a bendingwave it becomes.

This alters the sound of the rest of the frequencies ,that you don't necessarily want to alter ?

there are many such speakers on the market today, with the exception of the podium of course.

I have found that clamping a dml panel ,tends to make it sound more like a conventional type of speaker.

which is not a problem ,if you like the sound of conventional speakers ?

Dml panels can be manipulated in so many ways, it depends on what you want from them.

Steve.

From everything I have seen and heard, the panel will ring more and have more uneven FR when it is free. I guess it would impart more DML character in a way...but I do think a lightly suspended DML sounds DML enough.Leob.

If trying to run a panel full range or for PA use ,manipulating a panel is a useful tool, but if for home use you are rolling off the response below 300hz or so , it becomes unnecessary.

when damping the edges with foam or rubber you are restraining the reflections, reducing dml modes and boosting others,

the panel is being pushed more into a bendingwave panel speaker.

the more damping the more into a bendingwave it becomes.

This alters the sound of the rest of the frequencies ,that you don't necessarily want to alter ?

there are many such speakers on the market today, with the exception of the podium of course.

I have found that clamping a dml panel ,tends to make it sound more like a conventional type of speaker.

which is not a problem ,if you like the sound of conventional speakers ?

Dml panels can be manipulated in so many ways, it depends on what you want from them.

Steve.

I do listen loud enough at home sometimes for the plates to start shaking if not restricted in any way, and would not like to cut as high as 300Hz. For all the materials I tried, some kind of suspension seems essential to get good sound, also far what I consider normal home use. Maybe it is a matter of taste, but I'm actually quite surprised to see see disagreement on that since the difference to my ears is so obviously in the dampened plates favour when listening. That has been true for me regardless of plate material, exciter used or music I test with.

Leob.

If you are listening to a panel full range or XO at about 100hz then most panels will sound a little odd, the dropouts in the response in about the 300hz to 100hz will be very noticeable.

this is why I run the low frequency drivers and the dml panels together in this region.

This sorts out the dips without affecting the rest of the frequencies on the panel.

Steve.

If you are listening to a panel full range or XO at about 100hz then most panels will sound a little odd, the dropouts in the response in about the 300hz to 100hz will be very noticeable.

this is why I run the low frequency drivers and the dml panels together in this region.

This sorts out the dips without affecting the rest of the frequencies on the panel.

Steve.

Can you explain what you mean by "softens the dynamics". Is dynamics something that can be measured? All I hear and measure is a better full range frequency response.Your frequency plots show clearly that the foam with frame is louder.

The ply panel is much louder below about 3k.

The cf panel only below about 400hz,

The problem with using foam is that it softens the dynamics .

Eric

Christian.

thank you for the recording.

I'm the recording you can hear a lot of the room.

have you tried to make a recording of moving closer to the speakers ,to see if you can find the sweet spot, hopefully where the room sound mostly disappears ?

But not so close as to make them sound like headphones.

In the description of recforge they say it still has a stereo setup, you can also have dual mono.

some phones will not allow stereo setup I'm afraid.

the hi-Q recorder does list some phones that will work with their app.

It looks like I will have to pay for the hi-Q app when I get my new phone, I only hope the phone will allow the other mic to be used ?

Steve.

thank you for the recording.

I'm the recording you can hear a lot of the room.

have you tried to make a recording of moving closer to the speakers ,to see if you can find the sweet spot, hopefully where the room sound mostly disappears ?

But not so close as to make them sound like headphones.

In the description of recforge they say it still has a stereo setup, you can also have dual mono.

some phones will not allow stereo setup I'm afraid.

the hi-Q recorder does list some phones that will work with their app.

It looks like I will have to pay for the hi-Q app when I get my new phone, I only hope the phone will allow the other mic to be used ?

Steve.

Christian,+ @spedge

A panel reaching nearly clamped condition is louder than any other suspension modes.

Christian

Now I recall at least one source of that information: it was this paper:

https://eprints.soton.ac.uk/369232/1/Eprints.pdf

where they say:

But the caveat is (as Loeb pointed out), the the clamped plate has a higher fundamental frequency than other boundary conditions. So while it might be most efficient above its fundamental, its fundamental is higher. So there is a trade off. My experience so far is that a "simple" boundary (i.e. like a hinge which limits displacement but not rotation), rather than clamped is a pretty good compromise between high radiation efficiency without driving the fundamental needlessly higher.

Eric

Eric.

yes I agree, holding the edges does give a fuller sounding panel, I think I have said this ?

But the affect of this is similar (but not the same) to banging a drum skin and then doing the same with your hand on the skin edges.

The drum will have a very dead sound, all the vibrant sounds will disappear.

this gives the panel a sort of closed in sound, similar to ordinary speakers.

clamping is not a compromise I would make.

Although rigid clamping of my 3mm ply panels worked very well , for a heavy panel.

Steve

yes I agree, holding the edges does give a fuller sounding panel, I think I have said this ?

But the affect of this is similar (but not the same) to banging a drum skin and then doing the same with your hand on the skin edges.

The drum will have a very dead sound, all the vibrant sounds will disappear.

this gives the panel a sort of closed in sound, similar to ordinary speakers.

clamping is not a compromise I would make.

Although rigid clamping of my 3mm ply panels worked very well , for a heavy panel.

Steve

Loeb,It seems to me to be quite a complex subject how to suspend what parts of the panel and that it is really something you have to fine tune....neither fully rigid nor free hanging is optimal, but rigid is better than free.

I recall Tim from Tectonic speaking in some interview about plate mounting and bass response, and basically he said that they could have made the panel better at reproducing bass by having a looser suspension, but to the detriment of the rest of the spectrum for which then the suspension would be too loose.

I think that panel suspension, combined with panel size and aspect ratio, is the most under-appreciated aspect of DMLs on this forum. These are the things that (along with the panels weight and stiffness) determine the panel's natural frequencies, and hence pretty much dictates everything that happens below something like 500 Hz.

Eric

So dynamics can't be measured then? Maybe coloration is a better word?Eric.

yes I agree, holding the edges does give a fuller sounding panel, I think I have said this ?

But the affect of this is similar (but not the same) to banging a drum skin and then doing the same with your hand on the skin edges.

The drum will have a very dead sound, all the vibrant sounds will disappear.

this gives the panel a sort of closed in sound, similar to ordinary speakers.

clamping is not a compromise I would make.

Although rigid clamping of my 3mm ply panels worked very well , for a heavy panel.

Steve

Free edges is not a compromise I would make.

In fact, I am noticing that well mounted panels that give the best response normally do sound more like a bongo than a drum head when tapped.

Eric

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker