Hi Ray.

The figures for resonant frequency that I have quoted in this thread are actually 20% lower than the calculated figures. This is to account for this 2% overshoot and any other unseen factors. I would always prefer under-quoted specifications to over-quoted .

Niffy

I've just reread this post and have noticed that I made an error. The figures that I have quoted are actually 30% lower than the calculated figures and not 20%. I gave myself a larger margin of error than I remembered. This means that the actual resonant frequencies are almost certainly way above 20khz.

Niffy

Hi Stefano,

I have finally plugged the specifications for your cartridges into my analysis spread sheet. Here are the results in comparison to my cartridge.

ZYX 4D.

The low mass of this cartridge (4.1g) and is need for a lighter counterweight have helped push the resonant frequencies up even further. Horizontal would be 22.5khz and vertical 31.7khz. Both excellent. Tracking force variation remains low at 0.7%. However, due to the low compliance, the vertical cantilever compliance resonance would be 13.6hz which is too high. The lateral would be 6hz which is ok. The effective masses could both do with increasing. As the extra mass used to achieve this would also increase carriage rigidity the carriage resonant frequencies would increase further. The additional mass would slightly increase bearing friction but as the cartridge is low compliance the lateral tracking error would actually be less.

CLEARAUDIO TITANIUM V2

The slightly higher mass of this cartridge and a slightly heavier counterweight. Have reduced the carriage resonant frequencies. They are still good at 18.5khz vertical and 26.7khz lateral. The cantilever compliance resonances is slightly better than the xyz. Vertical is 11.4hz and lateral 5.5hz. Still a bit high especially the vertical. Again a slight increase in carriage mass would help. Due to having a bit more mass lower down, especially in the counterweight, tracking force variation are now only 0.18%.

CLEARAUDIO GOLDFINGER STATEMENT

This is a very heavy cartridge. In order to balance this cartridge I had to model the counterweight as being made of tungsten rather than stainless steel. This is an excellent material for this application but sourcing and fabrication are difficult. I also had to make the counterweight thicker which may cause it to foul the record when queuing. The increased mass has bought the resonant frequencies down. 16.9khz vertical and 24.3khz lateral. These are both still above what I can hear. The mass of the cartridge and the heavy counterweight have helped keep the effective mass up so the cantilever resonances are 10.3hz vertical and 4.8hz lateral. Tracking force variation was the best yet at 0.15%. The much higher masses would add about 20g to the total mass of the carriage. This would increase bearing friction by 35%. The lower compliance would mean that the lateral tracking error would still be low, almost exactly what I have with my cartridge. A little more vertical effective mass would be nice and if the counterweight doesn't cause problems should be a nice match. I wouldn't want to load the pin bearings much more than this.

I hope this helps. I think only a small change to the design would be required for any of the cartridges.

Niffy

I have finally plugged the specifications for your cartridges into my analysis spread sheet. Here are the results in comparison to my cartridge.

ZYX 4D.

The low mass of this cartridge (4.1g) and is need for a lighter counterweight have helped push the resonant frequencies up even further. Horizontal would be 22.5khz and vertical 31.7khz. Both excellent. Tracking force variation remains low at 0.7%. However, due to the low compliance, the vertical cantilever compliance resonance would be 13.6hz which is too high. The lateral would be 6hz which is ok. The effective masses could both do with increasing. As the extra mass used to achieve this would also increase carriage rigidity the carriage resonant frequencies would increase further. The additional mass would slightly increase bearing friction but as the cartridge is low compliance the lateral tracking error would actually be less.

CLEARAUDIO TITANIUM V2

The slightly higher mass of this cartridge and a slightly heavier counterweight. Have reduced the carriage resonant frequencies. They are still good at 18.5khz vertical and 26.7khz lateral. The cantilever compliance resonances is slightly better than the xyz. Vertical is 11.4hz and lateral 5.5hz. Still a bit high especially the vertical. Again a slight increase in carriage mass would help. Due to having a bit more mass lower down, especially in the counterweight, tracking force variation are now only 0.18%.

CLEARAUDIO GOLDFINGER STATEMENT

This is a very heavy cartridge. In order to balance this cartridge I had to model the counterweight as being made of tungsten rather than stainless steel. This is an excellent material for this application but sourcing and fabrication are difficult. I also had to make the counterweight thicker which may cause it to foul the record when queuing. The increased mass has bought the resonant frequencies down. 16.9khz vertical and 24.3khz lateral. These are both still above what I can hear. The mass of the cartridge and the heavy counterweight have helped keep the effective mass up so the cantilever resonances are 10.3hz vertical and 4.8hz lateral. Tracking force variation was the best yet at 0.15%. The much higher masses would add about 20g to the total mass of the carriage. This would increase bearing friction by 35%. The lower compliance would mean that the lateral tracking error would still be low, almost exactly what I have with my cartridge. A little more vertical effective mass would be nice and if the counterweight doesn't cause problems should be a nice match. I wouldn't want to load the pin bearings much more than this.

I hope this helps. I think only a small change to the design would be required for any of the cartridges.

Niffy

Last edited:

Hi,

Here are Nakamichi's computing Turntable pages from Electronics Today International Magazine. Hope there is some useful information. (Resolution is as per DiyAudio limitations. I also have high resolution files.)

Regards

Here are Nakamichi's computing Turntable pages from Electronics Today International Magazine. Hope there is some useful information. (Resolution is as per DiyAudio limitations. I also have high resolution files.)

Regards

Attachments

I also have Servo based Parallel Tracking Tonearm design by Mr. Rod Cooper from Wireless World. Another interesting article is about Mats and Clamps measurements by Mr. Edward Long from Audio Magazine. But I don't know if posting them would bring any copy right issues or not.

Regards.

Regards.

Hi Hiten,

Thanks for the interesting article. The whole system looks a bit overcomplicated. It would appear that the designer was given a design constraint in having to make the system fully automated. Having the whole measurement system rising up out of the plinth doing its thing then lowering back down has got to be there just to look funky. All of those mechanisms, platter cutouts and extra plinth components has got to compromise the deck to some extent. Another possible case of the cure being worse than the ailment? The modern style of deck design seems to be pared down to the minimum so it's unlikely that a system such as this would find commercial acceptance now. It would be nice to see what could be achieved with more modern technology and a minimalist design approach.

Niffy

Thanks for the interesting article. The whole system looks a bit overcomplicated. It would appear that the designer was given a design constraint in having to make the system fully automated. Having the whole measurement system rising up out of the plinth doing its thing then lowering back down has got to be there just to look funky. All of those mechanisms, platter cutouts and extra plinth components has got to compromise the deck to some extent. Another possible case of the cure being worse than the ailment? The modern style of deck design seems to be pared down to the minimum so it's unlikely that a system such as this would find commercial acceptance now. It would be nice to see what could be achieved with more modern technology and a minimalist design approach.

Niffy

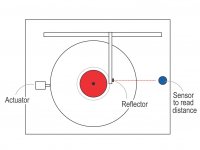

Yes I agree it is complicated. Simple solutions would be elegant. I was wondering if linear tonearm can be used to calculate offset distance. One can put tonearm on lead out groove of the record. The tonearm's side face will have some reflector which optical sensor reads and the movement/distance can be measured. Which can be fed to an actuator to move record or spindle. (A very crude illustration attached)

Regards

Regards

Attachments

I was wondering if those who built the linear arm would post pictures of their mounts, especially how you adjust them.

I should probably clarify my request......

I want to build an adjustable mount so that if I were to change cartridges, it will be a realtively easy matter to change not only vta but also align the stylus with the spindle and not have to build a new carriage.

I have found some inexpensive xy platforms on ebay, but I think that they would make the overall height too great and I would end up needing to male a larger carriage, thus increasing the weight.

The arm will be matched to a dual 1019 deck on a plinth that I will make for this purpose, so I suppose that I can varry the height to some extent by not adding layers of plywood in the area where the arm will reside......

Just looking for examples and suggestions that I can implement for less than about $150 or so......

I want to build an adjustable mount so that if I were to change cartridges, it will be a realtively easy matter to change not only vta but also align the stylus with the spindle and not have to build a new carriage.

I have found some inexpensive xy platforms on ebay, but I think that they would make the overall height too great and I would end up needing to male a larger carriage, thus increasing the weight.

The arm will be matched to a dual 1019 deck on a plinth that I will make for this purpose, so I suppose that I can varry the height to some extent by not adding layers of plywood in the area where the arm will reside......

Just looking for examples and suggestions that I can implement for less than about $150 or so......

Perhaps, you may use this.

Big Heavy Duty Metal Boom Stereo Microscope Camera Table Stand Holder 50mm Ring | eBay

Big Heavy Duty Metal Boom Stereo Microscope Camera Table Stand Holder 50mm Ring | eBay

Hi Arm builders

Hi Y all,

I am a bit late to the party here but i wanted to know

A. A link Where one can obtain borosilicate glass "C" section (so that one pair of bearings can be used-nice and simple )-as opposed to round sections.

B. a link to bearing relevant to this arm (Googled SKF- nothing sutable/no joy at my local "hobby shop")

I have been through the thread once but may have missed something as i am now blind!!😀

Cheers all

Johnny

Hi Y all,

I am a bit late to the party here but i wanted to know

A. A link Where one can obtain borosilicate glass "C" section (so that one pair of bearings can be used-nice and simple )-as opposed to round sections.

B. a link to bearing relevant to this arm (Googled SKF- nothing sutable/no joy at my local "hobby shop")

I have been through the thread once but may have missed something as i am now blind!!😀

Cheers all

Johnny

Checkout Swiss jewels. They have all kinds of bearing. Dunno why you want borosilicate. But anyways...

Checkout Swiss jewels. They have all kinds of bearing. Dunno why you want borosilicate. But anyways...

The borosilicate tubes are for the rails....

I bought mine from a glass blower.

While I was there we cut tubes using a oil cooled glass saw.

Slow going but it was able to cut a section out of the tube.

thanks for the reply

hI BOYZ,

Thank you for the heads up on Swiss jewels bearings, i shall follow that up, with regards to borsilaicat glass, that just what i read (its supposed to be harder?)- but most likely no big deal.

cheers JOHNNY

hI BOYZ,

Thank you for the heads up on Swiss jewels bearings, i shall follow that up, with regards to borsilaicat glass, that just what i read (its supposed to be harder?)- but most likely no big deal.

cheers JOHNNY

Hi Johnny

I tried a couple of different types of ball race bearings before moving on to using jewelled pin bearings. The best ball race bearings I found were from Boca bearings. The ones I used were the hybrid bearings. These have silicon nitride balls and 440 stainless steel races. They were noticeable better than the full ceramic zirconium oxide bearings I also tried. Borosilicate glass rods work very well. Even better is tungsten carbide. This is a much harder material than glass and helps to reduce rolling resistance (by about 20% compared to glass).

The silicon nitride hybrid bearings and tungsten carbide rods are definitely more expensive than standard grade bearings and glass rods but the performance improvements are definitely worthwhile.

My final version did away with ball race bearings entirely and used tungsten carbide pivots in sapphire vee jewel for the bearings and tungsten carbide rings as wheels. This is a big step up from in performance but is much more expensive and difficult to implement.

Niffy

I tried a couple of different types of ball race bearings before moving on to using jewelled pin bearings. The best ball race bearings I found were from Boca bearings. The ones I used were the hybrid bearings. These have silicon nitride balls and 440 stainless steel races. They were noticeable better than the full ceramic zirconium oxide bearings I also tried. Borosilicate glass rods work very well. Even better is tungsten carbide. This is a much harder material than glass and helps to reduce rolling resistance (by about 20% compared to glass).

The silicon nitride hybrid bearings and tungsten carbide rods are definitely more expensive than standard grade bearings and glass rods but the performance improvements are definitely worthwhile.

My final version did away with ball race bearings entirely and used tungsten carbide pivots in sapphire vee jewel for the bearings and tungsten carbide rings as wheels. This is a big step up from in performance but is much more expensive and difficult to implement.

Niffy

hI BOYZ,

Thank you for the heads up on Swiss jewels bearings, i shall follow that up, with regards to borsilaicat glass, that just what i read (its supposed to be harder?)- but most likely no big deal.

cheers JOHNNY

Hi Johnny

My extensive experimentation in developing my bearings showed that the hardness of the materials used does make a big difference in the rolling resistance of the wheels on the rail.

Niffy

Any chance of some more photos Niffy?Hi Johnny

I tried a couple of different types of ball race bearings before moving on to using jewelled pin bearings. The best ball race bearings I found were from Boca bearings. The ones I used were the hybrid bearings. These have silicon nitride balls and 440 stainless steel races. They were noticeable better than the full ceramic zirconium oxide bearings I also tried. Borosilicate glass rods work very well. Even better is tungsten carbide. This is a much harder material than glass and helps to reduce rolling resistance (by about 20% compared to glass).

The silicon nitride hybrid bearings and tungsten carbide rods are definitely more expensive than standard grade bearings and glass rods but the performance improvements are definitely worthwhile.

My final version did away with ball race bearings entirely and used tungsten carbide pivots in sapphire vee jewel for the bearings and tungsten carbide rings as wheels. This is a big step up from in performance but is much more expensive and difficult to implement.

Niffy

Linc

Hi,

I described my bearing design after this thread was restarted during the summer. I first mentioned my experiments into pin bearings in post 1988 on page 199. There's a bit of discussion on other interesting subjects until page 208 where I start going into more detail and including diagrams, photos and graphs. I would recommend reading the last 24pages.

Here are some photos of arm and deck, I don't have all the photos on my phone, where I'm writing this. Hope these do.

Niffy

I described my bearing design after this thread was restarted during the summer. I first mentioned my experiments into pin bearings in post 1988 on page 199. There's a bit of discussion on other interesting subjects until page 208 where I start going into more detail and including diagrams, photos and graphs. I would recommend reading the last 24pages.

Here are some photos of arm and deck, I don't have all the photos on my phone, where I'm writing this. Hope these do.

Niffy

Attachments

Sorry. I have no idea where the holiday swap notice came from. The last couple of photos are with previous versions of the wheels and bearings.

Niffy

Niffy

Last edited:

Beautiful work mate. Thanks for sharing again. Hard work going back through all these pages to find it!Hi,

I described my bearing design after this thread was restarted during the summer. I first mentioned my experiments into pin bearings in post 1988 on page 199. There's a bit of discussion on other interesting subjects until page 208 where I start going into more detail and including diagrams, photos and graphs. I would recommend reading the last 24pages.

Here are some photos of arm and deck, I don't have all the photos on my phone, where I'm writing this. Hope these do.

View attachment 583938

View attachment 583939

View attachment 583940

View attachment 583941

View attachment 583942

Niffy

Stealth Bomber

Hi Guys,

I have just spent 6 weeks reading thro' from 1 to 221 & am hooked🙂

3 years ago I finished making a 'Floater' [Arm floats on water across an ice cream tub] & was so pleased with the results, all I wanted to do was listen to my vinyl.

3 years later & I'm back - firstly following Colin's design & then onto to Niffy's.

Both with amazing work.

I have chosen to go with Niffy's design, mine being a direct copy (without the quality or expense) hope you don't mind Niffy?

Tonight I have more or less finished the 'Stealth' carriage so now I need to think about the support - with one or two thoughts on what I can do from garage remnants🙂

When complete I will take some pics & let you all know what it sounds like.

Again, Thanks for all the great work put in by Colin & Niffy

GC

ps. has anyone else gone along the Niffy line & got it working?

Hi Guys,

I have just spent 6 weeks reading thro' from 1 to 221 & am hooked🙂

3 years ago I finished making a 'Floater' [Arm floats on water across an ice cream tub] & was so pleased with the results, all I wanted to do was listen to my vinyl.

3 years later & I'm back - firstly following Colin's design & then onto to Niffy's.

Both with amazing work.

I have chosen to go with Niffy's design, mine being a direct copy (without the quality or expense) hope you don't mind Niffy?

Tonight I have more or less finished the 'Stealth' carriage so now I need to think about the support - with one or two thoughts on what I can do from garage remnants🙂

When complete I will take some pics & let you all know what it sounds like.

Again, Thanks for all the great work put in by Colin & Niffy

GC

ps. has anyone else gone along the Niffy line & got it working?

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm