But the head of the screws will scratch the floor! I prefer wheels.

That is easy to solve ! 🙂

I can put protective mats, some carpet, etc.

Also, they will not move very often, who is worried about cleaning ? 😱 😀

I don't know exactly your case, but in mine dust from nearer streets (unpaved streets) and webs are a very hard problem. I live in 1rst floor, so ants are not a problem, but spiderwebs and dust, pufffff....I need to clean almost once a week.

Then again, if not driven hard in a high ambient, might work fine for decades for all I know, but why gamble when there's other potentially cheaper, more environmentally safer ways to do it?

GM

With two decades I think I'll be fine . 😀

I thought that the speakers of this Eminence series have the "wing" of the classic "accordion" cone, it is a cloth covered with a semi - sticky material, it looks a lot like asphalt, you know what it is?

I have not yet decided what to do regarding the antiresonant material for the MDF panels....😱

If the maximum frequency that I intend to play on this subwoofer will be 100 Hz (at the most) I think I should leave it as it is, the MDF resonances are far above ...

I have to decide this issue before closing the cabinet, I know it is a remanded topic, but I would also be happy to receive opinions about it.🙂

For now I dedicated myself to building two supports to work in the cabinet placing it horizontally.

They are finished.

This has been "child's play" compared to the rest .....😉

If the maximum frequency that I intend to play on this subwoofer will be 100 Hz (at the most) I think I should leave it as it is, the MDF resonances are far above ...

I have to decide this issue before closing the cabinet, I know it is a remanded topic, but I would also be happy to receive opinions about it.🙂

For now I dedicated myself to building two supports to work in the cabinet placing it horizontally.

They are finished.

This has been "child's play" compared to the rest .....😉

Attachments

-

IMG_20190228_114622.jpg713.7 KB · Views: 70

IMG_20190228_114622.jpg713.7 KB · Views: 70 -

IMG_20190228_114134.jpg636.2 KB · Views: 67

IMG_20190228_114134.jpg636.2 KB · Views: 67 -

IMG_20190228_113919.jpg165.1 KB · Views: 69

IMG_20190228_113919.jpg165.1 KB · Views: 69 -

IMG_20190228_113626.jpg968.6 KB · Views: 198

IMG_20190228_113626.jpg968.6 KB · Views: 198 -

IMG_20190226_162051.jpg600.8 KB · Views: 200

IMG_20190226_162051.jpg600.8 KB · Views: 200 -

IMG_20190226_160544.jpg380.3 KB · Views: 200

IMG_20190226_160544.jpg380.3 KB · Views: 200 -

IMG_20190226_160534.jpg712.3 KB · Views: 216

IMG_20190226_160534.jpg712.3 KB · Views: 216

A lot of rain again, but it has already started to dry and I'm working again.

This step is about achieving the most perfect plane possible to assemble with the front panel.

The electric brush is useful but you have to make many passes of little disguise (0.5 mm is the minimum) because if you pass there is no return ....

In the corners I use the traditional manual brush, chisel, etc. and then sandpaper.

In this tool the method to regulate the depth of the blade is very unintuitive, but once you learn it, it is incredible .... if there is interest I could do an explanatory drawing ....🙄

This step is about achieving the most perfect plane possible to assemble with the front panel.

The electric brush is useful but you have to make many passes of little disguise (0.5 mm is the minimum) because if you pass there is no return ....

In the corners I use the traditional manual brush, chisel, etc. and then sandpaper.

In this tool the method to regulate the depth of the blade is very unintuitive, but once you learn it, it is incredible .... if there is interest I could do an explanatory drawing ....🙄

Attachments

I thought that the speakers of this Eminence series have the "wing" of the classic "accordion" cone, it is a cloth covered with a semi - sticky material, it looks a lot like asphalt, you know what it is?

