That's part of why I'm looking at fiberglass. Light, strong, and much easier to work with.

What about this fiberglass I'm suggesting?

Has anyone tried shellac on EPS instead if PVA?

Shellac is mentioned many times on the NXT RUBBISH forum .

Mainly for coating cc ,which I wasn't keen on.

It remained quite heavy and had a very long drying time that never really hardened ?

Yes I did try it on eps.

Steve.

I've just done another recording of the same Peter Gabriel track,but this time with the 6x9inch veneer panel on the left.

I was switching between the two panels to get the levels right , and I suddenly though why not compare the big xps epoxy coated panel with the small veneer panel.

Just so everyone can have a listen to what they would be missing if they only have a poor little panel.

To make it a fair comparison I crossed both panels over at 300hz.

And used the left channel signal only for both panels.

It's not easy getting the balance right as you don't know until you listen to the recording.

I did four recordings and this was the first, I think it's the closest?

I'll post it when I've processed the recording.

Steve.

I was switching between the two panels to get the levels right , and I suddenly though why not compare the big xps epoxy coated panel with the small veneer panel.

Just so everyone can have a listen to what they would be missing if they only have a poor little panel.

To make it a fair comparison I crossed both panels over at 300hz.

And used the left channel signal only for both panels.

It's not easy getting the balance right as you don't know until you listen to the recording.

I did four recordings and this was the first, I think it's the closest?

I'll post it when I've processed the recording.

Steve.

the left chanel still sounds a bit lower than the right but ive also got to contend with the higher output of the xps at xo.

i should have let the small panel xo at a lower frequency to match the xps ,but thought that this was getting a little complicated, i better keep it simple.

they sound quite similar in my room considering they are two different materials ?

they were both playing petty loud when i made the recording in a very crowded room.

steve.

i should have let the small panel xo at a lower frequency to match the xps ,but thought that this was getting a little complicated, i better keep it simple.

they sound quite similar in my room considering they are two different materials ?

they were both playing petty loud when i made the recording in a very crowded room.

steve.

Attachments

I totally forgot the reason for mounting the veneer panel.

I wanted to measure the 2.5k and the 9k peaks, but because of my fabric dome there is none.

This is from the front and back of the exciter.

When I get around to it I will try and attach a fabric dome to my first messy epoxy panel and see how it goes?

Steve.

I wanted to measure the 2.5k and the 9k peaks, but because of my fabric dome there is none.

This is from the front and back of the exciter.

When I get around to it I will try and attach a fabric dome to my first messy epoxy panel and see how it goes?

Steve.

I've just done another recording of the same Peter Gabriel track,but this time with the 6x9inch veneer panel on the left.

Can you describe better or show a photo on how is exactly that veneer panel?

Xrk971.

I have three panels drying at the moment.

This one is wood ply that peeled off from a 1940s draw in my shed.

I coated the ply in 50x50 pva.

It is 1mm thick and 9x6inches ,I've just glued the exciter with dome in position ,and cut the corners to reduce vibrations.

The first picture is about 4inches in front of the exciter.

The second is 3mtrs into the room,both are rolled off at 170hz to keep LF well away.

This is how easy it is to make a pretty good sounding panel speaker,wit very little effort of course I could improve on this with a little more effort, it's still drying so the response will change a little in a few days.

I could not use the panel without the dome as there was already a hole where the draw handle was 😀

So sorry, no comparison.

But it's all about the sound.

Although it's pretty good fun too.

I will when I get time do a recording ,hopefully with a higher quality conversion rate ,for you to make up your own mind whether it' sounds good ,or not?

Steve.

Carlmart.

On pages 330 and 332 is where I started that veneer test panel and recordings.

Steve.

Carlmart.

Page 335 also has some pictures and recording of the veneer panel and a card panel, which I cut to the same size and shape as the veneer panel to match them closely.

Steve.

Page 335 also has some pictures and recording of the veneer panel and a card panel, which I cut to the same size and shape as the veneer panel to match them closely.

Steve.

Steve,

Thanks for the pages numbers.

I was curious the board you call "veneer", and then you clarify it's 1mm veneer, which you are right you can't find that thickness anymore. Most of the ones I have seen as available now in Brazil I think are 0.5mm or about that.

I have veneered some speakers in the past, and the material always came in rolls. Contact glue was the one I used to apply the veneer.

So I wonder if such veneer could be used for panels, how to flatten them and how to keep them flat. Should a frame be used? Glued I guess, as nails or scews might affect the response. Am I right?

Please tell me if someone has used such veneer panels and the results.

I think I've seen photos from your painting panels with swatches of veneer glued to the back of the cloth.

