I think for bass the suspension is very important. I think that might be one reason canvas works quite well, because it comes with decent suspension included.I know this thread is "full range DMLs" but if you were going to make a panel specific for bass, what material would you choose?

From my somewhat limited experience I would probably choose same materials as usual for a bass plate. You want high efficiency for a bass, so EPS on the cheap and low effort, and making sandwich composites if I had more money and time. Of the materials I have tried (Polycarbonate, Ply, Printed plates and EPS), the EPS was not only by far most efficient but also has the most solid bass I think.

The consensus seems to be thinner more flexible materials and larger panels are better for bass, but seems like at loud levels it is also important how controllable it is. A plate that flexes a lot will displace more air, but also becomes really hard to suspend so you don't get the phasey effect of the plate counteracting the motion of the exciter when it is all wobbling around. With the 25mm EPS the plate is not moving more than a regular cone at similar levels it seems like, which is probably a reasonable target.

I have some 10mm EPS I will try as well, and I will se how much effect it has on the bass and the stability of the plate at high levels, but if it gives a noticeably louder bass response my fear is that it will also be more uneven and will probably become more difficult to suspend.

Also, I think the larger the plate the more it will affect the impulse response since the waves have more surface to travel, so they will travel longer time. So while larger plates should give deeper bass looking at the frequency domain, smaller plates probably give tighter bass when looking at the time domain.

Funny you should ask. I just spent the last week or so playing with ideas for DML sub. My latest plywood DML's work pretty well above 100 Hz, but really benefit from a sub. I think a regular pistonic sub works fine, but I thought it would be fun to have a fully DML system.I know this thread is "full range DMLs" but if you were going to make a panel specific for bass, what material would you choose?

Like Loeb suggested, I immediately thought of EPS. Mainly because of it's efficiency. Since bass is harder to get from DML, I thought the high efficiency of the EPS would allow enough low frequency output to balance with the plywood output above 100 Hz. Also, the problems EPS sometimes has (poor response at high frequency, and echo-y sound for voices), would be irrelevant below 100 Hz.

My basic idea was to make a reasonably sized panel that would have it's fundamental frequency at about 50 Hz, and hope that that single mode would provide decent output up to 100 Hz before any huge dips or spikes.

After playing around with a few different concepts, I ended up with a 635mm x 560mm EPS panel that's about 14 mm thick. The only reason it's not square is simply because the foam's elastic moduli are different in the two directions. With this panel's properties, this was the minimum size panel that would give me a fundamental around 50 Hz (when supported all around the perimeter). The panel is mounted in a frame with a double sided foam tape (3M 411, 1/4" wide, double thick). Since I care only about driving the fundamental mode, I put the exciter (DEAX25fhe) exactly in the center of the panel.

The FR of this panel is about as I hoped, it rises to a peak at about 60 Hz, then falls to a plateau about 5 dB lower from 70 to 120 Hz. It then dips a bit before rising to a nasty peak at 200 Hz, where both the 1,3 and 3,1 modes kick in. My plan is to add a low pass filter at 100 Hz to blend this with the plywood panels that will cover the rest. It does a pretty decent job on Pachelbel's Canon in D. I'm eager to hear it with the LPF when I get that added.

I also tried supporting only two edges first, instead of four, as that would have allowed for a smaller panel at the same fundamental frequency. I was disappointed in that result. I think the output was considerably weaker than with the 4 edges supported, but I can't seem to find the measurements! I tried a few other exciter placements too, but none seemed any better than dead center.

I also tried a different double sided tape around the perimeter, with lower damping than the 3M 411. On most panels, the damping of the tape has a big effect. But for this panel the only significant effects were above 150 Hz.

Eric

Thanks,Narenaud.

If you are not using for mixing or partying,

The quick and easy option would be the canvas art panel, but using a larger ply panel for better LF control.

The down side obviously would be that it is a full range dml panel 😄

You could try a small bass shaker on The panel I suppose ?

At a few hundred HZ the panel would be heavily into piston mode already, I would think ?

thinking about it , I would probably use my art canvas panel without the ply for everything above about 200hz and the art panel with the larger ply for everything below this.

This could be quite flexible as you could switch them easily to full range if needed.

I have not as yet tried using a larger panel on the art panel so can not guarantee it's performance.

Steve.

There are a few other options , but this would probably be the quickest and easiest option, I believe ?

Currently I have giant hybrid panels...6 feet by 3 feet made of carbon fiber and foam sandwich and Dow-corning XPS. They work well to about 13,000Hz and have high pass filter at 150Hz with only 6db/octave which means they still make some bas but are supplemented by my little powered sub. The "Bass panel" would serve to get rid of the box altogether and would need to be mostly smooth FR below, like 300Hz? I'd put a low pass filter somewhere below that. I get that really low frequencies are basically pistonic so it would seem a stiffer material would be better than canvas, right?

I read in another forum someone did a bass shaker on plywood for this purpose and that seems reasonable. Controlling the reverse phase off the back seems a problem. I wonder if I could make it like a giant shallow sealed box sub with some sound absorber inside. 110cm by 90cm would maybe 10cm thick would fit nicely on my wall below the TV between the giant panels.

Narenaud.

You say the fr is good up to 13k.

Do you have frequency plots , so I can see what is going on ?

I just this minute found your photos that you had missed from your post.

the panels are very close to the wall and you are probably getting a lot of cancellation going on.

This would not help the sound either.

putting a dml panel sub close to the wall ,would also compromise its low frequencies.

Steve

ps.

the canvas panel for sub use would have a larger ply panel glued to its fabric.

You say the fr is good up to 13k.

Do you have frequency plots , so I can see what is going on ?

I just this minute found your photos that you had missed from your post.

the panels are very close to the wall and you are probably getting a lot of cancellation going on.

This would not help the sound either.

putting a dml panel sub close to the wall ,would also compromise its low frequencies.

Steve

ps.

the canvas panel for sub use would have a larger ply panel glued to its fabric.

Narenaud.

the only panel type design I can think of that could work close to a wall would be a re-design of this old patent.

Steve.

https://patents.google.com/patent/US3164221A/en

the only panel type design I can think of that could work close to a wall would be a re-design of this old patent.

Steve.

https://patents.google.com/patent/US3164221A/en

Last edited:

So I have a few things to share in my tests.

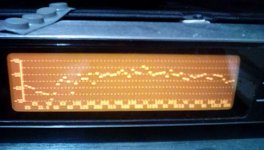

The first is the image. It is a white noise test that shows the initial response of long panels, no equivalent and no filtering. The results are clear, 'a saddle response with some equation required to flatten the response.

Attach 2 MP4 recordings to the boards. Both were recorded raw with no equivalent of any description. They were recorded in a room so there are some room reflections and some ground noise at the beginning of each recording is very clear. Sorry about that but I couldn't score at the level I wanted or else I wouldn't be popular.

https://vnvideoeditorpc.com/

The first is the image. It is a white noise test that shows the initial response of long panels, no equivalent and no filtering. The results are clear, 'a saddle response with some equation required to flatten the response.

Attach 2 MP4 recordings to the boards. Both were recorded raw with no equivalent of any description. They were recorded in a room so there are some room reflections and some ground noise at the beginning of each recording is very clear. Sorry about that but I couldn't score at the level I wanted or else I wouldn't be popular.

https://vnvideoeditorpc.com/

Eric.

I just took a quick photo of my low grade EPS panel.

As you can see in the fr plot the hf extends up to 16k before dropping off a little and then carrying on up to 20k and probably beyond.

This is easily attainable even as I say with low grade EPS ,the higher grades have no problem reaching 20k on there own without modifications.

I have still not heard the echo-y sound that you mentioned.

The only sound that I thought might be the echo you mentioned was on untreated panels with the original EPS hard skin ?

The plot is at 12inches but is pretty much unchanged in the HF at 3m.

Steve.

I just took a quick photo of my low grade EPS panel.

As you can see in the fr plot the hf extends up to 16k before dropping off a little and then carrying on up to 20k and probably beyond.

This is easily attainable even as I say with low grade EPS ,the higher grades have no problem reaching 20k on there own without modifications.

I have still not heard the echo-y sound that you mentioned.

The only sound that I thought might be the echo you mentioned was on untreated panels with the original EPS hard skin ?

The plot is at 12inches but is pretty much unchanged in the HF at 3m.

Steve.

Attachments

Not too stiff for our application?NaRenaud,

I totally agree. Wow. That's awesome. I've been wondering how to do nomex without prepreg. I have similar nomex, and similar fiberglass. Hmm...

Great post. Thank you!

Eric

Christian

Thank you NaReaud

I see my understanding of your design was incorrect.

How are the 2 exciters connected (probably already explained sorry)?

Christian

@LeobLeob and Christian.

the mystery remains for me too.

no resonance hump below 100hz and a very heavy smooth roll off after 4k ?

Steve.

Leob,

Could you remind us how the panel is suspended in your last FR?

