I'm testing fast prints with 2mm nozzle. Largest I have is 3mm so 4mm wall is possible at once in vase mode.

Open source Waveguides for CNC & 3D printing!

Open source Waveguides for CNC & 3D printing!

Of course they have different weights in the calculation, proportionately to the area they represent, that's the essence of it. The beauty of axial symmetry is that this can be calculated very easily just from one set of polars.

Yes, you're right. I found the post that started my thinking and can see where I got of track:

I thought about the error function criteria for the optimization algorithm a bit. Maybe I would define a target DI curve and evaluate the error function as the residual sum of squares between the target and an average DI curve calculated for a selected listening window (not necessarily containing the on-axis response). Maybe this all weighted with frequency somehow.

What i really notet was the "selected listening window". Perhaps you could elaborate?

Some thoughts: Clearly one wants the optimization to be weighted towards the listening window (in terms of smoothness i supose) but a hard limit can't be good can it? I worry if the optimization might just push response problems outside of this window if made too narrow.

I might be out of my depth on this topic, but i think the optimization is a powerfull tool with many interesting variables and just wanted to incourage further investigation.

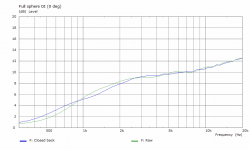

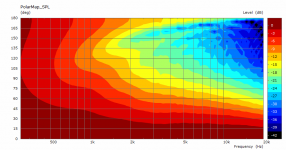

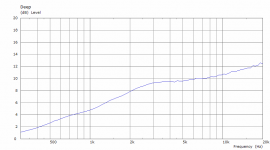

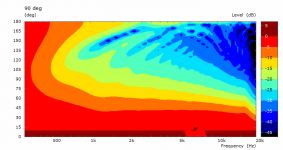

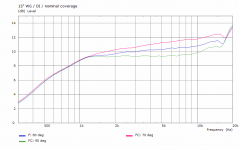

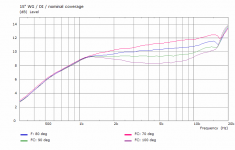

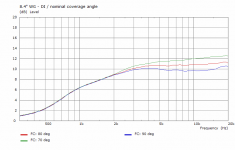

. The black DI curve is full space (i.e. the real DI), the blue curve for the front hemisphere only (just for comparison).

Did you do calculations of DI in VACS ?

- could you just keep the rollover rolling to close the "ball"? That would I think be interesting to see.

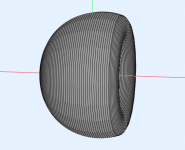

The raw shape "DE7" (just added thickness):

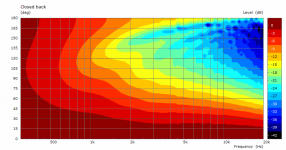

Closed-back:

Differences between the axial DIs:

Attachments

Last edited:

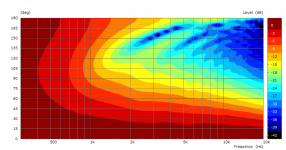

It doesn't really improve anything, IMHO. Here is a deeper one. The basic rollback is just good enough, if not better actually.

Attachments

Last edited:

It's hard to foresee all that could happen but once you reach a target of a flat and smooth DI, you can be sure that the direct sound (being it a selected angle or some average over a listening window) will track the power response closely, i.e. it will be possible to EQ for a flat and smooth overall response in the end. That's the rationale behind that.What i really notet was the "selected listening window". Perhaps you could elaborate?

Some thoughts: Clearly one wants the optimization to be weighted towards the listening window (in terms of smoothness i supose) but a hard limit can't be good can it? I worry if the optimization might just push response problems outside of this window if made too narrow.

Thank you sir!

A wondering turned into knowing. And I agree - not much in it. But it looks bloody powerful 😉

//

A wondering turned into knowing. And I agree - not much in it. But it looks bloody powerful 😉

//

Last edited:

Honestly, I don't like the looks 🙂 Too futuristic to me. - Or maybe not, probably dependent on a material. Concrete could be nice.

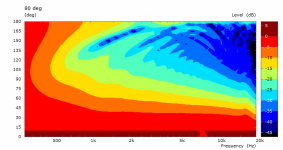

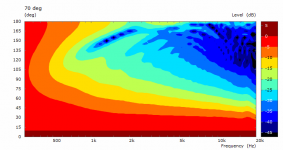

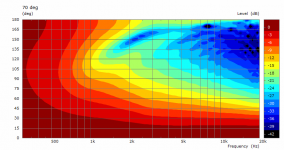

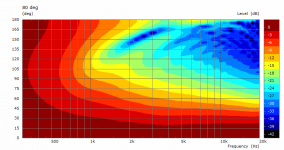

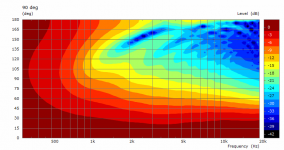

Added fourth with 100 deg -- three 15" waveguides with different nominal coverage angles (adjusted to the same overall diameter of 386 mm).

Attachments

Perhaps a different model would give a different result?I don't know. I don't mind.

That's all that matters, the model appears to be accurate, please try to find out what model is used.

I really don't care, I wouldn't understand it anyway. It's Joerg Panzer's ABEC / AKABAK. If you are intersted, I'm sure the information is available.

This really would be a task for some optimization, I guess, i.e. to specify a DI curve as a target and see what shape and size/length would come the closest. So far I'm not very certain what's going on here.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)