I'd forgotten that B&K recommended such a high resonant frequency. That's a tough call with many MM cartridges unless you go for DJ models with really low compliance. Still digesting the VTA/SRA article but have a wry smile as Mad Mikey Fremer claims you can't hear SRA changes of under 4 degrees.

Mad Mikey Fremer claims you can't hear SRA changes of under 4 degrees.

While the effects of LP de-magnetization are obvious, such rational consistency.

I'd forgotten that B&K recommended such a high resonant frequency.

B&K recommendation is being objected on the basis that arm-cart resonance will be excited due to it’s proximity to acoustic content.

This is IMO false.

Acoustic content is rarely present that low in a record grove, and if there is present it is of low amplitude, while the record eccentricity and warp is always present and at good amounts

Still digesting the VTA/SRA article but have a wry smile as Mad Mikey Fremer claims you can't hear SRA changes of under 4 degrees.

Bill, don’t lose your sleep if you have a spherical tip.

Don’t worry much with an elliptical one.

With hyper elliptical and line contact, yes.

George

My Benz is elliptical, My AT150MLx isn't. But I need an excuse to buy a digital microscope!

The bit I was digesting was over the relationship between SRA and VTA. I hadn't taken the cutting head into account. An interesting additional data point. Still need to locate an SME3009 SIII with its 5g effective mass!

The bit I was digesting was over the relationship between SRA and VTA. I hadn't taken the cutting head into account. An interesting additional data point. Still need to locate an SME3009 SIII with its 5g effective mass!

Change the shape of your stylus. It will ride in a different area of the groove. One possible benefit is groove walls damaged by mistracking will be avoided, but regardless, there is almost always a stylus shape that runs quieter than another. Some experimentation might offer positive benefits.

I hadn't taken the cutting head into account

Between 1970 and ~ 1990 they had managed to standardise the VTA to 15 degrees. Later they have moved to 20 degrees. Before 1970 there was no agreed upon angle.

So, I wouldn’t spend hours and effort on optimising the VTA on my arm (I’ve done it in the past).

A certain VTA is a match for one vinyl record, a mismatch for another.

George

I had to go away and study some images of cutting heads. Always good to learn something new. I am sure that somewhere amongst the OCD of collectordom someone has chapter and verse on VTAs used by major labels over the years.

I guess if you have a test record from a label and they always used the same heads you can optimise, otherwise its a route to madness and playing records is mad enough already.

I guess if you have a test record from a label and they always used the same heads you can optimise, otherwise its a route to madness and playing records is mad enough already.

I guess if you have a test record from a label and they always used the same heads you can optimise, otherwise its a route to madness and playing records is mad enough already.

The real OCD guys measure it for each LP by ear and record it.

I would like to see an analysis that includes both magnitude and phase of the sidebands. With some carts the change of SRA causes high frequency loss which is AM on top of the FM. Just curious about the relative magnitudes of the effects. When you read all this stuff the folks chasing .0001% distortion and nsecs of PIM seem really silly.

http://www.analogplanet.com/images/512MFVTA_article.pdf

Thank you, Scott. That's an interesting, and reasonably disciplined approach to tackling the odd audible phenomenum of how sensitive 'lock in' of detail can be versus SRA/VTA, especially for narrow contact profile stylus types.

Geometric error in offset angle, be it lateral or vertical (VTA), results in harmonic distortion, as was settled by Baerwald and others decades ago. So, it being the same for all stylus profiles, can't be the explanation.

Contrary to popular belief, pinch effect, where a stylus is pinched upward by groove shape, is not an artefact of high groove curvature. It has maxima at groove 'zero crossing points' when groove curvature is zero (by definition), but groove angle is high. This corresponds to peak levels within programme material, and is frequency independent.

What pinch effect produces is harmonic distortion proportional to programme level, arising as a stereo difference (vertical) signal. Nothing to do with high frequencies. It also adversely affects trackability, as the stylus has to accelerate vertically downwards even in response to a mono groove, which is the real cause of adverse high frequency performance associated with pinch effect.

Pinch effect does reduce significantly with stylus profile, but is not materially affected by the sorts of variation in VTA at issue. For these reasons, pinch effect can't be the explanation.

