damping/isolator & proofing tapes made from bitumen & tin for roof perhaps or liquid polymer that dry on air... Yes surely the easier part 😎

CAD files with Ath4.5.0

Thank you in advance!

That's looks great! Perfect work, Mr Mabat! May I ask you, did you make all this calculations and further CAD/CAM files via Ath4? I'm not a Windows user, for me it's a little bit complicated ))) Is it possible to discuss with you my project if you have a time to give me some advices please?In the meantime we are progressing on Tritonia baffles (milled from a solid MDF block) -

Thank you in advance!

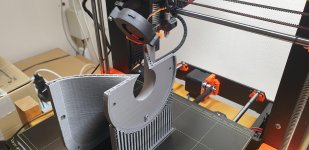

Thanks. The horn shape was created with Ath, imported into Fusion 360, exported to STEP (IGES) and handed over to a guy who has the machine - I don't know much about the rest.

Because ABEC was available only on Windows I didn't consider Linux release (if that's what you mean) but I still could do that - at least for the Ath tool itself. For the BEM part, you would still need ABEC3/AKABAK3 running on Windows.

I'll get back to you via PM.

Because ABEC was available only on Windows I didn't consider Linux release (if that's what you mean) but I still could do that - at least for the Ath tool itself. For the BEM part, you would still need ABEC3/AKABAK3 running on Windows.

I'll get back to you via PM.

Last edited:

Thank you for the answer Marcel! Finally I did the first calculations last night based on demo files just to understand ow it works and imported it to the Fusion, but it's still some issues with ABEC which I didn't solve yet ) Hope to hear from you soon!Thanks. The horn shape was created with Ath, imported into Fusion 360, exported to STEP (IGES) and handed over to a guy who has the machine - I don't know much about the rest.

Because ABEC was available only on Windows I didn't consider Linux release (if that's what you mean) but I still could do that - at least for the Ath tool itself. For the BEM part, you would still need ABEC3/AKABAK3 running on Windows.

I'll get back to you via PM.

Regards,

Roman

Roman, you are free to start a new thread where we can discuss your new project - as it is a shallow waveguide for a dome tweeter I guess it might interest a lot of people. I could contribute with the little know-how I have, or even adapt Ath more for dome tweeters a bit along the way. It would be interesting to watch the development.

Last edited:

My idea would be to apply a polyurethane foam on the rear, sand the edges on the front surface and make a fine epoxy coating.

Mabat - do you know if your friend machine waveguides using endmill only or with ball endmill too to get smooth surface?

Are those 30 mm thick layers of MDF?In the meantime we are progressing on Tritonia baffles (milled from a solid MDF block) -

It would take absolutely forever to get that type of finish with a square end mill... I'm willing to bet a ball end mill was used.Mabat - do you know if your friend machine waveguides using endmill only or with ball endmill too to get smooth surface?

Yeah I think ball end mill was used for the finish, I also think it's always used. This was on some professional machine, primarily used for other (serious) business. I believe 40 mm MDF was used.

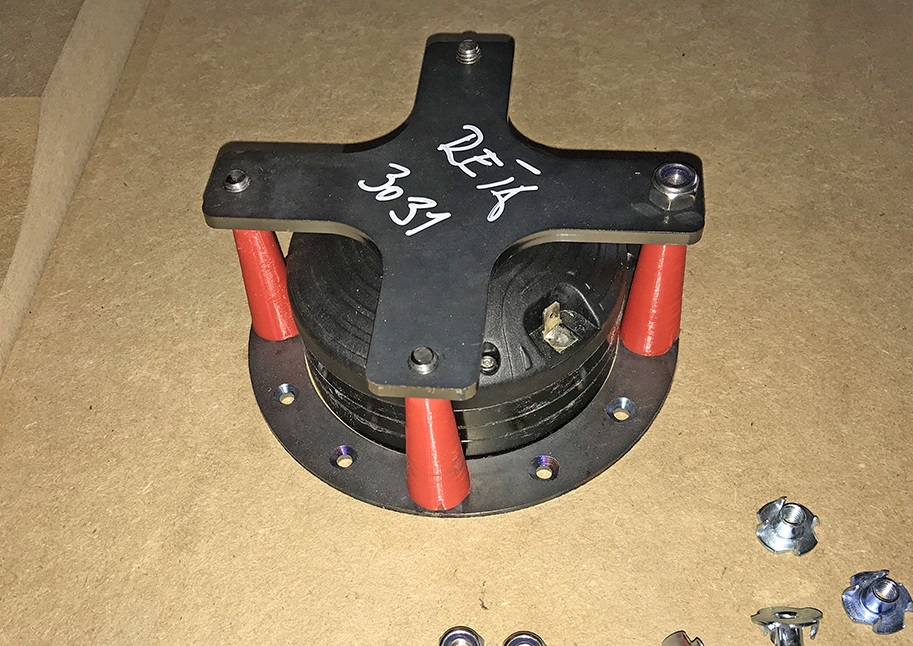

BTW, this is the mounting of the driver (designed as self-centering):

BTW, this is the mounting of the driver (designed as self-centering):

Attachments

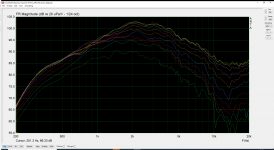

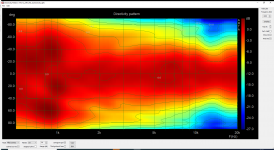

I have used version 4.5.0 to generate a model of a waveguide to be used with a dome tweeter. This is still a work in progress, but I can show you the current results.

The config file:

ABEC.MeshFrequency = 1000

ABEC.NumFrequencies = 30

ABEC.Polars.Diagonal = 0

ABEC.Polars.DiagonalInclination = 0

ABEC.Polars.Dist = 2

ABEC.Polars.Horizontal = 1

ABEC.Polars.Points = 8

ABEC.Polars.Step = 7.5

ABEC.Polars.Vertical = 1

ABEC.RadiationConditions = IB

ABEC.Source.Curv = 1

ABEC.Source.Radius = 21

ABEC.Source.Shape = spherical

ABEC.Source.Velocity = axial

ABEC.f1 = 800

ABEC.f2 = 12000

GCurve = SE

GCurve.Angle = 50

GCurve.SE.Exp = 2.3

GCurve.VertScale = 0.7

Length = 65

Mesh.AngularSegments = 64

Mesh.CornerSegments = 8

Mesh.DepthSegments = 24

Mesh.IBInterfaceRadiusRatio = 2.0

Mesh.InterfaceResolution = 7.0

Mesh.InterfaceStrip = 10.0

Mesh.LipSegments = 6

Mesh.ThroatResolution = 4.0

Mesh.WallResolution = 25.0

Morph.CornerRadius = 35

Morph.FixedPart = 0

Morph.StretchExp = 3

Morph.TargetShape = rect

Output.ABECProject = yes

Output.DestDir = C:\Use_your_path_here

Output.MSH = no

Output.STL = yes

Term.n = 4.0

Term.q = 0.995

Term.s = 0.7

Throat.Angle = 40

Throat.Diameter = 31

Throat.Ext.Length = 0

Throat.Profile = OS

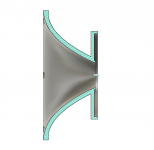

The wavegulde dimensions are 202 x 162 x 65mm.

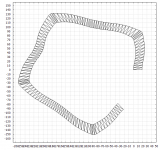

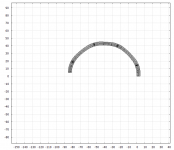

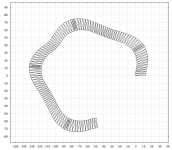

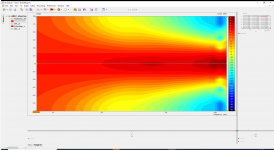

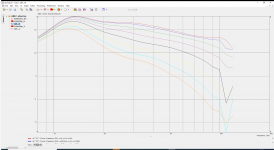

Here you see the ABEC simulation of the generated project file and also the generated STL file.

The config file:

ABEC.MeshFrequency = 1000

ABEC.NumFrequencies = 30

ABEC.Polars.Diagonal = 0

ABEC.Polars.DiagonalInclination = 0

ABEC.Polars.Dist = 2

ABEC.Polars.Horizontal = 1

ABEC.Polars.Points = 8

ABEC.Polars.Step = 7.5

ABEC.Polars.Vertical = 1

ABEC.RadiationConditions = IB

ABEC.Source.Curv = 1

ABEC.Source.Radius = 21

ABEC.Source.Shape = spherical

ABEC.Source.Velocity = axial

ABEC.f1 = 800

ABEC.f2 = 12000

GCurve = SE

GCurve.Angle = 50

GCurve.SE.Exp = 2.3

GCurve.VertScale = 0.7

Length = 65

Mesh.AngularSegments = 64

Mesh.CornerSegments = 8

Mesh.DepthSegments = 24

Mesh.IBInterfaceRadiusRatio = 2.0

Mesh.InterfaceResolution = 7.0

Mesh.InterfaceStrip = 10.0

Mesh.LipSegments = 6

Mesh.ThroatResolution = 4.0

Mesh.WallResolution = 25.0

Morph.CornerRadius = 35

Morph.FixedPart = 0

Morph.StretchExp = 3

Morph.TargetShape = rect

Output.ABECProject = yes

Output.DestDir = C:\Use_your_path_here

Output.MSH = no

Output.STL = yes

Term.n = 4.0

Term.q = 0.995

Term.s = 0.7

Throat.Angle = 40

Throat.Diameter = 31

Throat.Ext.Length = 0

Throat.Profile = OS

The wavegulde dimensions are 202 x 162 x 65mm.

Here you see the ABEC simulation of the generated project file and also the generated STL file.

Attachments

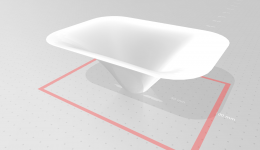

The Fusion360 add-in module were used to import the surface profile.

The profile were thickened by 5mm and I have added a mounting flange for the Seas H1212-06 27TBFC/G tweeter and also for attachment to the baffle.

I have removed the tweeter grille to get closer to the dome and the throat ID is at 31mm so it is covering about half of the surround.

The profile were thickened by 5mm and I have added a mounting flange for the Seas H1212-06 27TBFC/G tweeter and also for attachment to the baffle.

I have removed the tweeter grille to get closer to the dome and the throat ID is at 31mm so it is covering about half of the surround.

Attachments

Then the prototype was measured in a 600 x 800 mm baffle using ARTA with a Scarlett 2i2 sound card and a MicW 215L measurement microphone.

Measurents are done in 10 degrees steps from -90 to 90 degrees.

Directivity plot is showing a 30dB range.

Is there a way to normalize measurements in ARTA, or are you using another sw for this?

Measurents are done in 10 degrees steps from -90 to 90 degrees.

Directivity plot is showing a 30dB range.

Is there a way to normalize measurements in ARTA, or are you using another sw for this?

Attachments

Nice, I suggest you to use VitiuxCAD tool to convert pir files to the frequency domain (a breeze to use by the way) and then you can see polar maps at your convenience

Thank you very much for sharing, this is very interesting to see. Nice work.

Now it will be extremely interesting to see the simulation after you include the dome geometry in the throat (with Ath 4.6) - how good the match will be. So far my experience is that the surround of the diaphragm in the throat is not a good thing but then the measured data you show are pretty good, at least compared to what I have seen in the sims. It is also possible that the real-world situation is actually better than the with the theoretically rigid dome - that's one of the things to be seen.

Now it will be extremely interesting to see the simulation after you include the dome geometry in the throat (with Ath 4.6) - how good the match will be. So far my experience is that the surround of the diaphragm in the throat is not a good thing but then the measured data you show are pretty good, at least compared to what I have seen in the sims. It is also possible that the real-world situation is actually better than the with the theoretically rigid dome - that's one of the things to be seen.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design - The Practical Way