I noted a manufacturing difference in the old, discontinued LM3886T. It results in a stability difference.

Stability difference? Would you please elaborate? Are you talking about loop stability or thermal stability? The LM3886T and LM3886TF is the same chip with a different package. How would that possibly impact loop stability?

Thermal stability? Which issue are you seeing with the other package options? I've worked with the LM3886 for years and have yet to see any thermal stability issue, so I'm really curious what you're seeing.

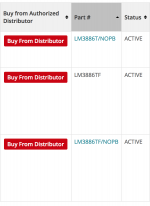

Both the LM3886T and LM3886TF are in current production at TI. See screen shot from TI's website below.

Tom

Attachments

clip pressure

I'm still curious about clip torque specs and how to apply them. Especially since the LM4870 data sheet says, and these are my words, to much pressure can damage the package. For all I know maybe I shouldn't use two HALA clips even though they are only about .4" wide and the LM4870 is 1.15" wide. Any thoughts or should I email TI.

I'm still curious about clip torque specs and how to apply them. Especially since the LM4870 data sheet says, and these are my words, to much pressure can damage the package. For all I know maybe I shouldn't use two HALA clips even though they are only about .4" wide and the LM4870 is 1.15" wide. Any thoughts or should I email TI.

Henry, we applaud your enthusiasm, however your obsession over the smallest of details is most tiresome.

The modulus-86 is, what it is...indeed yours are working well.

Enough now.

Dan.

The modulus-86 is, what it is...indeed yours are working well.

Enough now.

Dan.

We call it "Analysis Paralysis".

It prevents the simplest tasks being completed in a timely manner.

It prevents the simplest tasks being completed in a timely manner.

Everything yields to sufficient force...the LM4870 data sheet says, and these are my words, to much pressure can damage the package.

A heads up for those who are ordering their parts from Mouser. Make sure you click the button to send the parts that are in stock. When I placed my order I checked the wait until all parts are available button (There was one cap that was out of stock until the 29th of July). I received a message today that told me another cap is not available until the 2nd of November. By the time that date arrives there will likely be something else out of stock. I'll never get my order at this rate. I just contacted Mouser and instructed them to send the parts they have available. Frustrating.

Yes I had the same experience where all of my components were available except one capacitor that had a 12 week backlog. Had them send what they had and sourced the cap from Digikey where it was in stock.

I'll follow your lead.

You may want to have a look at ModuShop. Their 2U Dissipante series would be perfect for a MOD86 build. That's what Henry used.

I did the math at one point. Heat sinks from Heatsink USA, metal from Online Metals. If I recall correctly, the total was about $100 for 3 mm thick panels, 10 mm front panel. I paid about $150 shipped for the eBay chassis (BZ4309). ModuShop runs about $135 including shipping. You can get the ModuShop chassis through the DIY Audio Store as well.

Tom

Yes, I've priced them out, along with just about everyone else.

I did look at some Hammond chassis I liked, that would have costed out around $75.

In the end, though, I can buy thicker raw aluminum here in town from my choice of two industrial metal suppliers, plus enough to build a heatsink that measures out via calculation to be better than the highest spec Heatsink USA recommended model in your documentation, for well under $C 60 all in. In fact I was able to keep the quote under that price even if I substituted an all-copper heat sink.

That leaves room for constructing the heat sink: a specialized drill bit (0.01" undersized, about $C 40.00) for drilling aluminum or copper plate, which allows for an interference fit of ⅜" rods, using an arbour press. I could also drill holes into aluminum or copper plate with an ordinary drill bit, and either TIG weld the aluminum (buddy has the welder) or solder the copper. The press fit would look better and I think better conduct heat, though.

Sad but true that I can't buy a mass-manufactured box delivered to my door for less, but that's the reality so I have to live with it. China subsidizes their small packet mail so components are dirt cheap, but once it needs a box, the shipping cost goes through the roof.

Up until a couple of years ago the USPS was reasonable from the US to Canada but they have raised the cost of shipping in a box significantly (I can send a tracked, insured parcel the other way for ¼ the cost) so that you are now forced to use UPS or FedEx, and both have a laundry list of "extra" fees they tack onto the shipping cost. I'll bet the US-based vendors probably believe the rate card is all we pay, but that is far from the truth (and UPS/FedEx have the gall of charging a COD fee to account for collecting the other fees they tack on).

I just this month built a metal brake to bend steel and aluminum up to 20" wide, which cost me $4 for scrap metal and 2 stainless steel hinges, plus some bolts, nuts and spacers from the household parts bin.

I will be done the enclosure plus the heat sink for under $C 100 ($US 75), plus there is an opportunity to get creative with the overall appearance instead of using the admittedly handsome, but inevitably ordinary, premade box.

Last edited:

I believe this is easily solved (if it already hasn't been) by using socket head cap screws with internal hex drive. Allen keys fit well in low-clearance areas such as these.I've tried that. It's a pain to get to work. The reason the green caps on the Parallel-86 are spaced the way they are is actually so you can get a screwdriver in between the caps and tighten the screws on the clamping bar.

An externally hosted image should be here but it was not working when we last tested it.

However, as I said, it's a pain to use a clamping bar. There's also the little detail that the metal back may extend all the way to the edge of the mounting half-holes on the LM4780 package. This has caused some people to short out the VEE supply to the heat sink with spectacular fireworks and destroyed circuits to follow.

That is by far the best idea!

True.

Tom

My favourite UPS fee is the one they add on to "lend" you the money they pay out to Customs to account for the 5% sales tax due on every imported product valued over $20. Except UPS doesn't pay Customs anything when importing an item ... they settle on the 15th of the month following delivery.

