Hi papasteack,

I am not sure that what you are asking for is indeed possible 🙂.

The existing 'System Design From Specifications' tool is probably the best that I can do, unless someone can suggest a better approach.

Kind regards,

David

I think it would be possible and the technical details (equations) would actually be pretty simple but I'm not sure if it's a benefit for Hornresp to be able to do this and I'm not sure how it would fit into the Hornresp GUI.

Let me explain in a bit more detail.

First of all, you can't do it as suggested by papa. You can't move a single parameter and expect Hornresp to change the others and here's why. If you change fs the program would have no way to know if the change was due to changing moving mass or changing suspension compliance, so it wouldn't know which parameters to change to reflect those two very different scenarios.

So you would have to tell the software what was changed. The 3 main changes you can make to a driver are to change moving mass, change suspension compliance and change motor force.

For example, if you tell the software you are changing the moving mass you could use these equations, courtesy of Ron E and edited by GM. I use these equations for theoretical situations in which I change the moving mass of a driver and even host these equations on my old website.

mass(m) = 22.428*dia^4(cm)/(Fs^2*Vas(liters))

m' = m + mass added

mass ratio(mr) = m'/m

Fs' = Fs/mr^0.5

Qes' = Qes*mr^0.5

Qms' = Qms*mr^0.5

then: Qts' = Qes'*Qms'/(Qes'+Qms')

Vas is unchanged

n0 = 9.6352*10^-10*Fs'^3*Vas(liters)/Qes'

SPL = 112.018+10*Log(n0)

I have no idea how accurate these equations are at predicting the actual effects of adding mass and I would have no way to know without doing physical experiments, but I do know that at the very least they move the parameters in the correct direction.

The issue is that it's rarely (if ever) an actual benefit to add moving mass to a driver. You can usually achieve what you want by enclosure design and if that's not enough it's probably better to just pick a different driver.

The same kind of equations can be worked out for the two other situations - changing suspension compliance and changing motor force. It's pretty clear which parameters are affected when you change either of these.

So it could be done - you just need to specify what change you are making - changing moving mass, suspension compliance or motor force. It absolutely cannot be done on a "single parameter changes other parameters" basis because the software has no way to know what physical change caused that single parameter to change.

Now here's the three problems with Hornresp doing this.

1. It's not necessary, you can do it yourself. You can run the equations yourself or put them in a spreadsheet and manually change the t/s yourself.

2. Where does this fit in the Hornresp GUI? It's already pretty full, this feature would take up a good bit of space (as it has to have at least 3 lines of text and 3 input boxes) and this feature would almost never be used.

3. Making these types of changes are theoretical, in that even if you find the ideal parameters for any given purpose you probably won't find an existing driver with those exact t/s specs. Adding mass could be an end user mod to an existing driver but you can't remove mass from an existing driver, nor can you easily change motor force or suspension compliance so the sole purpose of this feature would be to narrow down what type of driver specs to target when driver shopping. Even then, you have to actually sim the real driver's t/s specs to determine it's ultimate suitability for the task at hand, so I don't see this feature being all that incredibly useful.

So take that all for what it's worth - it's definitely possible but might be hard to integrate into the GUI and I don't see the point.

I think it would be possible and the technical details (equations) would actually be pretty simple but I'm not sure if it's a benefit for Hornresp to be able to do this and I'm not sure how it would fit into the Hornresp GUI.

Let me explain in a bit more detail.

First of all, you can't do it as suggested by papa. You can't move a single parameter and expect Hornresp to change the others and here's why. If you change fs the program would have no way to know if the change was due to changing moving mass or changing suspension compliance, so it wouldn't know which parameters to change to reflect those two very different scenarios.

So you would have to tell the software what was changed. The 3 main changes you can make to a driver are to change moving mass, change suspension compliance and change motor force.

For example, if you tell the software you are changing the moving mass you could use these equations, courtesy of Ron E and edited by GM. I use these equations for theoretical situations in which I change the moving mass of a driver and even host these equations on my old website.

I have no idea how accurate these equations are at predicting the actual effects of adding mass and I would have no way to know without doing physical experiments, but I do know that at the very least they move the parameters in the correct direction.

The issue is that it's rarely (if ever) an actual benefit to add moving mass to a driver. You can usually achieve what you want by enclosure design and if that's not enough it's probably better to just pick a different driver.

The same kind of equations can be worked out for the two other situations - changing suspension compliance and changing motor force. It's pretty clear which parameters are affected when you change either of these.

So it could be done - you just need to specify what change you are making - changing moving mass, suspension compliance or motor force. It absolutely cannot be done on a "single parameter changes other parameters" basis because the software has no way to know what physical change caused that single parameter to change.

Now here's the three problems with Hornresp doing this.

1. It's not necessary, you can do it yourself. You can run the equations yourself or put them in a spreadsheet and manually change the t/s yourself.

2. Where does this fit in the Hornresp GUI? It's already pretty full, this feature would take up a good bit of space (as it has to have at least 3 lines of text and 3 input boxes) and this feature would almost never be used.

3. Making these types of changes are theoretical, in that even if you find the ideal parameters for any given purpose you probably won't find an existing driver with those exact t/s specs. Adding mass could be an end user mod to an existing driver but you can't remove mass from an existing driver, nor can you easily change motor force or suspension compliance so the sole purpose of this feature would be to narrow down what type of driver specs to target when driver shopping. Even then, you have to actually sim the real driver's t/s specs to determine it's ultimate suitability for the task at hand, so I don't see this feature being all that incredibly useful.

So take that all for what it's worth - it's definitely possible but might be hard to integrate into the GUI and I don't see the point.

To take your idea to the next possible position.

This can work as a curve fit if you have a target box and a target response.

A curve fit in the sense that the parameters can be calculated from a viewpoint of best response from the target enclosure size. But that would be best done against a sealed enclosure to simplify the possibilities.

It's basically reverse calculating the basic driver parameters as you have mentioned.

And to quite a degree this is already possible in Hornresp.

As for fit into the existing windows. Nope.

It would need an additional window. But many of the parameter entries are already in use within the program.

Marshall Leach has a set of parameters and the calculations to generate a best fit for a driver. And if I remember correctly so does Don Keele.

Just to add a bit more to this - if you have a fairly good idea of what you want (design goals) and a fairly good idea of how a given set (or even individual) t/s parameters will work in a given design, you don't even need this feature.

For example, about a year ago I wanted to find a driver that would need a small(ish) enclosure and that would have low(ish) excursion for a given voltage level. Having extensive experience with simulating a variety of things I knew that I was looking for a driver with moderate to low qts and very low Vas. I didn't even have to play around with adjusting parameters in the Loudspeaker Wizard, I just knew.

So I PM'ed a couple of guys that keep an eye on the driver market and asked them to list some low(ish) qts drivers with extremely low Vas and within minutes my sims were doing what I wanted.

The point is that once you have experience you will instinctively know what t/s parameters you need to accomplish a given goal, you don't really need a Wizard to help you figure it out. That experience starts by simulating a number of different drivers in any given design, finding out how they perform, and how the t/s affected that performance.

I realize most people don't want to put this amount of work into figuring stuff out empirically but having the Wizard do it for you isn't going to save that much time - you still have to take the t/s the Wizard tells you will work well and find an existing driver with those t/s, and since you won't find an exact match you have to know (or simulate) which t/s combination is the closest to ideal for your given project.

For example, about a year ago I wanted to find a driver that would need a small(ish) enclosure and that would have low(ish) excursion for a given voltage level. Having extensive experience with simulating a variety of things I knew that I was looking for a driver with moderate to low qts and very low Vas. I didn't even have to play around with adjusting parameters in the Loudspeaker Wizard, I just knew.

So I PM'ed a couple of guys that keep an eye on the driver market and asked them to list some low(ish) qts drivers with extremely low Vas and within minutes my sims were doing what I wanted.

The point is that once you have experience you will instinctively know what t/s parameters you need to accomplish a given goal, you don't really need a Wizard to help you figure it out. That experience starts by simulating a number of different drivers in any given design, finding out how they perform, and how the t/s affected that performance.

I realize most people don't want to put this amount of work into figuring stuff out empirically but having the Wizard do it for you isn't going to save that much time - you still have to take the t/s the Wizard tells you will work well and find an existing driver with those t/s, and since you won't find an exact match you have to know (or simulate) which t/s combination is the closest to ideal for your given project.

Just to add a bit more to this - if you have a fairly good idea of what you want (design goals) and a fairly good idea of how a given set (or even individual) t/s parameters will work in a given design, you don't even need this feature.

For example, about a year ago I wanted to find a driver that would need a small(ish) enclosure and that would have low(ish) excursion for a given voltage level. Having extensive experience with simulating a variety of things I knew that I was looking for a driver with moderate to low qts and very low Vas. I didn't even have to play around with adjusting parameters in the Loudspeaker Wizard, I just knew.

So I PM'ed a couple of guys that keep an eye on the driver market and asked them to list some low(ish) qts drivers with extremely low Vas and within minutes my sims were doing what I wanted.

The point is that once you have experience you will instinctively know what t/s parameters you need to accomplish a given goal, you don't really need a Wizard to help you figure it out. That experience starts by simulating a number of different drivers in any given design, finding out how they perform, and how the t/s affected that performance.

I realize most people don't want to put this amount of work into figuring stuff out empirically but having the Wizard do it for you isn't going to save that much time - you still have to take the t/s the Wizard tells you will work well and find an existing driver with those t/s, and since you won't find an exact match you have to know (or simulate) which t/s combination is the closest to ideal for your given project.

This is all true.

But is sidestepping the original question.

Can it be done?

Yes.

Does it have a purpose?

Yes indeed it does.

There are a growing number of people in the professional end of the market that are using Hornresp as a design tool.

A driver designer gets many a request for a fit of an existing enclosure to a best in performance driver.

So would I appreciate the application you bet.

Do I do this already?

Of course.

It just takes a fair amount of work over a few different programs to generate the desired results.

But that would be best done against a sealed enclosure to simplify the possibilities.

And wouldn't really work for anything other than the sealed box.

Marshall Leach has a set of parameters and the calculations to generate a best fit for a driver. And if I remember correctly so does Don Keele.

Leach's model is for a full size horn, not something that really popular as far as design goes and quite a bit different from sealed, ported tapped horn and undersized flh stuff that is popular.

Furthermore, the ideal parameters will change depending on the particulars of the design - the desired low knee frequency, the desired gain bandwidth and the desired compression ratio. So I'm not at all sure if you could reverse engineer Leach's model to be of any use for anything other than full size horns.

I'm not familiar with Keele's model but it's probably pretty similar to Leach's.

Does it have a purpose?

Yes indeed it does.

There are a growing number of people in the professional end of the market that are using Hornresp as a design tool.

A driver designer gets many a request for a fit of an existing enclosure to a best in performance driver.

I guess your perspective is different depending on who you are. I don't see a huge need for this as a diy'er that can't make my own drivers to my own spec. Big OEMs like B&C very likely are not using Hornresp and very likely have engineers that figure out what will work for their customers. And they have no interest whatsoever in creating specialty drivers for extremely small customers.

For a small OEM like you I suppose this could have a purpose, as you can create whatever driver specs you like and your customers are small fish that for the most part aren't smart enough to figure out what existing product will work best on their own (there is almost always an existing product in today's market that will work just fine) and therefore need (or want) specialized drivers.

You are a very special case here, diy'ers and large OEMs won't really benefit much from this feature. Especially since as I already mentioned, if you know what you are doing you already have a pretty good idea what t/s you need to accomplish a given goal.

I'd rather see development time and resources going to features that are more useful to a larger cross section of the program's end users, but obviously that's David's call.

Last edited:

This can work as a curve fit if you have a target box and a target response.

The other problem with this is what is the ideal target response and ideal target box?

If the tuning is high you want a more "max flat" target response, if your tuning is very low you want a more "EBS" style rising response. And that's just in general, lots of people want max flat response down to 4 hz, so what is the ideal target response? Everybody want a different response q curve shape.

What is the ideal target box? People want to build whatever they want, IB, OB, sealed, ported, a dozen different kinds of tl, tapped horn, back loaded horn, flh, a dozen different types of bandpass, and each of these different alignments can be sized differently and tuned for different gain bandwidth. So what is the ideal target box?

Unless you can curve fit for ALL target boxes and ALL target alignments, a curve fit approach is pretty useless except for the single box and curve it's meant to target.

Last edited:

Do you remember the post from David that BOSE is using Hornresp?

And the size of the BOSE interms of driver output?

One of the top ten in the world.

There are more things going on in the audio world than you seem to be aware of.

And the size of the BOSE interms of driver output?

One of the top ten in the world.

There are more things going on in the audio world than you seem to be aware of.

Yeah, I'm sure there's somebody at Bose that uses Hornresp for some purpose, given the scale of their operation it would be weird if they weren't familiar with Hornresp and using it in some capacity even if it isn't on their list of primary accepted and approved design tools.

But I'm also fairly confident that Hornresp is not their primary design tool for any given task and that they are not basing driver manufacturing decisions based on Hornresp. I'm pretty sure they have access to all the latest and greatest software - Hornresp is a good quick first step but not the last word in accuracy for anything given the large amount of software including ABEC, FEM and BEM software and all the other stuff I've likely never even heard of. And why not? It's all a business write off and it's all better than Hornresp for the application it's designed to excel at.

Futhermore, I'm not the least bit interested in making things easier for OEMs, especially Bose. What has Bose done for me lately other than make me try to convince people they don't need a $700 clock/radio?

But I'm also fairly confident that Hornresp is not their primary design tool for any given task and that they are not basing driver manufacturing decisions based on Hornresp. I'm pretty sure they have access to all the latest and greatest software - Hornresp is a good quick first step but not the last word in accuracy for anything given the large amount of software including ABEC, FEM and BEM software and all the other stuff I've likely never even heard of. And why not? It's all a business write off and it's all better than Hornresp for the application it's designed to excel at.

Futhermore, I'm not the least bit interested in making things easier for OEMs, especially Bose. What has Bose done for me lately other than make me try to convince people they don't need a $700 clock/radio?

@ Dr.B.Kolbrek

Congrats on your Phd 🙂 I also am finding the history very interesting too.

I noticed that David McBean was thanked as one of those who assisted you along the way 😉

*

😀 So True 😀

Congrats on your Phd 🙂 I also am finding the history very interesting too.

I noticed that David McBean was thanked as one of those who assisted you along the way 😉

*

Originally Posted by just a guy

What has Bose done for me lately other than make me try to convince people they don't need a $700 clock/radio?

😀 So True 😀

Thx guys for the answers. I do so too. Learning a driver target parameter set for a given box is not too hard. The problem is for a given box, if we want to sim différent drivers configuration for example, 2x10" powerful(qts) long throw Vs a single 12" powerful long throw Vs one 15" very powerfull moderate throw Vs 2x12" moderate power long throw in isobaric ...too much drivers paramètre set target to master to make a shopping choice ^^

This is something totally different. You can't change Sd and expect the Wizard to change all the parameters to follow suit - at least I don't know an easy way to do that. At the very minimum changing Sd will affect moving mass and suspension compliance (simply because it requires a different surround and spider and there's no way to know the suspension compliance of totally different parts) even if you keep the same motor and coil.

For something like this, I would just pick three or four different real world drivers, a 10 inch, a 12 inch, a different 12 inch meant for iso loading, and a 15 inch, enter the published t/s and run the sims.

This whole concept is foreign to me anyway - I chose my design goals, then I chose my driver(s), then I design the box. If the design goals are not met I change either the goals, the driver(s) or the box and do it again.

I'm not used to taking an existing box and finding drivers that would work in it. As far as I'm concerned this is backwards except when you have an expensive box without a driver for some reason. In the few cases I've had that situation (or helped someone in that situation) I can tell right away by the box type, size and tuning what kind of driver is going to work, so I sim a few drivers I think might work and pick one. This backwards process might be a small OEM's bread and butter but to be honest I'm not interested in their specialized needs and they should be smart enough to instinctively know what will work, if not they are not very good at their job and should probably find a new line of work.

As far as I'm concerned, using a Wizard for this doesn't save any time and worst of all you don't learn anything. if you do it empirically it doesn't really take any more time and the experience makes you become better at knowing what type of driver is going to work in any given situation.

For something like this, I would just pick three or four different real world drivers, a 10 inch, a 12 inch, a different 12 inch meant for iso loading, and a 15 inch, enter the published t/s and run the sims.

This whole concept is foreign to me anyway - I chose my design goals, then I chose my driver(s), then I design the box. If the design goals are not met I change either the goals, the driver(s) or the box and do it again.

I'm not used to taking an existing box and finding drivers that would work in it. As far as I'm concerned this is backwards except when you have an expensive box without a driver for some reason. In the few cases I've had that situation (or helped someone in that situation) I can tell right away by the box type, size and tuning what kind of driver is going to work, so I sim a few drivers I think might work and pick one. This backwards process might be a small OEM's bread and butter but to be honest I'm not interested in their specialized needs and they should be smart enough to instinctively know what will work, if not they are not very good at their job and should probably find a new line of work.

As far as I'm concerned, using a Wizard for this doesn't save any time and worst of all you don't learn anything. if you do it empirically it doesn't really take any more time and the experience makes you become better at knowing what type of driver is going to work in any given situation.

Last edited:

For example, if you tell the software you are changing the moving mass you could use these equations, courtesy of Ron E and edited by GM.

Hi just a guy,

Why not just change the value of Mmd in Hornresp, and if you want to know the resultant Thiele-Small equivalent parameter values, double-click on the Sd input box?

Kind regards,

David

So I'm not at all sure if you could reverse engineer Leach's model to be of any use for anything other than full size horns.

Hi just a guy,

In the book 'Introduction to Electroacoustics and Audio Amplifier Design' Marshall Leach gives simulation models for closed-box and vented-box loudspeaker systems, based on the work by Thiele and Small.

Kind regards,

David

This is something totally different. You can't change Sd and expect the Wizard to change all the parameters to follow suit - at least I don't know an easy way to do that. At the very minimum changing Sd will affect moving mass and suspension compliance (simply because it requires a different surround and spider and there's no way to know the suspension compliance of totally different parts) even if you keep the same motor and coil.

For something like this, I would just pick three or four different real world drivers, a 10 inch, a 12 inch, a different 12 inch meant for iso loading, and a 15 inch, enter the published t/s and run the sims.

This whole concept is foreign to me anyway - I chose my design goals, then I chose my driver(s), then I design the box. If the design goals are not met I change either the goals, the driver(s) or the box and do it again.

I'm not used to taking an existing box and finding drivers that would work in it. As far as I'm concerned this is backwards except when you have an expensive box without a driver for some reason. In the few cases I've had that situation (or helped someone in that situation) I can tell right away by the box type, size and tuning what kind of driver is going to work, so I sim a few drivers I think might work and pick one. This backwards process might be a small OEM's bread and butter but to be honest I'm not interested in their specialized needs and they should be smart enough to instinctively know what will work, if not they are not very good at their job and should probably find a new line of work.

As far as I'm concerned, using a Wizard for this doesn't save any time and worst of all you don't learn anything. if you do it empirically it doesn't really take any more time and the experience makes you become better at knowing what type of driver is going to work in any given situation.

I'm only trying to get the most from the least and tweak to learn with hornresp what parameter give me what.

It's a 4th bandpass : it depend a lot of qts value for the freq curve shape (so aim of course for high xmas/linear motor/low inductance), at the same time depend of mass of the cone as "filter", and qms need to be high for low loose. I didn't managed to understand the exact effect/taget for VAS. I try to get not too big front chamber, and not too long port, to get ripple 2 octave far from bandpass response. And i try small back chamber too, to get small box. It's as always, all about tweaking, but here box parameter are for this particular project less concerned about tweak than driver choice. And there's so much different speakers that would work, but loaded for exemple in isobaric, or by two for 10", or with very powerful motor for 15", that it would have helped in learning process if i could tweak driver parameter keeping thing equal, as done for segment size. I hardly see if the speakers i test in sims are the good choice of siming. By error i understood that it would work too with low qts 12" loaded in isobaric. It have the advantage of lower inductance due to weak motor, and weak motor mean light, wich compensate a bit for twice cone.

The speakers that works more or less are for example BMS 12s305, sica 12sr3cp, AE td12h, eminence kappalite 3012lf, b&c 12tbx100, 12plb100,sb34nrxl75-8, sica BS 12N/250A in iso (not enough xmax but older version got interesting klippel result), fane colossus 12b, oberton 15nxb700... And that only from datasheet, that can be more or less far from reality. I aim for lower qts than sim because it can be corrected easily, the inverse is not true.

As you said, it's not a real problem, it need only more work without this kind of magic tool. Same as all hornresp do should theorically be done with pencil and paper ^^.

Sorry for the off topic, and thanks for the interest. Maybe i just need help from someone who know well the driver market and understand thiele parameters. 😱

Last edited:

Hornresp Update 3980-161026

Hi Everyone,

The file import problem reported by GM in Post #6769 and confirmed by Sabbelbacke in Post #6770 has now been fixed.

Kind regards,

David

Hi Everyone,

The file import problem reported by GM in Post #6769 and confirmed by Sabbelbacke in Post #6770 has now been fixed.

Kind regards,

David

Hi just a guy,

Why not just change the value of Mmd in Hornresp, and if you want to know the resultant Thiele-Small equivalent parameter values, double-click on the Sd input box?

Kind regards,

David

In reality, mmd is not so much a problem. Cms/rms are the real hard part to see effect of for me. Maybe simply a VAS slider would have been closer to the parameters i look to. But the time i've spent tweaking, i start to understand better the effect of each one 😛, as with all others so much awesome and intuitives sliders you gived us to play with 🙂

@ David McBean

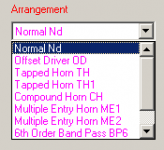

Hi, in the HR help file lists all these options for design

But in the Driver Arrangement box it shows only these ?

How do we get to see/choose All of them ?

Hi, in the HR help file lists all these options for design

LOUDSPEAKER MODELS

Direct Radiator in an Infinite Baffle

Direct Radiator in a Closed-Box Enclosure

Direct Radiator in a Vented-Box Enclosure

Sixth or Eighth Order Band Pass Enclosure

Aperiodic Bi-Chamber Enclosure

Damped Transmission Line Enclosure

Front-Loaded Horn

Back-Loaded Horn

Horn-Loaded Vented-Box Enclosure With Port Exit Located Outside Horn Mouth

Horn-Loaded Vented-Box Enclosure With Port Exit Located Inside Horn Mouth

Mass-Loaded Horn

Offset Driver Horn

Two-Way or Three-Way Multiple Entry Horn

Tapped Horn

Compound Horn

But in the Driver Arrangement box it shows only these ?

How do we get to see/choose All of them ?

Attachments

Some of the possible cabinets are done with the same driver arrangement, so the list of possible ones is bigger than the driver arrangement list.How do we get to see/choose All of them ?

For examlpe: Ported and sealed are both "normal Nd" but with different back chamber options selected...

@ David McBean

Hi, in the HR help file lists all these options for design

But in the Driver Arrangement box it shows only these ?

How do we get to see/choose All of them ?

You have to read the instructions. As I mentioned in the thread where this is being discussed, the flh with rear chamber ported into the mouth is actually done by using the TH option and the instructions tell you exactly how to do it. Take a flh sim, fill in Ap and Lpt and sim it as TH.

In other words, not all of these items have a specific alignment setting but all of the alignments are available by filling in the right input boxes.

- Home

- Loudspeakers

- Subwoofers

- Hornresp