Don't know if everybody used the same petroleum based chemical by C.P. Moyen as Lansing/Altec/JBL, but here's the modern water based version. Note both versions dried ~clear, so the color of the cloth surround dictates and why some are brown, red or black: https://www.parts-express.com/pedoc...9111X1517312X2dd27f09a5d3f2df0a44439528787efb

GM

I think I should leave it as it is, the MDF resonances are far above ...

Agreed, just brace it so all six sides are tied together with interlocking bracing to keep it from 'breathing', with an integral motor brace to mass load it to the cab and mass load the cab by placing removable heavy weights on top that's at least as heavy as the sub is and maybe [a lot] more.

Can't get around the physics of the situation, one way or another it needs to be very rigid.

GM

............

Can't get around the physics of the situation, one way or another it needs to be very rigid.

GM

GM, (your nick inevitably refers to cars) your recommendations are very logical.

So I've thought about refocusing the lower part of the cabinet, (where the speaker will go, see bracing in green) should bear most of the pressure of the speaker diaphragm. (Is this so the air pressure of the interior will be distributed equally among the 3 compartments? I tend to think this last, but how will the filling affect?)

I will add a reinforcement there (green in the drawing)

The total weight of the cabinet, being a prism of five faces, would be badly distributed. The front part is very heavy (almost 8 kg of the speaker and 24 kilos of the frontal panel), then, when supporting it on the floor it will be almost in balance!

To compensate for this (distribute the vertical forces) I will add marble plates in the back corner of the base (red in the drawing), and it would not be bad then another marble plate on top (red too), as you say .

I have heard WAF consult with lawyers, 😀 I hope it has nothing to do with all this ... 😱

Attachments

Don't know if everybody used the same petroleum based chemical by C.P. Moyen as Lansing/Altec/JBL, but here's the modern water based version. Note both versions dried ~clear, so the color of the cloth surround dictates and why some are brown, red or black: https://www.parts-express.com/pedoc...9111X1517312X2dd27f09a5d3f2df0a44439528787efb

GM

FMC ohhh, no! you are GM ! 😉

Thanks for the link, I think it's about this water based product, because it's not too sticky, rather it gives the feeling ....

OT :

Beware of trying to remove dust or pet hairs with painter's tape or similar from the tweeter domes!

It has happened to me that some tweeters (Audax TW034 for example) have a similar coating

- to deaden resonances - which we are talking about, but which is very sticky, but small particles of material are detached from the fabric along with the dirt !

Last edited:

GM, (your nick inevitably refers to cars) your recommendations are very logical.

So I've thought about refocusing the lower part of the cabinet, (where the speaker will go, see bracing in green) should bear most of the pressure of the speaker diaphragm. (Is this so the air pressure of the interior will be distributed equally among the 3 compartments? I tend to think this last, but how will the filling affect?)

I will add a reinforcement there (green in the drawing)

The total weight of the cabinet, being a prism of five faces, would be badly distributed. The front part is very heavy (almost 8 kg of the speaker and 24 kilos of the frontal panel), then, when supporting it on the floor it will be almost in balance!

To compensate for this (distribute the vertical forces) I will add marble plates in the back corner of the base (red in the drawing), and it would not be bad then another marble plate on top (red too), as you say .

I have heard WAF consult with lawyers, 😀 I hope it has nothing to do with all this ... 😱

No, just can be an added perk if done with this in mind. 😉

Hmm, missed some earlier posts and just now getting around to simming it as an offset driver in HR, but no clue how much acoustic resistance the drilled brace plates might effect performance, so while it's long enough to have 1/4 WL resonances, not sure how much gets damped, though in theory the two ends are high pressure points, another good reason to have the massive weight on the top.

Note that best to double up the bottom plate if not sitting hard on the floor.

For future reference, high aspect ratio cabs should ideally be braced along the line with with boards or similar on edge and tied together with a cross brace to help form the driver motor brace, leaving an otherwise open column.

Anyway, noticed you list it as 150 L, but HR says ~128.3 L before subtracting the driver's 796 cc, internal bracing, any added blocks of weight, so looking at a ~40 Hz F6 in 2pi space. Seems kind of high, so is this going to be enough once corner loaded?

GM

The actual volume I have not calculated because I start with the rough calculation of the cabinet, and as you say, should subtract the volume of reinforcements, speakers and other internal objects to know exactly the litraje. But being a sealed cabinet, with plenty of stuffing inside, it does not matter.

For all that I have read, the virtual volume that adds the padding is very controversial, so maybe a bit of trial and error with it is better when everything is finished.

That supposing that it is not satisfied with the result.

Then, the definitive and exact QTC will be an unknown, but I imagine that it will be something below the ideal of 0.707 "maximum plane".

Remember, I'm looking for an overdamped cabinet result for 20 to 40 hertz, QTC between 0.5 and 0.6 maybe.

For all that I have read, the virtual volume that adds the padding is very controversial, so maybe a bit of trial and error with it is better when everything is finished.

That supposing that it is not satisfied with the result.

Then, the definitive and exact QTC will be an unknown, but I imagine that it will be something below the ideal of 0.707 "maximum plane".

Remember, I'm looking for an overdamped cabinet result for 20 to 40 hertz, QTC between 0.5 and 0.6 maybe.

Anyway, noticed you list it as 150 L, but HR says ~128.3 L before subtracting the driver's 796 cc, internal bracing, any added blocks of weight, so looking at a ~40 Hz F6 in 2pi space. Seems kind of high, so is this going to be enough once corner loaded?

GM

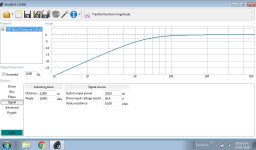

Win Isd is throwing F6 ~ 50 hz.

Applying 250 watts, power compression through.

Attachments

Last edited:

Well, but I guess in a sealed cabinet that does not matter at all

You have said six faces before, that does not correspond to this cabinet, remember that it is a triangular prism, it has five faces.

I think you are little involved in my project but I thank you anyway.

You have said six faces before, that does not correspond to this cabinet, remember that it is a triangular prism, it has five faces.

I think you are little involved in my project but I thank you anyway.

You're welcome!

Actually it does if left unobstructed, but not so sure about yours.

Bummer! 🙁 Too often I'm posting when dead tired, but can't sleep, so tend to be in 'auto' mode and lately been having too many 'senior moments'. Still, only cylinders are inherently rigid, so even triangles need proper bracing.

No less than almost all others, but no excuse, just sometimes you get what you pay for.

GM

Actually it does if left unobstructed, but not so sure about yours.

Bummer! 🙁 Too often I'm posting when dead tired, but can't sleep, so tend to be in 'auto' mode and lately been having too many 'senior moments'. Still, only cylinders are inherently rigid, so even triangles need proper bracing.

No less than almost all others, but no excuse, just sometimes you get what you pay for.

GM

Your contributions are always very valued, I hope your rest improves, something similar happens to me. 😉

It looks very creative! I did not think that so many ICs would be needed in the circuit ... I guess there is a conversion with a DAC, to convert the pulses of each turn to bits for the display...

Se lo ve muy creativo ! No pensé que se necesitarían tantos CI en el circuito .....supongo que hay una conversion con un DAC, para convertir los pulsos de cada giro a bits para el display

Se lo ve muy creativo ! No pensé que se necesitarían tantos CI en el circuito .....supongo que hay una conversion con un DAC, para convertir los pulsos de cada giro a bits para el display

It looks very creative! I did not think that so many ICs would be needed in the circuit ... I guess there is a conversion with a DAC, to convert the pulses of each turn to bits for the display...

Se lo ve muy creativo ! No pensé que se necesitarían tantos CI en el circuito .....supongo que hay una conversion con un DAC, para convertir los pulsos de cada giro a bits para el display

No, they are 40192/3 counters plus 4511 display drivers (a pair for each digit), a L4971 SMPS and some pulse conforming/debouncing.

- Home

- Loudspeakers

- Subwoofers

- Eminence Delta Pro 18 A in prism sealed 150 liters