Groove curvature is comfortably smaller than corresponding stylus contact radius for all practical stylus profiles. Curvature corresponds to slew rate in programme material, so is high for programme material with high slew rate. Loud high frequencies, such as cymbal crashes, for example. Even then, the fit is always comfortable even for conicals, and advantage via line contact profile styli is a matter of improved harmonic distortion - but harmonic distortion products being above the audioband, this is only audible as slight hf loss for high level high frequency sounds with conicals. Again, geometric error caused by VTA in such matters is small in the scheme of things, so can't be the explanation.

An important observation, backed by measurement in the paper Scott linked, linked is that SRA - not VTA - is the key parameter.

At risk of being very tedious, I believe the best explanation is that stylus-groove friction can depend critically on SRA, especially so for line contact profile styli. Small variations in SRA (also azimuth, and offset angle too to a lesser extent), critically affect friction coefficient for line contact types, I have measured.

For the reasons already set out on this thread, my opinion is firmly that VTA/SRA critical audible settings have their root in minimising friction. This is why 'setting by ear' can be the most successful approach, and is commonly cited. If the authors of that paper had thought to measure noise floor as it varied with VTA/SRA, they would very probably have seen that critically depend on the setting too.

LD

Last edited:

So if I read you right AND I were completely OCD about optimising each record then you could rip a section at different VTA and compare?

Follow on questions.

1. would this work for an intertrack silence. I am guessing this would get closer than nothing but (if I have been paying attention) the friction is increased by modulation as well as stylus velocity.

2. If one were to try and do it using analysis of a rip how would you approach it? With a test tone its easy, but with actual music do you just set enough fft bins to be able to find some with no music in and look at the noise there?

Maybe this guy isn't quite so barking Audiomods tonearms and tonearm kits Although I'm still not convinced about the swiss cheese anti-resonance drillings.

Follow on questions.

1. would this work for an intertrack silence. I am guessing this would get closer than nothing but (if I have been paying attention) the friction is increased by modulation as well as stylus velocity.

2. If one were to try and do it using analysis of a rip how would you approach it? With a test tone its easy, but with actual music do you just set enough fft bins to be able to find some with no music in and look at the noise there?

Maybe this guy isn't quite so barking Audiomods tonearms and tonearm kits Although I'm still not convinced about the swiss cheese anti-resonance drillings.

So if I read you right AND I were completely OCD about optimising each record then you could rip a section at different VTA and compare?

Yes, on some setups, if conditions are right, there will be a sweet spot associated with the exact shape of the stylus contact surface, the 3D angle it presents to the groove wall, and the nature of the vinyl surface, I am saying.

The sharpness of the phenomemum, when present, is illustrated in Fig 5 of the paper Scott linked.

Although there are various geometric aspects which vary very slightly with SRA, none of them are capable of enough effect to provide satisfactory explanation. The geometric effect on distortion of +/- 2 deg SRA is tiny, so some other explanation is needed.

1. would this work for an intertrack silence. I am guessing this would get closer than nothing but (if I have been paying attention) the friction is increased by modulation as well as stylus velocity.

I suppose one could have some contraption with a servo that varied VTA via a servo based on minimising surface noise at the push of a button? But I bet there'd be a queue of people asking for their money back when it didn't work in their circumstances !

If one were to try and do it using analysis of a rip how would you approach it? With a test tone its easy, but with actual music do you just set enough fft bins to be able to find some with no music in and look at the noise there?

Could look at the LF signature where there is no programme material ? That is a good marker for friction, which correlates with the sweet spot, IME.

Maybe this guy isn't quite so barking Audiomods tonearms and tonearm kits Although I'm still not convinced about the swiss cheese anti-resonance drillings.

Barking, I suspect many would consider us to be. I do like Rega arms, the underlying design.

LD

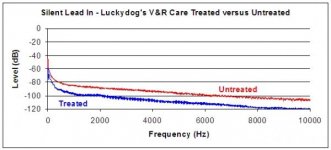

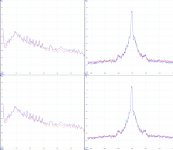

A time ago, I also tested home brew vinyl treatments that might 'permanently' reduce surface friction. Here's a plot that shows profound noise floor improvement from a 'silent' lead in groove.

Don't know 0dB reference level, so ignore absolute levels. But the relative improvement was profound, c 12 - 15dB after treatment over most of the audioband. Don't know the record, but looks typical IME.

IIRC, this treatment sufferered clogging, which was the snag with all the home brews I found.

Anyways, here's the plot:

LD

Don't know 0dB reference level, so ignore absolute levels. But the relative improvement was profound, c 12 - 15dB after treatment over most of the audioband. Don't know the record, but looks typical IME.

IIRC, this treatment sufferered clogging, which was the snag with all the home brews I found.

Anyways, here's the plot:

LD

Attachments

Initially my intention was to start a new thread since noise dependency on playing Dry/Wet around 10Hz and the effect of it in IM distortion around a reference tone is not exactly the theme of this thread.

I expected at least some difference in the 10Hz region when playing wet, but I didn't. So starting a new thread made no real sense.

I did the following:

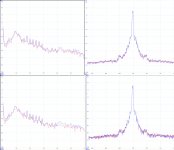

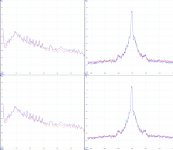

On a track with a 0 dB 1Khz test tone that was never played wet, I first made 5 recordings Dry and after that 5 recordings Wet. Each recording being sampled with 200Khz to avoid folding back of high frequency artefacts in the regions of interest, giving me spectra with 100Khz Bandwidth.

Filter Bandwidth was 0.37Hz.

Noise of the recording chain was 12dB or more below the recorded noise from the LP.

Because of the narrow filter bandwidth, I could only average 11 spectra, given the limited time length of the reference tone.

Since all spectra are almost copies of each other, I have displayed the spectra from 0-60Hz and from 850Hz to 1150Hz only for 2 Dry and for 2 Wet recordings.

The blue ovals correspond to 1Khz +/-9.5Hz and +/- 18Hz, where 9,5Hz is the resonance frequency of the Cart/Arm combination.

Two Dry Recordings

Two Wet Recordings

As you can see, Dry or Wet makes no difference at all. Not in the rumble region but also not in the IM product around the reference tone.

Clearly visible are the IM products around the reference tone in blue.

Also visible are +/-50Hz IM products some -75dB below the reference tone, quite harmless to my opinion, but nevertheless well reproducible.

The first IM components at +/-9.5Hz lies -45dB below the reference tone.

In Poul Ladegaard's often cited article, IM products are resp. -25dB and -35dB below reference for an undamped 9.5Hz and a 16Hz damped Arm/Cart resonance frequency, leading him to conclude that the higher res. frequency is better.

This again shows how careful one has to be when coming to conclusions, because with different equipment everything may look totally different.

I can only repeat what I have said before: the only thing that I have proved is that with my equipment and with my test record, playing Dry or Wet makes no difference at all.

Despite others who found (completely) different results, as well with noise reduction when playing Wet (Figure in posting #51) and also with the level of IM products related to the resonance frequency (B&K article from 1977), be careful not to jump to conclusions.

The LP world is obviously not that simple and dependant on many interrelated factors.

Hans

I expected at least some difference in the 10Hz region when playing wet, but I didn't. So starting a new thread made no real sense.

I did the following:

On a track with a 0 dB 1Khz test tone that was never played wet, I first made 5 recordings Dry and after that 5 recordings Wet. Each recording being sampled with 200Khz to avoid folding back of high frequency artefacts in the regions of interest, giving me spectra with 100Khz Bandwidth.

Filter Bandwidth was 0.37Hz.

Noise of the recording chain was 12dB or more below the recorded noise from the LP.

Because of the narrow filter bandwidth, I could only average 11 spectra, given the limited time length of the reference tone.

Since all spectra are almost copies of each other, I have displayed the spectra from 0-60Hz and from 850Hz to 1150Hz only for 2 Dry and for 2 Wet recordings.

The blue ovals correspond to 1Khz +/-9.5Hz and +/- 18Hz, where 9,5Hz is the resonance frequency of the Cart/Arm combination.

Two Dry Recordings

Two Wet Recordings

As you can see, Dry or Wet makes no difference at all. Not in the rumble region but also not in the IM product around the reference tone.

Clearly visible are the IM products around the reference tone in blue.

Also visible are +/-50Hz IM products some -75dB below the reference tone, quite harmless to my opinion, but nevertheless well reproducible.

The first IM components at +/-9.5Hz lies -45dB below the reference tone.

In Poul Ladegaard's often cited article, IM products are resp. -25dB and -35dB below reference for an undamped 9.5Hz and a 16Hz damped Arm/Cart resonance frequency, leading him to conclude that the higher res. frequency is better.

This again shows how careful one has to be when coming to conclusions, because with different equipment everything may look totally different.

I can only repeat what I have said before: the only thing that I have proved is that with my equipment and with my test record, playing Dry or Wet makes no difference at all.

Despite others who found (completely) different results, as well with noise reduction when playing Wet (Figure in posting #51) and also with the level of IM products related to the resonance frequency (B&K article from 1977), be careful not to jump to conclusions.

The LP world is obviously not that simple and dependant on many interrelated factors.

Hans

As you can see, Dry or Wet makes no difference at all.

Thank you, Hans. However, it's now clear from the LF signature that, for whatever reason, you were not successful in altering friction. Your result, ie lack of difference, follows on from that, as expected IMO.

Had you measured friction coefficient directly, I believe we could have been certain. But the LF signature being identical between wet and dry is strong evidence that friction coefficient was unaltered, for whatever reason. I have never known friction remain unaltered between wet and dry playback, I should say.

I think I would deduce that, however unlikely, you were somehow unsuccessful in wetting the record, Hans. Or that recordings somehow got muddled. Otherwise, it would take a remarkable coincidence for friction to remain exactly unaltered.

Whatever, the LF signature suggests friction coefficient was unaltered, and so was surface noise. Which is as would be predicted, and does not contradict the correlation.

The curious matter is why friction coefficient should remain unaltered; that demands exploration and examination I feel.

...be careful not to jump to conclusions.

Likewise. Especially when results are unexpected, unexplained, and lacking direct measurement of the test variable: friction coefficient in this case !

The LP world is obviously not that simple and dependant on many interrelated factors.

That much we can agree !

LD

Last edited:

LDThank you, Hans. However, it's now clear from the LF signature that, for whatever reason, you were not successful in altering friction.

You present yourself as being an expert in LP noise, but so far your expertise seems mainly in making lots of noise.

Other than making the wildest accusations and changing the subject all the time, I havent seen a single analysis from you with real substance, not a very scientific approach indeed.

You won't win the war with such an attitude.

Hans

You won't win the war with such an attitude.

OK, so you look upon it as a war. I certainly don't !

Fact is that you did not measure friction coefficient, Hans. Despite it being the experimental variable at issue, a method being available to measure it, and it being pointed out as an omission in your previous tests. Whatever.

So we are left to look at the signature of LF cart-arm resonance as a marker for friction coefficient. IIRC I've posted three cases which clearly show this marker in action. However, your test results clearly show this marker is absent, therefore it's reasonable to conclude you were unsuccessful in reducing friction, for whatever reason.

Perhaps you wet the wrong track, perhaps not enough water, perhaps that record is unwettable without a surfactant, perhaps it dried out, perhaps you muddled the recorded files......who knows ? 101 possible reasons, but it seems you were not successful in reducing friction and that is why you obtained the result you did. Perfectly valid result, but not successfully testing the variable at hand, on the face of it. Essentially, you have run a blind control, and obtained the expected result.

C'mon, it's not only common sense, the phenomenum is typically clearly audible and well established. You must be at least curious as to why you obtained such an odd result, Hans?

LD

Last edited:

I ran an RB250 for 9 years then traded it in as part of a good deal on the SME345 I have had for the last 18. I don't care if the SME is no better, it just looks good, which is worth no end of SQ in the mind 🙂

Although audiomods don't sort the lack of azimuth adjustment they do have an interesting quadrant anti-skate that I haven't yet got my head around but might be useful (for those who believe in anti-skate). Wouldn't look out of place on the KD-550.

Although audiomods don't sort the lack of azimuth adjustment they do have an interesting quadrant anti-skate that I haven't yet got my head around but might be useful (for those who believe in anti-skate). Wouldn't look out of place on the KD-550.

LD, you raised an interesting point- surfactant. Presumably the old Lencoclean wet play liquid had some (if anyone still has any, I can figure out what it is). I'd appreciate if anyone running these tests say what the fluid was, DI/DW, water plus Photoflo, water plus IPA, whatever. Wettability is an important variable.

- Home

- Source & Line

- Analogue Source

- Reducing Record Surface Noise - I want to know all Approaches