Probably less than a dB at HF for stuff like V15-3 & better.The part that is confusing me is the order of magnitude we are looking for without a reference to his later research. we talking less than 1dB or lots of dB and at what frequency does it start.

Much of Don's stuff was in our Engineering Memos. He didn't publish again until after he retired.

But IIRC, the stuff about waiting 24 hrs wasn't a formal Memo but a note stuck in the Test Record cupboard.

Being a green young whippersnapper at the time, playing truant with cartridges, I used it as an excuse to beard the great Dr. Barlow in his den. 😱 I had only known him by reputation up to that point. 🙂

Last edited:

Yes to all that. The effects with good cartridges would be about 1dB at HF.I have played the same cut twice or more numerous times and never heard a difference. For that matter isn't this standard practice in many situations, equipment comparisons using LP's would be rendered useless.

The test is made more difficult in that no two consecutive plays can be perfectly aligned.

It's difficult, if not impossible to do DBLTs on vinyl playback. BLTs are possible but still difficult.

I haven't seem him around in the last week,

Here I am 😀

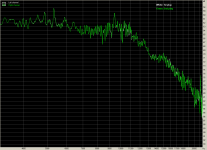

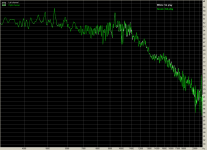

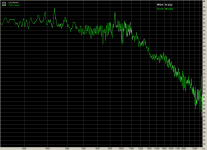

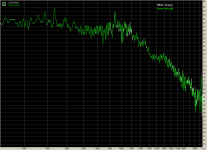

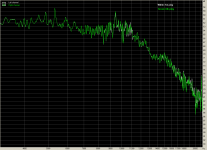

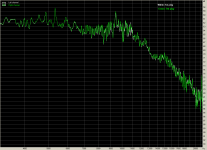

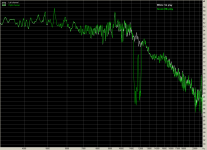

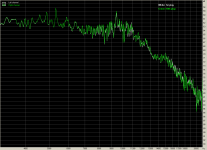

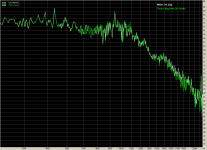

Stanton MKV H2 cartridge on Kenwood KD-3100 turntable, to Hagerman Bugle RIAA pre, to M-Audio Audiophile USB card. 24bit/96KHz recordings.

22d Celcius ambient temp (+/- 0.1).

FFTs (4096 samples) zoomed in the range 3KHz to 22KHz

If there is interest, I can upload the trimmed and aligned wav recordings.

I excercised the cartridge by playing for 20 minutes a music vinyl LP (Lightning Hopkins).

Then I played Side 2 Band 7 (full freq sweep ) from HFN Test LP for ten consecutive times. Repetition interval 40 seconds.

Then, I played the same freq sweep track after 2h 45min.(again I had excercised the cartridge by playing for 20 minutes the same music vinyl LP).

I don't promise but I may do one more recording after a day or so.

George

Attachments

Richard: Sure I have seen a Shure paper on cantilever design but can't find it at the moment. However this High Fidelity Phonograph Cartridge - Technical Seminar | Shure Technical FAQ has some stuff. If you look at the stylus cutaways there you can see the V15-III and IV were designed with variable stiffness along the length, not unlike an tapered tube, but easier to fabricate. By the V clearly low mass mania had set in hence the (now) unobtanium tube. I'll keep searching.

George: You really are the shopkeeper. https://youtu.be/7goleREp884?t=142 up until 2:30. Not that I would accuse you of wearing a Fez. There really was some weird stuff on TV in the 70s, but I grew up on it 🙂

George: You really are the shopkeeper. https://youtu.be/7goleREp884?t=142 up until 2:30. Not that I would accuse you of wearing a Fez. There really was some weird stuff on TV in the 70s, but I grew up on it 🙂

Last edited:

Not that I would accuse you of wearing a Fez. There really was some weird stuff on TV in the 70s, but I grew up on it 🙂

No problem with the Fez.🙂

The first time I watched TV was during the live relay of Apollo 9 landing on the moon.

We had our first B&W TV about 10 years later.

George

I'm just too young for that. The Apollo 8 xmas broadcast to the world co-incided with my coming home from the hospital. When I saw Jim Lovell's flight suit in the museum in chicago it was oddly poignant even though I was oblivious at the time!

BTW bar one anomaly I can't see any FR differences.

BTW bar one anomaly I can't see any FR differences.

Here I am 😀

I don't promise but I may do one more recording after a day or so.

George

Thanks for all the work! What we need is some estimator for the expected deviations due to all factors like speed variation, etc. before any conclusions can be made. Not many points even at 1dB difference in any case. Last time I searched as many folks thought repeat plays of short duration were bad because the vinyl was heated past it's plastic flow point as any other reason.

IOW MHO is it's more folklore.

Your deviations seem to group in a few places like around 10kHz, it might be useful to do a repeat play of a 10kHz only band and try to align them exactly? BTW I have come across folks that for critical setups of very expensive phono front ends will always use a new copy of a test LP, the $50 is trivial compared to the $100k+.

Last edited:

What we need is some estimator for the expected deviations due to all factors like speed variation, etc. before any conclusions can be made.

With this Kenwood TT, the trimmed and aligned recordings differ by anything btn 0.3ms and 2ms in an overal duration of 18s 450ms.

Notable exception, the recording of 8th play (the one with the FFT drop btn 11KHz and 12KHZ) which is 121ms shorter ! I don't know what it happened there. Maybe Mr. Benn passed by at the time

Your deviations seem to group in a few places like around 10kHz, it might be useful to do a repeat play of a 10kHz only band and try to align them exactly?

Recordings from a quiet (blank) groove show FFT variation at 5-10KHz range solely due to differences in click-pop content (if you declick the recordings, the FFT difference goes away).

BTW I have come across folks that for critical setups of very expensive phono front ends will always use a new copy of a test LP, the $50 is trivial compared to the $100k+.

$50 is a lot of money these days. 🙂

George

Recordings from a quiet (blank) groove show FFT variation at 5-10KHz range solely due to differences in click-pop content (if you declick the recordings, the FFT difference goes away).

George

Good to know, I suspected these other factors were at play.

Well, I don't see a basis.Don Barlow circa 1978 said about 24hrs and it would be measurable on a Frequency Response sweep.

One has to be so careful as to method in such things, because even removing the record from the platter between tests can introduce such changes. And random events, including environmental fators such as acoustic and electrical noise, surface noise, can affect interpretation. And besides, surely the place to look for groove deformation would be harmonic distortion due to alteration of waveshape, rather than f response which might or might not even show any effect to any extent anyways..........??

Flexural Stiffness is to the 3rd power of thickness which gives a big advantage to lighter materials. A hollow cantilever favours the 4th power of diameter but its more complicated cos you need to consider wall thickness bla bla .. Anyway, its all in Structural Engineering 101

Recently I posted an equation for stiffness of cantilever which is classic bending physics. Stiffness follows the 4th power of tube radius, and has a fairly complex inverse relationship with wall thickness. There's no escaping that fat tube cantilevers make best use of mass budget, if rigidity at low mass is the aim.

Speaker cones flex, and fibrous materials are lossy. Cones can also be modelled as transmission lines, and ideally the surround would be lossy, as in termination, however loss within the cone can be also be good thing. Cantilevers aren't so different, methinks......here's to a fibre cantilever (!)For cone materials, the winner isn't carbon, kevlar etc. It's Unique Fibrous Material (aka paper) ..

I don't have any baggage from back in the day, I just examine today what survived by way of explanation, which often doesn't stand scrutiny IMO. I'd like to think a few designers understood what was really going on, but that was commercially sensitive. The stuff that was published, especially as marketing material, might have got lost in translation, I suppose. But literature from the time was pretty consistently off the mark, and many axiomatic things accepted which can't be right, IMO. So as I see it there's a chance cartridges were 'right for the wrong reasons' I figure, probably empirical, which perhaps leaves open the door for opportunity to be better now and in the future. I prefer to think there were designers who had it all worked out, but kept it quiet as commercially sensitive, but I might be wrong.........I just don't believe SHURE didn't check out fat tapered Al cantilevers in their modelling.

On the face of it, if fat tube cantilevers can be outperformed, an alternate explanation beyond high rigidity at low mass is needed.........

LD

Last edited:

Yes please George.If there is interest, I can upload the trimmed and aligned wav recordings.

....

I don't promise but I may do one more recording after a day or so.

I can use these directly and make a bit more sense than looking at the raw curves.

WAV files are good.

__________________________

The AES paper has Figs 4 - 12 from the section Design Considerations of the Vl5 Type IV Phonograph Cartridge - L. R. Happbillshurv said:Sure I have seen a Shure paper on cantilever design but can't find it at the moment. However this High Fidelity Phonograph Cartridge - Technical Seminar | Shure Technical FAQ has some stuff. If you look at the stylus cutaways there you can see the V15-III and IV were designed with variable stiffness along the length, not unlike an tapered tube, but easier to fabricate. By the V clearly low mass mania had set in hence the (now) unobtanium tube.

I think it is AES E-Library Dynamic Modeling and Analysis of a Phonograph Stylus

I'd forgotten that V15-4 went back to a reinforced Aluminium cantilever. Lucky just re-invented it 😀

__________________________

Don't miss out on the pearls of wisdom in the FAQ section at the end of

High Fidelity Phonograph Cartridge - Technical Seminar | Shure Technical FAQ

Loadsa subtle hints on cartridge design that aren't covered in the previous technical sections including "high stylus compliance, often assumed to improve performance across the entire audio spectrum, can actually degrade the playback of high frequencies" ... which I can confirm from my own poor efforts at cartridge design 🙂

Which reminds me ... Lucky does your mythical analysis of cantilever behaviour include the characteristics of the rubber bung?

Last edited:

WAV files are good.

There will be there for a few days.

L1st R2nd.wav

https://www.dropbox.com/s/aorikjzanxg9jp6/L1st%20R2nd.wav?dl=0

L1st R3rd.wav

https://www.dropbox.com/s/oqulb23guk0vzzu/L1st%20R3rd.wav?dl=0

L1st R4th.wav

https://www.dropbox.com/s/euhvknab9pdah07/L1st%20R4th.wav?dl=0

L1st R5th.wav

https://www.dropbox.com/s/pr5jyfbc6nr4ohk/L1st%20R5th.wav?dl=0

L1st R6th.wav

https://www.dropbox.com/s/uylrl0rlw1szkox/L1st%20R6th.wav?dl=0

L1st R7th.wav

https://www.dropbox.com/s/e8ejub29j2tefod/L1st%20R7th.wav?dl=0

L1st R8th.wav

https://www.dropbox.com/s/nbcryrd6u74460e/L1st%20R8th.wav?dl=0

L1st R9th.wav

https://www.dropbox.com/s/i2kibvawypraiwc/L1st%20R9th.wav?dl=0

L1st R10th.wav

https://www.dropbox.com/s/2jwcpbmspydptte/L1st%20R10th.wav?dl=0

L1st R2h 45min later level.wav

https://www.dropbox.com/s/cw68v18z527vn0k/L1st%20R2h%2045min%20later%20level.wav?dl=0

Tonight or tomorrow I will record the 24h+ delayed one

George

Loadsa subtle hints on cartridge design that aren't covered in the previous technical sections including "high stylus compliance, often assumed to improve performance across the entire audio spectrum, can actually degrade the playback of high frequencies" ... which I can confirm from my own poor efforts at cartridge design 🙂

Which reminds me ... Lucky does your mythical analysis of cantilever behaviour include the characteristics of the rubber bung?

Well to young whippersnappers like me a compliance of 23 is still pretty high! Anyway gwan, tell us what you found out when let loose with wire and diamonds.

BTW from my point of view fat cantilevers never really went away. I know since Be was banned (still darned useful in satellites) Boron and sapphire have been trendy I am not sure the manufacturers really believed it, just they needed the story to be in the game. But it is a game.

Now this leads to the heresy behind my starting this thread, which is that, as much as I love my Benz micro moving coil its an artisan product, hand made, no two the same. Whereas ortofon crank out MMs by the thousand to the same basic design since the VMS days with the process control than comes with a production line. So it's entirely possible that the MM is actually better, just doesn't have the fancy dress and nice story behind it. And cos its cheap we can pimp it if we work out what to pimp 🙂.

Intrigued I have been trying to work out when Boron became the cantilever of choice. Appears to have been around 1998. Guessing that was when supplies became readily available. Looking at Ortofon through the last 40 years their top end carts went

Al-Sapphire*-Al-boron. Now the MC7500 and Rohmann (same cart just one is titanium and one plain old hogged from solid Al) have a lovely tapered thinwall design but looking at reports (and the one I got off ebay needing a rebuild) this was possibly a step too far as a lot of the 7500/Rohmann ended up with a twisted cantilever if too much antiskate was used.

So other than warranty returns, why did they change. Well the marketing material is interesting. As well as the usual weight/stiffness (effective tip mass down to 0.22mg

from 0.25) they make a big fuss about the speed of sound in boron being 3x that of Al. I wonder why that is important 🙂. Oh the switch also coincides with an increase in trackability from 80um to 100um. Interesting but not conclusive and one would hope the switch to Boron was for more than marketing...

*Only MC5000 but this had a higher -3dB point that all others until the A90 came along.

Al-Sapphire*-Al-boron. Now the MC7500 and Rohmann (same cart just one is titanium and one plain old hogged from solid Al) have a lovely tapered thinwall design but looking at reports (and the one I got off ebay needing a rebuild) this was possibly a step too far as a lot of the 7500/Rohmann ended up with a twisted cantilever if too much antiskate was used.

So other than warranty returns, why did they change. Well the marketing material is interesting. As well as the usual weight/stiffness (effective tip mass down to 0.22mg

from 0.25) they make a big fuss about the speed of sound in boron being 3x that of Al. I wonder why that is important 🙂. Oh the switch also coincides with an increase in trackability from 80um to 100um. Interesting but not conclusive and one would hope the switch to Boron was for more than marketing...

*Only MC5000 but this had a higher -3dB point that all others until the A90 came along.

Shure report measuring vinyl-tip compliance and elastomer properties in 1977

Alan Groh's June 1977 JAES article (here: http://shure.custhelp.com/ci/fattach/get/29245/) reports that "Record-tip compliance C1 is considered a constant and was determined experimentally" (page 387).

C1 is assigned a value of 0.05uF in Figure 4, in which C2 (corresponding to the compliance of the stylus shank assembly) is assigned a value of 0.38uF. This would indicate vinyl-tip compliance of about 1/8th of stylus assembly compliance.

Groh also discusses a model of the elastomer, assigning it frequency-dependent compliance and damping (equations 8 and 9 respectively) with experimentally determined parameters. It's an important component - Van den Hul has interesting things to say at Question 27 of his FAQ (here: http://www.vandenhul.com/faq/general/phono-cartridges-faqs).

Alan Groh's June 1977 JAES article (here: http://shure.custhelp.com/ci/fattach/get/29245/) reports that "Record-tip compliance C1 is considered a constant and was determined experimentally" (page 387).

C1 is assigned a value of 0.05uF in Figure 4, in which C2 (corresponding to the compliance of the stylus shank assembly) is assigned a value of 0.38uF. This would indicate vinyl-tip compliance of about 1/8th of stylus assembly compliance.

Groh also discusses a model of the elastomer, assigning it frequency-dependent compliance and damping (equations 8 and 9 respectively) with experimentally determined parameters. It's an important component - Van den Hul has interesting things to say at Question 27 of his FAQ (here: http://www.vandenhul.com/faq/general/phono-cartridges-faqs).

Last edited:

Thanks for the link. I would agree that the elastomer is critical. We've all driven a car where the shocks are on the way out!

I would agree that the elastomer is critical.

As to the repeat play issue, why can't the elastic deformation and recovery properties be measured statically? Someone must have done it.

EDIT - Yes, the scientific framework exists (beyond me though). http://www.eng.utoledo.edu/mime/fac...PlaseiedFatemi-JMS-Vol.43-No4-pp1191-1199.pdf

Last edited:

Yes, the scientific framework exists

Nice paper. Vinyl elasticity is maintained, though modified and dependent on (among other things) temperature and past strain history. The latter can be modelled with a historical kernel function, which could easily consume more computing power than we had in the 1980s.

As to LD's comment on measuring distortion rather than frequency response I agree. Intuitively, to me at least, there would be a second harmonic component of stress applied by the stylus which could leave a residual strain with some relaxation time. Unfortunately there is a strong second harmonic distortion due to tracing error with many stylus geometries, so I see this as very difficult to instrument. From that paper the stress/time signature is important in which case I would think the residual strain could be very small.

Last edited:

- Home

- Source & Line

- Analogue Source

- mechanical resonance in MMs