It's so many options that I get lost a lot.

Another thing I've seen on your panels is a dome over the exciter, with a hole for it. What's the reason for that dome? Where did you get the dome?

I've also made a question about fiberglass panels, that used for pcbs, that nobody commented on. A friend of mine said dampness would be very low.

Thanks for the pages numbers.

I was curious the board you call "veneer", and then you clarify it's 1mm veneer, which you are right you can't find that thickness anymore. Most of the ones I have seen as available now in Brazil I think are 0.5mm or about that.

I have veneered some speakers in the past, and the material always came in rolls. Contact glue was the one I used to apply the veneer.

So I wonder if such veneer could be used for panels, how to flatten them and how to keep them flat. Should a frame be used? Glued I guess, as nails or scews might affect the response. Am I right?

Please tell me if someone has used such veneer panels and the results.

I think I've seen photos from your painting panels with swatches of veneer glued to the back of the cloth.

It's so many options that I get lost a lot.

Another thing I've seen on your panels is a dome over the exciter, with a hole for it. What's the reason for that dome? Where did you get the dome?

I've also made a question about fiberglass panels, that used for pcbs, that nobody commented on. A friend of mine said dampness would be very low.

veneer, pap-board a.o.

Hello carlmart

My goal is to use renewable material and a frequency range from 50Hz to 15 kHz.

After a pause in experimenting with DML (cardboard, honeycomb cardboard and kraftplex), I started again with kraftplex in the size of Steeve's veneer panel. One panel is damped at the surrounding with a rice foam cake (baked in the oven) to achieve some damping. The result so far does not meet my expectations in tonal balance (body). When it came out from the oven, I experienced a very fine tonal balance at the first listening. Next day it lost most of the body and adding some water didn't helped. The other panel (kraftplex) I'm working now will get some heavy rubber at the surrounding to achieve damping. There may be also other ways for damping small panels, like mounting in a canvas frame a.o.

About your idea to work with pcb-boards, please give it a try. Earlier in this thread some colleagues worked with Perspex and achieved fine results

Eric.

btw: title should be veneer, pcb-board a.o.

Hello carlmart

My goal is to use renewable material and a frequency range from 50Hz to 15 kHz.

After a pause in experimenting with DML (cardboard, honeycomb cardboard and kraftplex), I started again with kraftplex in the size of Steeve's veneer panel. One panel is damped at the surrounding with a rice foam cake (baked in the oven) to achieve some damping. The result so far does not meet my expectations in tonal balance (body). When it came out from the oven, I experienced a very fine tonal balance at the first listening. Next day it lost most of the body and adding some water didn't helped. The other panel (kraftplex) I'm working now will get some heavy rubber at the surrounding to achieve damping. There may be also other ways for damping small panels, like mounting in a canvas frame a.o.

About your idea to work with pcb-boards, please give it a try. Earlier in this thread some colleagues worked with Perspex and achieved fine results

Eric.

btw: title should be veneer, pcb-board a.o.

Last edited:

Carlmart.

I would treat the veneer exactly the same way I treat card ,undiluted pva in the centre of the 0.5mm card or veneer ,then place the panel to dry between two flat ply boards.

The veneer or card should be flat after drying.

I usually coat both sides of the card panel with the 50x50 mix and hang the panel up to dry.

The veneer panel I put quite a few coats of neat pva to try and fill some of the bad cracks in the veneer,with no audible problems.

If it bends too much I would apply a little heat with a hair dryer and place between the ply sheets again ,this should then stay flat when cool.

I use 0.5mm card from old cornflakes boxes,or pizzas,which are free to experiment with 😀

Have you listened to my veneer and card recordings ?

I have just made and shown the reason for the dome in a recording ?

I made the dome myself , it's very easy.

For a full range canvas panel the 2mm ply is needed on the centre, not veneer.

Fiberglass ,I would expect to have a bit of a hard sound ,those are very small panels,but there is no harm in trying them? If you want to spend the money?

I believe I do have some expensive fiberglass panels a friend purchased and gave me a few years ago,but they had problems I didn't want to deal with ,if I remember correctly.

If you are looking for a stand alone full range panel I would go for the canvas and ply panel,you may not need anything else as these go a lot lower than most book shelf speakers already (if used away from the back wall !!! ).

The veneer and card have to have a low end driver to fill in the frequencies below 300hz, even though they will go down to about 130hz ?

Steve

I would treat the veneer exactly the same way I treat card ,undiluted pva in the centre of the 0.5mm card or veneer ,then place the panel to dry between two flat ply boards.

The veneer or card should be flat after drying.

