5 Mil Kapton ® Tapes are made from Kapton ® Polyimide film with Silicone adhesive

Yes that correct but this link

https://www.kaptontape.com/Kapton_Films.php

Is for Kapton Film not Tape

It says.

5 Mil Kapton® Film also known as Polyimide Film, Heat Resistant Film or a High Temperature Film, is ideal for insulating circuit boards, high temperature powder coating and transformers manufacturing.

Am I not seeing something?

Sent from my SM-G920I using Tapatalk

https://www.kaptontape.com/Kapton_Films.php

Is for Kapton Film not Tape

It says.

5 Mil Kapton® Film also known as Polyimide Film, Heat Resistant Film or a High Temperature Film, is ideal for insulating circuit boards, high temperature powder coating and transformers manufacturing.

Am I not seeing something?

Sent from my SM-G920I using Tapatalk

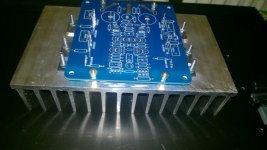

The clamping method also has the advantage of ease in mounting. As we don't need to align the devices' mounting holes that precisely, we can first solder them to the PCB and clamp afterwards. Otherwise, threading 27 legs of nine already fastened devices simultaneously through the corresponding PCB's holes looks like a rather challenging task, at least to me.

Best regards!

Best regards!

The clamping method also has the advantage of ease in mounting. As we don't need to align the devices' mounting holes that precisely, we can first solder them to the PCB and clamp afterwards. Otherwise, threading 27 legs of nine already fastened devices simultaneously through the corresponding PCB's holes looks like a rather challenging task, at least to me.

Best regards!

I never do the soldering before clamping the transistors to the heatsink. It can break the soldering, or can make unnecessary force if the part is not properly positioned. (2nd picture)

Precise mechanical arrangment makes the screewing possible too. The first picture shows testing the mechanical arrangement, with a bit long screws.

Sajti

Attachments

What are those silver clips on your transistors? Are these you clamps or are they clips to temporarily hold you transistors in place while you solder?I never do the soldering before clamping the transistors to the heatsink. It can break the soldering, or can make unnecessary force if the part is not properly positioned. (2nd picture)

Precise mechanical arrangment makes the screewing possible too. The first picture shows testing the mechanical arrangement, with a bit long screws.

Sajti

Sent from my SM-G920I using Tapatalk

What are those silver clips on your transistors? Are these you clamps or are they clips to temporarily hold you transistors in place while you solder?

Sent from my SM-G920I using Tapatalk

They are clamps. Fixing the transistors on the heatsink. They are quite easy to use, and You don't need to use screw.

Developed by Fischerelektronik.

Sajti

They are clamps. Fixing the transistors on the heatsink. They are quite easy to use, and You don't need to use screw.

Developed by Fischerelektronik.

Sajti

Found here:

Retaining Spring Heat Sink Hardware | Newark element14

...among other places. That will give you the part numbers and official descriptions.

Thank you.Found here:

Retaining Spring Heat Sink Hardware | Newark element14

...among other places. That will give you the part numbers and official descriptions.

Sent from my SM-G920I using Tapatalk

I was just wondering with my honey badger PCB build. Which transistors do you guys prefer for Q10 and Q11-Q13

The build manual lists.

Q10 either a MJE350G or a KSA1381.

Q11-Q13 either a MJE340G or a KSC3503.

I would appreciate and would like to hear everybody's thoughts on these transistors.

Also the KSA1381 lists hFE Grades eg. hFE C Grade, hFE D grade, hFE E grade etc....

What does this mean?

Sent from my SM-G920I using Tapatalk

The build manual lists.

Q10 either a MJE350G or a KSA1381.

Q11-Q13 either a MJE340G or a KSC3503.

I would appreciate and would like to hear everybody's thoughts on these transistors.

Also the KSA1381 lists hFE Grades eg. hFE C Grade, hFE D grade, hFE E grade etc....

What does this mean?

Sent from my SM-G920I using Tapatalk

I prefer KSC3503/KSA1381. Don't care with the different Hfe class, they have different function.

Sajti

Sajti

Ok thanks. I was just asking about the hFE classes as the only ones available were E class so I'm not sure if this matters.I prefer KSC3503/KSA1381. Don't care with the different Hfe class, they have different function.

Sajti

Sent from my SM-G920I using Tapatalk

Ok thanks. I was just asking about the hFE classes as the only ones available were E class so I'm not sure if this matters.

Sent from my SM-G920I using Tapatalk

You can find the definition of the Hfe classes, in the pdf documentation. E grade looks OK for this amplifier.

Sajti

I am using 600VA 45V toroids in my build.

These transformers are noiseless when the psu is unloaded.

When loaded they mechanically hum.... the hum is not heard in the speakers, it is purely mechanical.

What tx manufacturer should I contact to have big toroids that do not mechanically hum ?

Best

Ricardo

These transformers are noiseless when the psu is unloaded.

When loaded they mechanically hum.... the hum is not heard in the speakers, it is purely mechanical.

What tx manufacturer should I contact to have big toroids that do not mechanically hum ?

Best

Ricardo

Are the transformers driven directly by the mains?

Do you have them rigidly coupled to the chassis?

Have you tried a DC blocking capacitor bank?

What bias/quiescent current are you drawing?

Do you have them rigidly coupled to the chassis?

Have you tried a DC blocking capacitor bank?

What bias/quiescent current are you drawing?

Last edited:

I am drawing 200mA per device (3 positive and 3 negative) so 600mA per bank.

The TX is directly connected to the mains.

The TX is bolted to the chassis.

I did not try DC blocking caps because I do not know what voltage to choose for 230VAC

The TX is directly connected to the mains.

The TX is bolted to the chassis.

I did not try DC blocking caps because I do not know what voltage to choose for 230VAC

There can be DC offset on the mains which can cause hum in larger transformers. This is worth reading Mains DC and Transformers

600mA is quite a high continuous current. That could exaggerate the mechanical hum/buzz.

The Tx bolted solidly to the chassis can turn the chassis into a sound box that amplifies the TX mechanical Hum/buzz.

Placing the TX on some soft spacers rather than on one hard thin rubber washer may reduce the noise amplification.

Hanging the Tx from a bar across the chassis can reduce the sound box effect.

The DC blocker can have an effect or not depending on how susceptable the Tx is to saturation effect of unbalanced AC from the mains.

You will need a bank of low voltage polarised capacitors in back to back format and with diode protection/bypass in case there is excessive current demand during start up or abuse. Bi-polar are too expensive and too big for this DC blocking duty.

In addition to reading that link there is also a very informative Thread on the Forum.

The Tx bolted solidly to the chassis can turn the chassis into a sound box that amplifies the TX mechanical Hum/buzz.

Placing the TX on some soft spacers rather than on one hard thin rubber washer may reduce the noise amplification.

Hanging the Tx from a bar across the chassis can reduce the sound box effect.

The DC blocker can have an effect or not depending on how susceptable the Tx is to saturation effect of unbalanced AC from the mains.

You will need a bank of low voltage polarised capacitors in back to back format and with diode protection/bypass in case there is excessive current demand during start up or abuse. Bi-polar are too expensive and too big for this DC blocking duty.

In addition to reading that link there is also a very informative Thread on the Forum.

Last edited:

I am building a DC blocking circuit now, but I believe the trouble comes from drawing high current from the TX.

The ideas you gave me on isolation might cure the issue.

The ideas you gave me on isolation might cure the issue.

I am using 600VA 45V toroids in my build.

These transformers are noiseless when the psu is unloaded.

When loaded they mechanically hum.... the hum is not heard in the speakers, it is purely mechanical.

What tx manufacturer should I contact to have big toroids that do not mechanically hum ?

Best

Ricardo

I've had good luck with Toroidy. Quality is good, and prices (incl. shipping to Switzerland) are okay.

I have not seen any substantial DC on the grid power around here. But things tend to be different in Valais... 😉

- Home

- Amplifiers

- Solid State

- diyAB Amp The "Honey Badger" build thread