This is my latest project, I like complicated dead things that have sat unloved for decades, in this case for the past 27 years. I have a dated service tag from January 6th, 1993..

This is a 1979 vintage (dated from the newest capacitors removed and replaced) Pioneer CT-F1000 3 head, 2 motor, dual capstan cassette deck with Dolby B and a lot of discrete circuitry on a bunch of little circuit boards.

In this case the transport was completely knackered - I still haven't gotten it fully sorted out, but it plays and FF fine and rewinds to a point on the tape where the required torque becomes more than the supply hub can deliver.

The transport is solenoid/logic controlled and all of that is working fine - the remaining problems are the plastic components used for FF and rewind functions.

I have replaced around 120 electrolytic capacitors so far.

Deck sounds surprisingly good, much better than I expected which provides additional motivation.

This is a 1979 vintage (dated from the newest capacitors removed and replaced) Pioneer CT-F1000 3 head, 2 motor, dual capstan cassette deck with Dolby B and a lot of discrete circuitry on a bunch of little circuit boards.

In this case the transport was completely knackered - I still haven't gotten it fully sorted out, but it plays and FF fine and rewinds to a point on the tape where the required torque becomes more than the supply hub can deliver.

The transport is solenoid/logic controlled and all of that is working fine - the remaining problems are the plastic components used for FF and rewind functions.

I have replaced around 120 electrolytic capacitors so far.

Deck sounds surprisingly good, much better than I expected which provides additional motivation.

Attachments

...I saw a website once that was selling discs (CDs that is) with dubs from the original factory masters (on 35mm mag tape!) used to make the optical discs, but they weren't cheap! Dunno if they're still around...

Holy hell - the Optigan LIVES! Lots of crazy stuff on this site (behold the Pianoptigan!!):

Optigan.com

Bose soundtouch 30 aquired for £100 with a smashed top panel, previous owner said a hammer fell from the loft hatch landing on the speaker leaving a nasty hole, was going to fix and sell since these make good money but now i heard it i find the horn loaded speakers so revealing on certain music im gonna keep it a while.

Made a new panel from fibreglass in black and flatted and polished it up to piano gloss you would never realise it wasnt origional accept it doesnt have the carbon print the factory covers had.

While i had it in bits i was quite impressed by the engineering, couldnt resist a look at the sub driver and its very well made, so are the tweeters both have large magnets and are horn loaded in the enclosure, the mids/tweeters are horn loaded with scoops in the front and the sub exits at the rear.

Amp looks substantial too, actually very impressed (maybe it helps that i work in electronics manufacture so i know the modern styles of pcb layout and components so have a pretty good idea what the quality is like).

Made a new panel from fibreglass in black and flatted and polished it up to piano gloss you would never realise it wasnt origional accept it doesnt have the carbon print the factory covers had.

While i had it in bits i was quite impressed by the engineering, couldnt resist a look at the sub driver and its very well made, so are the tweeters both have large magnets and are horn loaded in the enclosure, the mids/tweeters are horn loaded with scoops in the front and the sub exits at the rear.

Amp looks substantial too, actually very impressed (maybe it helps that i work in electronics manufacture so i know the modern styles of pcb layout and components so have a pretty good idea what the quality is like).

Kevin, you are much braver than I. I would shut the case and never open it again if I opened something up with that many wires (and sub assemblies)! 😱

Tony.

Tony.

No, not what I last repaired, but some of the first, and most memorable.....I surely can't remember every TV and radio I fixed as a kid, but the things I used myself are remembered.....

They were chased out of the home by the now ubiquitous Japanese plastic keyboard that provided a much wider palette of sound (timbre) choices for far less weight. No fancy wood box though......I still have a 1958 vintage Hammond M3.

The first has to be the Mellotron, each key was connected to a long vertical strip of magnetic tape which contained 3 switch selectable tracks of things like string instruments, vocal choirs, or complete orchestral ensembles. Definitely a temperamental beast, especially when taken on tour by a rock band. I have only physically interacted with one of these once, and it was in the early 70's. The unit I played with was a much larger console made from dark wood that ran on tubes. This M-400 was the most popular.

Inside a Mellotron M400: How the Mellotron Works - YouTube

Today the drum machine lives on inside the PC, or as a small plastic box full of digital samples. Early vintage drum machines ran on analog circuitry triggered by digital logic gates.......but drum machines go back further than that.

In the late 60's I found a Wurlitzer Side Man from 1959 in the trash, dragged it home and took it apart. It was a mechanical marvel that used a sliding idler wheel to create a variable speed rotating arm that swept a bunch of spring finger brushes across a phenolic PC board with contact points plated on it. This created the trigger signals for some analog "drums" made with 12AU7's and neon light bulbs.

My trash dump find had badly worn contacts on the PC board and the ends of the brushes. I soldered lots of tiny pieces of brass onto the ends of both, replaced a few leaky caps, and the machine came back to life.....for a year or two......this one on Youtube is identical to the one I had:

Vintage Drum Machine From 1959 In 4K - YouTube

In about 1967 I went to see a young upstart guitar player do the opening act for the Monkees. His name was Jimi Hendrix. This show finally convinced me that I would never be a rock star, but also convinced me that I had to have one of those grey boxes that he had on the floor.

Today the guitar looper is a common digital box that gives the player the ability to save and playback sample "loops" of their own playing live and on the fly. Common today, but a neat trick in 1961. The Echoplex was a looping device that used a magnetic tape loop that came in various lengths, and a playback head on a movable slider to adjust the delay length.

The Echoplex still lives on in digital form. The Echoplex EP-1 was all tube and tape and dates from the early 60's. That is what that I bought used and quite dead from a guy at one of the recording studios that I hung around as a kid. I had restored life to it and eventually sold it. The EP-2 was a better tube unit, and the EP-3 was solid state. I haven't seen any of the newer units, as I got away from the musician crowd when I left Miami in 1973.

Here is an EP-1 I found on Youtube:

Maestro Echoplex EP1 tape echo - YouTube

then came the sudden death of the home organ fad, and people stopped buying them almost overnight!

They were chased out of the home by the now ubiquitous Japanese plastic keyboard that provided a much wider palette of sound (timbre) choices for far less weight. No fancy wood box though......I still have a 1958 vintage Hammond M3.

Jim, you ever hear of the Optigan organ?...an interesting concept - one of the first sampled keyboards, heh!

The first has to be the Mellotron, each key was connected to a long vertical strip of magnetic tape which contained 3 switch selectable tracks of things like string instruments, vocal choirs, or complete orchestral ensembles. Definitely a temperamental beast, especially when taken on tour by a rock band. I have only physically interacted with one of these once, and it was in the early 70's. The unit I played with was a much larger console made from dark wood that ran on tubes. This M-400 was the most popular.

Inside a Mellotron M400: How the Mellotron Works - YouTube

Today the drum machine lives on inside the PC, or as a small plastic box full of digital samples. Early vintage drum machines ran on analog circuitry triggered by digital logic gates.......but drum machines go back further than that.

In the late 60's I found a Wurlitzer Side Man from 1959 in the trash, dragged it home and took it apart. It was a mechanical marvel that used a sliding idler wheel to create a variable speed rotating arm that swept a bunch of spring finger brushes across a phenolic PC board with contact points plated on it. This created the trigger signals for some analog "drums" made with 12AU7's and neon light bulbs.

My trash dump find had badly worn contacts on the PC board and the ends of the brushes. I soldered lots of tiny pieces of brass onto the ends of both, replaced a few leaky caps, and the machine came back to life.....for a year or two......this one on Youtube is identical to the one I had:

Vintage Drum Machine From 1959 In 4K - YouTube

In about 1967 I went to see a young upstart guitar player do the opening act for the Monkees. His name was Jimi Hendrix. This show finally convinced me that I would never be a rock star, but also convinced me that I had to have one of those grey boxes that he had on the floor.

Today the guitar looper is a common digital box that gives the player the ability to save and playback sample "loops" of their own playing live and on the fly. Common today, but a neat trick in 1961. The Echoplex was a looping device that used a magnetic tape loop that came in various lengths, and a playback head on a movable slider to adjust the delay length.

The Echoplex still lives on in digital form. The Echoplex EP-1 was all tube and tape and dates from the early 60's. That is what that I bought used and quite dead from a guy at one of the recording studios that I hung around as a kid. I had restored life to it and eventually sold it. The EP-2 was a better tube unit, and the EP-3 was solid state. I haven't seen any of the newer units, as I got away from the musician crowd when I left Miami in 1973.