Last edited:

whatever

I get the message: I shouldn't be asking such pedestrian questions in this thread. I'll email the appropriate makers and maybe I'll get a good answer.

I was referring to the LM4870 and info in the data sheet. I will be putting together a Parallel86 and wondered how to determine the appropriate clamping force for the LM4870.Henry, we applaud your enthusiasm, however your obsession over the smallest of details is most tiresome.

The modulus-86 is, what it is...indeed yours are working well.

Enough now.

Dan.

I get the message: I shouldn't be asking such pedestrian questions in this thread. I'll email the appropriate makers and maybe I'll get a good answer.

A heads up for those who are ordering their parts from Mouser. Make sure you click the button to send the parts that are in stock.

[...]

I just contacted Mouser and instructed them to send the parts they have available. Frustrating.

That's one of the things I really dislike about Mouser. I do my best to keep the projects free of out-of-stock parts, but I simply can't keep up. Digikey does a much better job at keeping parts in stock, but most seem to prefer Mouser anyway.

Another caveat emptor: Mouser has developed a new trick where if you click the "only show parts in stock" checkbox, the search engine will still return parts that are not in stock if Mouser has an order in with the manufacturer. You have to make sure the parts are actually in stock (stock qty > 0) and not just kinda-sorta in stock in a marketing sort-of-way.

In 99.9 % of cases, you can find a substitute component that'll work just as well that is in stock with Mouser, so a full order is usually only a few button clicks away.

My favourite UPS fee is the one they add on to "lend" you the money they pay out to Customs to account for the 5% sales tax due on every imported product valued over $20.

There's a solution to this: Set up an account with FedEx. All it takes is a credit card. You then tell the shipper to charge the CUSTOMS charges to your FedEx account. They can split up the shipping and customs charges. That way the package shows up on your doorstep and the customs fee (5 % GST) just trickles out of your credit card account. No additional processing fees.

Tom

Last edited:

I should have mentioned that I thank god modern plugs have a wide and narrow blade or I would probably be using candles and a water wheel.I was referring to the LM4870 and info in the data sheet. I will be putting together a Parallel86 and wondered how to determine the appropriate clamping force for the LM4870.

I get the message: I shouldn't be asking such pedestrian questions in this thread. I'll email the appropriate makers and maybe I'll get a good answer.

the limit of 150N/mm2 would be for localised pressure on high spot contacts between the clamp and the moulding/package.Mounting spec from the LM4870 data sheet.

maximum torque of 50 N-cm. Additionally, it is best to use washers under the

screws to distribute the force over a wider area or a screw with a wide flat head.

To further distribute the mounting force a solid mounting bar in front of the package and secured in place with the two mounting screws may be used. Other mounting options include a spring clip. If the package is secured with pressure on the front of the package the maximum pressure on the molded plastic should not exceed 150N/mm2. I dont know if the mm2 is the surface of the lm4870 or the surface area of the bar. If it is the surface area of the IC, does anyone one know what the resultant force would be?

If the whole clamping area were 10mm by 20mm, then the maximum load would come to 150 * 10 * 20 = 30kN, or about 3tonne, or 3ton, or 3000kg.

If you have a clip with a contact area of 1mm by 4mm and a clamping load of 16lbs, then you have ~16/2.2046*9.81 / 1 / 4 = 18N/mm²

2.2046 converts lbs to kg and 9.81 converts kg to Newtons. (or 1Newton is ~ ¼lb)

Or working in the other direction:

How small can I make the contact area for a clamping force of 16lbs.

16lbs is ~ 71N and would need an area just under 0.5mm² to reach that 150n/mm², i.e. a probe 1mm by 0.5mm could safely apply that 16lbs clamping force without damaging the package.

Last edited:

Be patient. I was just getting ready for bed after a night of dancing.I'm still curious about clip torque specs and how to apply them. Especially since the LM4870 data sheet says, and these are my words, to much pressure can damage the package. For all I know maybe I shouldn't use two HALA clips even though they are only about .4" wide and the LM4870 is 1.15" wide. Any thoughts or should I email TI.

I'm up now attending to your query.

learn how to use the data given in the sheets.I was referring to the LM4870 and info in the data sheet. I will be putting together a Parallel86 and wondered how to determine the appropriate clamping force for the LM4870.

I get the message: I shouldn't be asking such pedestrian questions in this thread. I'll email the appropriate makers and maybe I'll get a good answer.

... (snip) ...

There's a solution to this: Set up an account with FedEx. All it takes is a credit card. You then tell the shipper to charge the CUSTOMS charges to your FedEx account. They can split up the shipping and customs charges. That way the package shows up on your doorstep and the customs fee (5 % GST) just trickles out of your credit card account. No additional processing fees.

Tom

I have a much better solution than that, Tom. I have an account with a customs broker, and give THEM my CC details.

Free Shipping, usually, to the US warehouse, then they carry the item across the border and ship it to me, next day air Purolator, for $10~20 on their account (which enjoys a heavy volume discount).

Their brokerage fees are also significantly lower than FEdEx's and in comparison to UPS's, about 1/4th. (UPS claims to be at the mercy of their broker when it comes to fees, which are the highest in the industry. Of course they don't tell you the broker is a wholly-owned subsidiary).

Here's a little-known fact: UPS sued Canada Post not once, but twice, under NAFTA, claiming that the Post Office didn't have the legal right to deliver parcels, only lettermail.

Last edited:

Most Frightening Post on diyAudio

Be patient. I was just getting ready for bed after a night of dancing.

- Home

- Amplifiers

- Chip Amps

- Modulus-86 build thread