Port dimensions!

I can't find where you noted it, but going by 40 cm2, it should be 2 and 13/16th " diameter, correct?

I can't find where you noted it, but going by 40 cm2, it should be 2 and 13/16th " diameter, correct?

It was in my original sim, so assuming you've built the 600 cm^2 internal CSA [area]: [40.49 cm^2*4/pi]0.5 = 7.18 cm/2.54 = 2.83" = ~2-13/16"

Works for me! 😉 , though 2-3/4" or 2-7/8" is close enough.

GM

Works for me! 😉 , though 2-3/4" or 2-7/8" is close enough.

GM

The "piano towers" (working title) are coming along!

Having a Christmas break helps... Though I'm not sure I'm getting any more done than when I just worked on it every spare evening.

Just hoping I can find out how to bring the grain out of the Birch. It's apparently hard to stain and finish!! These pieces have a lot of stormy looking grain.

Having a Christmas break helps... Though I'm not sure I'm getting any more done than when I just worked on it every spare evening.

Just hoping I can find out how to bring the grain out of the Birch. It's apparently hard to stain and finish!! These pieces have a lot of stormy looking grain.

The "piano towers" (working title) are coming along!

Having a Christmas break helps... Though I'm not sure I'm getting any more done than when I just worked on it every spare evening.

Just hoping I can find out how to bring the grain out of the Birch. It's apparently hard to stain and finish!! These pieces have a lot of stormy looking grain.

View attachment 803883

Prefatory caution that I have only tried this on solid highly figured maple, not (yet) on Baltic Birch plywood, but ferric nitrate in a dilute solution, followed by judicious and careful use of a heat gun, does a remarkable job of giving a warm reddish brown that accentuates rather than masking grain figure (with highly figured tiger maple it looks literally nearly holographic). This is the classic technique for highly figured flintlock 'Kentucky longrifles.' Until you use the heat it looks like a dreadful and even slightly opaque olive-brown, upon application of heat it turns warm brown with tremendous 3-d depth of the grain figure. I read somewhere of someone using isopropyl alcohol rather than water as the solvent in the application solution, to avoid raising grain in the wood the way water does. When I've used it, I've just scuffed the wood surface with Scotchbrite to take off the raised grain (avoid steel wool, steel fibers can linger in wood pores and lead to black spots later). Suppliers for stockmakers sell the fluid (sometimes called "Aquafortis" which isn't really accurate, as that term refers to nitric acid, a precursor to iron nitrate), but I got a batch of powdered ferric nitrate, lab grade, via eBay, at modest cost, and its going to be a life supply. If you choose to use this, try it first on scrap of the same wood you intend to finish, and try different dilutions for your preferred tone and depth of color in the particular wood that you are working with.

Hi .

I am following the project with interest and I was thinking of creating a nearfield library with the W6-2144 in DCAAV since the specifications are suitable for this type of configuration, do you think it is possible?

I am following the project with interest and I was thinking of creating a nearfield library with the W6-2144 in DCAAV since the specifications are suitable for this type of configuration, do you think it is possible?

hello!!

busiest summer.

back to speaker work. Never could see a diagram that shows where stuffing should be.

I'm planning on bracing it, 1 f/b brace, and 2 side/sides. Front/Back brace will be just below the speaker, angled (and holed out), just below half way down the airspace.

I would be the Side braces about 70% and 35% perhaps, just to avoid harmonic numbers.

Just been sanding to prepare for finishing, and deciding how soon I want to glue. I want to leave one side unglued, in case I need to remove stuffing, etc.

I created a "port" in the false bottom so that I can add a BSC later, if needed.

I'll add photos from my cell.

busiest summer.

back to speaker work. Never could see a diagram that shows where stuffing should be.

I'm planning on bracing it, 1 f/b brace, and 2 side/sides. Front/Back brace will be just below the speaker, angled (and holed out), just below half way down the airspace.

I would be the Side braces about 70% and 35% perhaps, just to avoid harmonic numbers.

Just been sanding to prepare for finishing, and deciding how soon I want to glue. I want to leave one side unglued, in case I need to remove stuffing, etc.

I created a "port" in the false bottom so that I can add a BSC later, if needed.

I'll add photos from my cell.

do you think it is possible?

Greets!

Hmm, if you mean creating a HR DCR/DCAAV Wizard Record of a MLTL, then mostly yes [don't see a way to directly compare to a MLTL in the Wizard], otherwise no clue what you're wanting.

Anyway, converting my previously posted ~36 Hz [GM] MLTL yields a ~extra 1/2 octave [~25 Hz Fb] of usable BW, i.e. build the original except one ~18 mm panel thickness taller [divider] and add a 2nd vent of the same design in the bottom chamber, though all things considered, I doubt one can hear the difference by just adding the vented divider to the existing MLTL [mine or any others] as they tend to have enough extra net Vb over a basic BR to merely adjust its stuffing density [at most].

GM

Attachments

Never could see a diagram that shows where stuffing should be.

Greets!

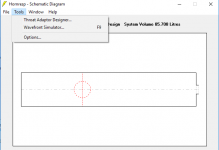

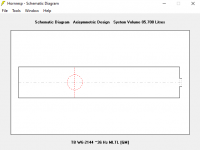

It's shown in my HR sim's Loudspeaker Wizard's 'Schematic' and percentage wise in the 'Filling' window = 100% down to the driver's centerline plus 30% further down, so ~49.82 + [92.9*0.3] = ~77.7 cm i.d., though not that critical.

GM

Ok.

100% would just be stuffed loosely, down to driver center line, right? I could put a wood brace across there to keep the stuffing above.

Does Poly settle at all over time? Does anyone know of a better method to keep it in place?

30% , would that mean taking the "normal amount", and just breaking a third off, approx, then fluffing it out to occupy the space?

100% would just be stuffed loosely, down to driver center line, right? I could put a wood brace across there to keep the stuffing above.

Does Poly settle at all over time? Does anyone know of a better method to keep it in place?

30% , would that mean taking the "normal amount", and just breaking a third off, approx, then fluffing it out to occupy the space?

Normally it would be shaded, right?

Correct. Are you using the new Wizard specific to the MLTL? If so, stuffing/filling apparently isn't an option, hence my design done in the original Loudspeaker Wizard.

GM

Ok, I'll move the fat brace down to 78cm to hold the 30% zone up, and put a narrow brace behind driver to hold the 100% stuffing above that.

Any issues with the size of that fat brace? I drilled lots of holes, so it shouldn't affect the performance much, right?

Any issues with the size of that fat brace? I drilled lots of holes, so it shouldn't affect the performance much, right?

Glued all but one side panel.

Set then up for tuning. They sound feast against the wall!

And by feast i mean great!

Folk, classical, etc sounds warm/intimate. Vocals image nicely... Maybe not quite as precise a earlier... But I sit further away, so I'm not surprised.

Soundtracks are full of weight! Bladerunner 2049 is epic!

Rock almost becomes dry, you can pick apart all the elements!

Techno, DnB... Every low note is well balanced.

Now to convince someone that the WAF is higher than it appears... I just want to finish them and put them back in the living room.

Set then up for tuning. They sound feast against the wall!

And by feast i mean great!

Folk, classical, etc sounds warm/intimate. Vocals image nicely... Maybe not quite as precise a earlier... But I sit further away, so I'm not surprised.

Soundtracks are full of weight! Bladerunner 2049 is epic!

Rock almost becomes dry, you can pick apart all the elements!

Techno, DnB... Every low note is well balanced.

Now to convince someone that the WAF is higher than it appears... I just want to finish them and put them back in the living room.

- Home

- Loudspeakers

- Full Range

- W6-2144 - Design time!!