dc heating on these is easy as the currents are low. remove as much residual ripple as possible and then insert a dropping resistor to yield the correct voltage. I would set this slightly less then recommended to increase life.

eg 5v supply 3.7 ohm resistor. 2 tubes in series with 2.2 ohm resistor on 5 v supply

eg 5v supply 3.7 ohm resistor. 2 tubes in series with 2.2 ohm resistor on 5 v supply

Last edited:

It maybe best to try balanced this way any hum gets canceled and you don’t need special

Regulators and if you use an output and load it plate to plate lower then you will also lower 3rd harmonic and the more 2nd will be canceled from balanced topology

I will try this because I have several 26 tubes

Regulators and if you use an output and load it plate to plate lower then you will also lower 3rd harmonic and the more 2nd will be canceled from balanced topology

I will try this because I have several 26 tubes

but this is NOT correct...it says RIGHT in the tube data AC heating!

I know, but that's a modern adaptation. Back in 1936 or whatever it was, radios ran on batteries. Even the B+. Cap technology was such that AC supplies had very high levels of hum. A couple of 8uf caps didn't get you a lot of filtering. It's interesting to read radio books and magazines from that era. And the consumer/home loudspeakers of that era didn't have the low frequency extension that we're used to today. This enabled primitive AC supplies, and the low filament voltage of a 26 helps to some extent.

The #26 datasheet does say AC or DC, but the curves are drawn with DC on the filaments.

If your OG speaker from 1935 is down 30dB at 60Hz (which is likely), then the hum won't matter much.

Having said that, a 1.5V filament is clearly designed for batteries.

If your OG speaker from 1935 is down 30dB at 60Hz (which is likely), then the hum won't matter much.

Having said that, a 1.5V filament is clearly designed for batteries.

I read through all 461 pages .... 😴

It seems the gyrator with Rod's filament is the way to go. I think I can handle the gain of the gyrator design. I have a Soundsmith MI cart going through a 50dB tube phono feeding a TSE 45 into 104dB K-horns. I built a 0dB buffer preamp that isn't enough but with my 20dB Hafler 915, 1/2 way on the volume gets me to my ideal listening level.

My system is a microscope for noise so the DHT pre must be dead quiet!

The million dollar question is what tube? 26, VT25, 01a? I prefer as neutral as possible with a flat frequency response. I fell in love with DHT's after building my TSE that runs Cunningham CX345's.

Has anyone here built a 45 DHT pre?

It seems the gyrator with Rod's filament is the way to go. I think I can handle the gain of the gyrator design. I have a Soundsmith MI cart going through a 50dB tube phono feeding a TSE 45 into 104dB K-horns. I built a 0dB buffer preamp that isn't enough but with my 20dB Hafler 915, 1/2 way on the volume gets me to my ideal listening level.

My system is a microscope for noise so the DHT pre must be dead quiet!

The million dollar question is what tube? 26, VT25, 01a? I prefer as neutral as possible with a flat frequency response. I fell in love with DHT's after building my TSE that runs Cunningham CX345's.

Has anyone here built a 45 DHT pre?

Hello, welcome to the DHT preamp madness!

For the ultimate lowest noise possible, here are my few tips after building (far) too many DHT preamp/line stages:

1. Split power supply from main chassis and put it as far as you can. Connection with umbilical power cord is perfectly fine.

2. Build with a very thick top plate. 4mm or more. I also use the IKEA wooden chop boards which are fantastic. I have no shielding and my system is dead quiet in high efficient speakers. This will help with the microphonic feedback of some DHTs

3. Source several valves. These are very old DHTs and you may encounter some noisy ones (for sure)!

4. Watch out your layout and ground scheme. This can make a difference between a sterling build and a noise one!

5. Filament bias sounds better!

I’d go for VT25/801a or 01a. They are my preferred at this stage. However I lately built some mid-mu DHT stage which sound fantastic (e.g. EML20-A mesh). The 26 is also great sounding.

If you don’t need much gain, try the 71a as has lower mu\

I tried 46 (triode strapped) before with filament bias. A crazy built which provided heating to my room!. Both 45 and 46 are great valves but harder to build in filament bias.

Hope this helps.

Cheers

Ale

For the ultimate lowest noise possible, here are my few tips after building (far) too many DHT preamp/line stages:

1. Split power supply from main chassis and put it as far as you can. Connection with umbilical power cord is perfectly fine.

2. Build with a very thick top plate. 4mm or more. I also use the IKEA wooden chop boards which are fantastic. I have no shielding and my system is dead quiet in high efficient speakers. This will help with the microphonic feedback of some DHTs

3. Source several valves. These are very old DHTs and you may encounter some noisy ones (for sure)!

4. Watch out your layout and ground scheme. This can make a difference between a sterling build and a noise one!

5. Filament bias sounds better!

I’d go for VT25/801a or 01a. They are my preferred at this stage. However I lately built some mid-mu DHT stage which sound fantastic (e.g. EML20-A mesh). The 26 is also great sounding.

If you don’t need much gain, try the 71a as has lower mu\

I tried 46 (triode strapped) before with filament bias. A crazy built which provided heating to my room!. Both 45 and 46 are great valves but harder to build in filament bias.

Hope this helps.

Cheers

Ale

Yep - all of the above as Ale says. I've also been building this way for years. It's something you come to by trial and error. Keep the filament supplies and the HT away from these DHTs, the chokes in particular. I've been using Neutrik 4 pole Speakons for the HT and 4 pole XLRs for the filaments. Cheap and plentiful and the Speakons are well shrouded.

In my experience the 45 is one of the least microphonic DHT to use in a preamp that feeds into a sensitive system.

Ale's tips are excellent. I would add that the power supply design is very important. Definely use filament supply, Coleman regulators, Ale's gyrators and a good quality coupling capacitor. I had very good results with rectifiers TV dampers, choke input HV supply, oil polypropilene caps.

Good luck,

Radu

Ale's tips are excellent. I would add that the power supply design is very important. Definely use filament supply, Coleman regulators, Ale's gyrators and a good quality coupling capacitor. I had very good results with rectifiers TV dampers, choke input HV supply, oil polypropilene caps.

Good luck,

Radu

dht lives on. another one bites the ....

Hello

I am gathering my parts to build 01a amp. And i am hoping that i will be able to try #26 tube in the near future. I've always considered these tubes as the end of the road or the holy grail of all tubes.

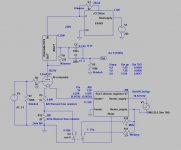

Anyways, I've already purchased Rod's power supply and regulator. Thanks Rod they arrived about 2 weeks ago. They look great. And I am going to use Ale's gyrator cx301a schematic. I have two questions to begin with.

1. i can either do B+ of 260v or 135 v. Which supply one would be less demanding for the transistors?

2. my filament transformer output will be a double 18v. So I may end up with 20v or so. what would be an ideal voltage? I can bring it down in between 18 to 12 v i guess.

That's it for now.

Thanks,

Hello

I am gathering my parts to build 01a amp. And i am hoping that i will be able to try #26 tube in the near future. I've always considered these tubes as the end of the road or the holy grail of all tubes.

Anyways, I've already purchased Rod's power supply and regulator. Thanks Rod they arrived about 2 weeks ago. They look great. And I am going to use Ale's gyrator cx301a schematic. I have two questions to begin with.

1. i can either do B+ of 260v or 135 v. Which supply one would be less demanding for the transistors?

2. my filament transformer output will be a double 18v. So I may end up with 20v or so. what would be an ideal voltage? I can bring it down in between 18 to 12 v i guess.

That's it for now.

Thanks,

Hi Euro 21

If I may ask, is cascode ccs better sounding as say compared to the gyrator by Ale ?

Thks

If I may ask, is cascode ccs better sounding as say compared to the gyrator by Ale ?

Thks

Depends on. "Better sounding" is very subjective thing.

Each tube and each application requires different loading and produces different output parameters, which (together with components) are -mostly- determine the "sounding".

I use this type CCS everywhere -more than a decade- with great satisfaction, but Ale's gyrator is also very good (for example in my 10/801 preamp).

In general (with a very simplified approach) if I need very large anode load, I use cascode CCS, if small output impedance is important, use "gyrator" with well planned semiconductor types.

Each tube and each application requires different loading and produces different output parameters, which (together with components) are -mostly- determine the "sounding".

I use this type CCS everywhere -more than a decade- with great satisfaction, but Ale's gyrator is also very good (for example in my 10/801 preamp).

In general (with a very simplified approach) if I need very large anode load, I use cascode CCS, if small output impedance is important, use "gyrator" with well planned semiconductor types.

Hi Euro 21,

thanks for the reply. I was worried that the DN2540 and Rod's regulator might be running too hot. But you've addressed my concern!

thank you

soldering begins today

thanks for the reply. I was worried that the DN2540 and Rod's regulator might be running too hot. But you've addressed my concern!

thank you

soldering begins today

I was worried that the DN2540 and Rod's regulator might be running too hot.

R.C. regulator need appropriate heat sink area (in my #26 preamp it is first Pentium processor heatsink 🙂 inside the preamp box), but the real radiator is the filament bias resistor. I use for cooling an old Pentium server passive heatsink on the cover plate.

If you want to use compact preamp box, must to use such solution, like me in the 10/801 box: heatsink in sides.

p.s. the large box is #26 preamp, the compact is the 801.

Attachments

Last edited:

First, your amp looks beautiful. Your heat sinks look impressive. And yes, I am going with the filament bias route.

Are you referring to the 20-25 ohm filament resistor? If so, i am going with 100w rated resistor. I tend to overkill when it comes to heat.

thank you

but the real radiator is the filament bias resistor

Are you referring to the 20-25 ohm filament resistor? If so, i am going with 100w rated resistor. I tend to overkill when it comes to heat.

thank you

TVC

Euro 21,

BTW, I was reading a different site and one person mentioned that having a TVC would be important.

Would you explain what TVC is?

thank you

Euro 21,

BTW, I was reading a different site and one person mentioned that having a TVC would be important.

Would you explain what TVC is?

thank you

I use -old- Stevens & Billington TX-102 (copper) Transformer Volume Control. I fell in love with TVC "sound", but today it's an expensive fun. :-(

Some years ago I bought -probably made by Promitheus- nanocrystalline C-core TVC. Now before buying it, you must visit the bank in sky mask. :-( C-core Transformer Volume Control | Hifi Collective

Some years ago I bought -probably made by Promitheus- nanocrystalline C-core TVC. Now before buying it, you must visit the bank in sky mask. :-( C-core Transformer Volume Control | Hifi Collective

- Home

- Amplifiers

- Tubes / Valves

- #26 pre amp