Here is an EP-1 I found on Youtube:

Maestro Echoplex EP1 tape echo - YouTube

Honestly, I think you guys lamenting "the good old" days with cars are high. My 1st personal car was a 1979 Olds, purchased new from an order sheet by the family. The frequency that that thing broke was amazing. Sure it was easier to work on, it had to be. Nowadays there are reports of LS V-8's being taken apart with the factory cylinder hone still visible at 100,000 km. 40 years ago you had a major service due at 100,000 km and had to watch your oil level regularly. Sepia must be clouding your brains.

The 1970s and 1980s were not the good old days for cars to me, especially from the perspective of American cars. They were, for the most part, crap.

More or less, the "good old days" of cars I'm referring to is 2000-2013 (mostly) Japanese cars. There are many examples of excellent design and build, combined with ease of service.

I know it's regional, but around here I see a whole lot of Camrys, Corrolas, Accords, Civics, 4runners/Highlanders, Subarus, and Lexus of that vintage. Honorable mention goes to Lincoln Town Cars and Navigators. And there's reasons people drive these vehicles 20+ years. For vehicles that old, it boils down to reliability, and money. If they weren't reliable, and/or came with exorbitant cost of ownership, then you wouldn't see so many of them. And a lot of these cars look very clean too, in spite of the harsh conditions they're subjected to by our local weather.

Notice that most of these vehicles aren't at all glamorous, but driving to work every day isn't very glamorous either.

At 12.5 miles/gallon in the city, my old (1996) but in nice shape Lincoln Mark VIII sits silently in the rear driveway now.

I suppose one day, maybe after it becomes "classic car" status, I'll post it for sale.

I suppose one day, maybe after it becomes "classic car" status, I'll post it for sale.

My 2010 Toyota burns oil 🙁 70k (miles), owned from new and it now gets through around 5 to 6 litres per 10k miles. Its a known design fault, oil scrapper rings are too feeble and stick. Other than that though and its been the best car I've owned.

There was at least one Toyota engine that had problems. I have a neighbor that had a nice Camry and the engine had a knock. He drove it for a couple years that way.

Sometimes those noises appear in oil burners because people don't check their oil. Of course, burning oil in a modern engine can lead to a clogged catalytic converter.

Some models and power trains just last a lot longer. You kind of have to do your homework when looking at used cars. I'm thinking about picking up a 10 year old (or so) RAV4. I was reading that there's a small four cylinder engine in some of them that's mated to a simple 4 speed automatic that "runs forever." I know it's not high performance, but at this stage of the game longevity and cost of ownership are paramount. I may be spoiled by my Subaru but let's face it, it's knackered. And they require a lot of maintenance, repairs aren't the simplest, etc. So I'm looking at used Toyotas.

Sometimes those noises appear in oil burners because people don't check their oil. Of course, burning oil in a modern engine can lead to a clogged catalytic converter.

Some models and power trains just last a lot longer. You kind of have to do your homework when looking at used cars. I'm thinking about picking up a 10 year old (or so) RAV4. I was reading that there's a small four cylinder engine in some of them that's mated to a simple 4 speed automatic that "runs forever." I know it's not high performance, but at this stage of the game longevity and cost of ownership are paramount. I may be spoiled by my Subaru but let's face it, it's knackered. And they require a lot of maintenance, repairs aren't the simplest, etc. So I'm looking at used Toyotas.

I just replaced the front sway bar linkage on my 1991 Toyota Previa van. Checked fluids. Has 303,000 miles currently.

Either myself or just the kids will take it camping next week in Moab, UT as long as no year 2020 sort of disaster happens. I70 was closed a month or so ago due to fires and there was a big fire just north of where we would go.

Was going to go last spring but they closed the campground.

Either myself or just the kids will take it camping next week in Moab, UT as long as no year 2020 sort of disaster happens. I70 was closed a month or so ago due to fires and there was a big fire just north of where we would go.

Was going to go last spring but they closed the campground.

Guess why this HP 5328A didn't work (bought as a parts mule at a hamfest):

I got a great carcase out of it, a 10MHz oscillator, beefy power supply. This is the second non-working HP5328 I've owned. I have a working variety which is great and a HP5326 which sits near a Hallicrafters receiver.

I got a great carcase out of it, a 10MHz oscillator, beefy power supply. This is the second non-working HP5328 I've owned. I have a working variety which is great and a HP5326 which sits near a Hallicrafters receiver.

Attachments

w-Wow! There's a reasonable chance that's a factory defect, no? How tight was that lead jammed in there?

When I cut my component leads I dont let them fly everywhere.

I hold the lead at top end and cut the bottom of it then put off cut in a pile to bin later.

I hold the lead at top end and cut the bottom of it then put off cut in a pile to bin later.

Several years ago I spotted an HP8643A RF signal generator on Ebay for a very low price. It was listed as "untested." Five minutes on Google revealed that there was a test equipment repair and cal facility operating out of the same address, so the generator was NOT untested, it was dead and likely had many of its plugin modules exchanged for defective units.

I decided to call the phone number for the cal lab and ask just what the deal was. At least the guy on the phone was honest. Both SMPS's were dead, and one module was known defective. He told me which one, and I had a spare, so I bought the generator.

One SMPS had the usual blown mosfet and a shorted diode that likely blew the mosfet. The other........

It would work sometimes, and not start up other times. Sometimes a good whack with a mallet would bring life, then it would die again. This meant that there were no dead parts inside, just an intermittent. It would take me a week to find it.

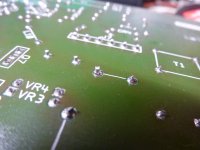

If you look carefully at the solder connection in the center of the picture you see a lead from a large toroidal inductor. The red enamel coating on the wire is visible on both pins, but the pin on the right did get some solder. The left pin was never soldered at the factory, and this is a 1980's vintage generator. It has worked flawlessly since I soldered it over 3 years ago.

The TEK 2232 scope that has been seen in most of my scope screen pictures for the last 10 years likely has a similar problem. It will fail to power up occasionally or spontaneously reboot whenever it feels like it. It was sold to me as defective over 10 years ago. A test at the auction site proved this to be true, however it worked fine when I got it home. I have been smacking it as needed for 10 years!

I decided to call the phone number for the cal lab and ask just what the deal was. At least the guy on the phone was honest. Both SMPS's were dead, and one module was known defective. He told me which one, and I had a spare, so I bought the generator.

One SMPS had the usual blown mosfet and a shorted diode that likely blew the mosfet. The other........

It would work sometimes, and not start up other times. Sometimes a good whack with a mallet would bring life, then it would die again. This meant that there were no dead parts inside, just an intermittent. It would take me a week to find it.

If you look carefully at the solder connection in the center of the picture you see a lead from a large toroidal inductor. The red enamel coating on the wire is visible on both pins, but the pin on the right did get some solder. The left pin was never soldered at the factory, and this is a 1980's vintage generator. It has worked flawlessly since I soldered it over 3 years ago.

The TEK 2232 scope that has been seen in most of my scope screen pictures for the last 10 years likely has a similar problem. It will fail to power up occasionally or spontaneously reboot whenever it feels like it. It was sold to me as defective over 10 years ago. A test at the auction site proved this to be true, however it worked fine when I got it home. I have been smacking it as needed for 10 years!

Attachments

B&K Sweep Function Generator

My newly purchased B&K Sweep Function Generator (from 1980) came with a manual and diagram. The manual has a chapter on calibration, so I checked the settings.

The dial for 1000 Hz. had to be turned to around 1100 Hz. It turned out one preset potentiometer was defect (wiper didn’t make proper contact, spraying didn’t help), so I replaced the potentiometer. Still couldn’t align the frequency properly with the dial knob, so I increased the resistor that’s in series with the potentiometers. Calibration is OK again now.

As the distortion of this unit is not lower than my main function generator I’ve decided to put it on Ebay.

Regards, Gerrity

My newly purchased B&K Sweep Function Generator (from 1980) came with a manual and diagram. The manual has a chapter on calibration, so I checked the settings.

The dial for 1000 Hz. had to be turned to around 1100 Hz. It turned out one preset potentiometer was defect (wiper didn’t make proper contact, spraying didn’t help), so I replaced the potentiometer. Still couldn’t align the frequency properly with the dial knob, so I increased the resistor that’s in series with the potentiometers. Calibration is OK again now.

As the distortion of this unit is not lower than my main function generator I’ve decided to put it on Ebay.

Regards, Gerrity

Attachments

Whenever I'm hunting for an intermittent, and the client is hanging around, I always say something like, "Incidentally, this is a legitimate diagnostic procedure," before I start smacking stuff around. Usually gets a chuckle, and breaks the tension a bit. 🙂...I have been smacking it as needed for 10 years!

I laughed whenever I got a call like this for a TV repair at the shop.

Customer says, "It just need a little work, because once it warms up and I give it a good SMACK, it's fine."

Reminds me of those customer who'd put a quarter on a tonearm to "make it play better" 😱

Customer says, "It just need a little work, because once it warms up and I give it a good SMACK, it's fine."

Reminds me of those customer who'd put a quarter on a tonearm to "make it play better" 😱

Many older ham radio operators will recognize this as the venerable Motorola HT-220 walkie talkie. This particular unit is a UHF version about 50 years old. It still works.

I started at Motorola on the first work day of 1973 as an assembly line tech fixing, tuning and assembling these things. On average each unit had 1.2 defects in it when they were built. This is where serious troubleshooting skills are built. The test equipment we had was less than state of the art.....that's putting it mildly. Some of it still ran on vacuum tubes.

The primary diagnostic instrument was a Cushman CE-3 FM communications monitor. These were about 6 years old when I started. Despite the frustration some of the equipment caused, hitting, or otherwise "abusing" any of the test equipment was a firing offense, and a lot of firing or quitting in general happened in the early days. The average work week was 60 hours, burnout was common and the turnover rate was high.

After about a year and a half I left the factory for a 10 year stint in the cal lab, where among many jobs, my primary task was to improve the test equipment in that factory......some of that stuff hadn't been calibrated in years.

The old Cushmans were quite temperamental, and somewhat intermittent. I would get a call to the factory and my first line of troubleshooting was to draw my trusty HT-220 and give the Cushman a serious whack with the battery end of the radio. One of the factory bosses asked why I was allowed to abuse the equipment. I replied that I was properly trained in the art of "RAM TUNING" and I did not consider that "abuse." Upon further discussion I said that I would be "deaf" to the sound of a wood spacer block or fist hitting the side or the top of said instrument, but broken controls, screens or CRT's could still be grounds for an "incident report" and the repercussions it might bring.

It would take me about 3 years but I got every one of those old machines rebuilt or replaced with CE-5's, and made several serious improvements in the throughput of that factory.

I started at Motorola on the first work day of 1973 as an assembly line tech fixing, tuning and assembling these things. On average each unit had 1.2 defects in it when they were built. This is where serious troubleshooting skills are built. The test equipment we had was less than state of the art.....that's putting it mildly. Some of it still ran on vacuum tubes.

The primary diagnostic instrument was a Cushman CE-3 FM communications monitor. These were about 6 years old when I started. Despite the frustration some of the equipment caused, hitting, or otherwise "abusing" any of the test equipment was a firing offense, and a lot of firing or quitting in general happened in the early days. The average work week was 60 hours, burnout was common and the turnover rate was high.

After about a year and a half I left the factory for a 10 year stint in the cal lab, where among many jobs, my primary task was to improve the test equipment in that factory......some of that stuff hadn't been calibrated in years.

The old Cushmans were quite temperamental, and somewhat intermittent. I would get a call to the factory and my first line of troubleshooting was to draw my trusty HT-220 and give the Cushman a serious whack with the battery end of the radio. One of the factory bosses asked why I was allowed to abuse the equipment. I replied that I was properly trained in the art of "RAM TUNING" and I did not consider that "abuse." Upon further discussion I said that I would be "deaf" to the sound of a wood spacer block or fist hitting the side or the top of said instrument, but broken controls, screens or CRT's could still be grounds for an "incident report" and the repercussions it might bring.

It would take me about 3 years but I got every one of those old machines rebuilt or replaced with CE-5's, and made several serious improvements in the throughput of that factory.

Attachments

This is the main reason I usually make some kind of an announcement before bringing the smackdown - most non-tech people are not likely to understand that there is actually a certain calibration to our percussive ministrations. Knowing where and how hard to hit is all part of the art - it's not just random violence.Upon further discussion I said that I would be "deaf" to the sound of a wood spacer block or fist hitting the side or the top of said instrument, but broken controls, screens or CRT's could still be grounds for an "incident report" and the repercussions it might bring.

After this many years (like many of you I'm sure), I often know exactly where to whack something in order to dislodge a welded relay contact etc., and can sometimes (temporarily) relieve the symptoms with a single blow. This tends to impress, and I can't say I don't enjoy the reaction. 😀

Last edited:

- Home

- Member Areas

- The Lounge

- What did you last repair?