Christian

I have just gone mad , and pulled apart my art canvas panel so that I can try and attach a larger panel.

I had to cut out the old small ply panel as the pva was not going to let it go without damaging it anyway.

Hopefully the panel will be dry enough tomorrow to glue the exciter in place.

I found an old crate that had 2mm thick sides that fitted nicely after cutting.

I know it's not great quality , but will do for testing to see if the low frequencies improve ?

Steve.

I had to cut out the old small ply panel as the pva was not going to let it go without damaging it anyway.

Hopefully the panel will be dry enough tomorrow to glue the exciter in place.

I found an old crate that had 2mm thick sides that fitted nicely after cutting.

I know it's not great quality , but will do for testing to see if the low frequencies improve ?

Steve.

Attachments

I really have to start working on a suspension solution :\ Now they are hanging from strings, unbraced and unframed, but on the FR I posted I held on to the bottom corners. It makes the response a bit smoother, and is necessary to get good clean sound on high levels. But I did take one without holding the panel as well...I have not saved it, but as I recall it was quite similar but with little extra dips and bumps in bass response.

Next I will try same setup of exciters on the 25kg/m3 EPS, and will post graph with the freely hanging panels as well.

Re-watched this video, and it has an interesting explanation of how the cluster of exciters on Tectonic panels works to expand the "primary radiation centre", and how it effects the balance of directly emitted sound and diffuse tail from the propagation of waves in the plate:

And I will do the other way by helding at the corners... Hopefully it will explain the differences.I really have to start working on a suspension solution :\ Now they are hanging from strings, unbraced and unframed, but on the FR I posted I held on to the bottom corners. It makes the response a bit smoother, and is necessary to get good clean sound on high levels. But I did take one without holding the panel as well...I have not saved it, but as I recall it was quite similar but with little extra dips and bumps in bass response.

Next I will try same setup of exciters on the 25kg/m3 EPS, and will post graph with the freely hanging panels as well.

Christian

Tectonic patentRe-watched this video, and it has an interesting explanation of how the cluster of exciters on Tectonic panels works to expand the "primary radiation centre", and how it effects the balance of directly emitted sound and diffuse tail from the propagation of waves in the plate:

Have a look to this patent : WO2016118341A1 Audio transducer stabilization system and method

Not read it completly but seems showing details of the Tectonic design.

That's a very strange thing.Narenaud.

the only panel type design I can think of that could work close to a wall would be a re-design of this old patent.

Steve.

https://patents.google.com/patent/US3164221A/en

If you watch his testing it's fairly flexible, but with extremely high stiffness to weight.Not too stiff for our application?

Christian

It would be cool to put some lighting effects behind it.

Each "exciter" is 8 ohm's and they are parallel so the amp sees 4 ohms. One of the exciters though is a Dayton spider that has 4 exciters in a plastic frame wired parallel-series to give final 8 ohm's.Thank you NaReaud

I see my understanding of your design was incorrect.

How are the 2 exciters connected (probably already explained sorry)?

Christian

At first I had both exciters close together on the CF panel but then moved the spider to the XPS and it sounds better that way. Doing side-by-side tests comparing the Dayton "balanced spring" exciter to the spider, I don't particularly like the spider.

I'm sorry I only have my ears to go by as I've never used REW or similar software and have yet to download or learn to use such a thing. I do have an old H1n mic in a drawer and intend to pull it out eventually and do some tests.

To my ears, the spider does sound a bit more even on a slow tone sweep, but it also sounds less crisp with actual music. Looking at it, the even square arrangement of 4 exciters seems not very good based on other people's experiments so I took apart the other spider and separated the 4 individual (10w cup) exciters. I then epoxied these to a spine in a straight line with a stepped distance between the exciters...1 is almost touching 2, 2 is a few centimeters from 3, and 3 is more than that from 4. I didn't measure because there doesn't seem to be any math to say what is best so I guessed. I knew I didn't want equal distances though. I'll mount that on a roughly 1 square meter panel (36 inches by 39 inches) that will sit below a same-sized panel with the central CF plate with the balanced spring exciter. My thought is the right speaker sounds really good but uncoupling it into 2 panels might give a more even response by decreasing the interactions of the two components.

I also plan to do a thin fiberglass skin on those and my epoxy is out for delivery to the house. When it arrives I'll start skinning. The XPS is super cheap so it it fails I'll go back to plain. The skinned panels would have an aesthetic advantage and also be more durable. I worry about these getting damaged from people rough housing in the area or just from me moving my TV on it's articulating arm.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker