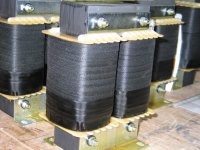

Given a choice, I use E-I core types. All kinds of reasons. From my point of view, a toroidal transformer is best used for very short chassis', like a 1U high case in a rack.

-Chris

-Chris

They have huge radiated EM fields unless you use a GOSS band. And in most EI power transformers, the secondary is wound over the primary so the interwinding capacitance is of the same order as a similarly powered torroid.

commercial offerings of the japanese amps not only used a copper belly band, they also wrapped a mu metal band around the periphery of the EI core, two laps around in most cases i have seen to totally cover the whole of the EI traffo...

if you run EI's at low flux densities and very far from saturation, radiation will be much lower...

if you run EI's at low flux densities and very far from saturation, radiation will be much lower...

The lowest impedance you can get is with the MD core transformers. Here is the list for the same nominal power transformers:

M core 100% (highest impedance)

Ei core 94%

Toroidal 66%

PM core 38%

MD core 28% (lowest impedance)

For audio it would be best to use MD core transformer. But there are no manufacturers who produce such transformers, or are they very rare.

MD core transformer ? How it look ?

commercial offerings of the japanese amps not only used a copper belly band, they also wrapped a mu metal band around the periphery of the EI core, two laps around in most cases i have seen to totally cover the whole of the EI traffo...

if you run EI's at low flux densities and very far from saturation, radiation will be much lower...

The physics doesn’t support that. But each to his own.

And in most EI power transformers, the secondary is wound over the primary so the interwinding capacitance is of the same order as a similarly powered torroid.

That is simply incorrect.

In a toroidal transformer the surface area between primary and secondary is multiples larger than in an EI, so by definition there is more capacitive coupling (not taking screens into consideration).

Note I said of the same order.

For EI’s wound on the opposite arms of the windows - typical for PCB mount types (see for example Piltron transformers) - the interwinding capacitance is indeed low. But for high power EI with secondary wound over the primary, the capacitance is hundreds of pF.

For EI’s wound on the opposite arms of the windows - typical for PCB mount types (see for example Piltron transformers) - the interwinding capacitance is indeed low. But for high power EI with secondary wound over the primary, the capacitance is hundreds of pF.

My transformer hums a little, not due to DC, is it ok to use NTCs to drop the voltage slightly?By running a 400V input transformer at 220V you are in effect running the transformer at a much lower flux density - the result is you get much better tolerance to DC mains.

I’ve just measured a 300VA Marantz EI transformer (from a PM 7000 integrated amp).

The pri to sec interwinding capacitance is 588 pF

The pri to sec interwinding capacitance is 588 pF

Last edited:

My transformer hums a little, not due to DC, is it ok to use NTCs to drop the voltage slightly?

This has come up before somewhere on the forum. Problem is you have to drop some volts and you have to dissipate some power some where for it to be effective.

That's what I wondered, thanks, it's not too bad, only aware of it when no music's playing, means I don't forget to turn amp off when I go to bed. 🙂

For EI’s wound on the opposite arms of the windows - typical for PCB mount types (see for example Piltron transformers) - the interwinding capacitance is indeed low.

How, in your opinion, does an "Ei wound on the opposite arms of the windows" look like??

Never heard of these this type...

The physics doesn’t support that. But each to his own.

the thing with EI's are the three air gaps compared to toroids' one and some see none at all, so that core saturation is less likely to happen in EI's compared to toroids, these air gaps also acts like relief valves albeit small valves...these gaps are also likely to be the source of emi...

the japanese must have realised this and so they wrapped mu metal shields along the periphery of the EI core.....they must have known something others did not...

i am just trying to second guess them, and this mumetal wrapping of the core is something not available to most diy'ers like me....i have been winding my own irons for more than 40 years now, not as commercial entity but purely as a hobby..

there are also naysayers for the copper belly bands, so i guess it really boils down to individual preference....if only someone could conduct a study and come up with data..

but for my traffo builds, low flux density compared to commercial traffo is normal practice been doing that for ages...

Last edited:

That's a senseless option when the right core material is apparently not available.

What does make sense is a UI core, which is the geometric (not electromagnetic!) equivalent to a single c-core.

Like this:

Apt Hollman APT1 used the UI core, i will use them if i have them...

in this case, there are two air gaps..

My transformer hums a little, not due to DC, is it ok to use NTCs to drop the voltage slightly?

if that is a mechanical humming, then a dip in polyurethane varnish will help..

NTC's are useful in mitigating turn on surges...

That's a senseless option when the right core material is apparently not available.

What does make sense is a UI core, which is the geometric (not electromagnetic!) equivalent to a single c-core.

Like this:

Seems your opinion doesn't count for much in these matters. They are supplied just like I showed and I’ve used them for hi-pot applications in industrial electronics.

Any more comments on the EI interwinding capacitance?

Any more comments on the EI interwinding capacitance?

on power traffos do they matter? why?

audio transformers, yes they matter..

- Home

- Amplifiers

- Solid State

- Are toroidal transformers best?