I usually coat both sides of the card panel with the 50x50 mix and hang the panel up to dry.

The veneer panel I put quite a few coats of neat pva to try and fill some of the bad cracks in the veneer,with no audible problems.

If it bends too much I would apply a little heat with a hair dryer and place between the ply sheets again ,this should then stay flat when cool.

I use 0.5mm card from old cornflakes boxes,or pizzas,which are free to experiment with 😀

Have you listened to my veneer and card recordings ?

I have just made and shown the reason for the dome in a recording ?

I made the dome myself , it's very easy.

For a full range canvas panel the 2mm ply is needed on the centre, not veneer.

Fiberglass ,I would expect to have a bit of a hard sound ,those are very small panels,but there is no harm in trying them? If you want to spend the money?

I believe I do have some expensive fiberglass panels a friend purchased and gave me a few years ago,but they had problems I didn't want to deal with ,if I remember correctly.

If you are looking for a stand alone full range panel I would go for the canvas and ply panel,you may not need anything else as these go a lot lower than most book shelf speakers already (if used away from the back wall !!! ).

The veneer and card have to have a low end driver to fill in the frequencies below 300hz, even though they will go down to about 130hz ?

Steve

Kraftplex

Sorry, I‘ve forgotten to specify the Kraftplex board. It is 1 mm thick and has small, fine corrugated structures on the surface. Informationen about the product are here: Kraftplex.com.

Sorry, I‘ve forgotten to specify the Kraftplex board. It is 1 mm thick and has small, fine corrugated structures on the surface. Informationen about the product are here: Kraftplex.com.

Thanks, Eric and Steve. Your comments are very enlightening.

There's a store downtown that sells things made with a material similar to Kraftplex. They probably have separate boards to sell too, in different sizes, and quite likely not expensive.

Is this the one you tried?

https://shop.kraftplex.com/epages/61603095.sf/en_GB/?ObjectPath=/Shops/61603095/Products/6306-56x34

Yes, I did listen to your veneer and card recordings. I think it was one that played the same music and you edited it, cutting from one board to another one, some with sub speaker. I noticed the sub, and at first I thought it didn't have one, and was happy to listen to a good bass. Thought it was just the boards.

BTW: how or using what program did you edit the tracks? It was completely precise. Congrats on that. I am sound engineer, with trained ear, and couldn't find any misses.

Can't say I listened to the one with dome, but I think I did. Will look for it and see if I can find it.

The canvas frame idea has been the one I like better. My only limitation are the sizes I will find for sale. The ply wood be better to round the corners, and how thin are the one I can find.

Over here there's a compacted fiber material that I don't know the name of in the USA or Europe:

https://www.leomadeiras.com.br/mdf-mdp-e-chapas-de-fibra/chapas-de-fibra/010401

Has anyone tried it? It's shiny and hard on one side, and raw on the other. It comes in 2.5mm, 3.5mm and 4mm on the other.

What about Formica?

You seemed to imply pcb fiberglass panels are expensive, but not those sold by Aliexpress that I showed. If I got it right.

The most usual size you use is which?

Carlos

There's a store downtown that sells things made with a material similar to Kraftplex. They probably have separate boards to sell too, in different sizes, and quite likely not expensive.

Is this the one you tried?

https://shop.kraftplex.com/epages/61603095.sf/en_GB/?ObjectPath=/Shops/61603095/Products/6306-56x34

Yes, I did listen to your veneer and card recordings. I think it was one that played the same music and you edited it, cutting from one board to another one, some with sub speaker. I noticed the sub, and at first I thought it didn't have one, and was happy to listen to a good bass. Thought it was just the boards.

BTW: how or using what program did you edit the tracks? It was completely precise. Congrats on that. I am sound engineer, with trained ear, and couldn't find any misses.

Can't say I listened to the one with dome, but I think I did. Will look for it and see if I can find it.

The canvas frame idea has been the one I like better. My only limitation are the sizes I will find for sale. The ply wood be better to round the corners, and how thin are the one I can find.

Over here there's a compacted fiber material that I don't know the name of in the USA or Europe:

https://www.leomadeiras.com.br/mdf-mdp-e-chapas-de-fibra/chapas-de-fibra/010401

Has anyone tried it? It's shiny and hard on one side, and raw on the other. It comes in 2.5mm, 3.5mm and 4mm on the other.

What about Formica?

You seemed to imply pcb fiberglass panels are expensive, but not those sold by Aliexpress that I showed. If I got it right.

The most usual size you use is which?

Carlos

Last edited:

100ohms.

Kraftplex looks like a compressed wood fibre board similar to hardboard,but without the chemicals.

It could possibly sound similar ?

I'm not sure what you are hoping to achieve by mounting the panel with rubber damping.

what problems Are you having that the rubber will cure ?

My card and veneer panels in the recording , have no bad sounding problems,and they were playing at a high volume.

Voices were very natural,I was very impressed with them.

Steve.

Kraftplex looks like a compressed wood fibre board similar to hardboard,but without the chemicals.

It could possibly sound similar ?

I'm not sure what you are hoping to achieve by mounting the panel with rubber damping.

what problems Are you having that the rubber will cure ?

My card and veneer panels in the recording , have no bad sounding problems,and they were playing at a high volume.

Voices were very natural,I was very impressed with them.

Steve.

Thanks, Eric and Steve. Your comments are very enlightening.

There's a store downtown that sells things made with a material similar to Kraftplex. They probably have separate boards to sell too, in different sizes, and quite likely not expensive.

Is this the one you tried?

https://shop.kraftplex.com/epages/61603095.sf/en_GB/?ObjectPath=/Shops/61603095/Products/6306-56x34

Carlos

Hello Carlos

Yes, this looks like the one I'm working with.

That's nice, that it is now available in small quantities. I've got one large sheet (1m2) from a colleague, who had to order once a large quantity.

It's easy to work with.

Eric

Hello Steve100ohms.

Kraftplex looks like a compressed wood fibre board similar to hardboard,but without the chemicals.

It could possibly sound similar ?

I'm not sure what you are hoping to achieve by mounting the panel with rubber damping.

what problems Are you having that the rubber will cure ?

My card and veneer panels in the recording , have no bad sounding problems,and they were playing at a high volume.

Voices were very natural,I was very impressed with them.

Steve.

The sound with the Kraftplex panel without any ‚cure‘ is far from natural, is distorted in lower bass region at higher volumes. When I listened to my rise foam ‚cured panel‘ coming fresh from the oven, some of these issues weren’t present at moderate volume. Now I‘ve cured it with some heavy rubber near the edges. It sounds good, similar to the rise foam type at it’s best state😉 Need some more time to check out the things and will publish measurements and recordings.

Eric

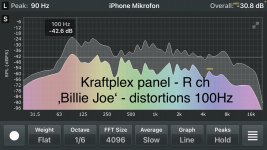

Kraftplex cure

Hello Steve

some photos about the things so far:

- Kraftplex panel with rice foam cake, front view (size of board is not 6to9)

- music graph* 'fresh from the oven'

- music graph* Kraftplex panel without cure (at 100 Hz the peak shows the distortions)

- Kraftplex panel with rubber damping, rear view

- music graph* with rubber damping cure

*(the grey graph shows the holded peaks, while the colored area is the instant capture)

it's just to illustrate and no science

Eric

Hello Steve

some photos about the things so far:

- Kraftplex panel with rice foam cake, front view (size of board is not 6to9)

- music graph* 'fresh from the oven'

- music graph* Kraftplex panel without cure (at 100 Hz the peak shows the distortions)

- Kraftplex panel with rubber damping, rear view

- music graph* with rubber damping cure

*(the grey graph shows the holded peaks, while the colored area is the instant capture)

it's just to illustrate and no science

Eric

Attachments

-

245EDD97-87A3-4B28-9BAD-5290DFD20EC2_1_201_a.jpeg438.7 KB · Views: 257

245EDD97-87A3-4B28-9BAD-5290DFD20EC2_1_201_a.jpeg438.7 KB · Views: 257 -

2317FC7E-D278-40C9-B0D2-2EE59E1F90F0_1_201_a.jpeg185.4 KB · Views: 377

2317FC7E-D278-40C9-B0D2-2EE59E1F90F0_1_201_a.jpeg185.4 KB · Views: 377 -

5BD60E65-6E9F-4078-924B-0F9709DDF471_1_201_a.jpeg199.5 KB · Views: 365

5BD60E65-6E9F-4078-924B-0F9709DDF471_1_201_a.jpeg199.5 KB · Views: 365 -

E2C7D9CD-607C-4B93-BB6B-D191E7556C54_1_201_a.jpeg537.5 KB · Views: 242

E2C7D9CD-607C-4B93-BB6B-D191E7556C54_1_201_a.jpeg537.5 KB · Views: 242 -

4936A6FD-EA87-49A2-BCA0-6D5711ACEFE7_1_201_a.jpeg190.4 KB · Views: 378

4936A6FD-EA87-49A2-BCA0-6D5711ACEFE7_1_201_a.jpeg190.4 KB · Views: 378

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker